Large-scale sprocket tooth-form automatic measurement device based on machine vision

A technology of machine vision and automatic measurement, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of relying on manual measurement, high work intensity, heavy workload, etc., to achieve both measurement accuracy and field of view, and reduce inspection Difficulty, effects of increased cost of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

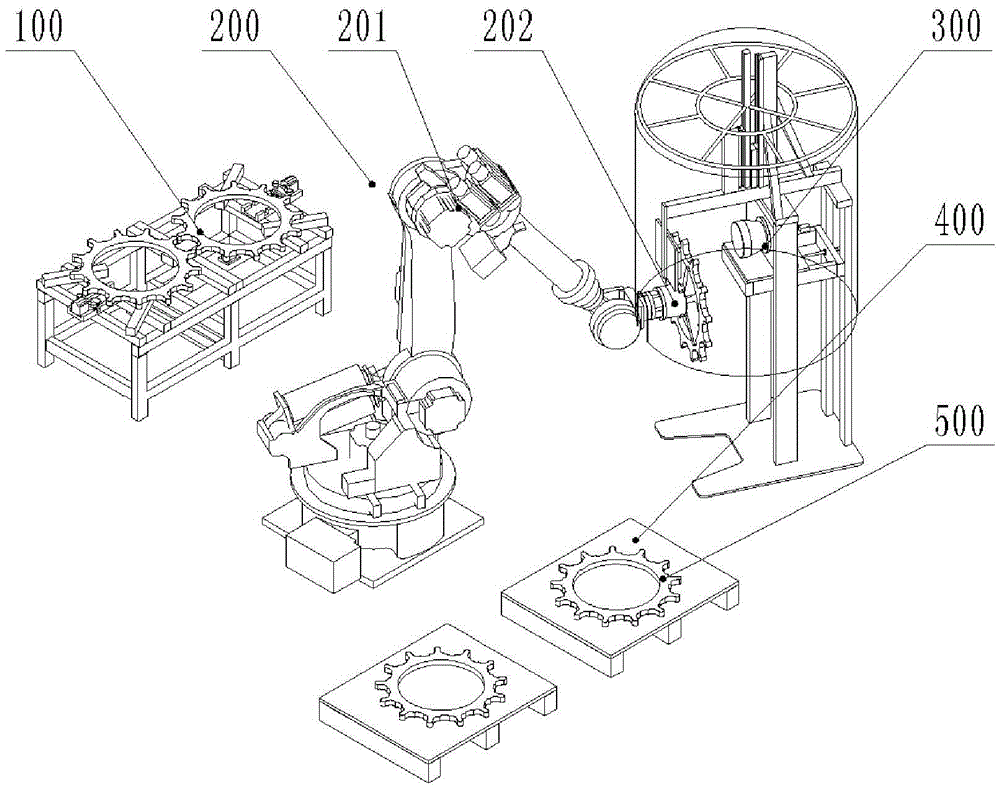

[0025] as attached figure 1 As shown, the present invention is a large-scale sprocket tooth shape automatic measuring device based on machine vision, which includes a feeding bin 100, a handling robot system 200, a visual inspection system 300 and a feeding bin 400;

