Patents

Literature

38 results about "Structural robustness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Robustness is the ability of a structure to withstand events like fire, explosions, impact or the consequences of human error, without being damaged to an extent disproportionate to the original cause - as defined in EN 1991-1-7 of the Accidental Actions Eurocode.

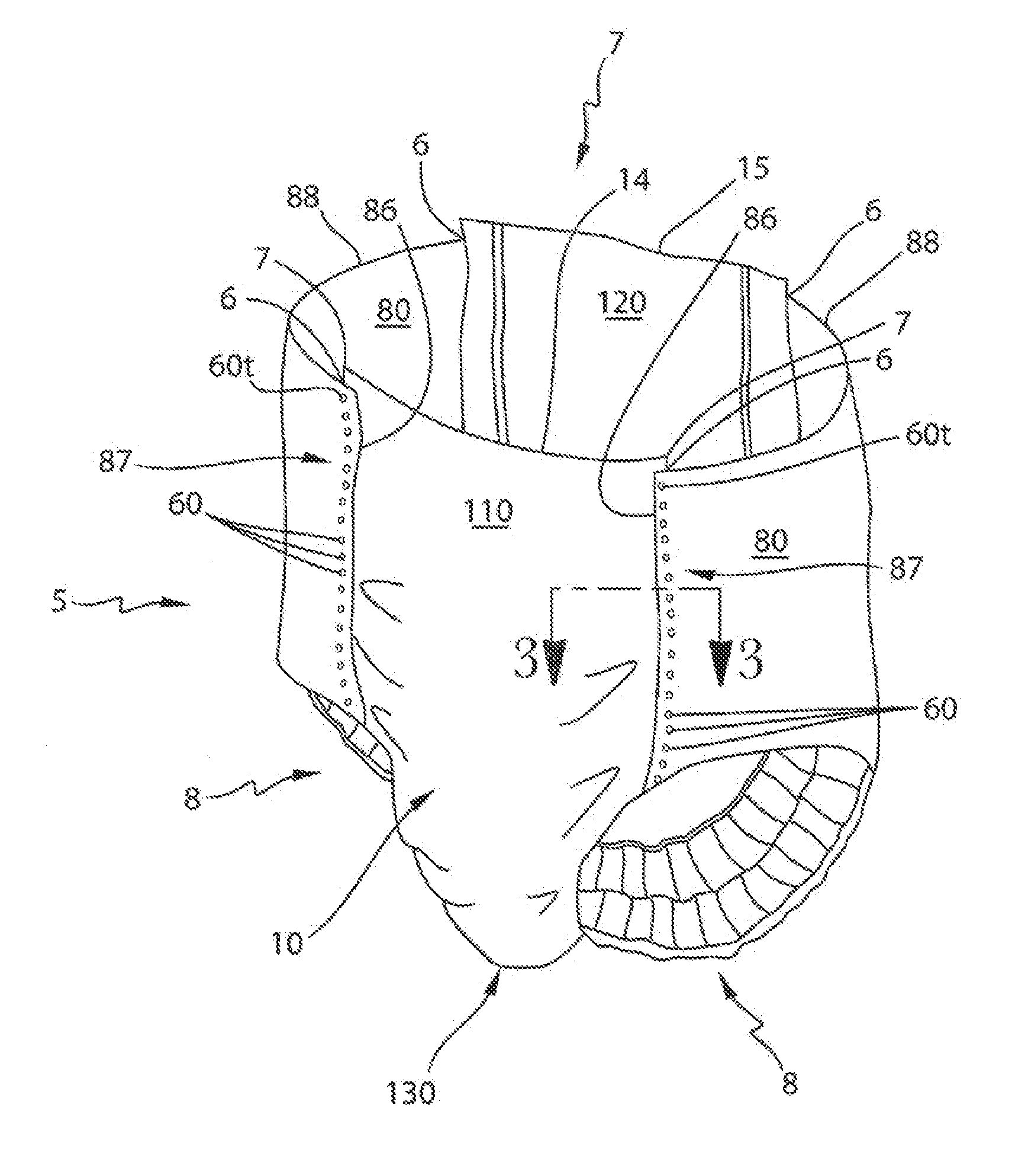

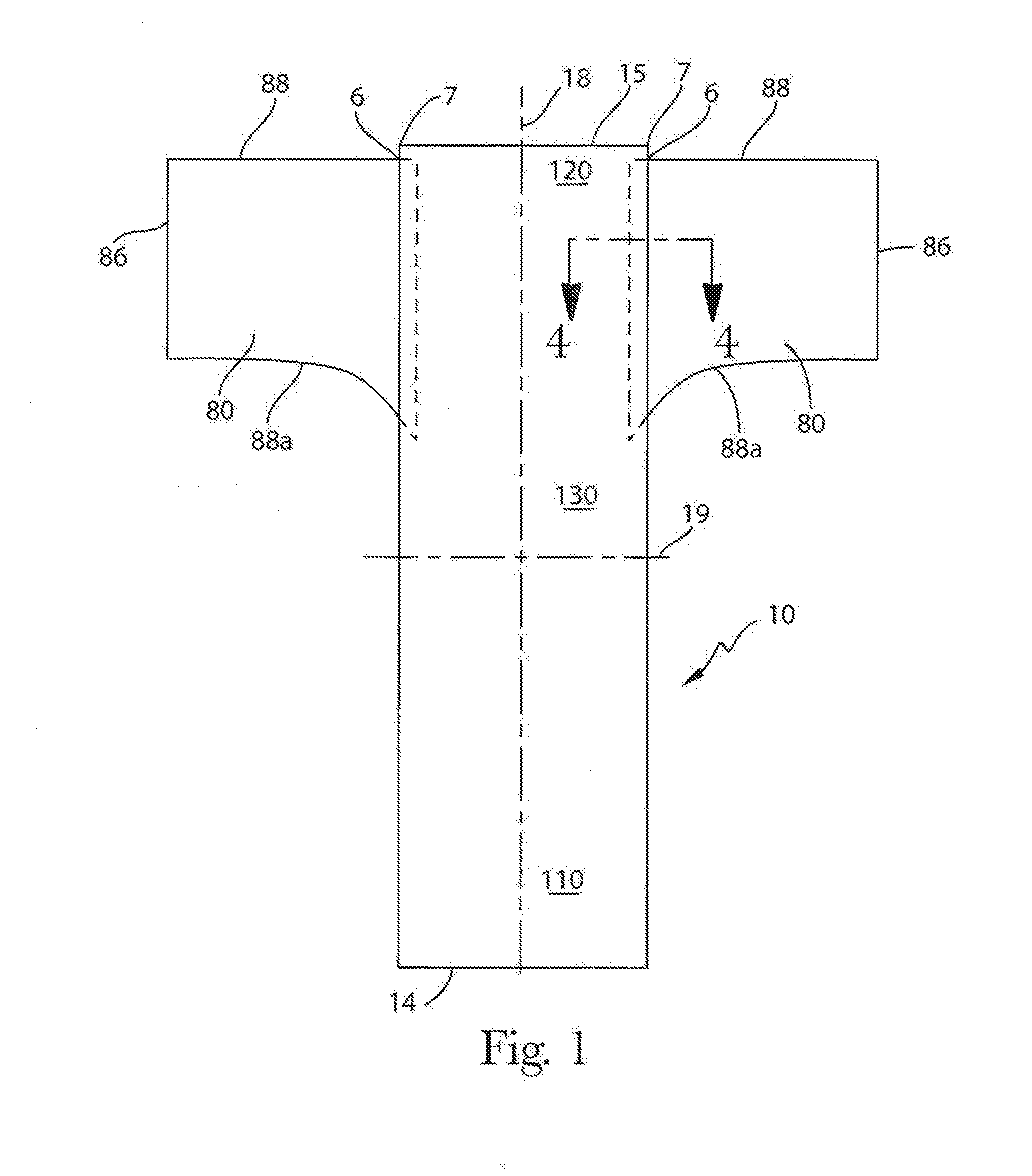

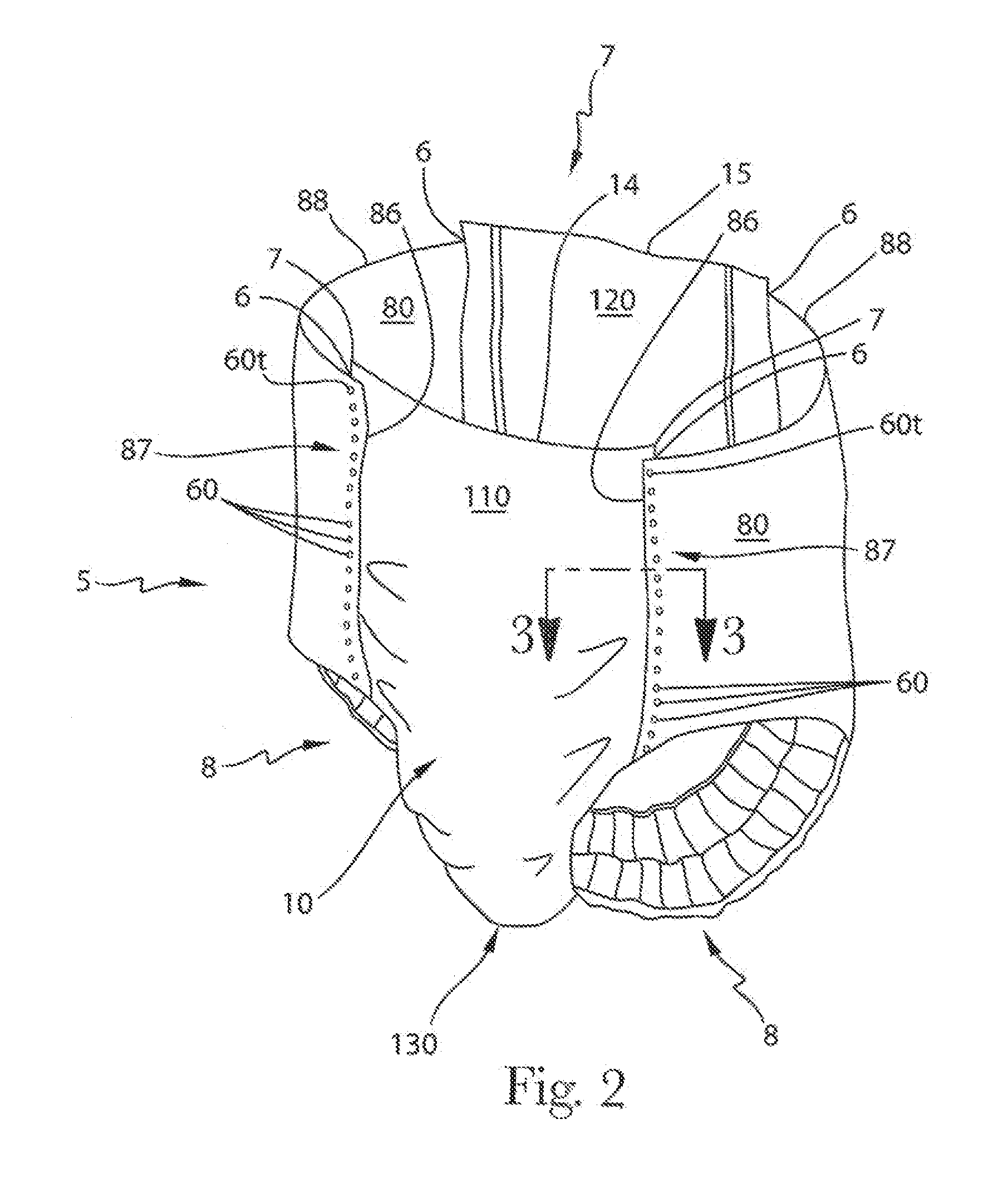

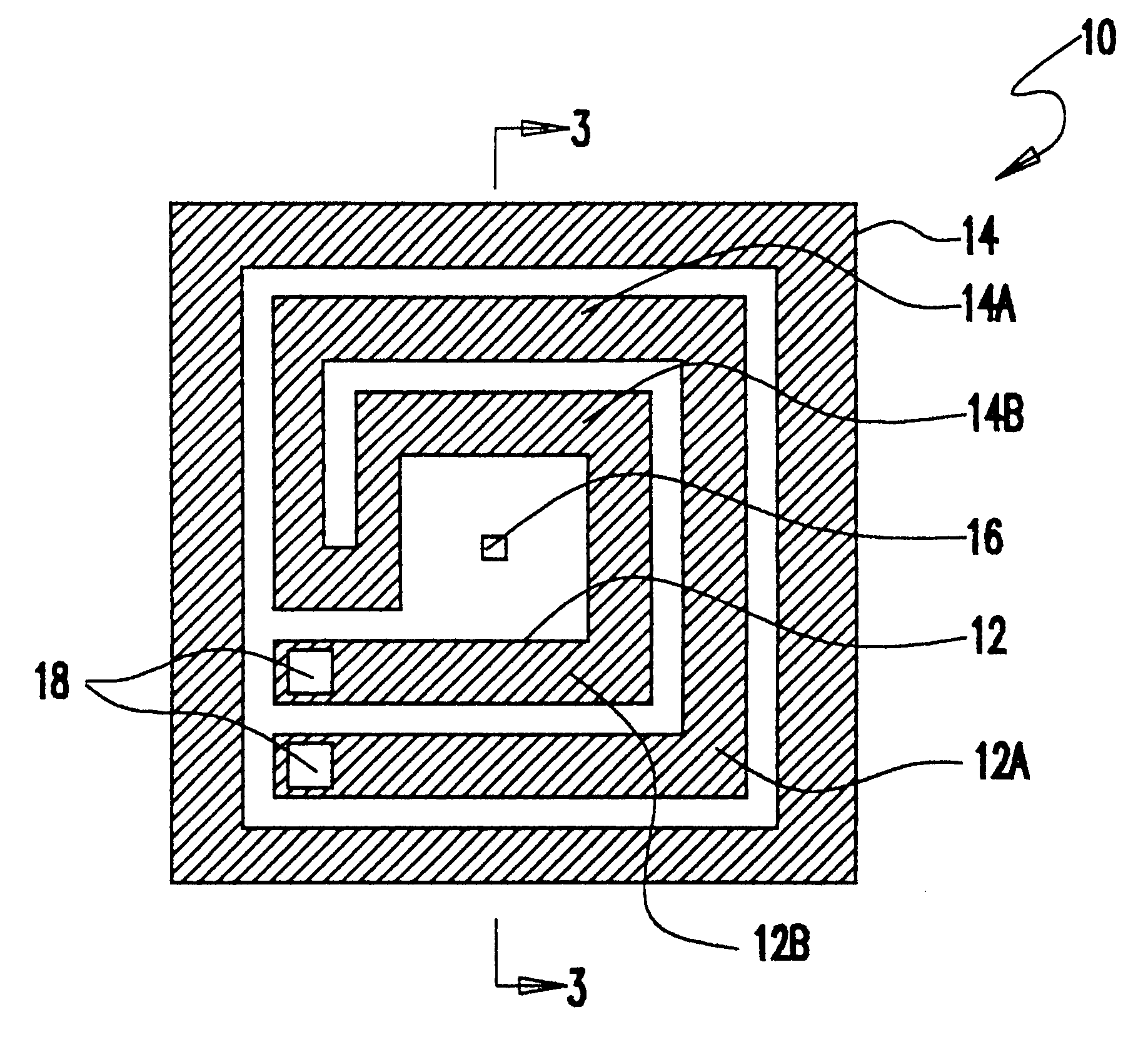

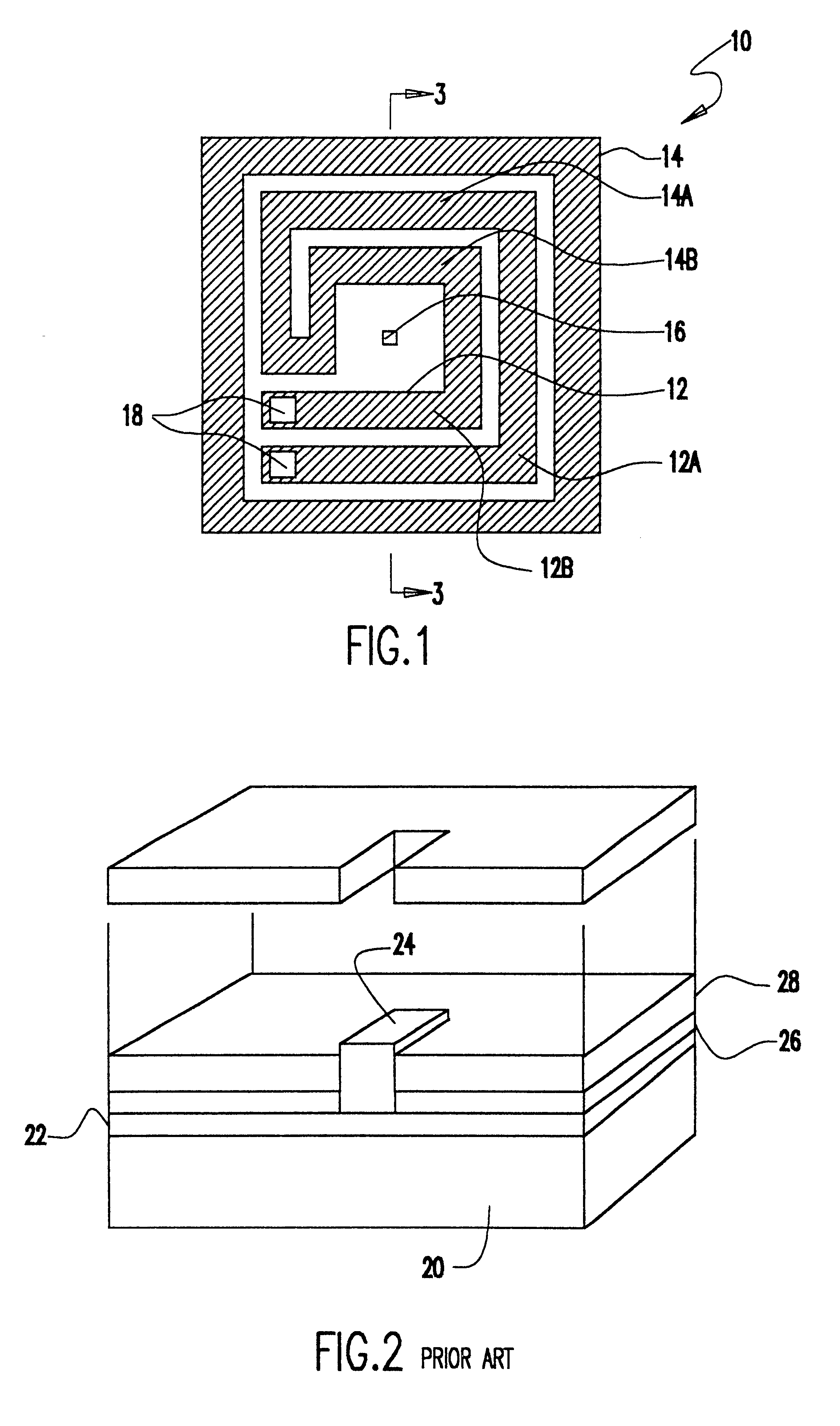

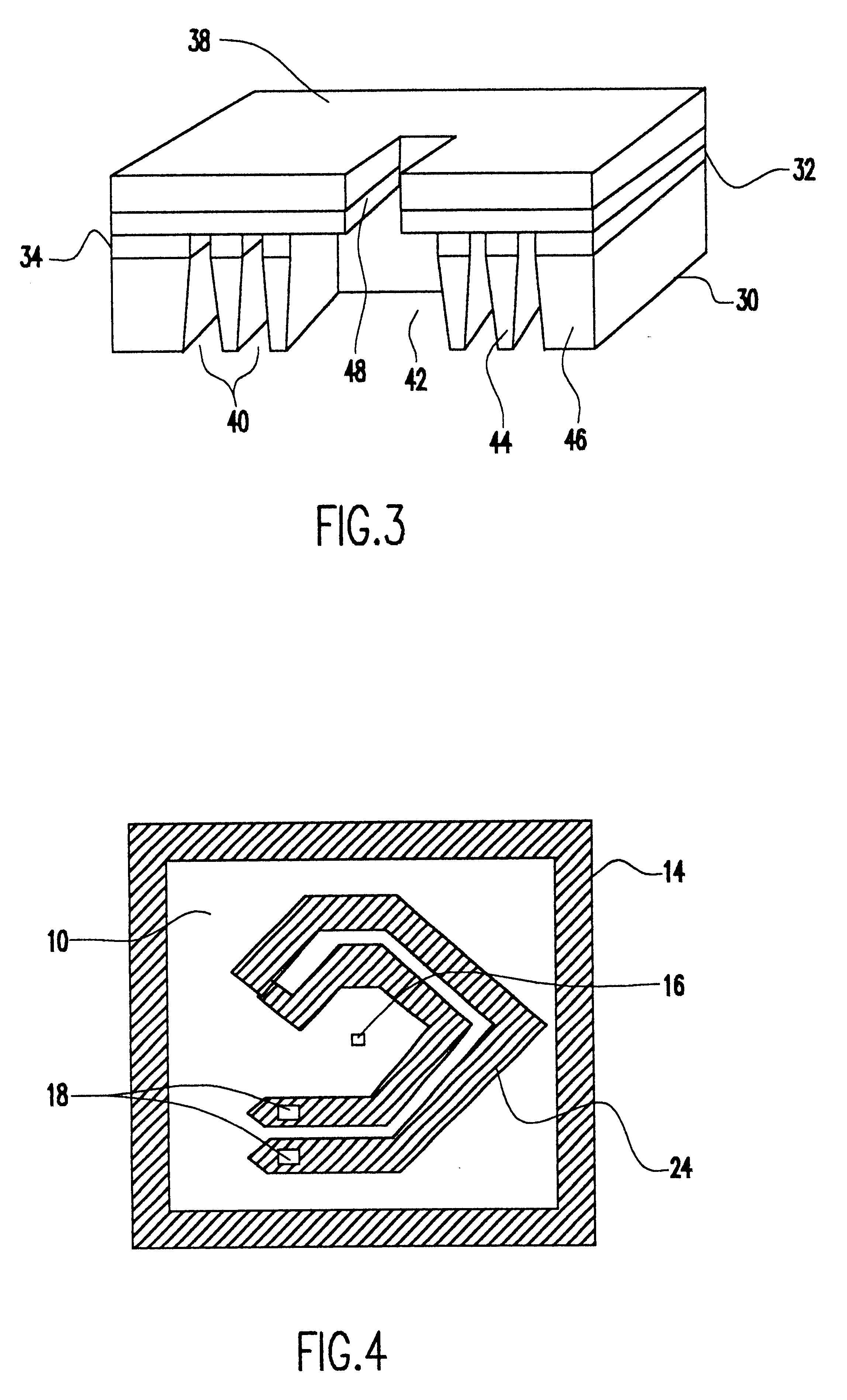

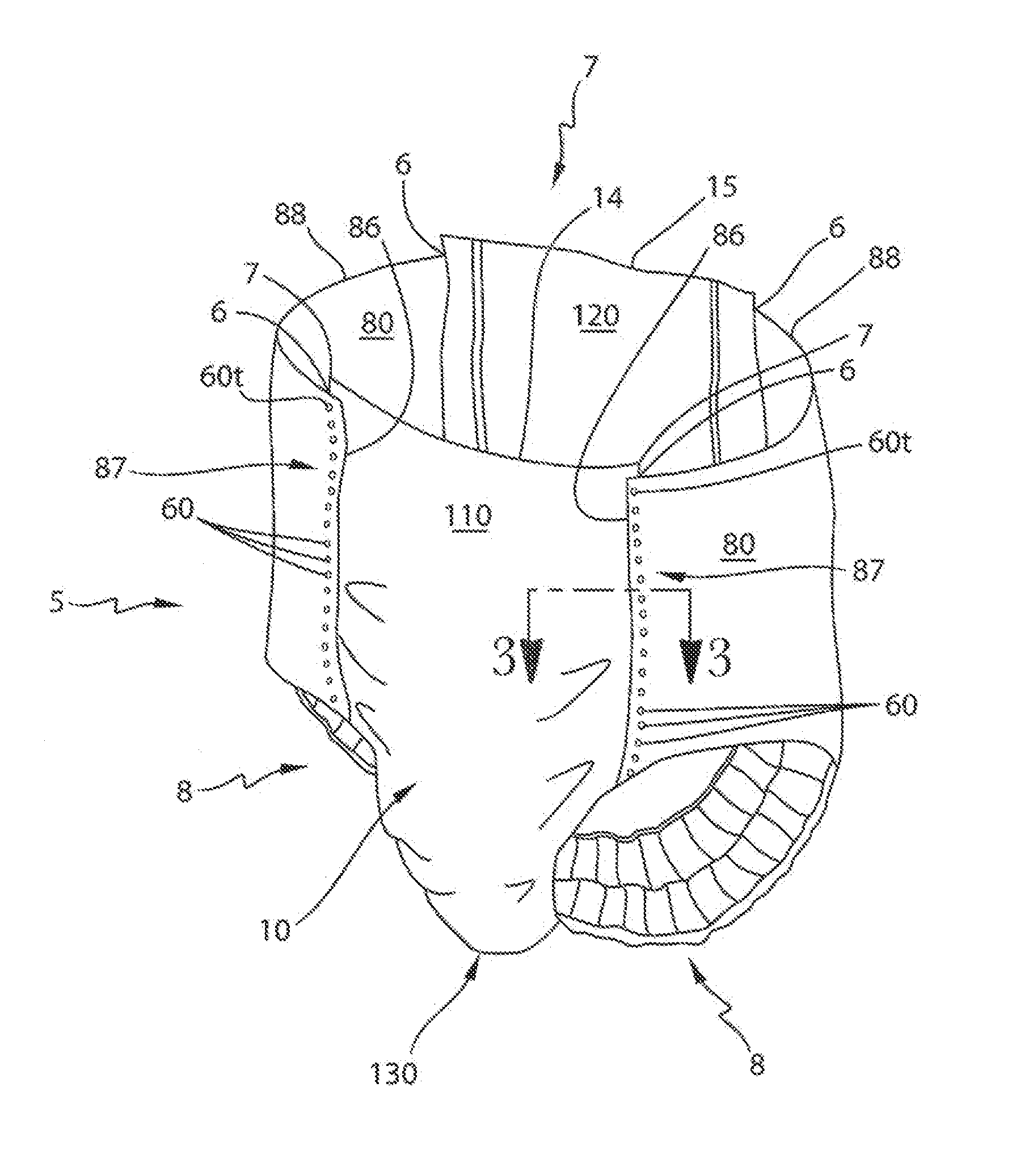

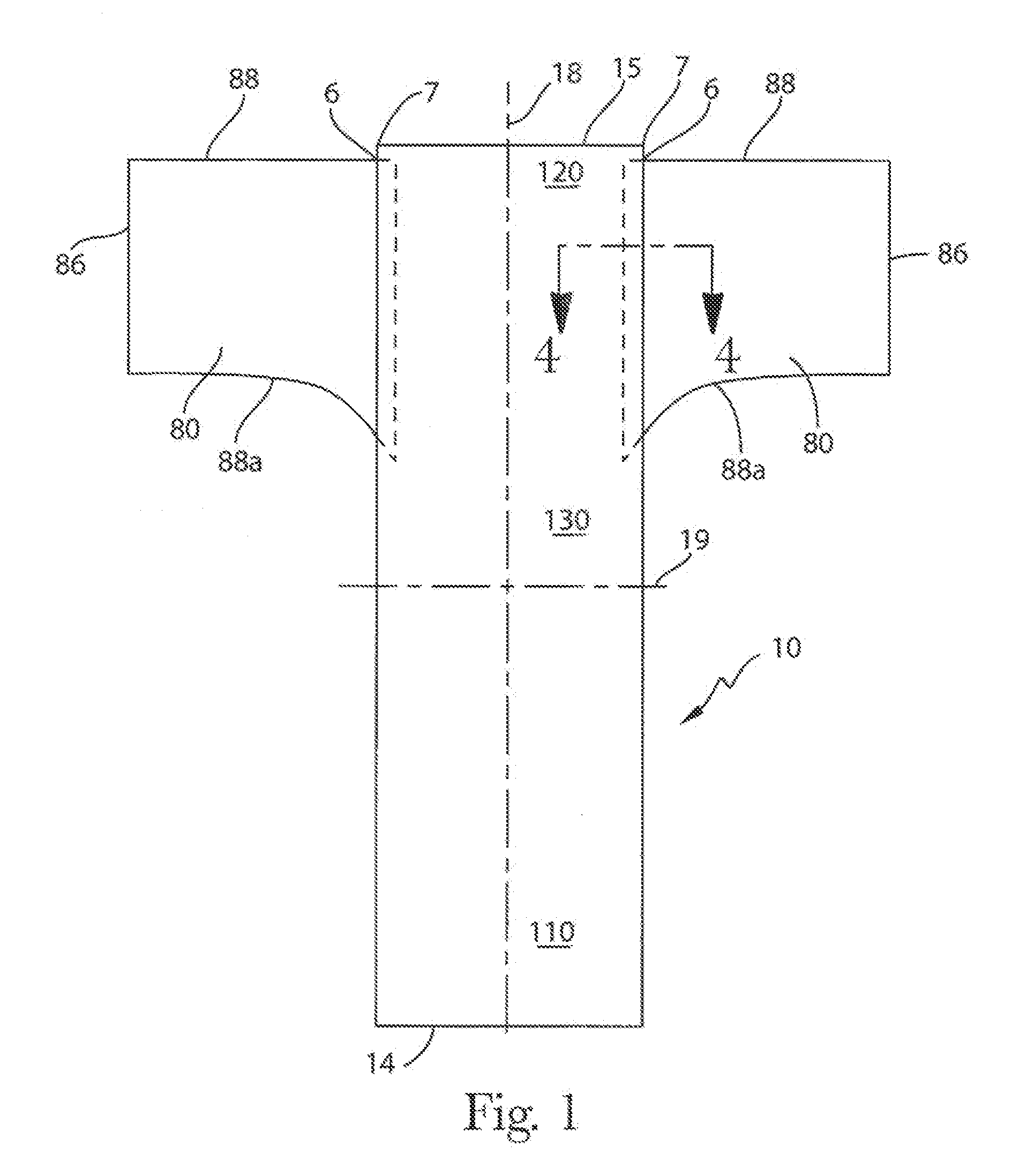

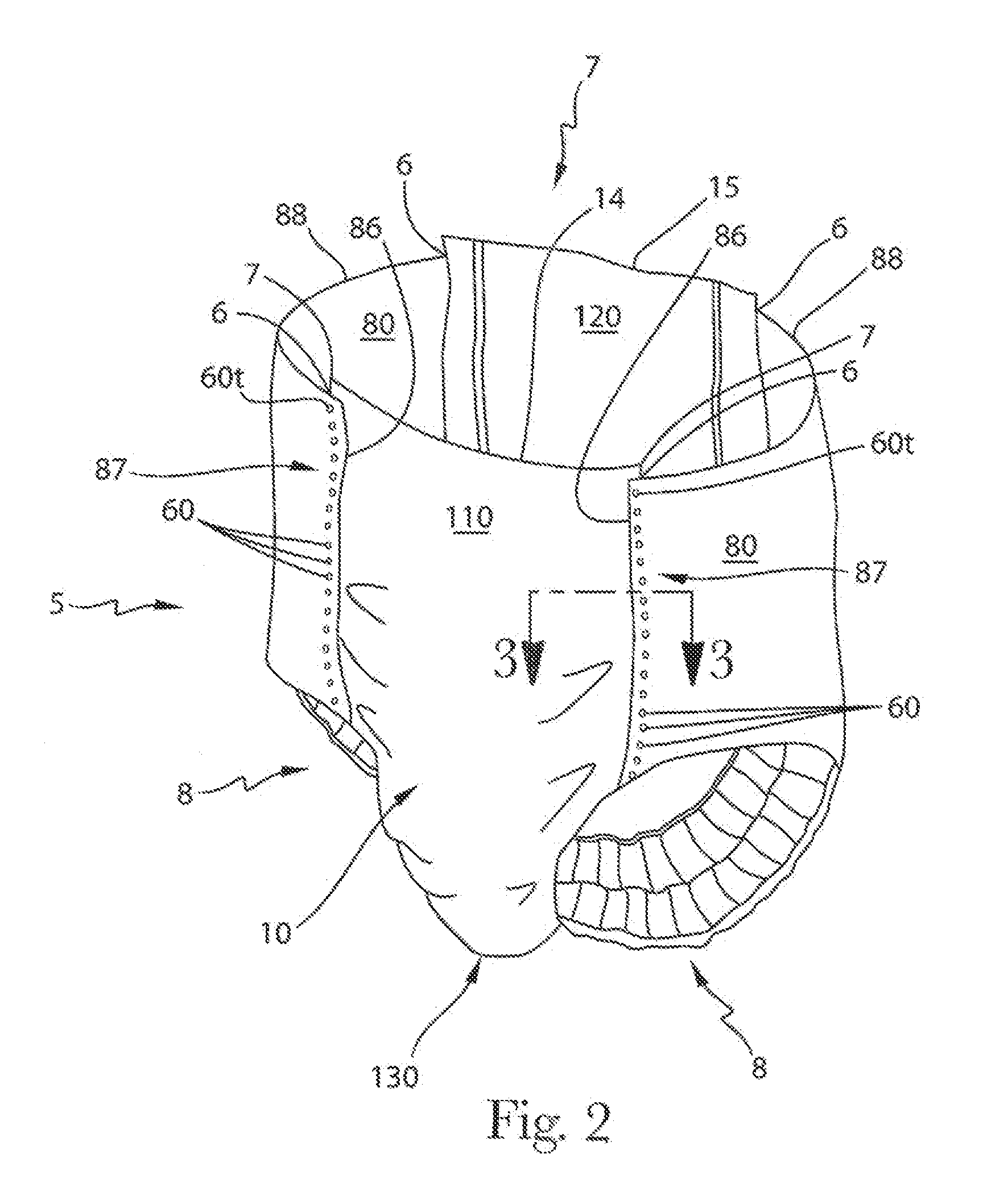

Disposable absorbent pant with efficient design and convenient single section side stretch panels

A disposable absorbent pant having single-section side stretch panels is disclosed. The pant may have features including seams of overlapping configuration or sandwiched configuration, or a belt configuration. A seam of overlapping configuration may be formed by bonds with features that provide for tensile strength in a lateral direction, while providing enhanced tearability for convenient removal, and may include additional