Intermediate-refractive index anti-blue-light impact-resistant lens and manufacturing process thereof

A production process and impact-resistant technology, applied in the direction of optical filters, optics, optical components, etc., can solve problems such as sunburn, difficult performance, macular degeneration of the human eye, etc., to reduce lens costs, reduce process chains, increase The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

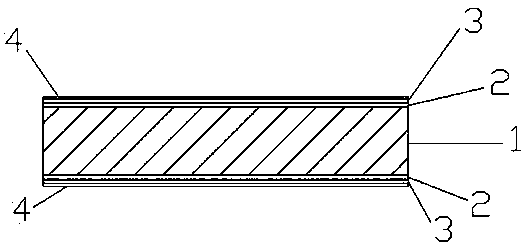

[0030] Such as Figure 1-2 As shown, this embodiment provides a kind of anti-blue light anti-impact lens, including a resin lens 1, the front and rear surfaces of the resin lens 1 are provided with a hardened layer 2, and the surface of the hardened layer 2 is provided with an anti-impact lens. Layer 3, the surface coating layer 4 is provided on the surface of the impact-resistant layer 3 . The hardening layer 2 uses UV430 hardening layer.

[0031] This embodiment also provides a manufacturing process of a medium-fold anti-blue light and impact-resistant lens, and the manufacturing process steps are as follows:

[0032] Step 1: Process the resin lens semi-finished product into a resin substrate, clean it or directly clean the resin substrate, and dry it;

[0033] Step 2: Put the hardening fixture on the above lens into the automatic hardening machine for hardening. The hardening is one layer of impact-resistant layer with impact-resistant particles, and the second layer is o...

Embodiment 2

[0037] The difference from Example 1 is: the resin material with a refractive index of 1.60 is cured into a resin substrate according to the process, cleaned with ultrasonic waves, clamped, and then coated with a UV430 hard layer on the front and rear surfaces of the resin lens by dip coating. Then, the impact-resistant layer is coated on the surface of the UV430 hardened layer by dip coating, and finally the coating layer is coated on the front and rear surfaces of the UV430 hardened layer by a vacuum coating machine.

[0038] This process can not only effectively improve production efficiency, but also reduce production costs, effectively block harmful blue light, and greatly improve the impact resistance of the lens, which plays a very good role in protecting eyesight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com