Large cylindrical forge piece forging and rolling composite production technology

A rolling compounding and production process technology, applied in the field of large cylindrical forging forging rolling compounding production process, can solve the problems of complex free forging process, low production efficiency, high energy consumption, etc., and is beneficial to final forming and production. The effect of high efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] A kind of forging and rolling composite production process of large cylindrical forgings, it comprises the following preparation steps:

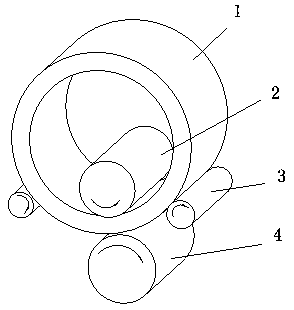

[0023] Step 1. Heat the steel ingot according to the design requirements and place it on the free forging equipment for upsetting, elongating and punching. When the forging ratio of the steel ingot is ≥ 4.6, prepare a cylindrical forging blank 1. Measure the surface temperature of the blank 1. When When the surface temperature of the blank 1 is lower than the final forging temperature + 100°C, the blank 1 is heated until the surface temperature of the blank 1 is greater than or equal to the final forging temperature + 100°C; the blank 1 that meets the temperature requirements is lifted to the top of the rolling equipment, The cylinder wall of the blank 1 is loaded between the upper roll 2 and the lower roll 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com