features including indicia of a tearing location, a tear-inducing notch, and structure to grasp for tearing. A seam of sandwiched configuration may provide a finished outward appearance. A belt configuration provides counterbalancing of lateral tension forces and reduces demand for structural robustness in backsheet materials, seams and bonds. Sandwiched and belt configurations allow for extended lateral width of side panels and increased stretch, without extending overall hoop circumference at risk of unduly loose fit.

Owner:THE PROCTER & GAMBLE COMPANY

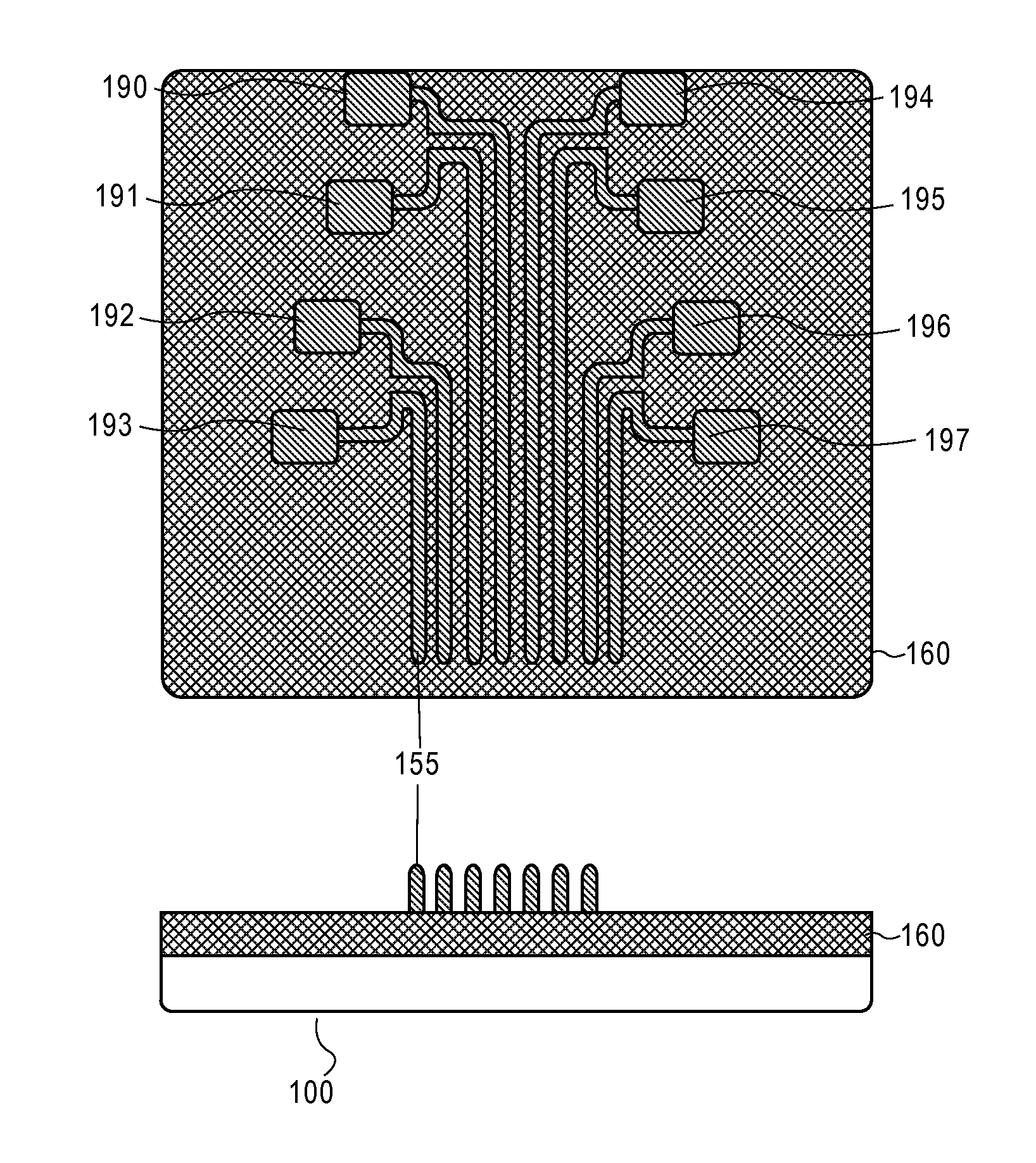

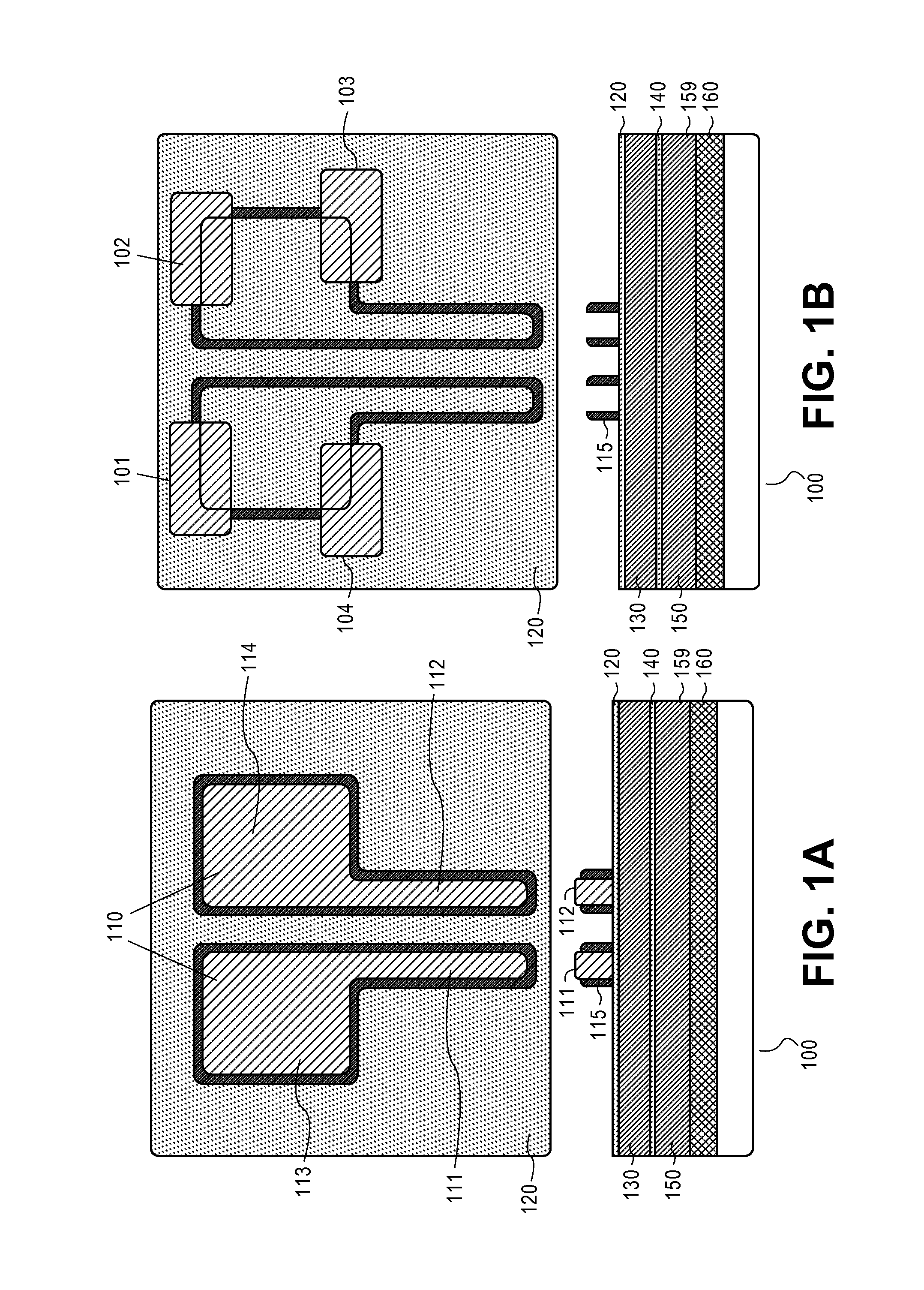

Pitch division patterning techniques

ActiveUS20110151668A1Semiconductor/solid-state device manufacturingOriginals for photomechanical treatmentEngineeringSpatial isolation

Embodiments of the invention comprise pitch division techniques to extend the capabilities of lithographic techniques beyond their minimum pitch. The pitch division techniques described herein employ additional processing to ensure pitch divided lines have the spatial isolation necessary to prevent shorting problems. The pitch division techniques described herein further employ processing acts to increase the structural robustness of high aspect ratio features.

