Additive for removing ammonia nitrogen in electrolytic manganese residues and removal method thereof

A technology for electrolytic manganese slag and additives, which is applied in the field of additives for removing ammonia nitrogen in electrolytic manganese slag and its removal, can solve the problems of high dependence on primary resources, high temperature conditions, and high energy consumption, and achieve shortened process chains, The effect of high removal rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

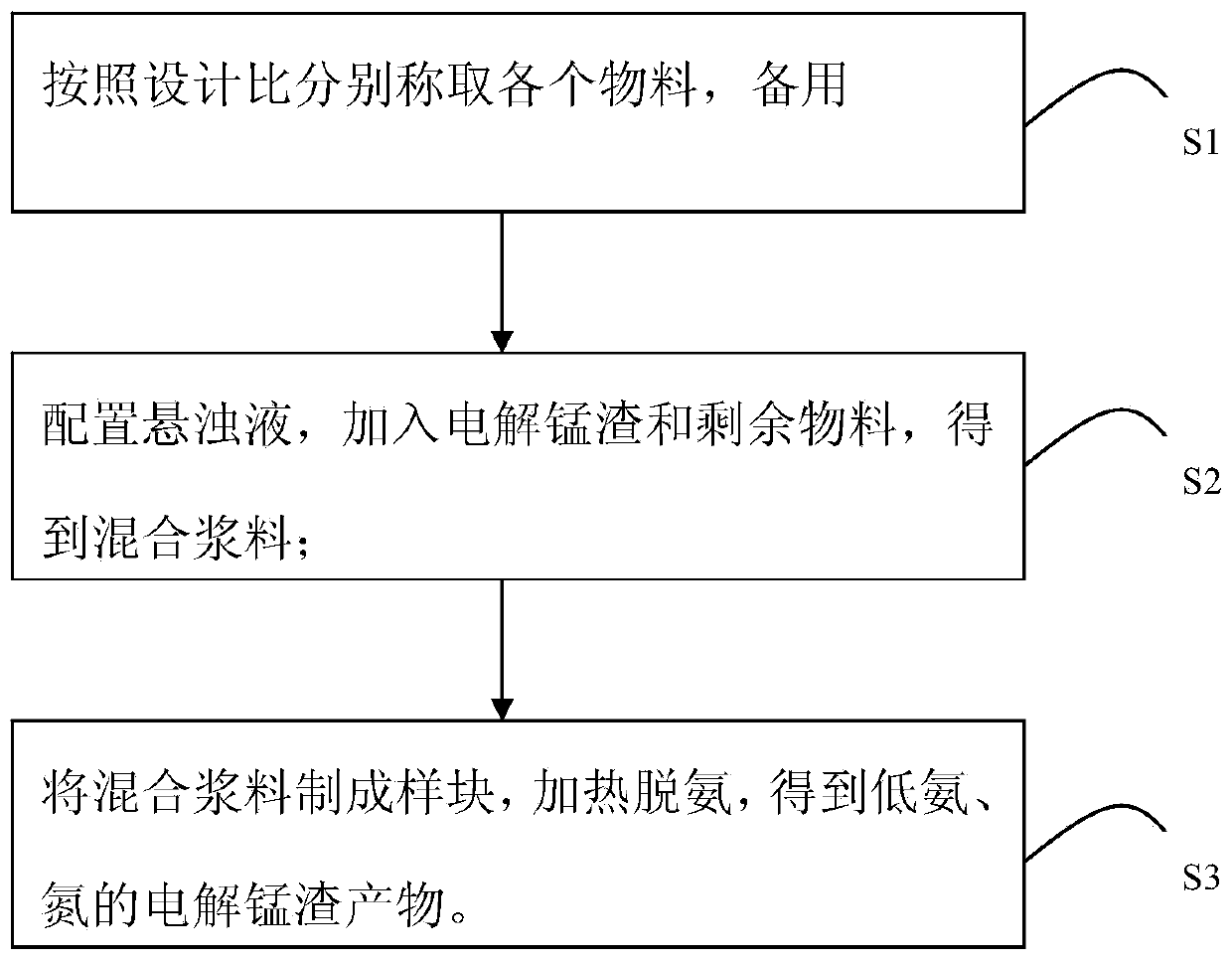

Method used

Image

Examples

Embodiment 1

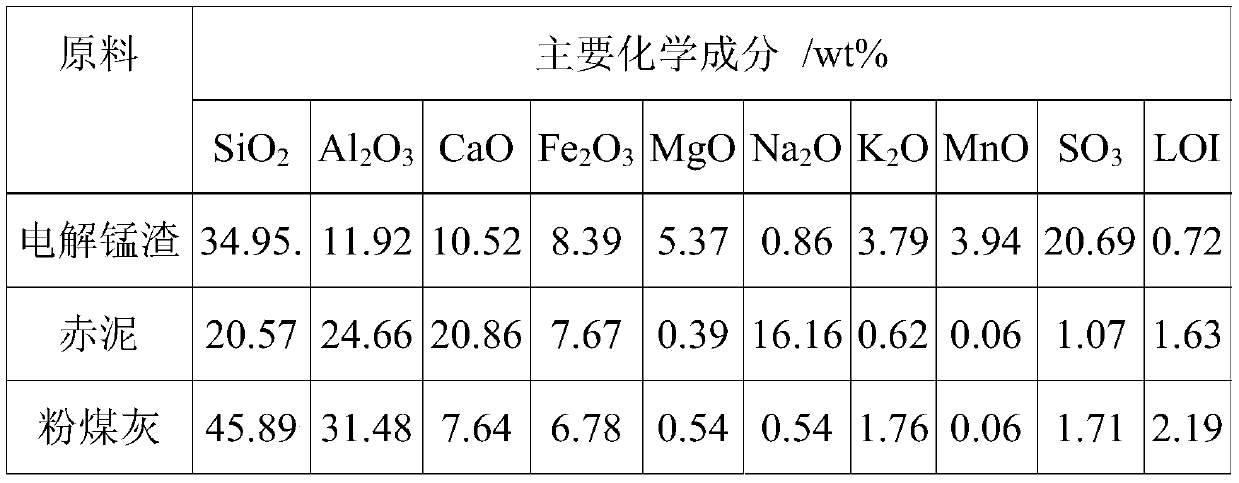

[0051]Accurately weigh 1g of water reducing agent and 90g of deionized water at room temperature and mix evenly. Put 19 parts of alkaline solid waste and water into the mixer and stir until the alkaline solid waste is evenly dispersed in the water without obvious large particles. Then add 100 parts of electrolytic manganese slag, stir evenly, add 8 parts of calcium-containing basic compound in batches and stir evenly, add 35 parts of red mud and stir evenly, and stir 24 parts of fly ash to obtain a slurry. Quickly pour the viscous slurry into a pan and spread it out, and keep it warm at 60°C for 50 minutes to obtain an electrolytic manganese slag product with low ammonia and nitrogen. Take 100 parts of low-ammonia products, mix with 10 parts of ordinary cement and 12 parts of water, put them into a 2cm×2cm×2cm mold, vibrate to form and seal the mold with a plastic wrap, and place it in a constant temperature box at 20°C and 90% humidity. After 1 day of curing, take out the dem...

Embodiment 2

