Improved method for driving roll used for hot rolling moulding of rail traffic bearing collar

A rail transit and bearing ring technology, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problem of aggravating the geometric depression in the middle part of the bearing ring, so as to improve the metal utilization rate, reduce the processing time, and reduce the cutting process The effect of margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

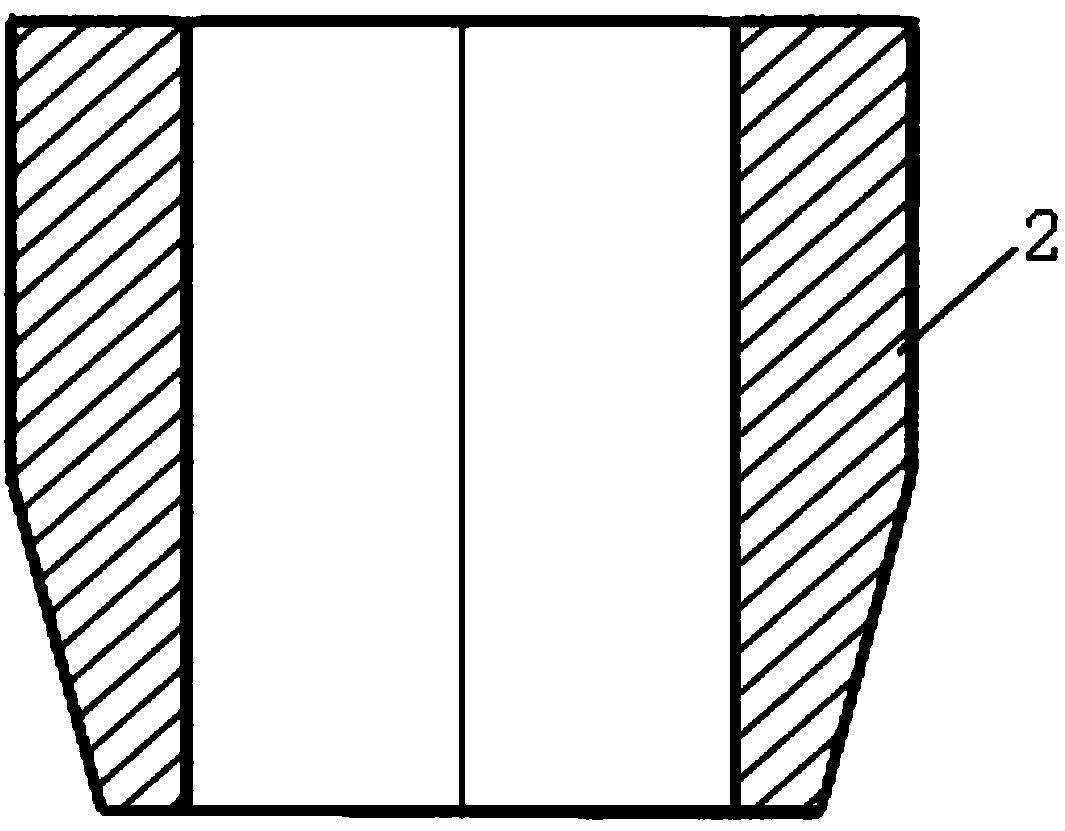

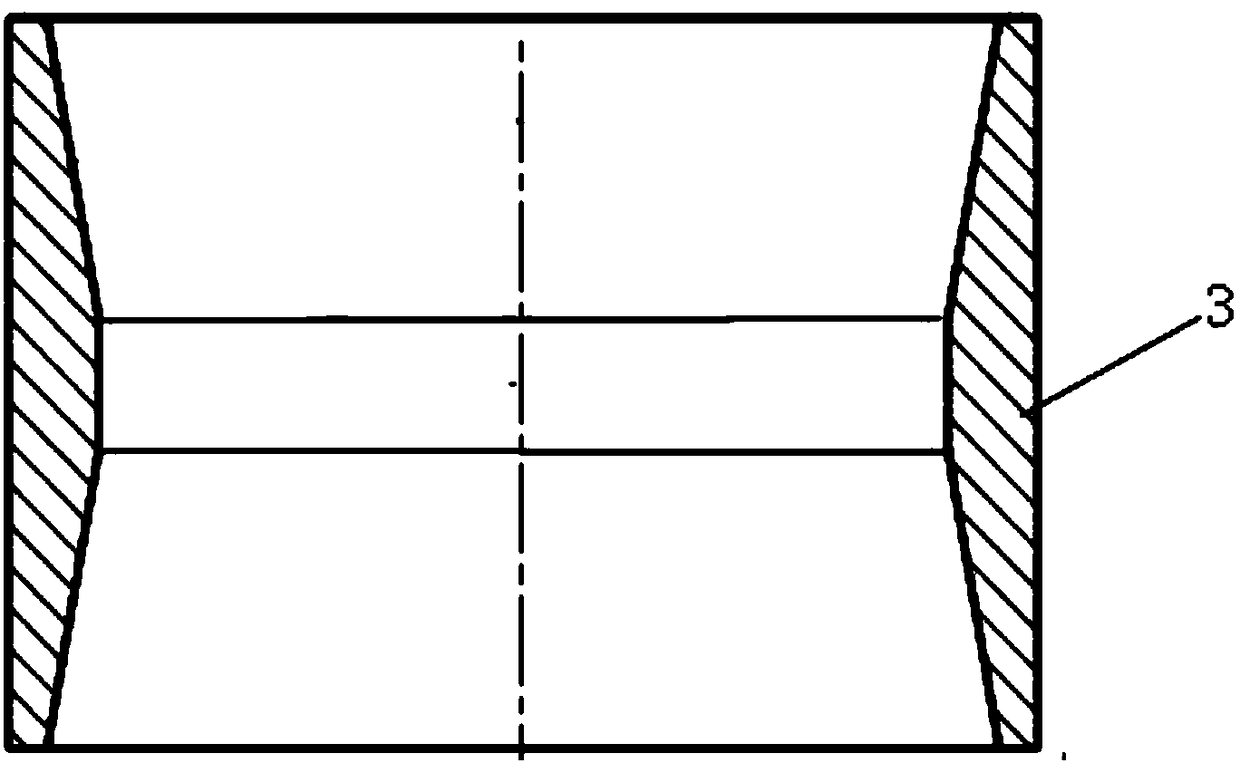

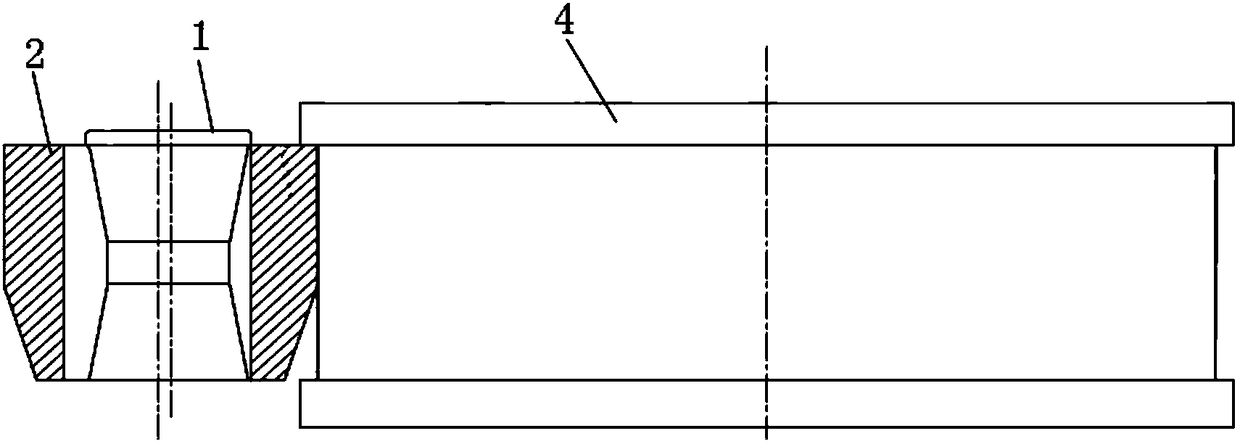

[0023] 1) The outer diameter D of one end of the tapered blank of the bearing outer ring produced by the Railway Bearing Company is 166mm, the inner diameter d is 101.14mm, the ring height H is 165mm, and the cone angle α is 77°. The hot rolling process parameters are shown in Table 1. Bearing rings obtained by hot roll forming with drive rolls (see Figure 4 ). The recessed position is determined to be in the middle of the ring by a special measuring tool, the recessed depth reaches 2.5 mm, and the recessed length reaches 43 mm.

[0024] 2) In the secondary quenching, the heating temperature is 800-810°C, the holding time is 5500s, and press quenching is used (see Figure 5 ) is quenched in quenching oil, the middle part of the bearing ring has no support to cool down and shrink, and the depth of the depression is further increased by 0.4mm.

[0025] 3) According to steps 1) and 2), determine the concave position and concave amount of the bearing ring, improve the structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com