Owner:INTEL CORP

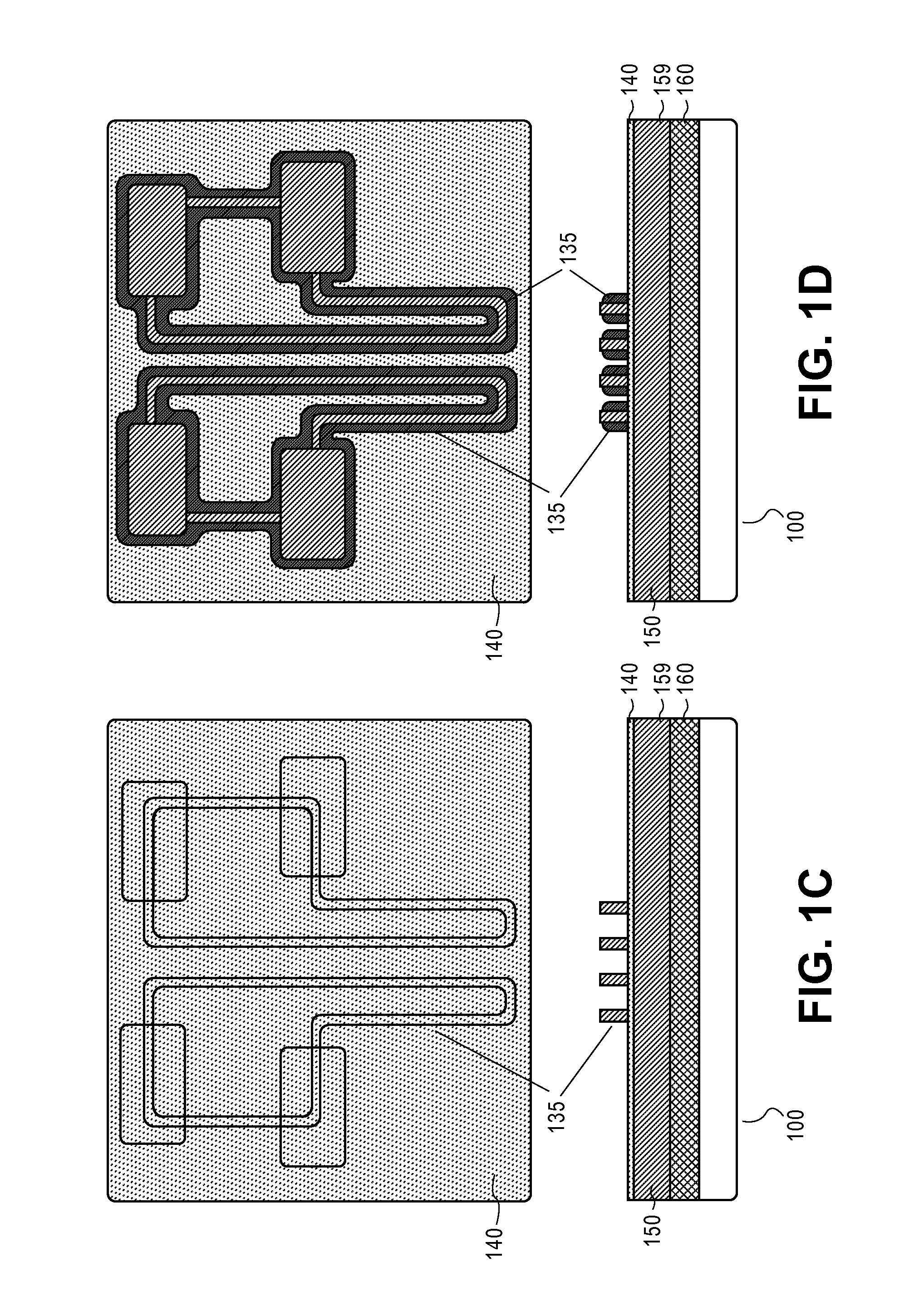

Structure robustness optimization design method containing interval parameter uncertainty

ActiveCN106096127AAvoid lossImprove effectivenessGeometric CADSpecial data processing applicationsEvolution algebraAlgorithm

The invention discloses a structure robustness optimization design method containing interval parameter uncertainty. The method comprises the following steps that a structure robustness optimization design model based on an internal is built; sample points are obtained by adopting a Latin hypercube sampling and co-simulating technique; a Kriging proxy model for predicting a target function and a constraint function is constructed; an interval robustness optimization design model is solved by adopting a double layer-nested genetic algorithm, left boundaries and right boundaries of the target function and the constraint function are calculated in the inner layer of the genetic algorithm, and in the outer layer of the genetic algorithm, total interval constraint violation degree vectors of all design vectors are calculated, and the feasibility of the total interval constraint violation degree vectors is judged; all the design vectors are subjected to advantage and disadvantage sorting according to a superior relationship criterion based on the interval constraint violation degree vectors; when a largest evolution algebra or convergence threshold value is achieved, the optimal solution of the robustness optimization design model is output, and the structure robustness optimization design containing interval parameter uncertainty is achieved.

Owner:ZHEJIANG UNIV

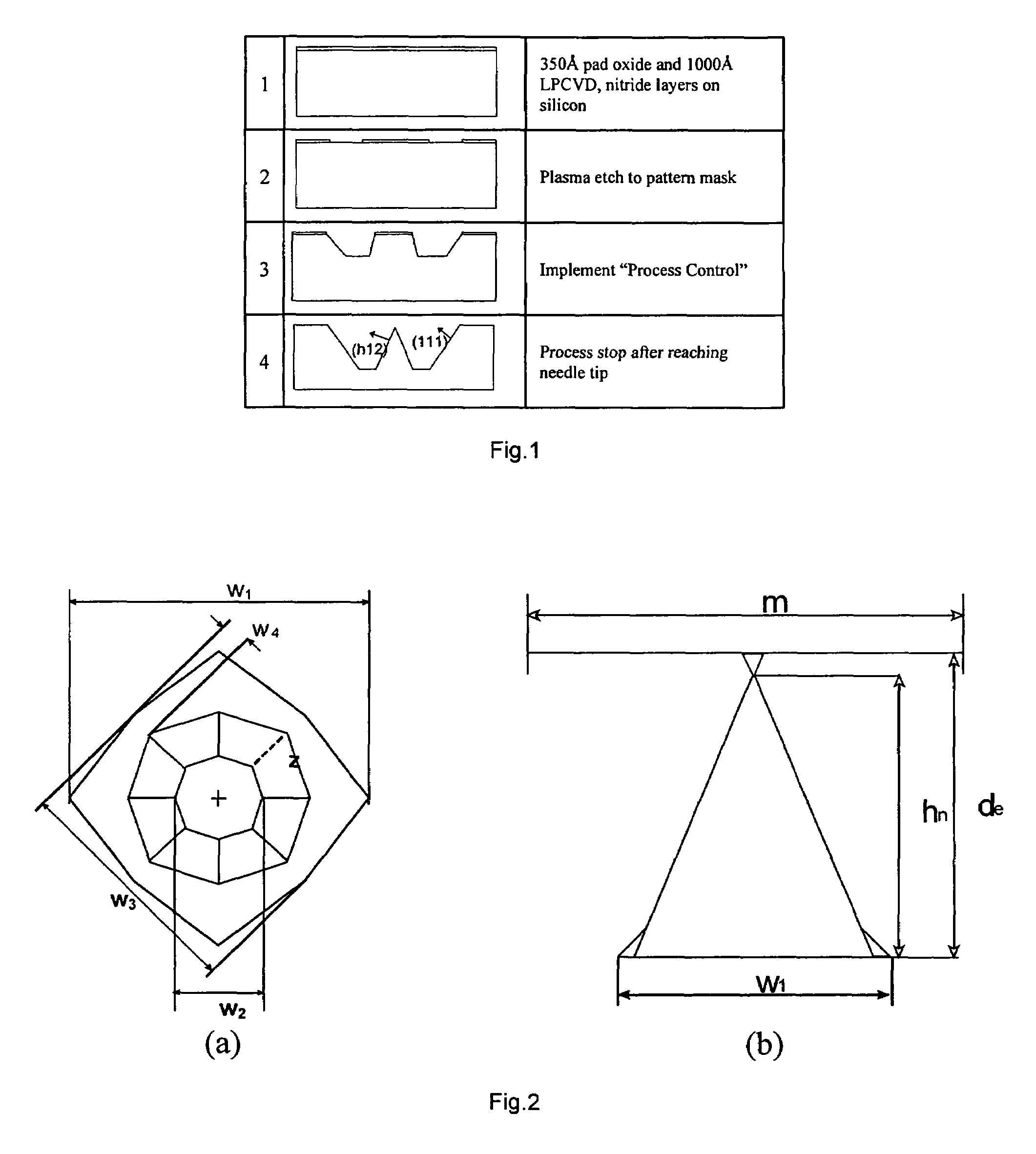

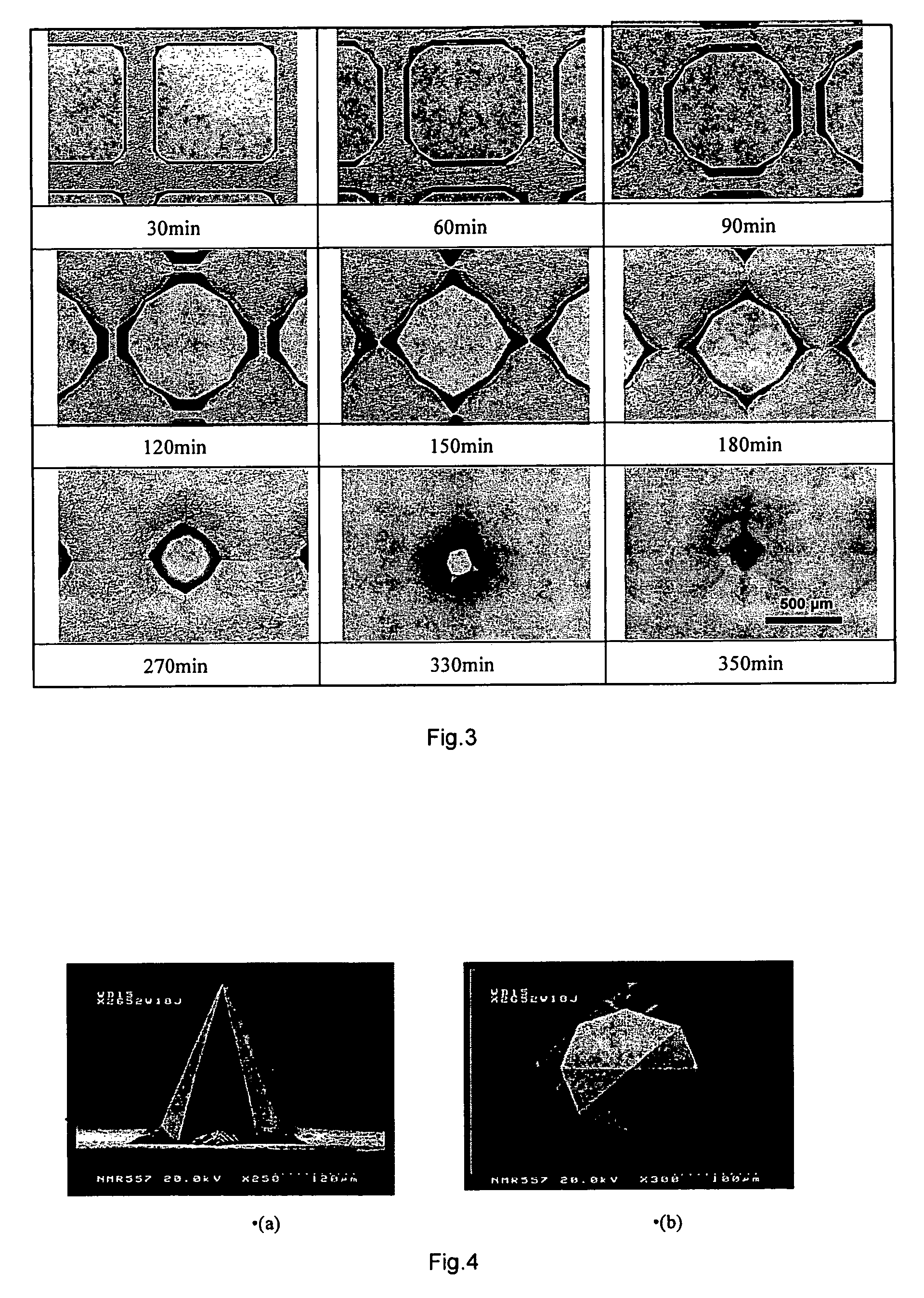

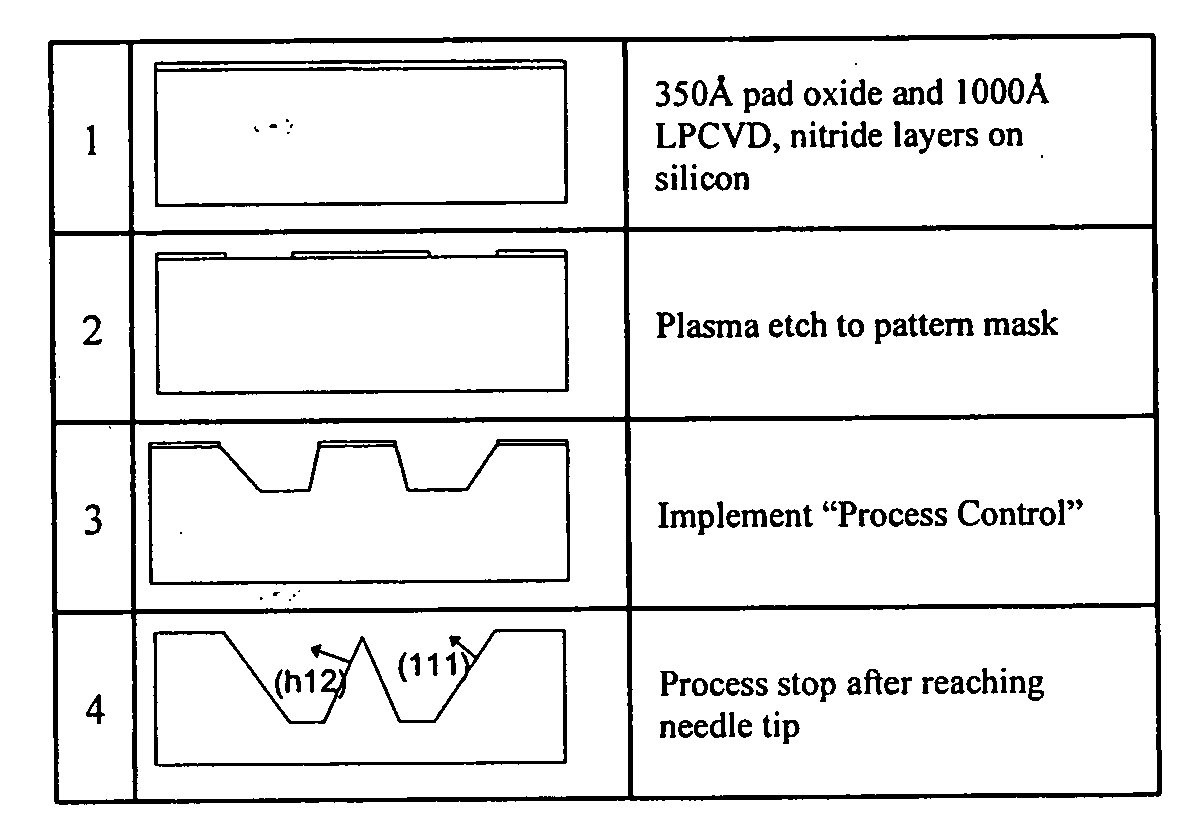

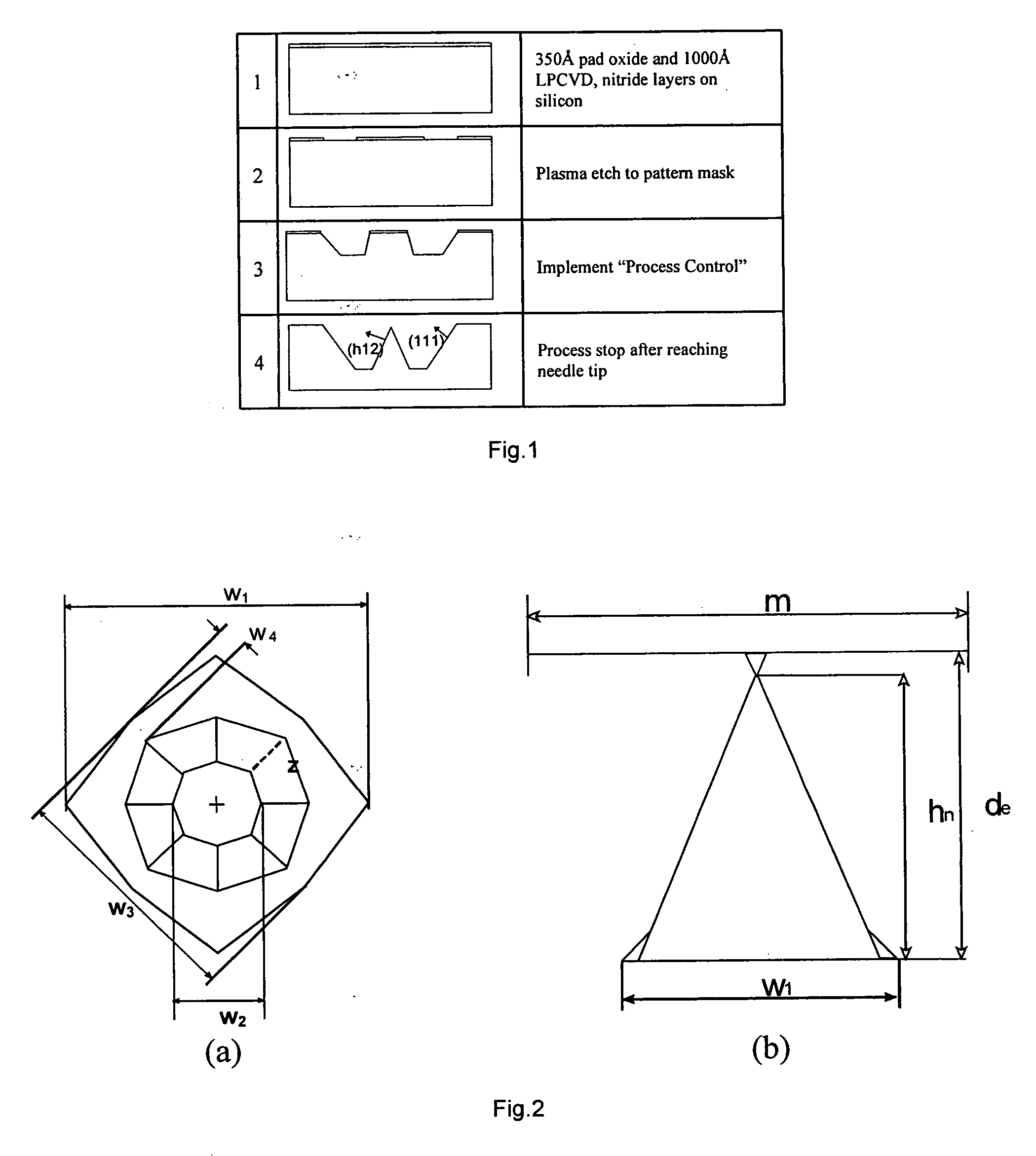

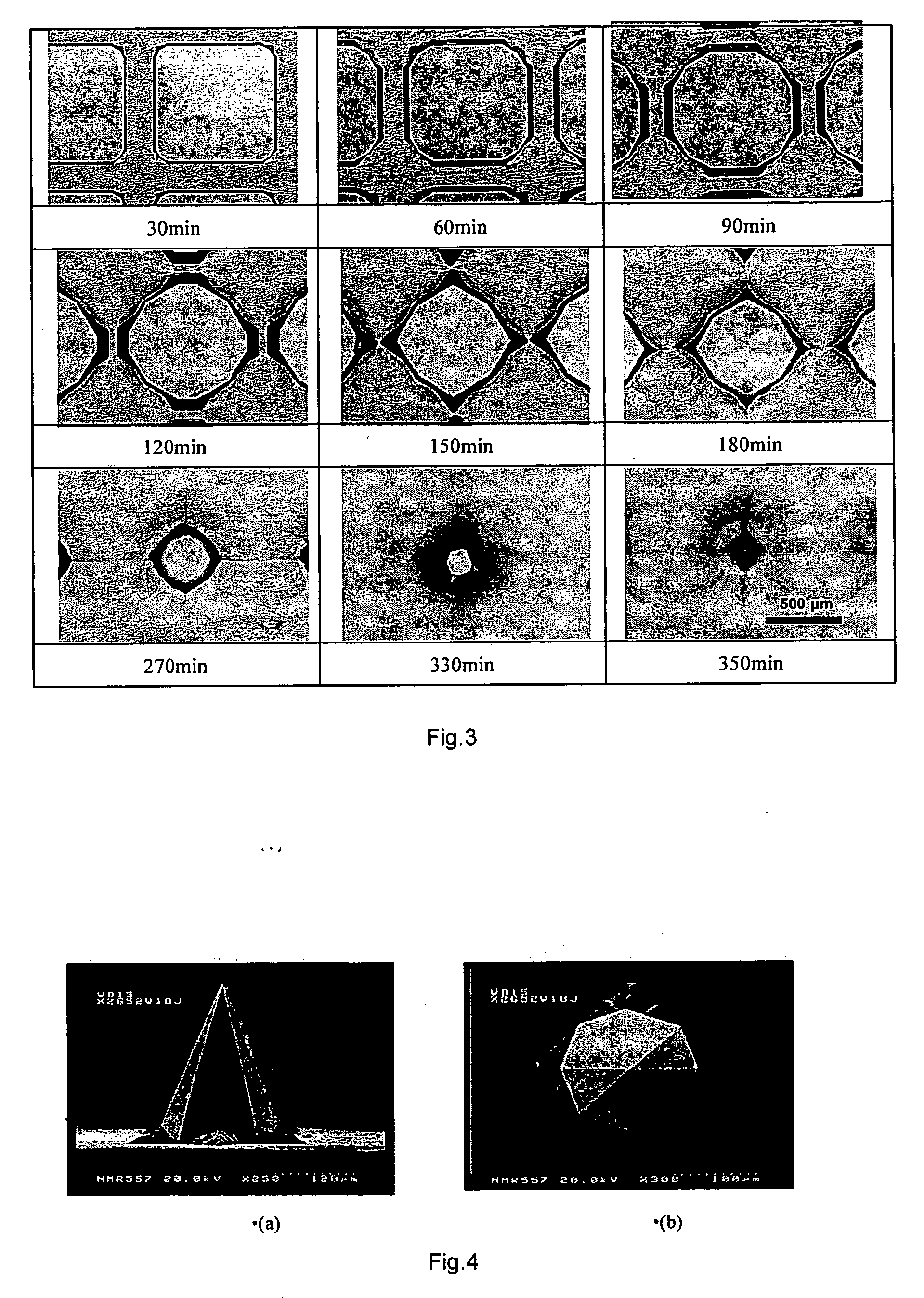

Wet etch processing

A method of wet etching produces high-precision microneedle arrays for use in medical applications. The method achieves precise process control over microneedle fabrication, at single wafer or batch-level, using wet etching of silicon with potassium hydroxide (KOH) solution by accurately identifying the etch time endpoint. Hence, microneedles of an exactly required height, shape, sharpness and surface quality are achieved. The outcome is a reliable, reproducible, robust and relatively inexpensive microneedle fabrication process. Microneedles formed by KOH wet etching have extremely smooth surfaces and exhibit superior mechanical and structural robustness to their dry etched counterparts. These properties afford extra reliability to such silicon microneedles, making them ideal for medical applications. The needles can also be hollowed. Wet etched silicon microneedles can then be employed as masters to replicate the improved surface and structural properties in other materials (such as polymers) by moulding.

