Low-noise double-shaft concrete mixer

A concrete mixer, low-noise technology, applied in cement mixing devices, mechanical equipment, clay preparation devices, etc., can solve problems such as high noise, and achieve the effects of eliminating noise, shortening process chain, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

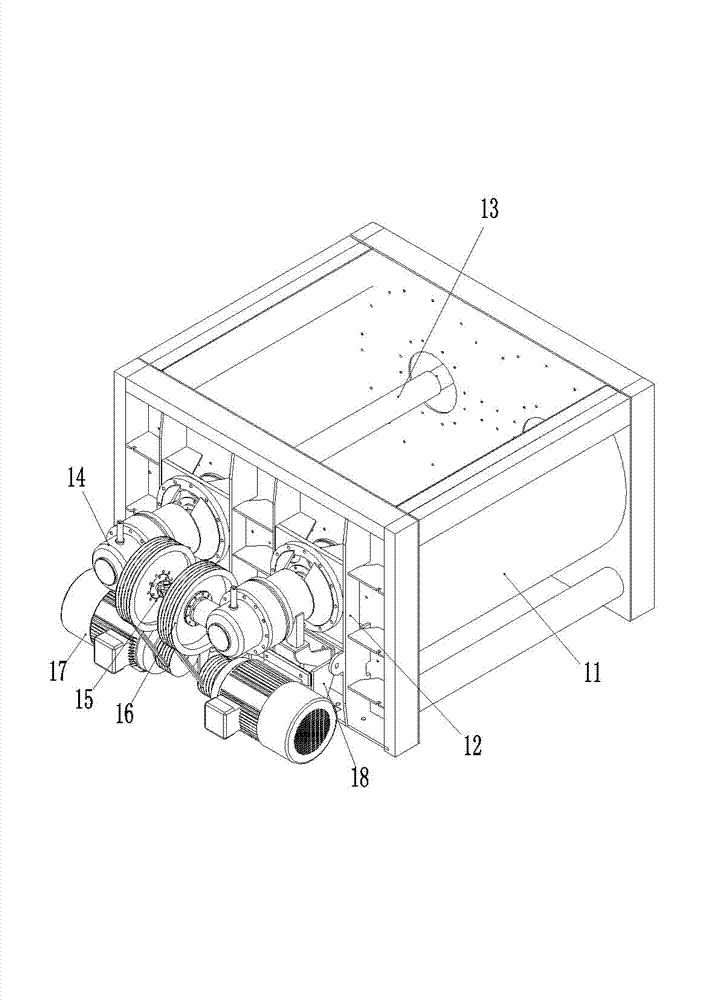

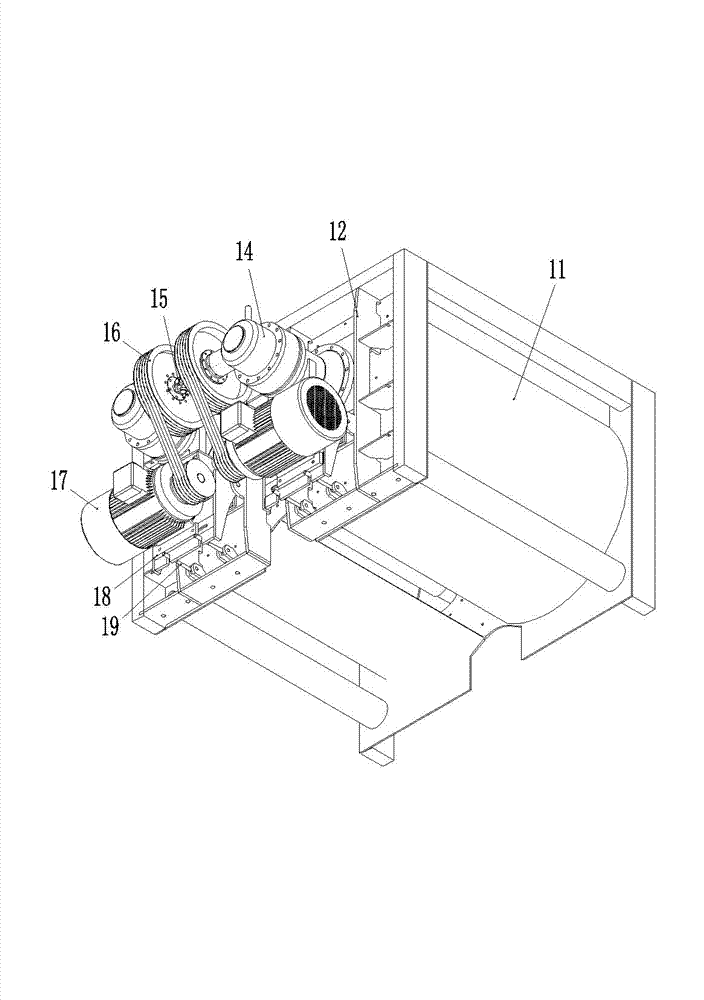

[0013] Embodiment 1 of the low-noise twin-shaft concrete mixer of the present invention, as Figure 1-2 As shown, the mixing drum 11 is included, and the mixing drum 11 includes two end plates arranged at intervals one after the other and a coaming plate connected between the two end plates. In this embodiment, the outer sides of the two end plates are respectively provided with ribs The plate 12 and the rib plate 12 are used to increase the strength of the end plate; the mixing drum 11 is equipped with a stirring shaft 13, and there are two stirring shafts 13, and the two stirring shafts are arranged at intervals of one left and one right and are respectively mounted on the stirring shaft through bearing rotation. On the end plate of the cylinder 11, in this embodiment, each stirring shaft 13 is connected to a speed reducer 14 through a front-end transmission. In this embodiment, the speed reducer 14 is a planetary speed reducer, including an input shaft and an output shaft pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com