Permanent magnet linear oscillation motor with stator

A permanent magnet linear and oscillating motor technology, applied in electrical components, electromechanical devices, etc., can solve the problems of difficult heat dissipation, poor structural robustness, large mover inertia, etc., and achieve low cost, good working performance, and high power density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

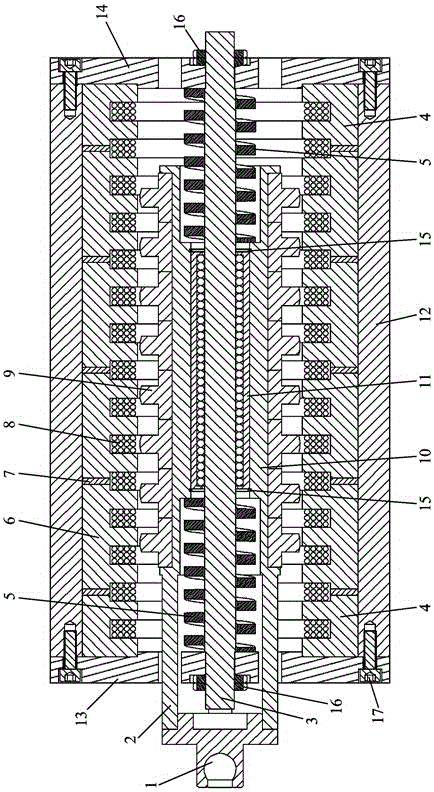

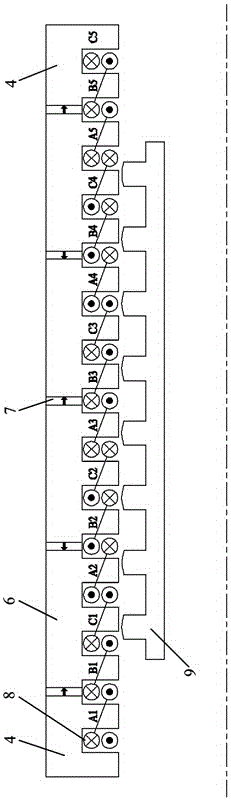

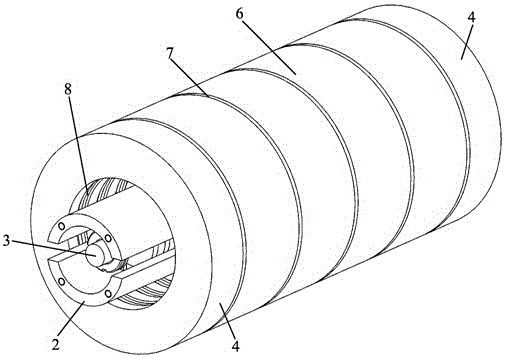

[0018] refer to figure 1 , image 3 and Figure 4 As shown, a stator permanent magnet linear oscillating motor of the present invention at least includes a connecting shaft end 1, an output bearing bush 2, a mover core shaft 3, a stator end ring gear 4, a resonant spring 5, a stator intermediate gear ring 6, a permanent magnet Steel ring 7, armature winding 8, mover gear ring 9, mover installation sleeve 10, linear sliding bearing 11, base sleeve 12; the mover mandrel 3 is axially arranged on the base sleeve In the center of cylinder 12, the mover mandrel 3 is fixed between the motor front end cover 13 and the motor rear end cover 14 through lock nuts 16; the motor front end cover 13 and the motor rear end cover 14 are respectively fixed on the machine body At both ends of the seat sleeve 12, there is a mover installation sleeve 10 in the middle of the mover core shaft 3; the mover gear ring 9 is sequentially nested on the outer surface of the mover installation sleeve 10 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com