[0054] Accurately weigh 1g of water reducing agent and 90g of room temperature manganese slag leachate and mix evenly. Put 19 parts of alkaline solid waste and water into a mixer and stir until the alkaline solid waste is evenly dispersed in the water without obvious large particles. Then add 100 parts of electrolytic manganese slag, stir evenly, add 8 parts of calcium-containing basic compound in batches and stir evenly, add 35 parts of red mud and stir evenly, and stir 24 parts of fly ash to obtain a slurry. Quickly pour the viscous slurry into a pan and spread it out, and keep it warm at 60°C for 50 minutes to obtain an electrolytic manganese slag product with low ammonia and nitrogen. Take 100 parts of low-ammonia products, mix with 10 parts of ordinary cement and 12 parts of water, put them into a 2cm×2cm×2cm mold, vibrate to form and seal the mold with a plastic wrap, and place it in a constant temperature box at 20°C and 90% humidity. After 1 day of curing, take out the...

Embodiment 3

[0057] Accurately weigh 1g of water reducing agent and 90g of manganese slag leachate and mix evenly, put 19 parts of alkaline solid waste and water into a mixer and stir until the alkaline solid waste is evenly dispersed in the water without obvious large particles. Then add 100 parts of electrolytic manganese slag, stir evenly, add 8 parts of calcium-containing basic compound in batches and stir evenly, add 35 parts of red mud and stir evenly, and stir 24 parts of fly ash to obtain a slurry. Quickly pour the viscous slurry into a pan and spread it out, and keep it warm at 60°C for 50 minutes to obtain an electrolytic manganese slag product with low ammonia and nitrogen. Take 100 parts of low-ammonia products, mix with 10 parts of ordinary cement and 12 parts of water, put them into a 2cm×2cm×2cm mold, vibrate to form and seal the mold with a plastic wrap, and place it in a constant temperature box at 20°C and 90% humidity. After 1 day of curing, take out the demoulding, put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com