Layer-by-layer production method during laser melting (sls) in gravity die casting operations

A hard mold casting and hard mold technology, applied in the field of laser sintered casting molds, can solve problems such as piston modeling consumption, and achieve the effects of reducing research and development time, saving cost and time, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

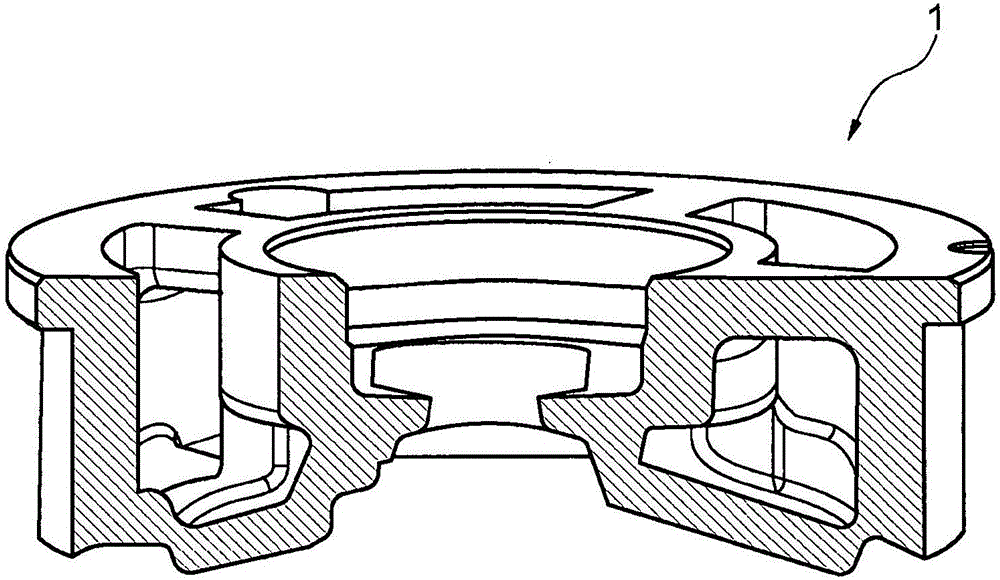

[0096] figure 1 Shown is a piston upper part 1 produced in a gravity die casting process in a casting mold produced by DMLS.

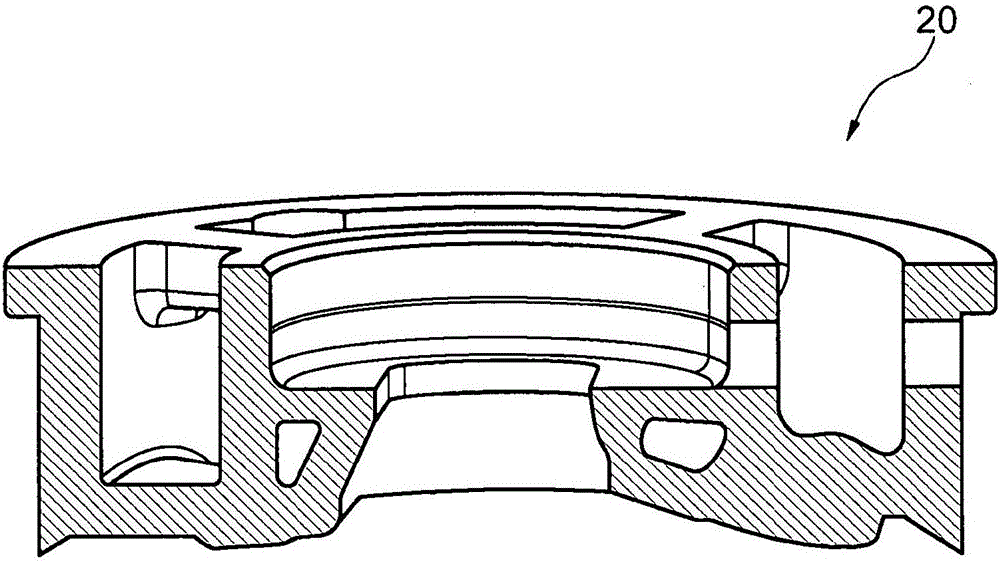

[0097] figure 2 Another piston upper 20 is shown made in a gravity die casting process in a casting mold made by DMLS.

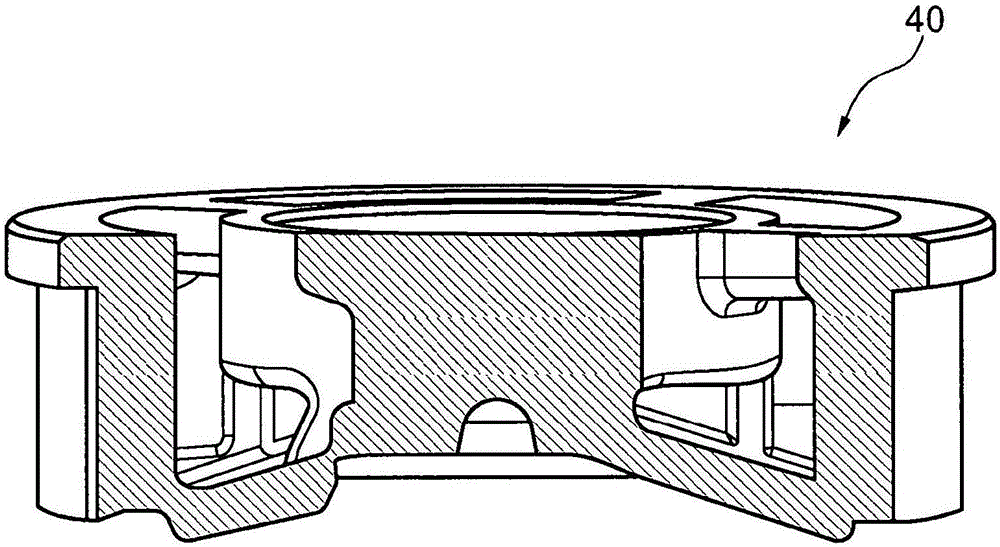

[0098] image 3 Another piston upper 40 is shown made in a gravity die casting process in a casting mold made by DMLS.

[0099] Figure 4 A and 4B show two views of another embodiment of the piston upper part 60 . In region 61 , the contact region of the sintered bottom, not shown here, of the casting mold, likewise not shown, can be seen. By means of DMLS, a sintered bottom for use in a casting mold for producing a piston is produced. The sintered bottom is used when manufacturing the piston upper portion 60 by a gravity die casting process. When manufacturing the sintered bottom, the micropores were structured by DMLS with a porosity of 0% or a density of 7.8 g / cm3. Embed 18,000 microwells with a diameter D of 0.2 mm. As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com