Owner:UNIV COLLEGE CORK NAT UNIV OF IRELAND CORK

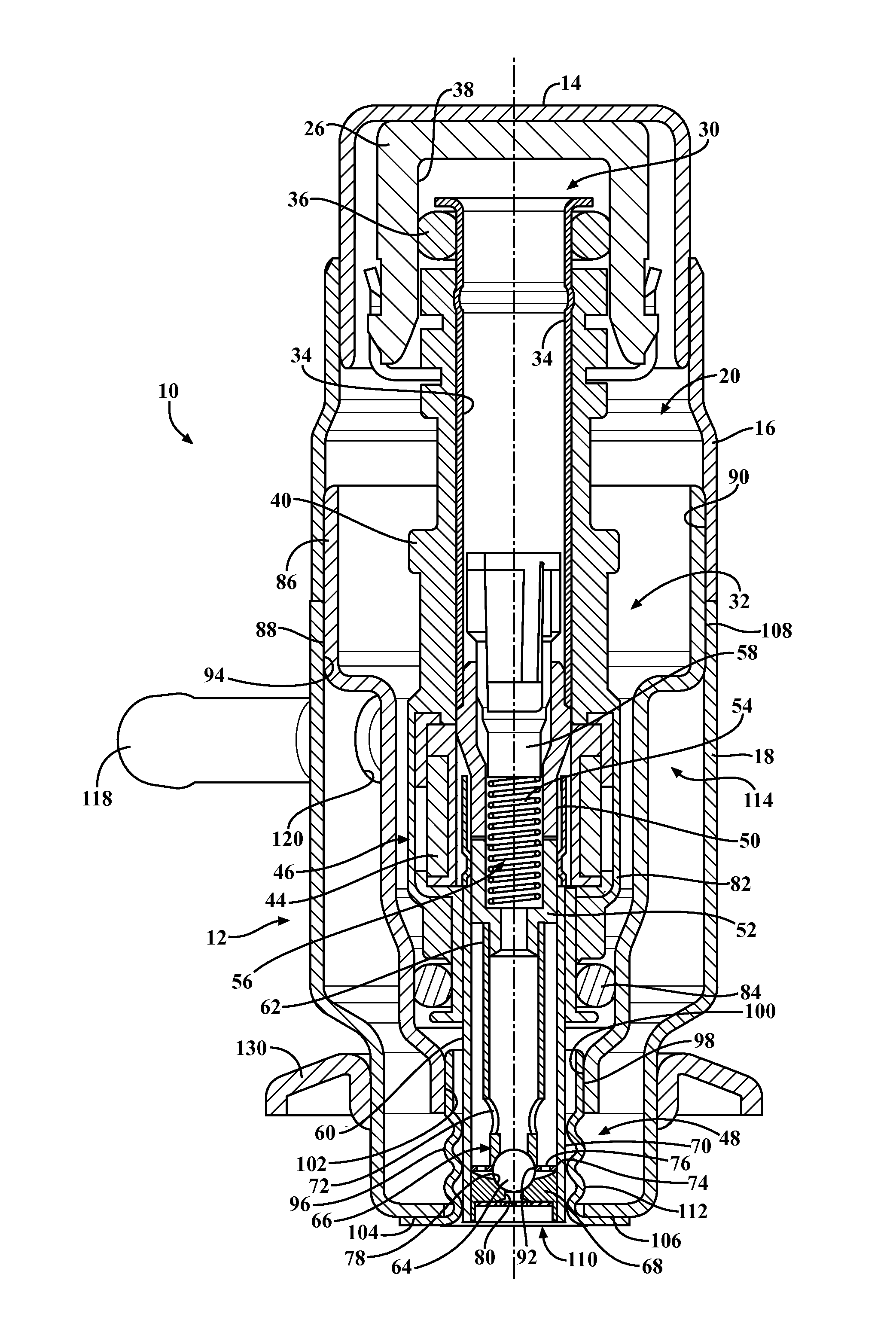

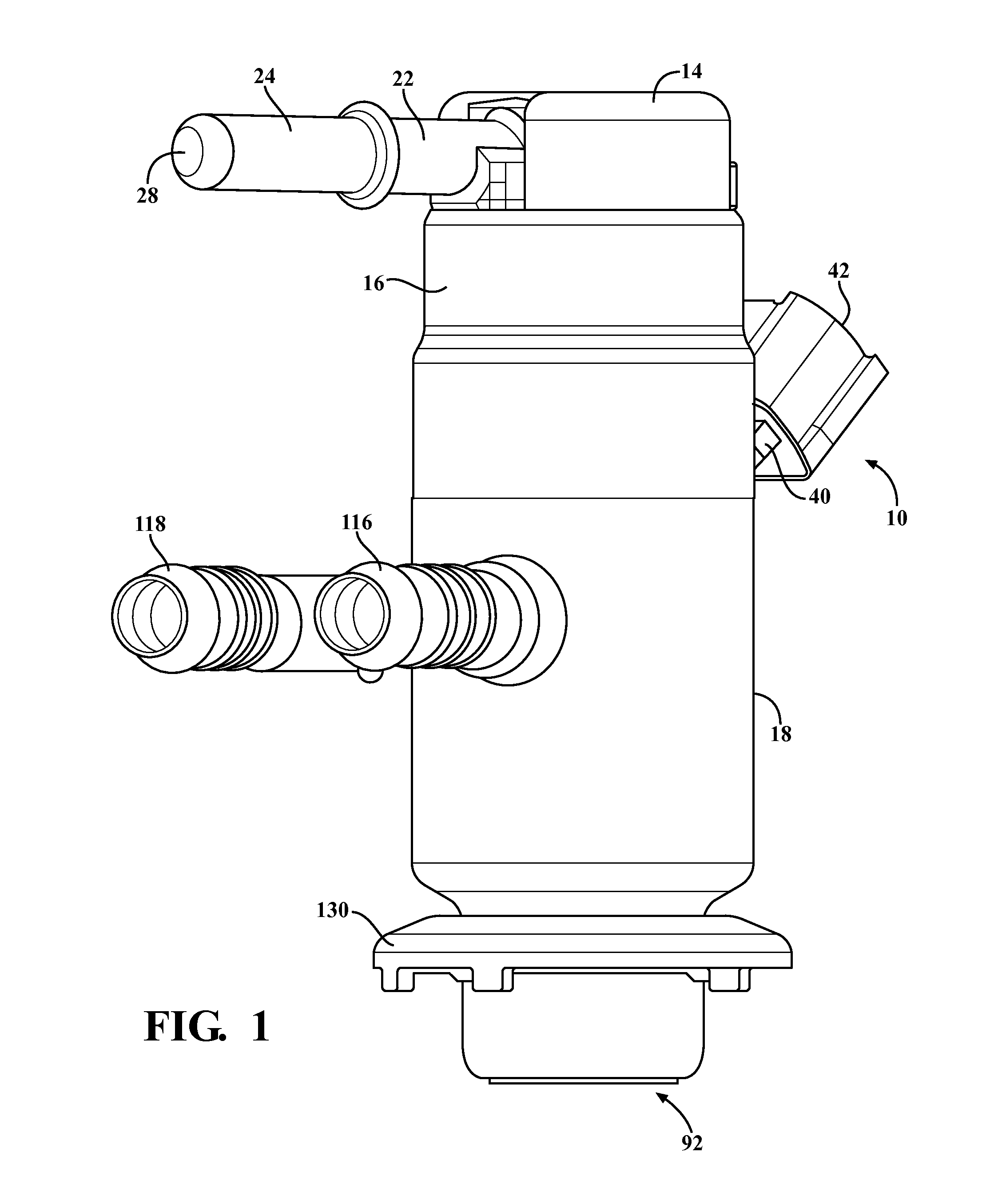

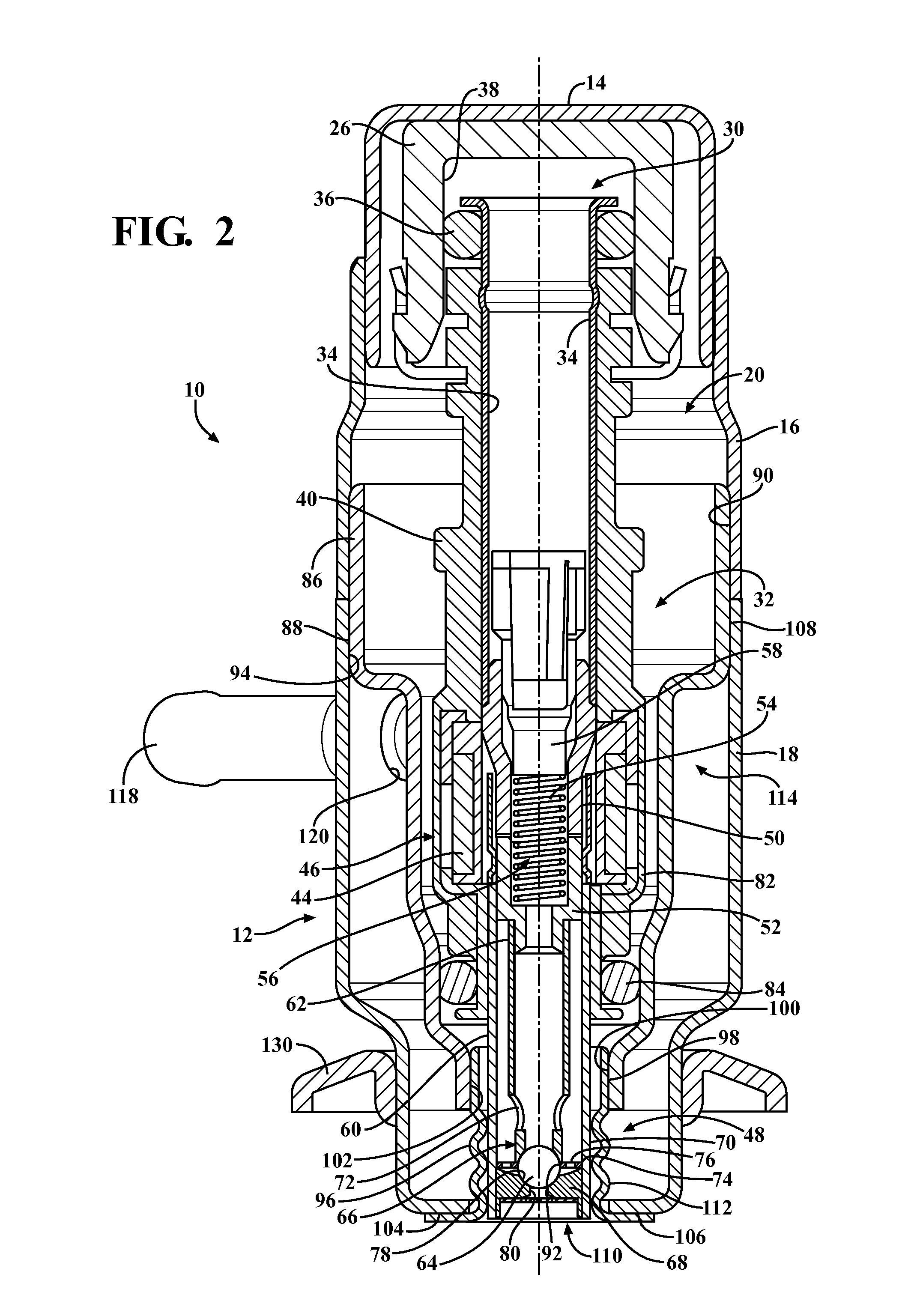

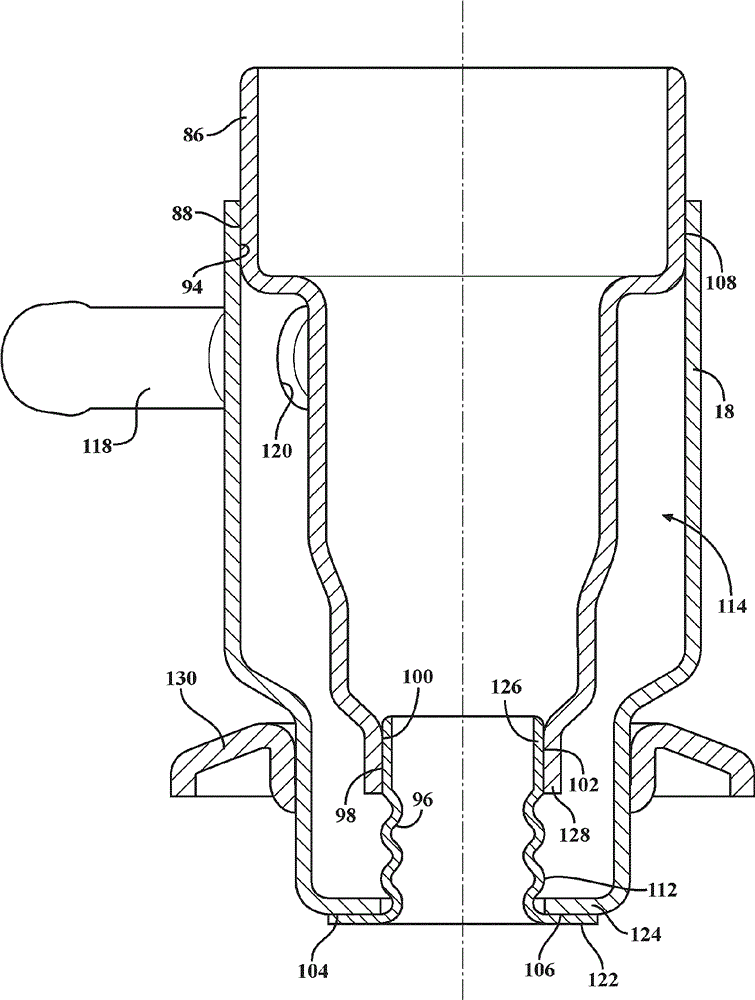

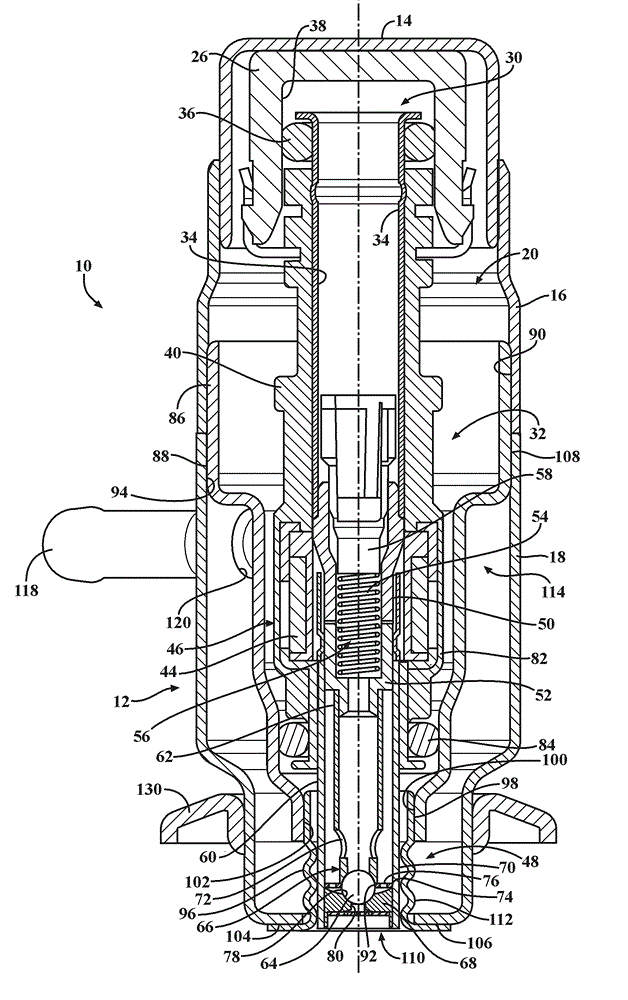

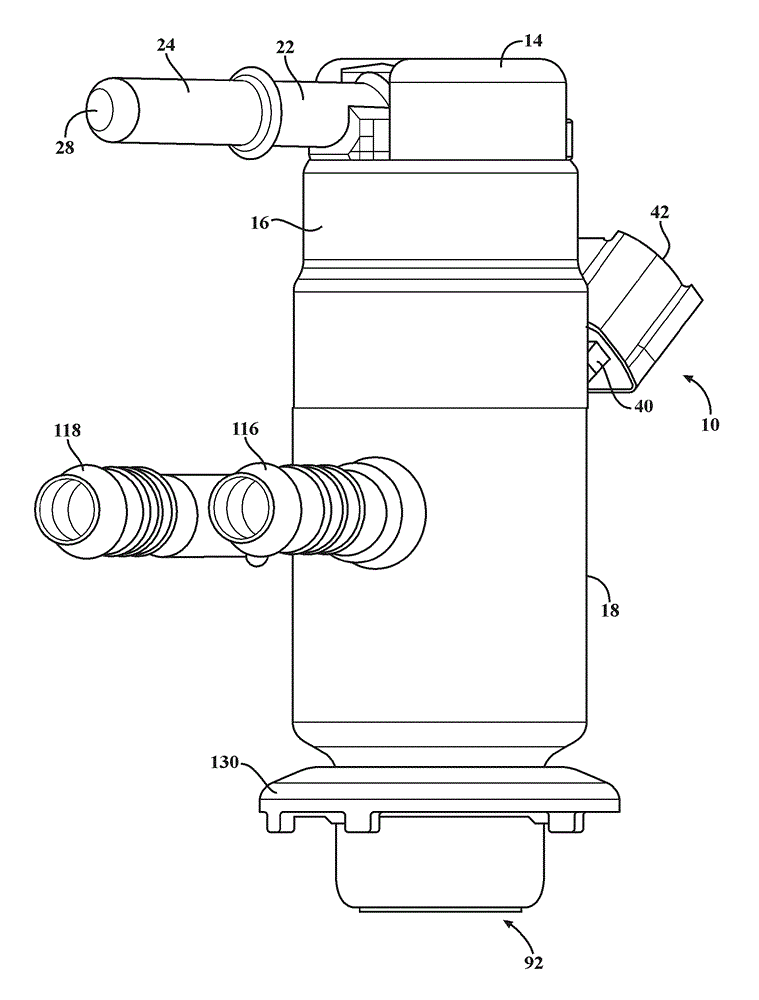

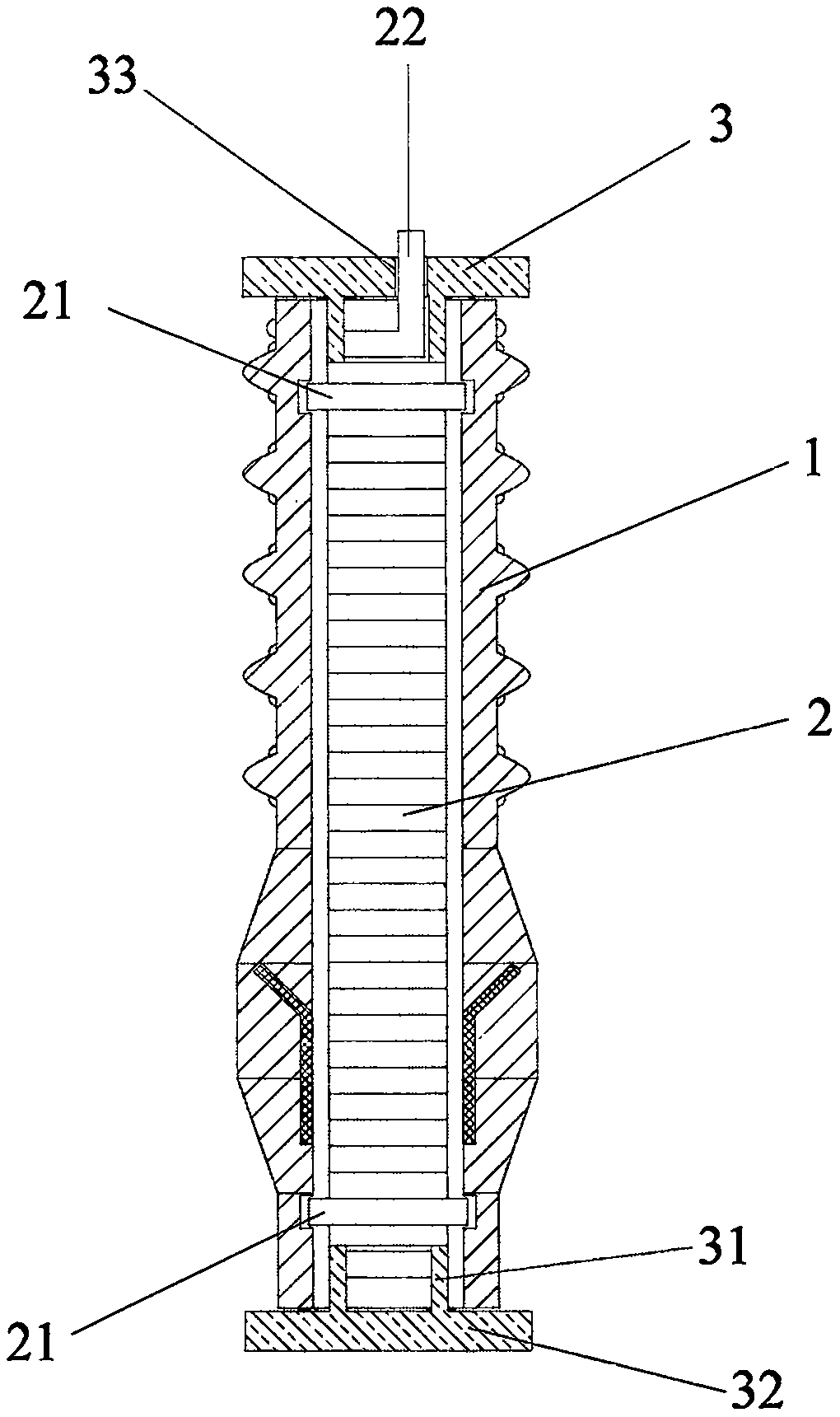

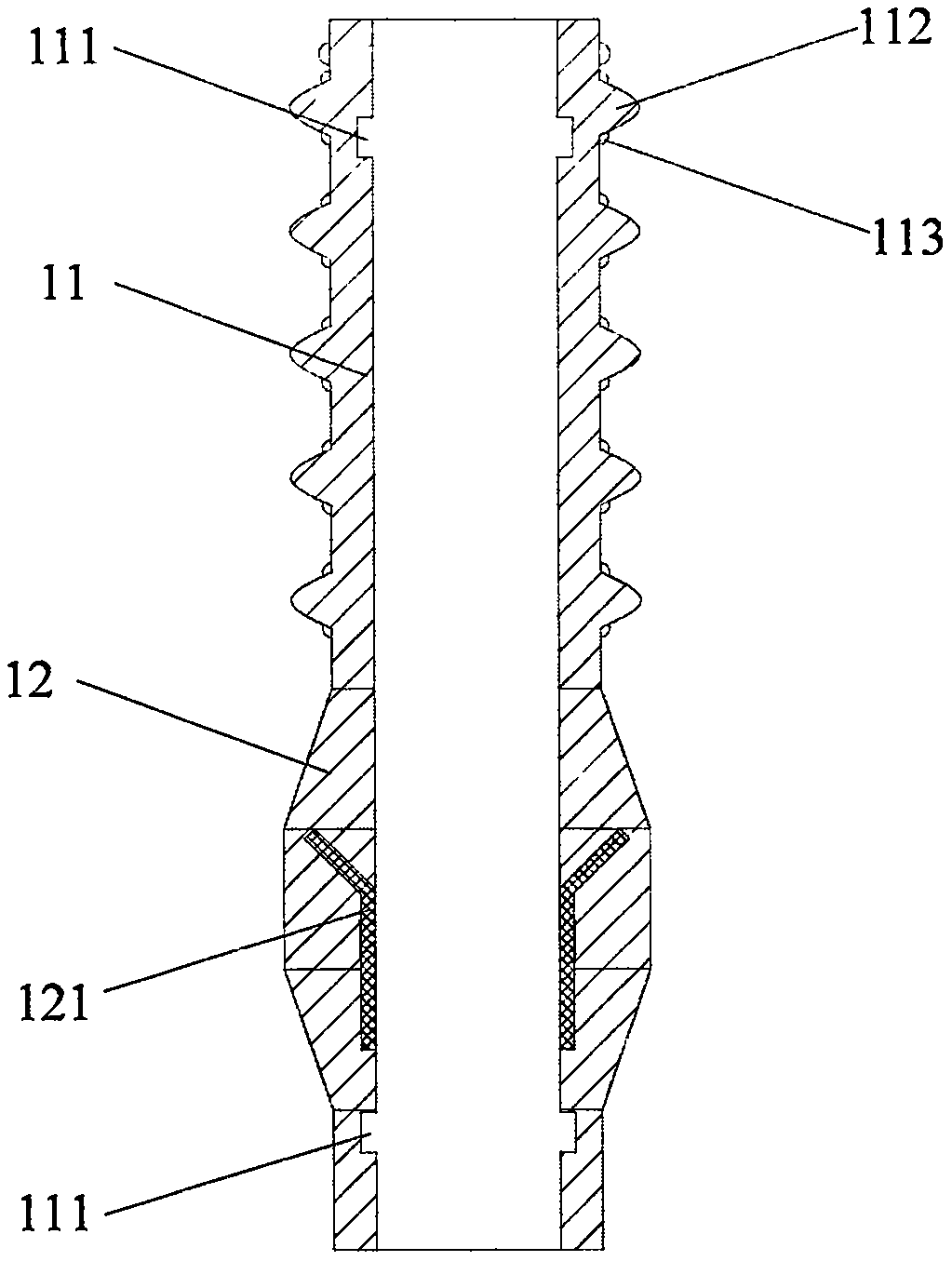

Liquid cooled reductant delivery unit for automotive selective catalytic reduction systems

InactiveUS20150059322A1Sufficient structural robustnessImprove corrosion resistanceInternal combustion piston enginesExhaust apparatusActive coolingCoolant flow

A reductant delivery unit having active cooling which is constructed to have sufficient structural robustness, and to improve corrosion resistance of the assembly, where an attack on the base injector is conceivable with the use of incorrect coolant media. The reductant delivery unit has an upper shield, a lower shield connected to the upper shield, and an inner sleeve. The reductant delivery unit also includes a lower sleeve connected to the inner sleeve and the lower shield. A liquid cooling cavity is formed by the connection between the inner sleeve and the lower shield, the lower sleeve and the lower shield, and the lower sleeve and the inner sleeve. Coolant flows into the liquid cooling cavity to provide a cooling function to an injector partially located within the inner sleeve, and a corrugated portion of the lower sleeve transfers heat away from at least a portion of the injector.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Wet etch processing

InactiveUS20070134829A1MicroneedlesSemiconductor/solid-state device manufacturingManufacturing technologyPotassium hydroxide

A method of wet etching produces high-precision microneedle arrays for use in medical applications. The method achieves precise process control over microneedle fabrication, at single wafer or batch-level, using wet etching of silicon with potassium hydroxide (KOH) solution by accurately identifying the etch time endpoint. Hence, microneedles of an exactly required height, shape, sharpness and surface quality are achieved. The outcome is a reliable, reproducible, robust and relatively inexpensive microneedle fabrication process. Microneedles formed by KOH wet etching have extremely smooth surfaces and exhibit superior mechanical and structural robustness to their dry etched counterparts. These properties afford extra reliability to such silicon microneedles, making them ideal for medical applications. The needles can also be hollowed. Wet etched silicon microneedles can then be employed as masters to replicate the improved surface and structural properties in other materials (such as polymers) by moulding.

