Method for manufacturing intermediate formed body of driven gear of rear axle of small and medium-sized automobile

A technology of automobile rear axle and driven gear, which is applied in the directions of wheels, vehicle parts, transportation and packaging, etc., can solve the problems of poor mechanical properties of intermediate formed bodies, poor mechanical properties of driven gears, and damage to metal fiber structure, etc. High efficiency, avoid folding, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0054] A method for manufacturing an intermediate formed body of a rear axle driven gear of a small and medium-sized automobile, comprising the following steps:

[0055] A. The blank is formed into a workpiece 11 through an upsetting step, and the height of the workpiece 11 is H5;

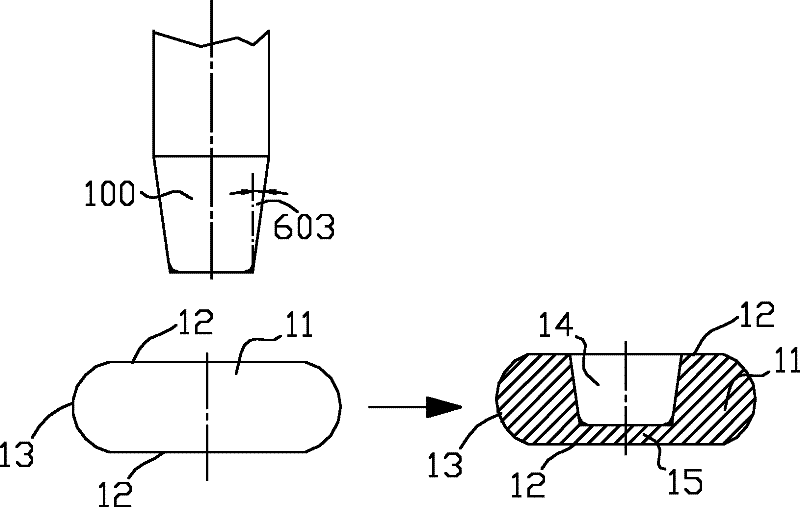

[0056] B, the workpiece 11 that step A obtains is placed on the punching station that is provided with conical punch 100, as figure 1 As shown, a frustum-shaped punching hole 14 and a punching skin 15 are formed on the workpiece 11 by a punch 100. The height of the punching skin 15 is greater than 0 and less than 6 mm, and the cone angle of the punch 100 is A3 Angle 603, the diameter of the small end of the punch 100 is d5, and the preferred mode of d5 is 45mm;

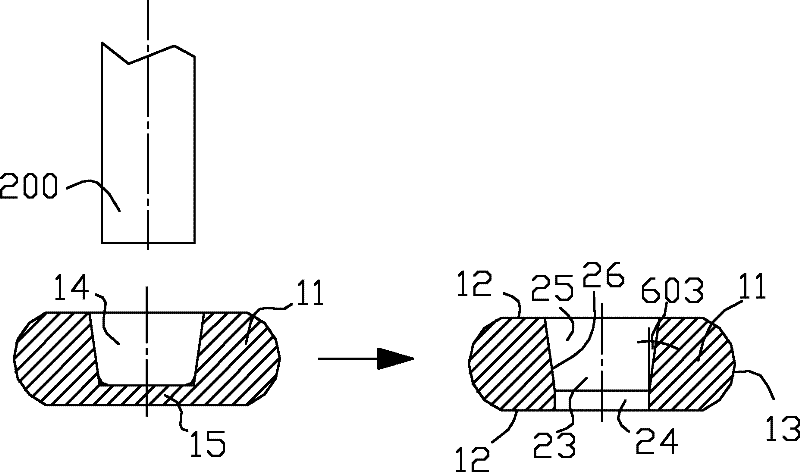

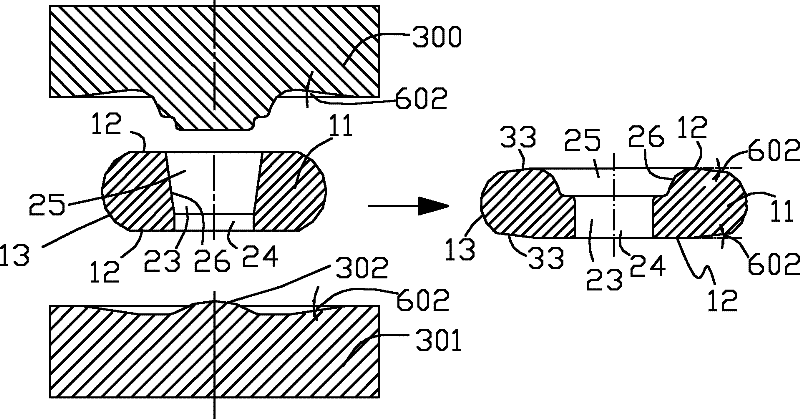

[0057] C, place the workpiece 11 again on the punching and peeling station provided with a cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com