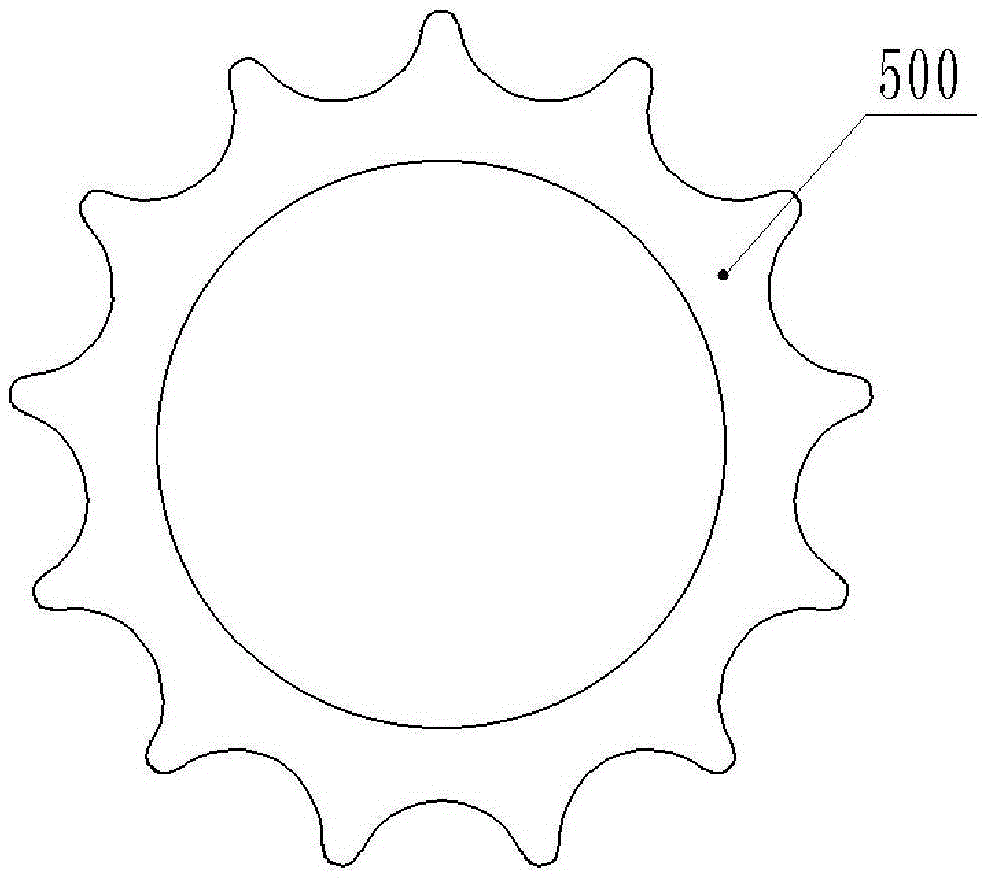

[0026] The feeding bin 100 is provided with a positioning cylinder and a positioning block for positioning the sprocket part 500;

[0027] The handling robot system 200 is composed of a handling robot 201 and a sprocket gripper 202, and the sprocket gripper 202 is connected to the sixth axis of the handling robot 201 through a mounting flange;

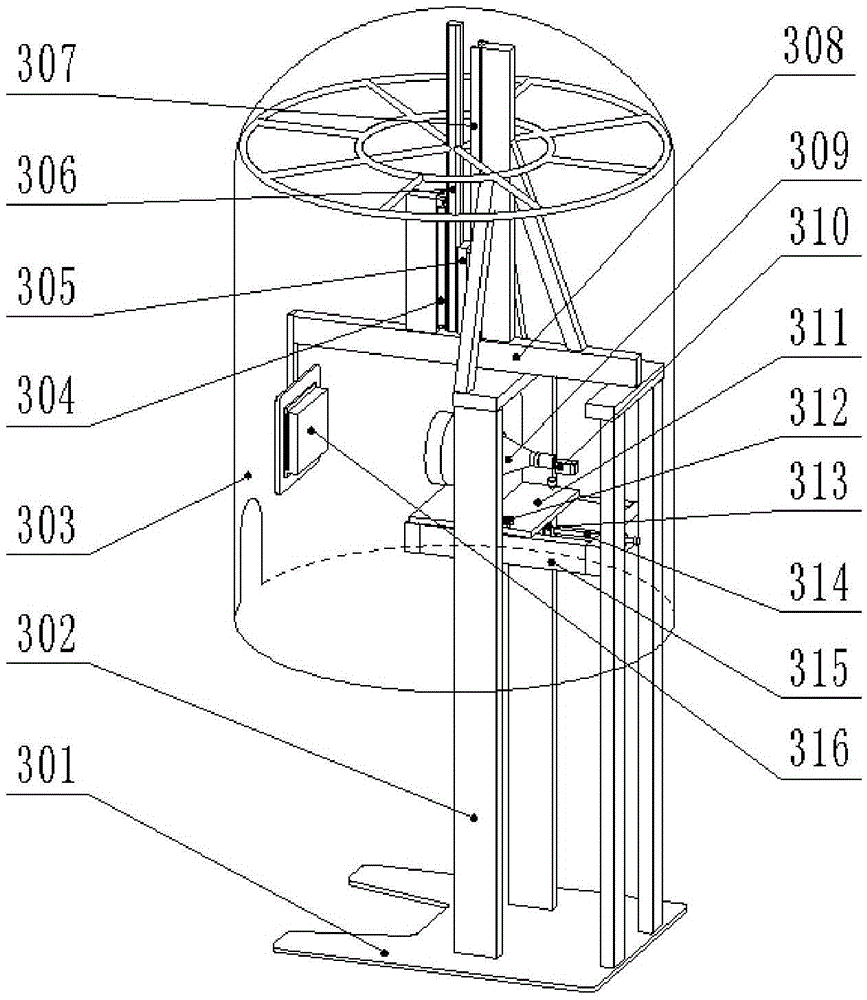

[0028] The visual inspection system 300 is composed of a frame, a visual measuring device and a shading device; the frame is used for installing the visual measuring device and the shading device; the visual measuring device is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com