Owner:UNIV COLLEGE CORK NAT UNIV OF IRELAND CORK

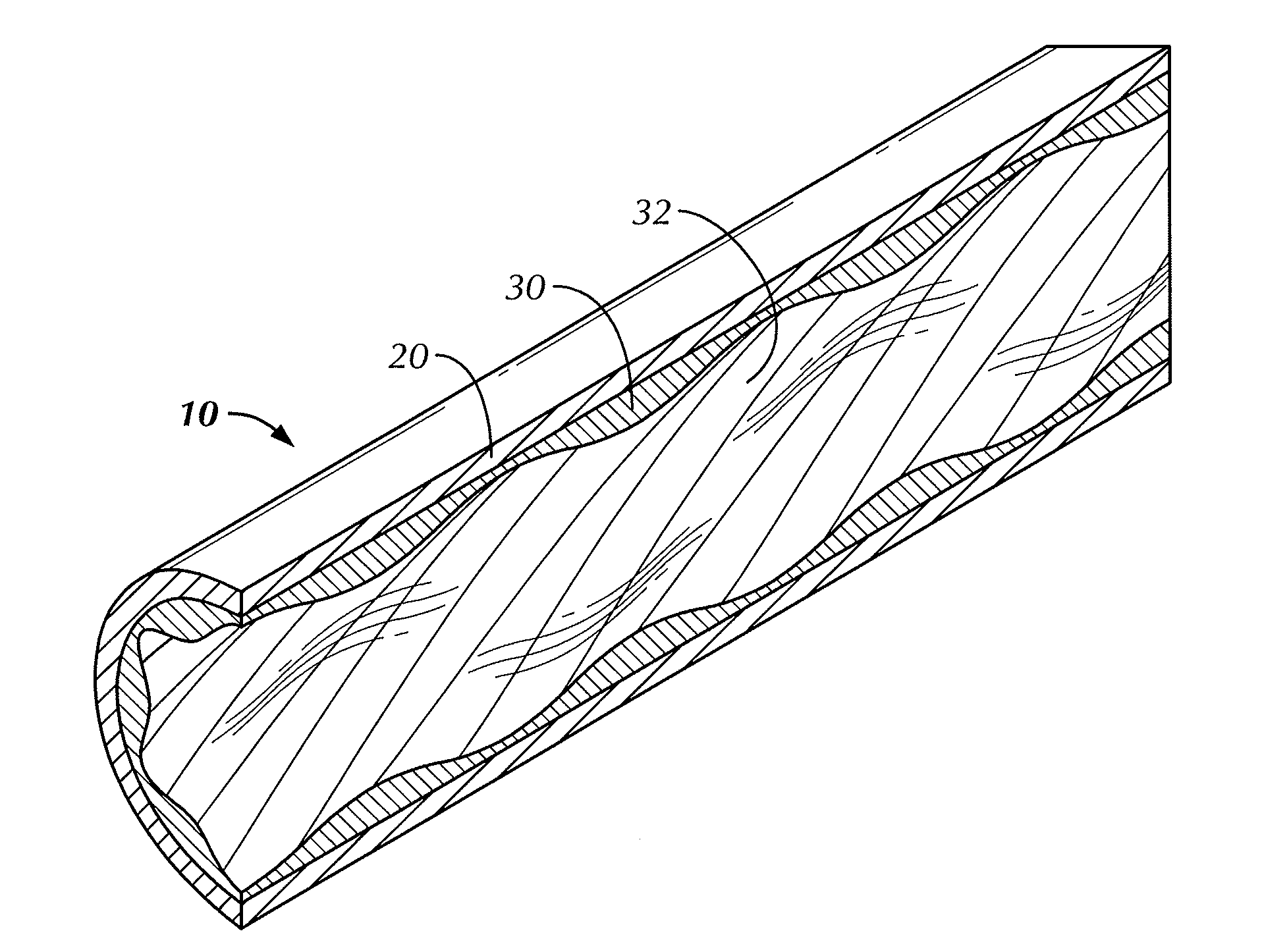

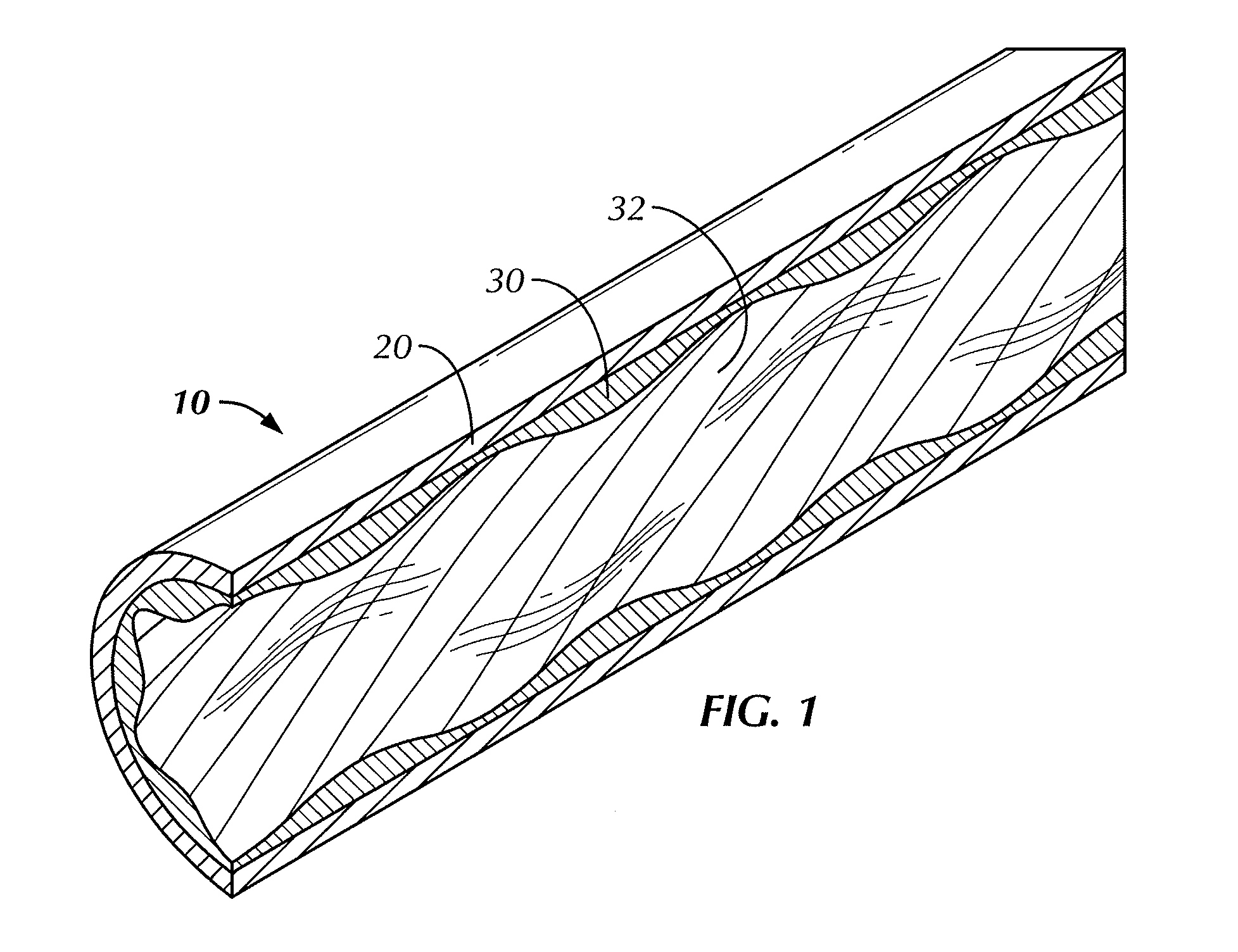

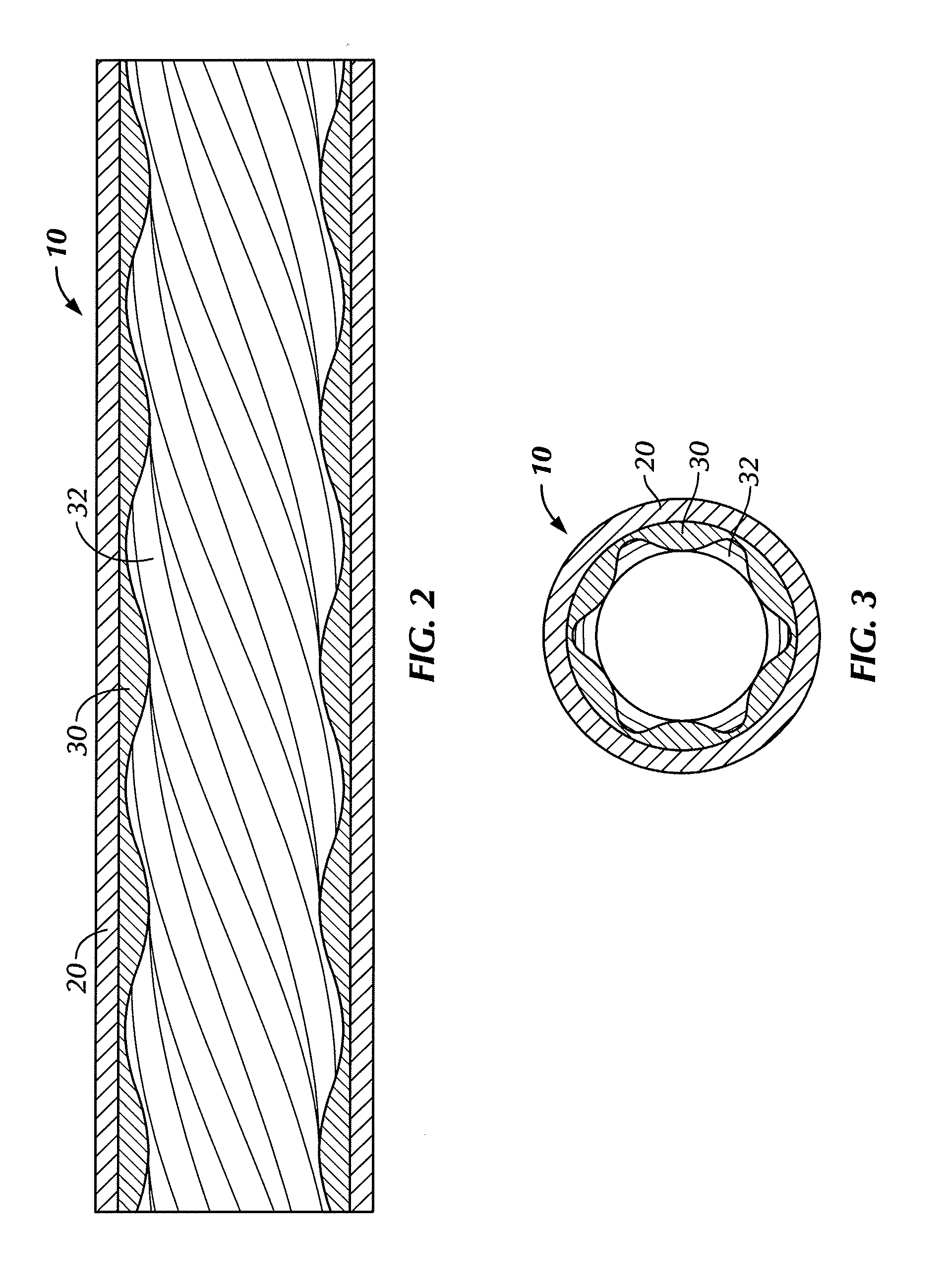

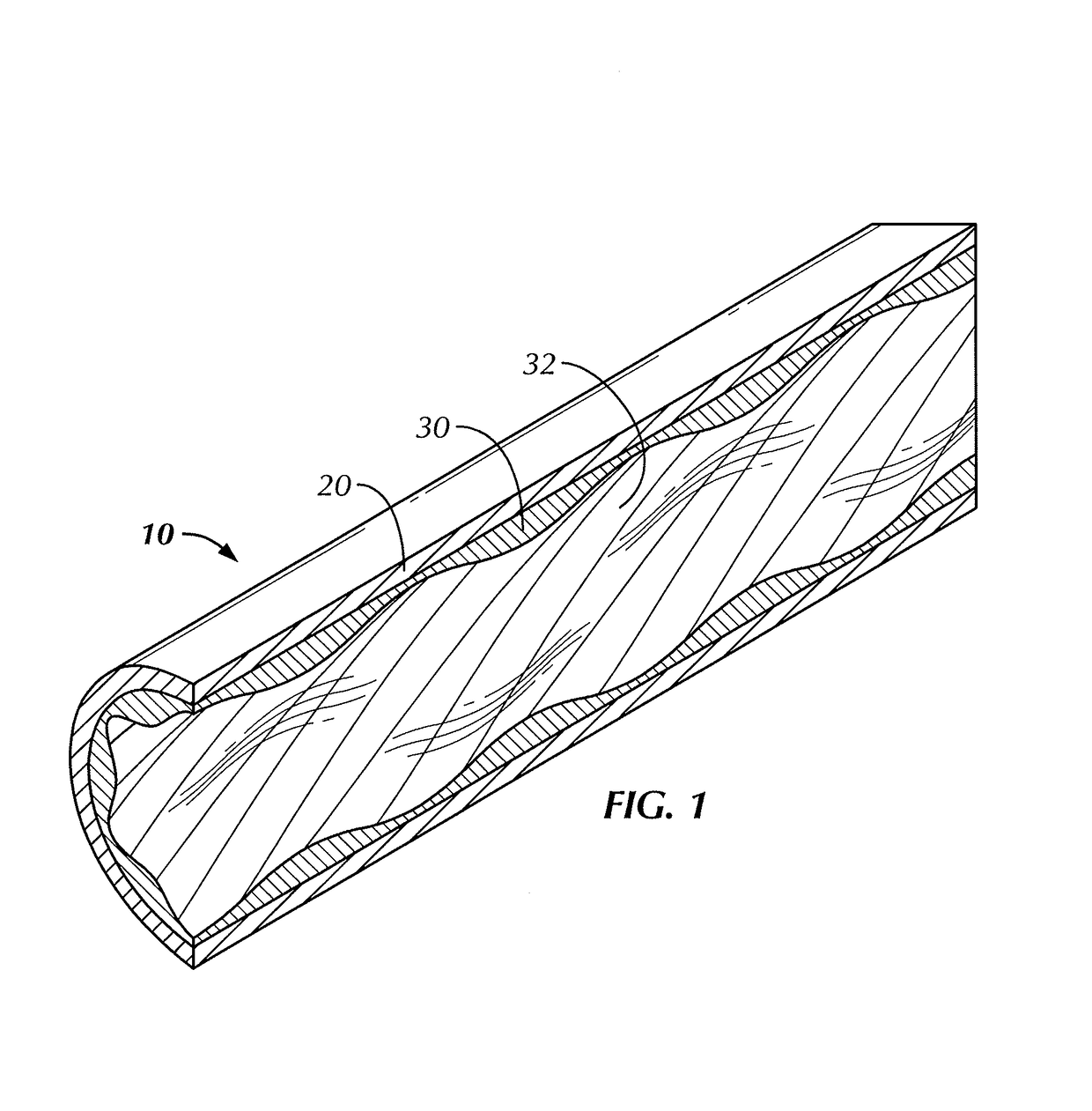

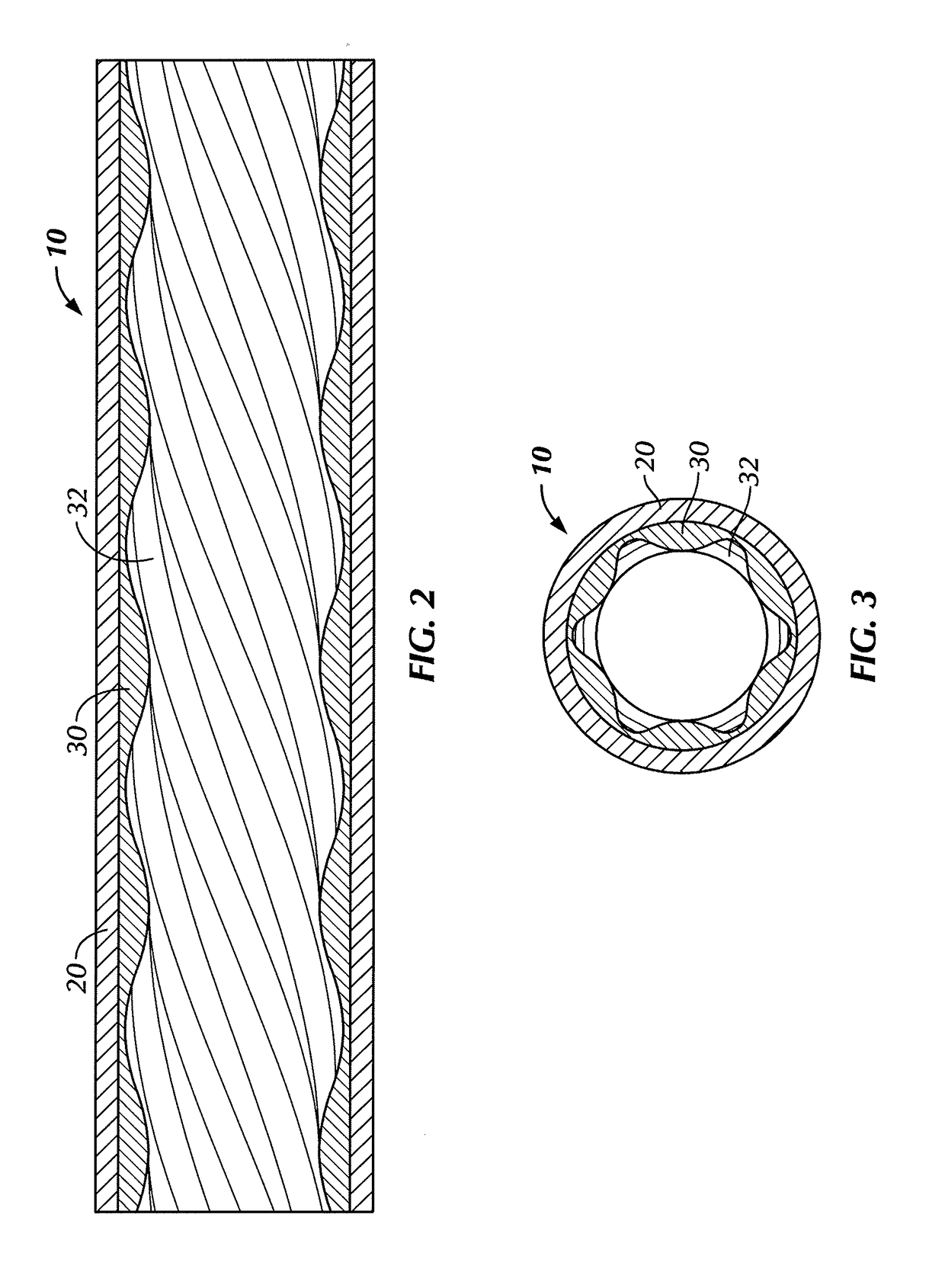

Graphene enhanced elastomeric stator

ActiveUS20150233373A1Improved polymerSimple structureSpecific nanostructure formationMaterial nanotechnologyCross-linkElastomer

An enhanced elastomeric stator assembly and method of making the same is disclosed. The elastomeric stator may be structurally, thermally, and / or chemically enhanced through the incorporation of graphene particles, cross-linkable polymers, coupling agents that extend cross-links, and by the reduction of filler material. The graphene particles can be incorporated in functionalized or non-functionalized form or in a combination thereof, the functionalized graphene increasing the number of cross-links in the overall structure, thereby enhancing the structural robustness of the elastomeric stator. The compound can be formulated to have a relatively low viscosity and other characteristics that allow the material to flow through a mould cavity.

Owner:REMY TECHNOLOGIES LLC

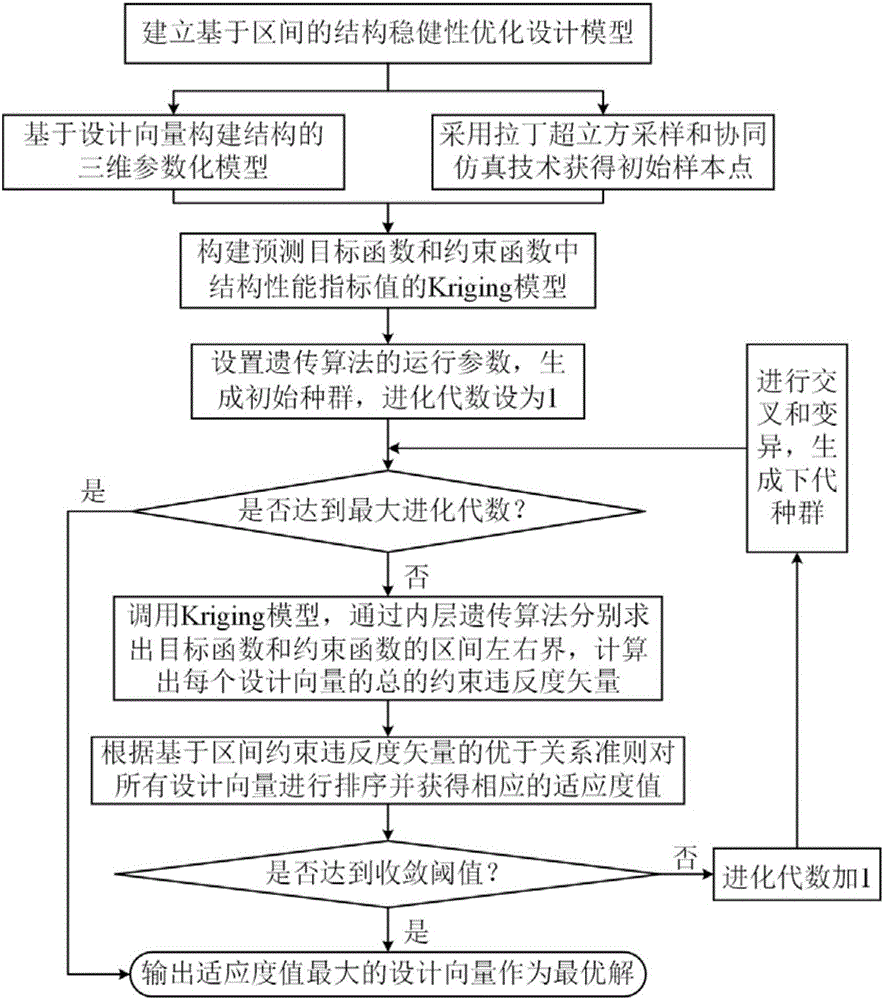

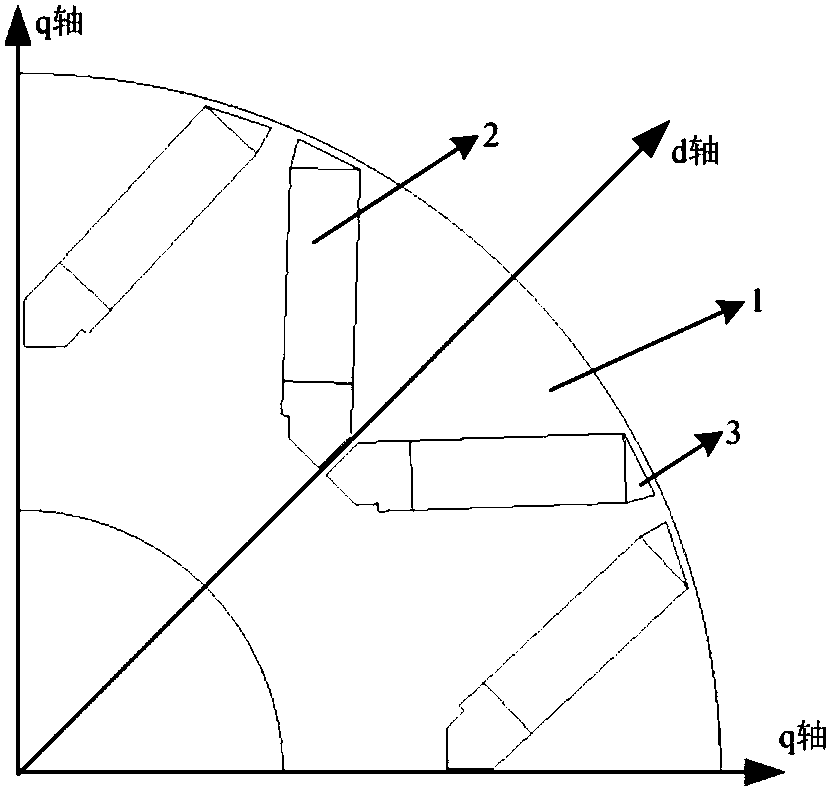

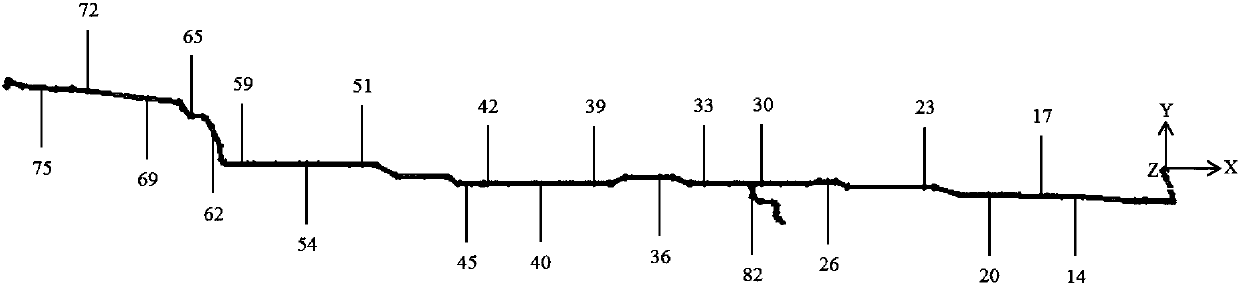

Permanent magnet cavity structure robust design method capable of reducing iron loss of built-in permanent magnet motor

ActiveCN104967262AReduce iron consumptionReduce electromagnetic torqueMagnetic circuit rotating partsManufacturing stator/rotor bodiesHarmonicElectric machinery

The invention relates to a permanent magnet cavity structure robust design method capable of reducing iron loss of a built-in permanent magnet motor. The method comprises steps: initial permanent magnet cavity structures of the motor are determined, and the built-in permanent magnet motor adopts a single layer of U-type permanent magnet structures; the permanent magnet cavity structures of the motor are improved, triangular permanent magnet cavity expansion structures are added at places, near the surface of a rotor iron core, at two sides of each U-type permanent magnet cavity, and the permanent magnet cavities between adjacent poles are connected; and a Taguchi method is used for optimizing the permanent magnet cavity improved structures. The permanent magnet cavity structures of the built-in permanent magnet motor with the single layer of U-type permanent magnet structures are improved, the improved structure can effectively reduce the harmonic component in an air-gap magnetic field, iron loss of the stator and the rotor of the motor is reduced obviously, the optimized permanent magnet cavity structure enables electromagnetic torque ripple and cogging torque of the motor to be reduced obviously, and smooth operation of the motor is enhanced.

Owner:TIANJIN UNIV

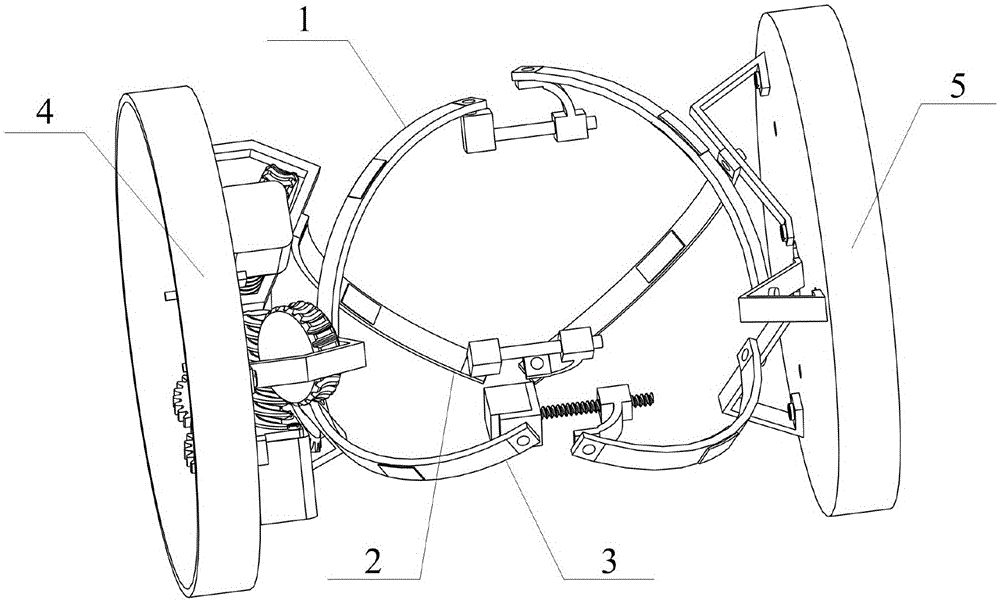

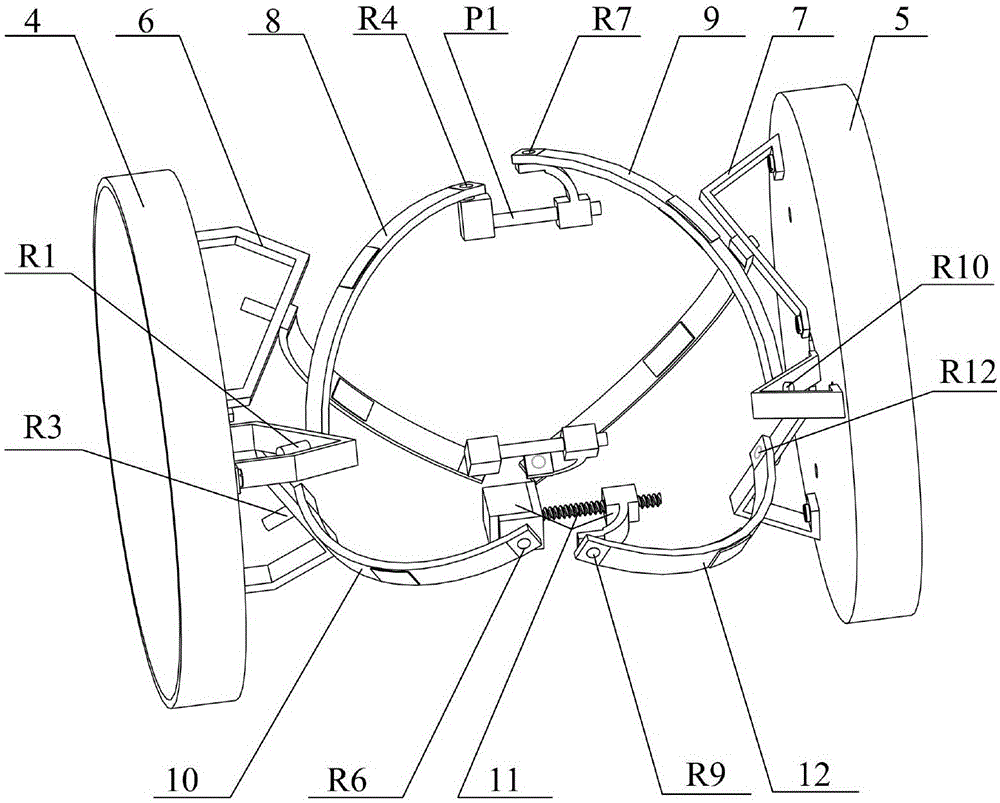

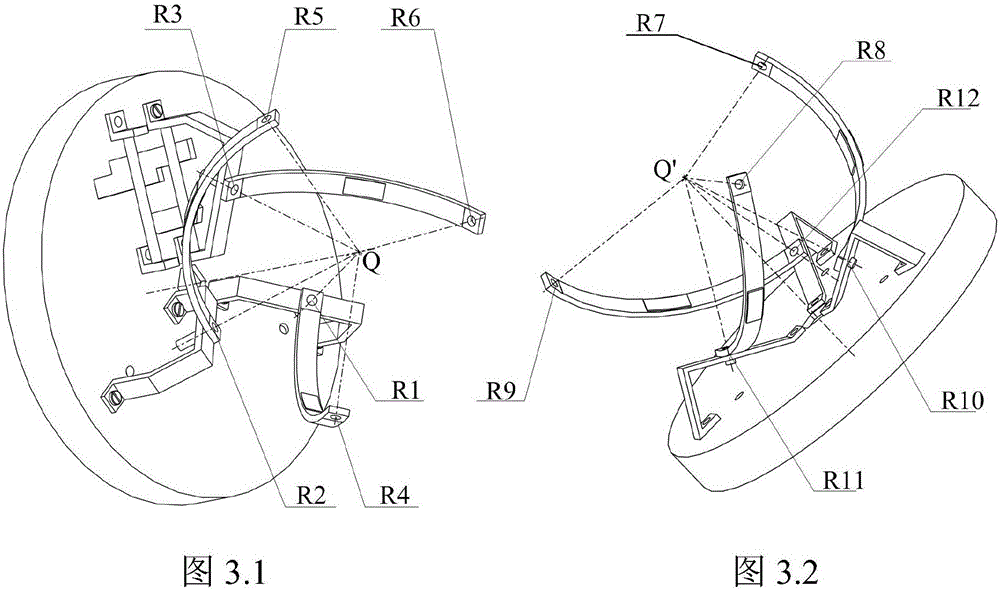

Metamorphic knuckle mechanism of snake-imitation rescuing robot

A metamorphic knuckle mechanism of a snake-imitation rescuing robot comprises a knuckle left end cover, a knuckle right end cover, two RRPRR branches and one RRPRR metamorphic branch. Metamorphic knuckles have two mechanism forms, and the work space and mobility can be changed. In the mechanism form I, a movable pair P in the RRPRR metamorphic branch is in an active moving state, a rotation pair R is in a following state, and then the knuckles have one moving freedom degree and two rotating freedom degrees. In the mechanism form II, the movable pair P in the RRPRR metamorphic branch is in a minimum displacement and locking state, the rotation pair R is in an active state, the knuckles are changed into parallel spherical knuckles in a metamorphic manner, and three rotation freedom degrees are achieved. The metamorphic knuckle mechanism has the beneficial effects of being good in flexibility, high in bearing capability and good in structural robustness and is suitable for the snake-imitation rescuing robot. By means of mutual cooperation of the two mechanism forms of the multiple metamorphic knuckles, the flexibility and adaptability of the snake-imitation rescuing robot under different environments can be effectively improved.

Owner:BEIJING UNIV OF CHEM TECH

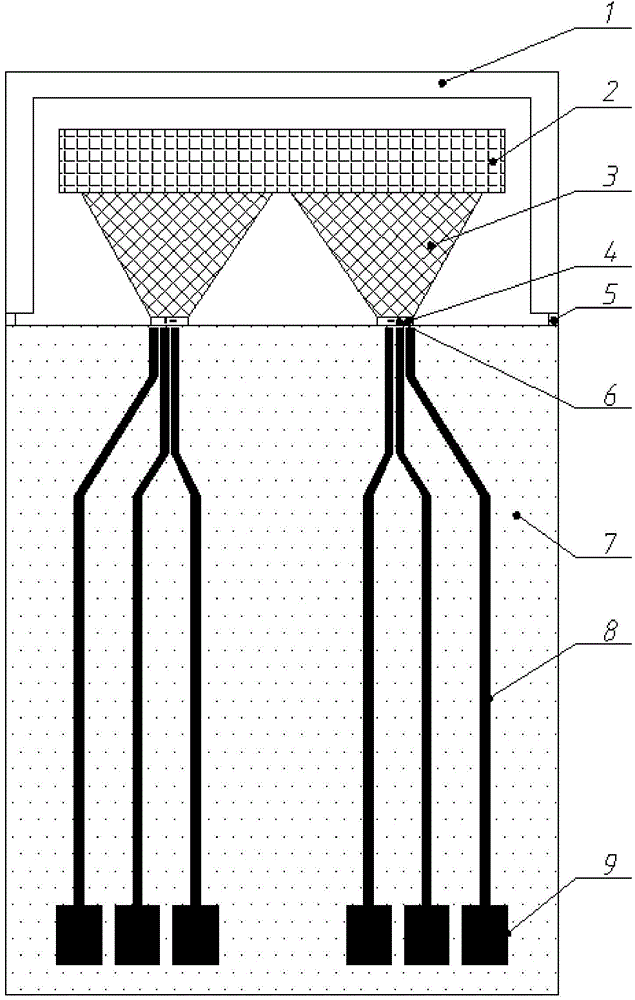

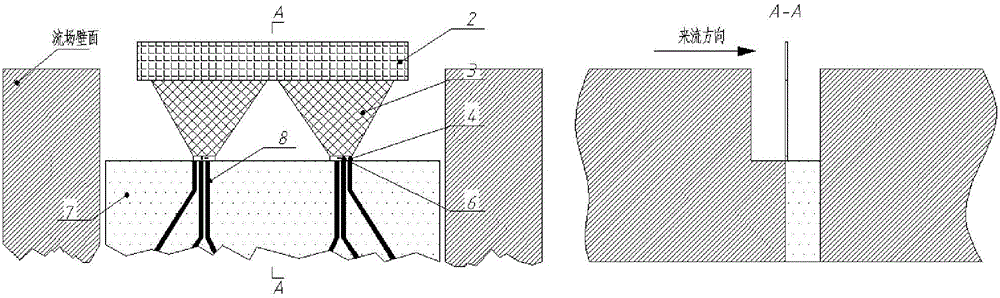

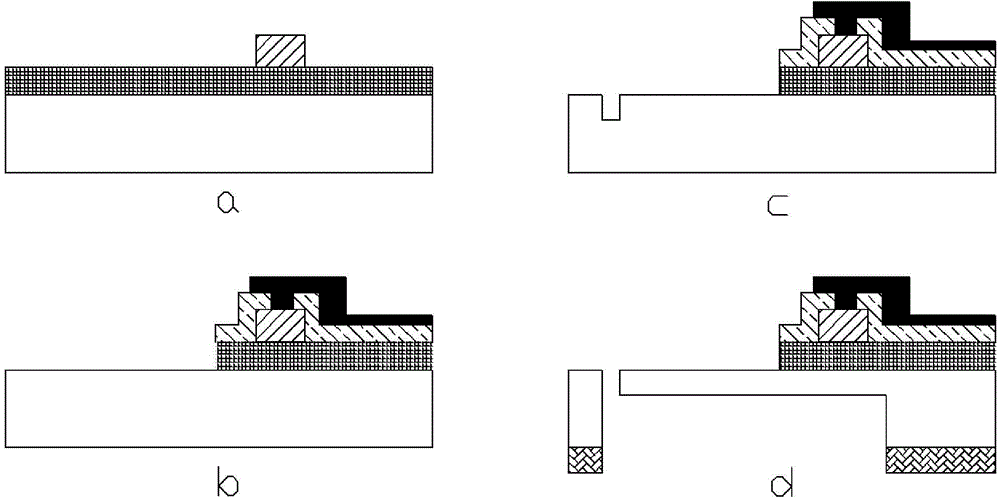

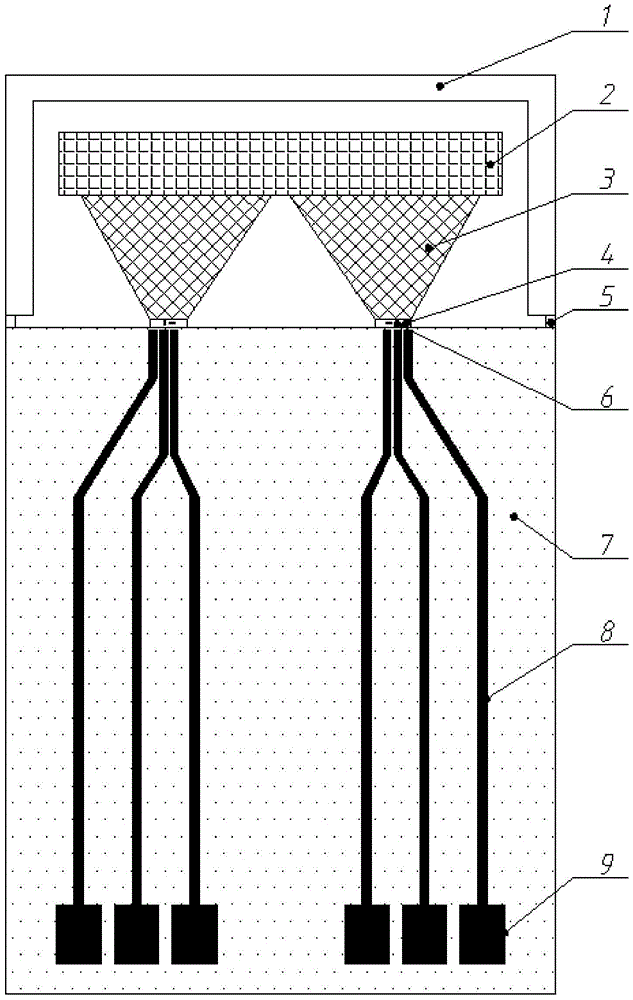

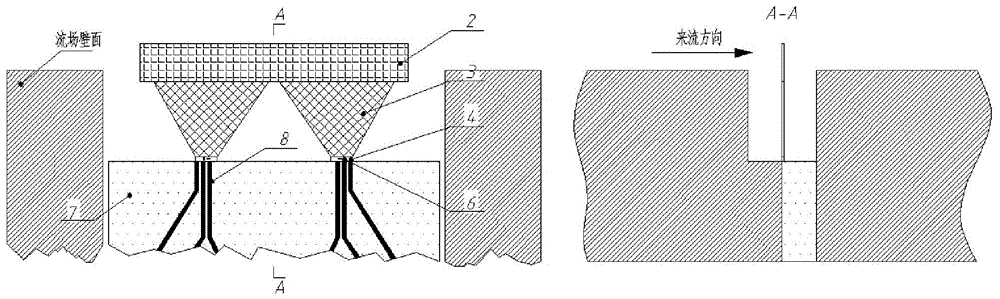

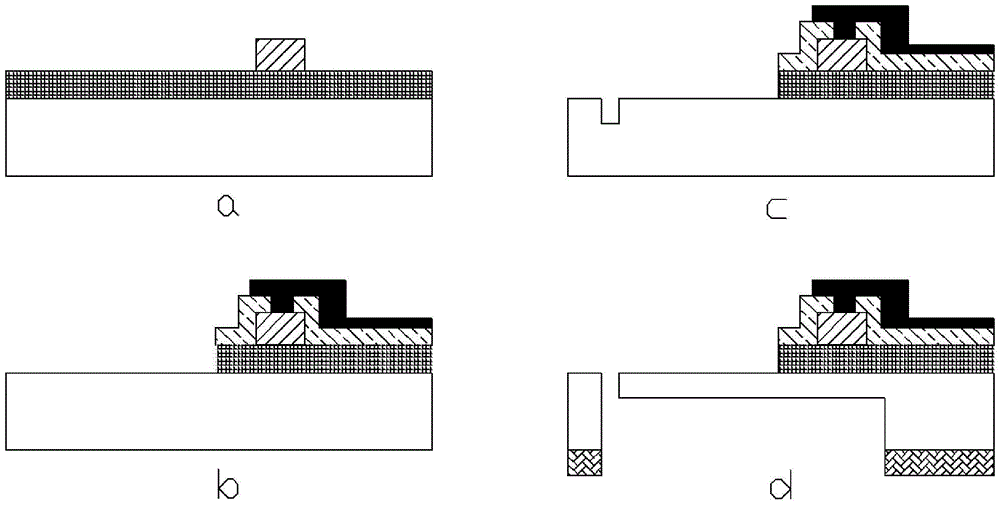

Bottom separation plate microsensor capable of being used for measuring wall shear stress in high temperature environment and manufacturing method thereof

ActiveCN103954383AReduce failureEnables wall shear stress measurementDecorative surface effectsForce measurementElectrical resistance and conductanceCombustion chamber

Owner:NORTHWESTERN POLYTECHNICAL UNIV

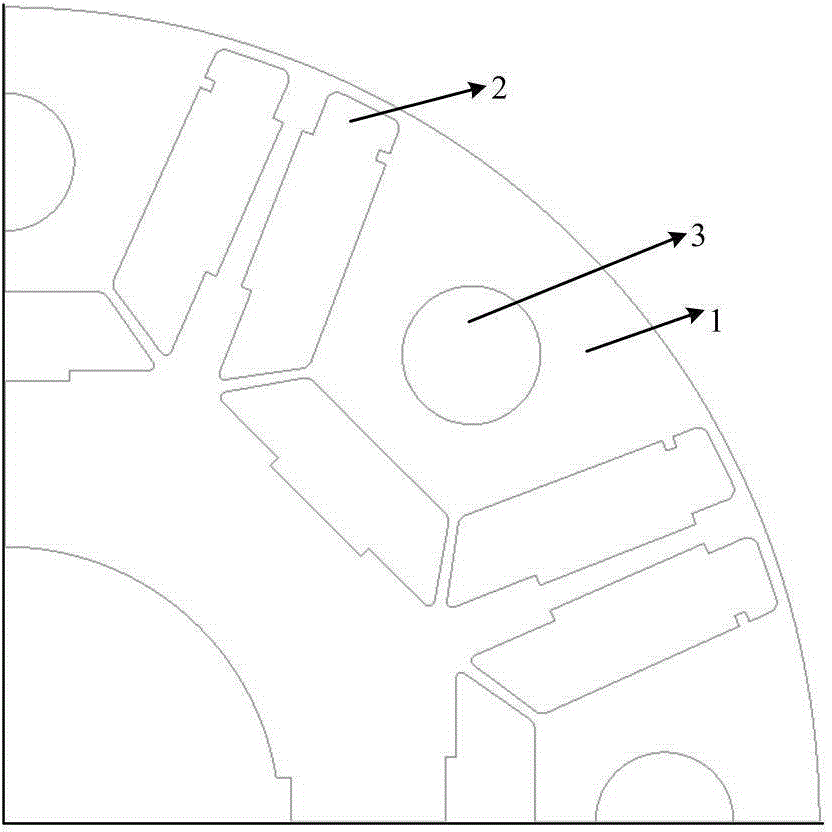

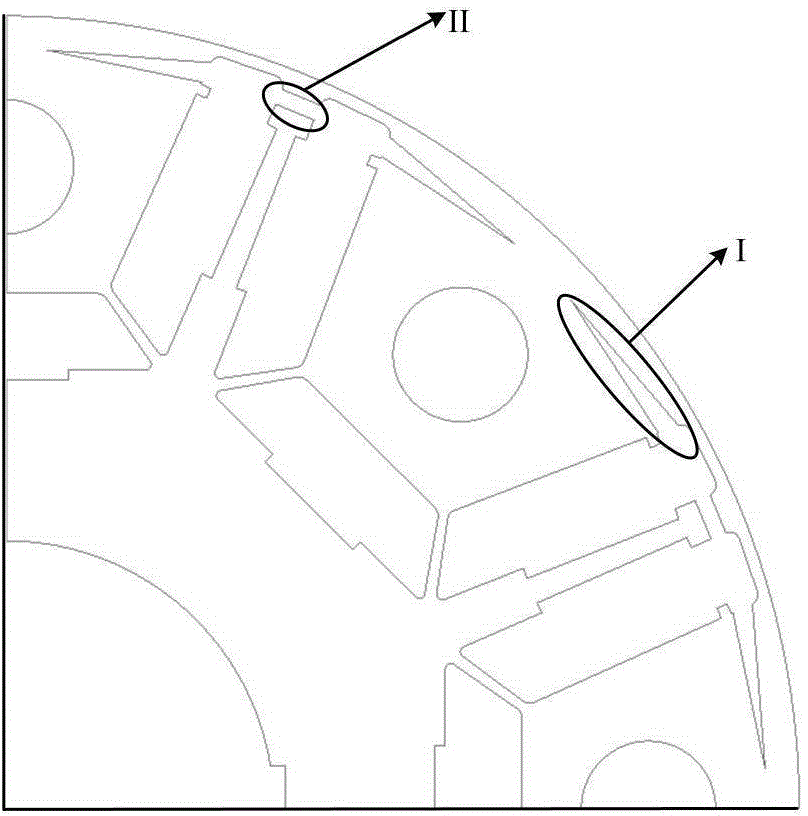

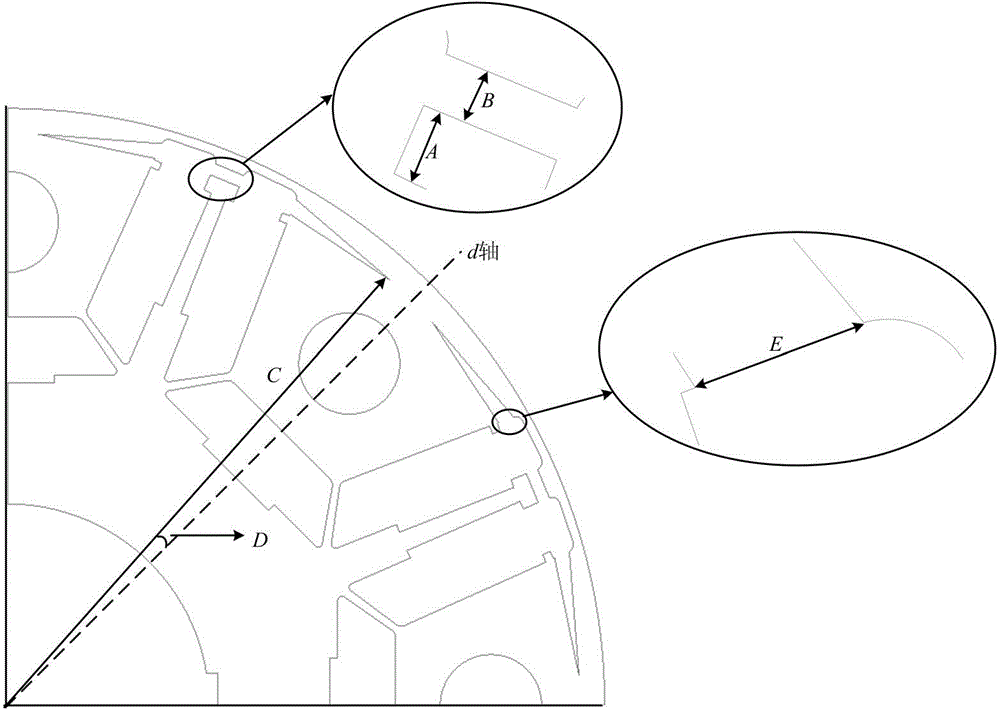

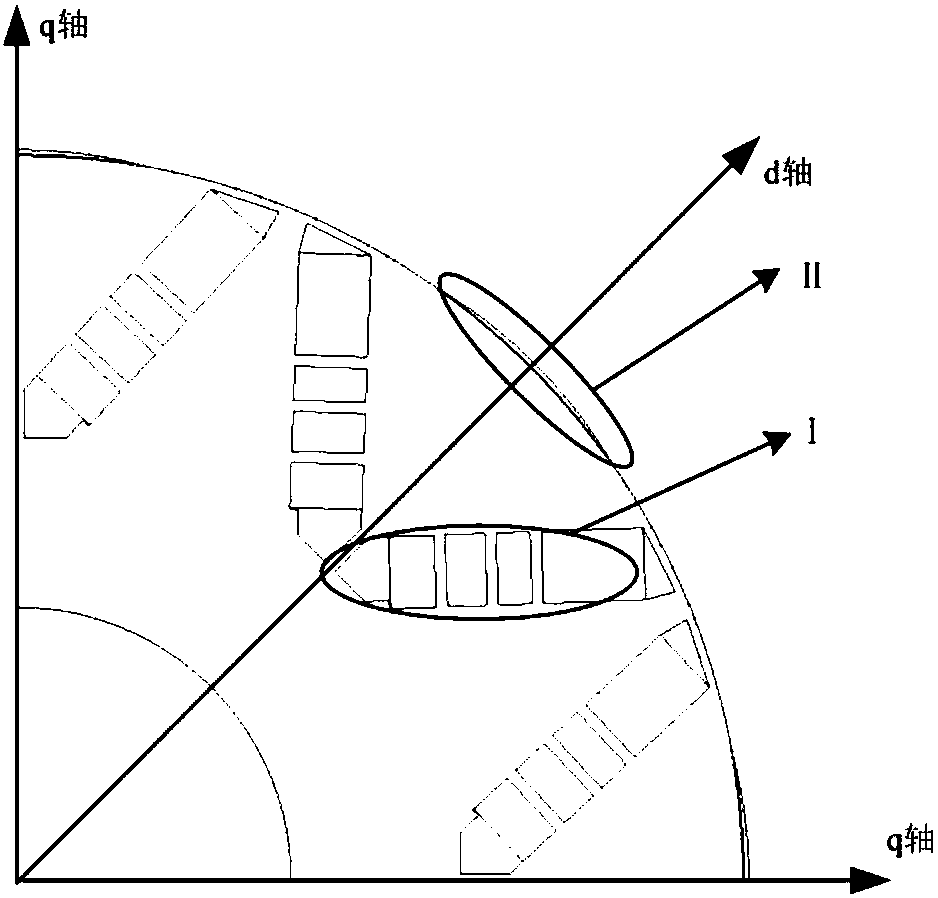

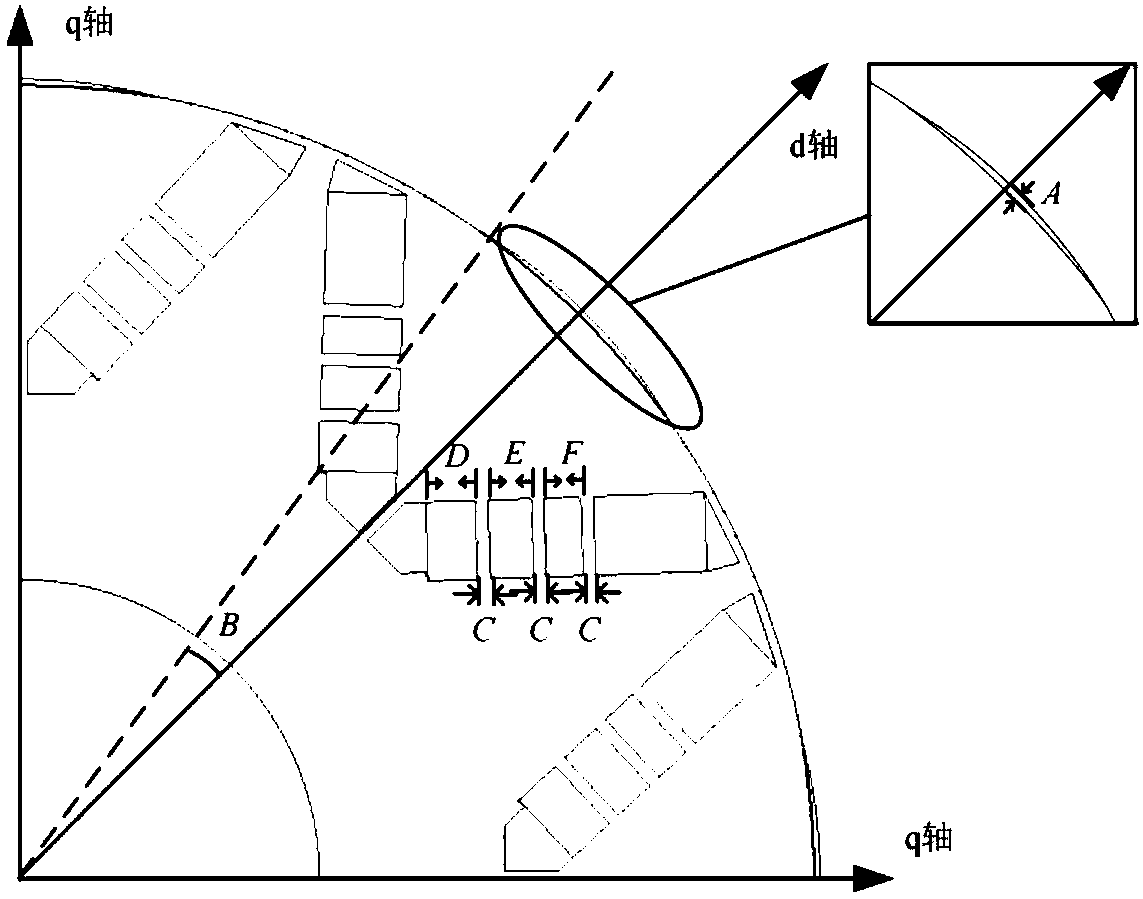

Rotor structural robustness design method for widening built-in permanent magnet synchronous motor speed range

ActiveCN108566004AExtended speed rangeImprove stabilityMagnetic circuit rotating partsPermanent magnet synchronous motorEngineering

The invention relates to a rotor structural robustness design method for widening a built-in permanent magnet synchronous motor speed range. The method comprises: determining the initial rotor structure of a motor and providing a permanent magnet with a single-layer V-shaped structure; improving the rotor structure of the motor; using a Taguchi method to optimize the above improved structural scheme, and determining an optimization variable, an optimization objective and a constraint condition; establishing a factor level table; performing finite element simulation on the motor under differentconditions, and obtaining the values of d-axis inductance, the q-axis inductance and the electromagnetic torque under different factor levels; performing average value analysis; performing variance analysis on a result based on the average analysis; and determining the optimal solution and improving a prototype.

Owner:TIANJIN UNIV

E-beam shape aperature incorporating lithographically defined heater element

InactiveUS6326634B1Radiation/particle handlingElectrode and associated part arrangementsResistOhmic contact

A resistive heater element is integrally formed with a beam shaping aperture foil by lithographic patterning of a doped semiconductor layer of which the aperture foil is formed over an insulator, resulting in a device of greatly increased structural robustness and reliability. Heat provided to the aperture foil by the heater element greatly reduces the accretion of deposits thereon which can distort the aperture shape and / or, deflect the beam when electrostatic charge accumulates thereon. The lithographic patterning process for fabricating the integral heater and aperture foil is only slightly increased in complexity from the current process for fabricating an aperture foil alone by an additional resist application and exposure, ohmic contact formation and use of an additional etchant and is of high yield.

Owner:GLOBALFOUNDRIES INC

Reducing agent delivery unit of liquid cooling of selective catalytic reduction system of motor vehicle

InactiveCN105443207AInternal combustion piston enginesExhaust apparatusActive coolingStructural stability

The invention discloses a reducing agent delivery unit with an active cooling function. According to the reducing agent delivery unit, the structural stability is high enough, the corrosion resistance of components is improved, and the situation that a base ejector is corroded due to the utilization of incorrect cooling agent media is avoided. The reducing agent delivery unit is provided with an upper protection cover, a lower protection cover connected to the upper protection cover, and an inner sleeve and further comprises a lower sleeve which is connected to the inner sleeve and the lower protection cover. A liquid cooling cavity is formed through the connection between the inner sleeve and the lower protection cover, the connection between the lower sleeve and the lower protection cover as well as the connection between the lower sleeve and the inner sleeve. Cooling agents flow into the liquid cooling cavity and provide a cooling function for an ejector which is partially located in the inner sleeve. In addition, a corrugated part of the lower sleeve is used for transferring and dissipating heat away from at least part of the ejector.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

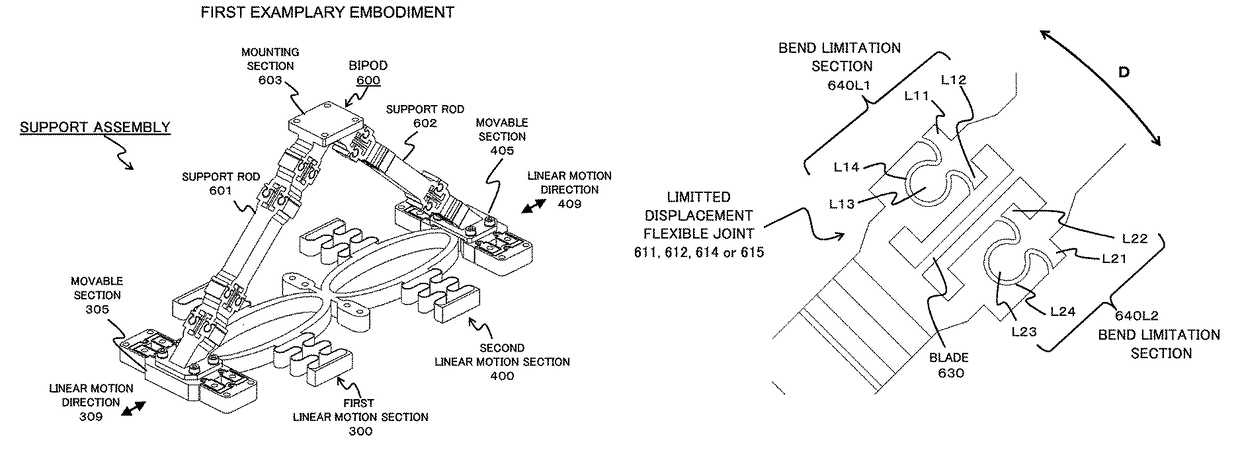

Linkage rod including limited-displacement flexible mechanism

ActiveUS20170030514A1Easy to fallEasy to manufactureMicromanipulatorDoor/window protective devicesFlexible MechanismsEngineering

A linkage rod including a limited-displacement flexible mechanism has structural robustness and allows easy reduction in weight and size, simple production and easy operation. The linkage rod including at least one limited-displacement flexible mechanism, wherein the limited-displacement flexible mechanism comprises at least one limited-displacement flexible joint which comprises: a flexible member; and at least one bend limitation section which is arranged in parallel with the flexible member so that the bend limitation section limits a bend of the flexible member.

Owner:NEC CORP

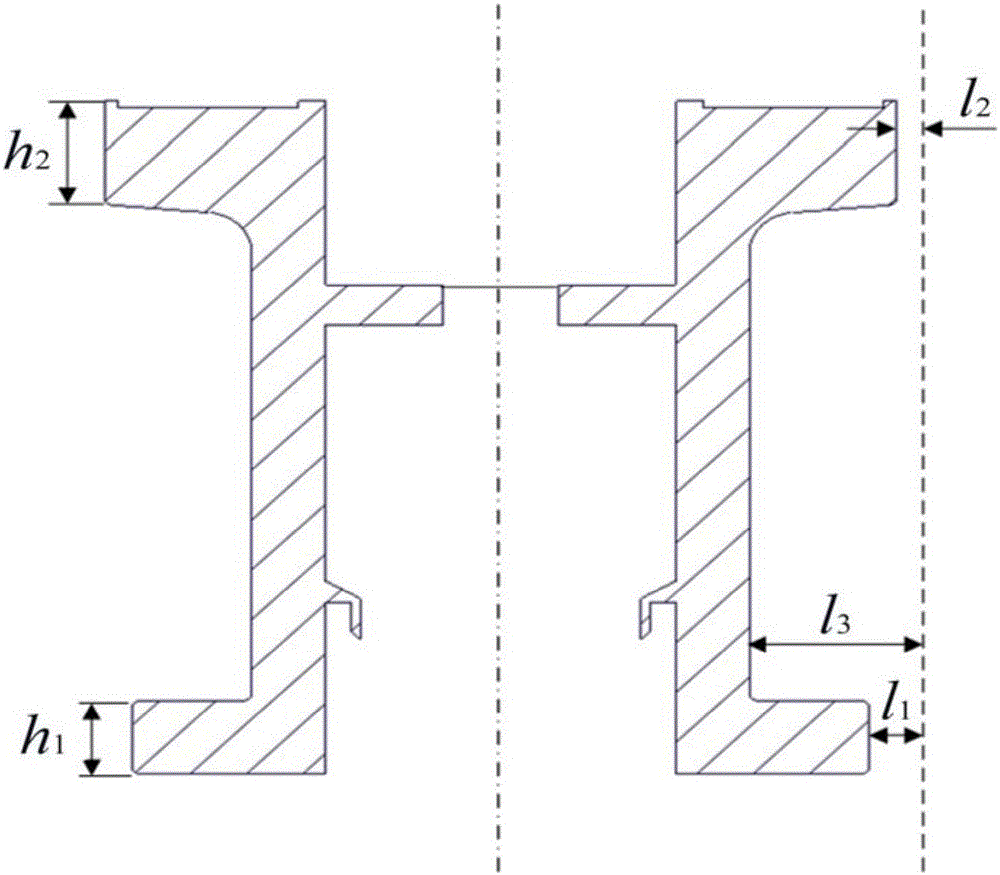

Axisymmetric silicon micromechanical gyroscope sensitive structure and manufacturing method thereof

ActiveCN108007448AStrong anti-interference accelerationStrong speedSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesStress concentrationGyroscope

The invention discloses an axisymmetric silicon micromechanical gyroscope sensitive structure and a manufacturing method thereof, wherein the sensitive structure comprises an elastic frame with bonding anchor points on both sides, an axisymmetric through-hole region is arranged on the elastic frame and 'H'-shaped supporting beams are arranged on the symmetric axis of the axisymmetric through-holeregion, two axisymmetric sensitive mass blocks are arranged on each of two sides of each 'H'-shaped supporting beam, and are arranged in the through-hole region, and one side of each sensitive mass block is connected with the corresponding 'H'-shaped supporting beam through a coupling beam; the manufacturing method comprises the step of using a wet-dry combination method to prepare the sensitive structure on a single silicon wafer. The axisymmetric silicon micromechanical gyroscope sensitive structure disclosed by the invention realizes complete axisymmetric distribution, reduces the loss, decreases the stress concentration, lowers the motion coupling, and improves the mechanical sensitivity; the manufacturing method disclosed by the invention has the advantages of simple processing technology, high processing quality, high structural robustness, high stability, wide application range and the like.

Owner:湖南天羿领航科技有限公司

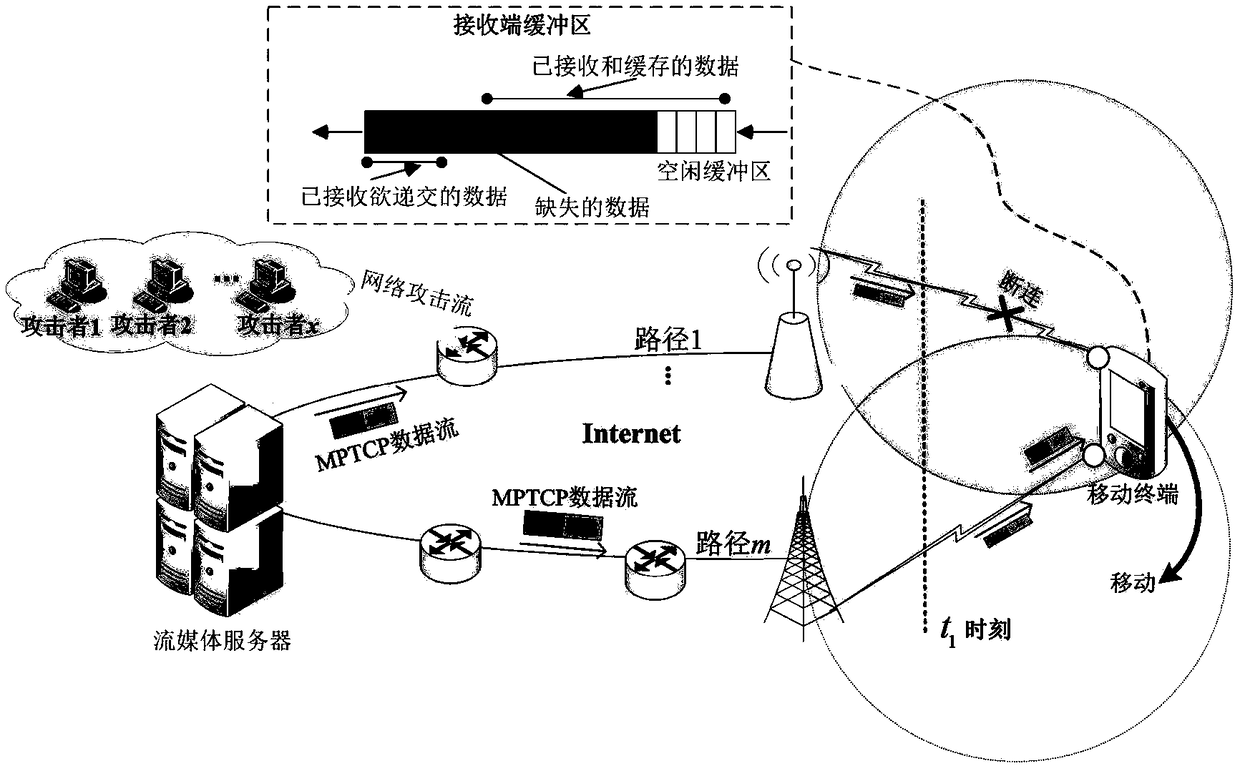

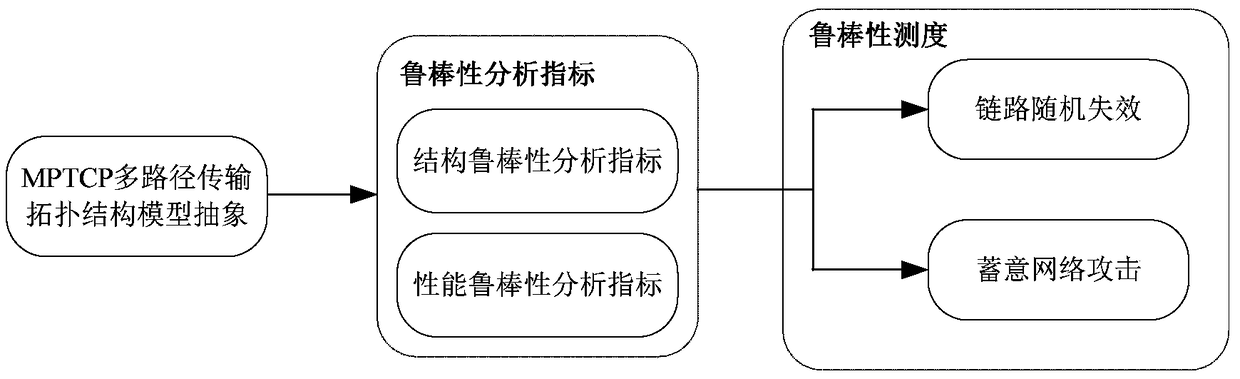

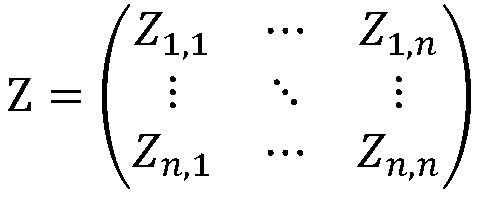

Multipath based robustness transmission evaluation method

ActiveCN108924869ARobust Accurate CharacterizationReaction resistanceData switching networksSecurity arrangementRobustificationTransport system

The invention relates to a multipath based robustness transmission evaluation method for evaluating the structural robustness and performance robustness of the multipath system, which comprises the following steps of a step 1, abstracting an MPTCP multipath transmission topology model, and abstracting an MPTCP multipath transmission system into an unprivileged network with n nodes and m edges; a step 2, analyzing the robustness evaluation index of the MPTCP multipath transmission system; and a step 3, deleting nodes with large sample introduction probability and measuring the robustness of theMPTCP multipath transmission system. According to the multipath based robust transmission evaluation method for evaluating the structural robustness and performance robustness of the multipath systemin the invention, natural connectivity and efficiency function E(G) are used as the evaluation indexes of structural robustness and performance robustness respectively, which can scientifically evaluate the robustness of multipath, can accurately characterize the robustness of complex networks and can well reflect the resistance of the multipath transmission system against decline of community caused by behaviors such as random failures of network links and network attacks in the data transmission process.

Owner:JIANGXI NORMAL UNIV

Disposable absorbent pant with efficient belted design and adjustable size manufacturability

A disposable absorbent pant having single-section side stretch panels is disclosed. The pant may have features including seams of overlapping configuration or sandwiched configuration, or a belt configuration. A seam of overlapping configuration may be formed by bonds with features that provide for tensile strength in a lateral direction, while providing enhanced tearability for convenient removal, and may include additional features including indicia of a tearing location, a tear-inducing notch, and structure to grasp for tearing. A seam of sandwiched configuration may provide a finished outward appearance. A belt configuration provides counterbalancing of lateral tension forces and reduces demand for structural robustness in backsheet materials, seams and bonds. Sandwiched and belt configurations allow for extended lateral width of side panels and increased stretch, without extending overall hoop circumference at risk of unduly loose fit.

Owner:THE PROCTER & GAMBLE COMPANY

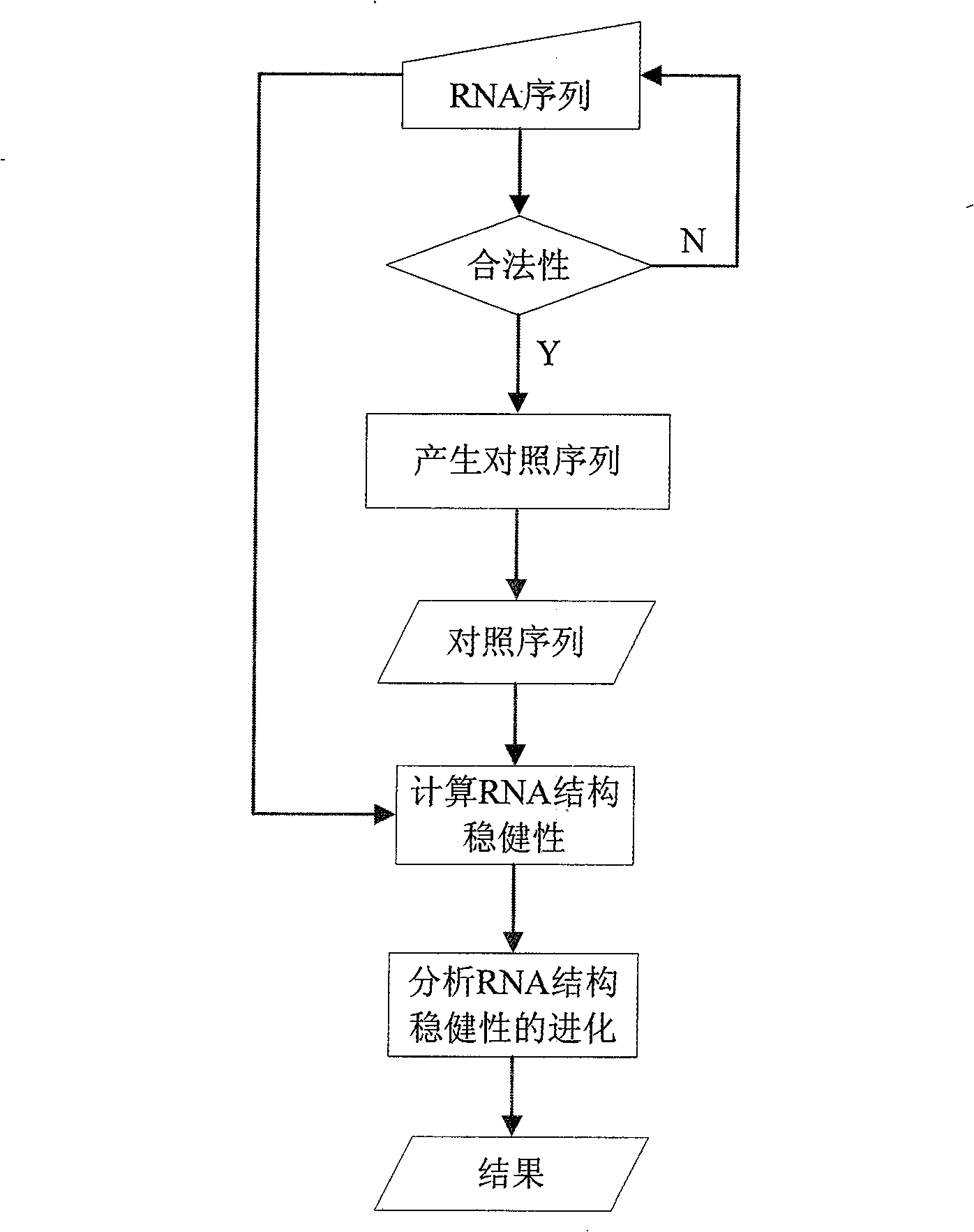

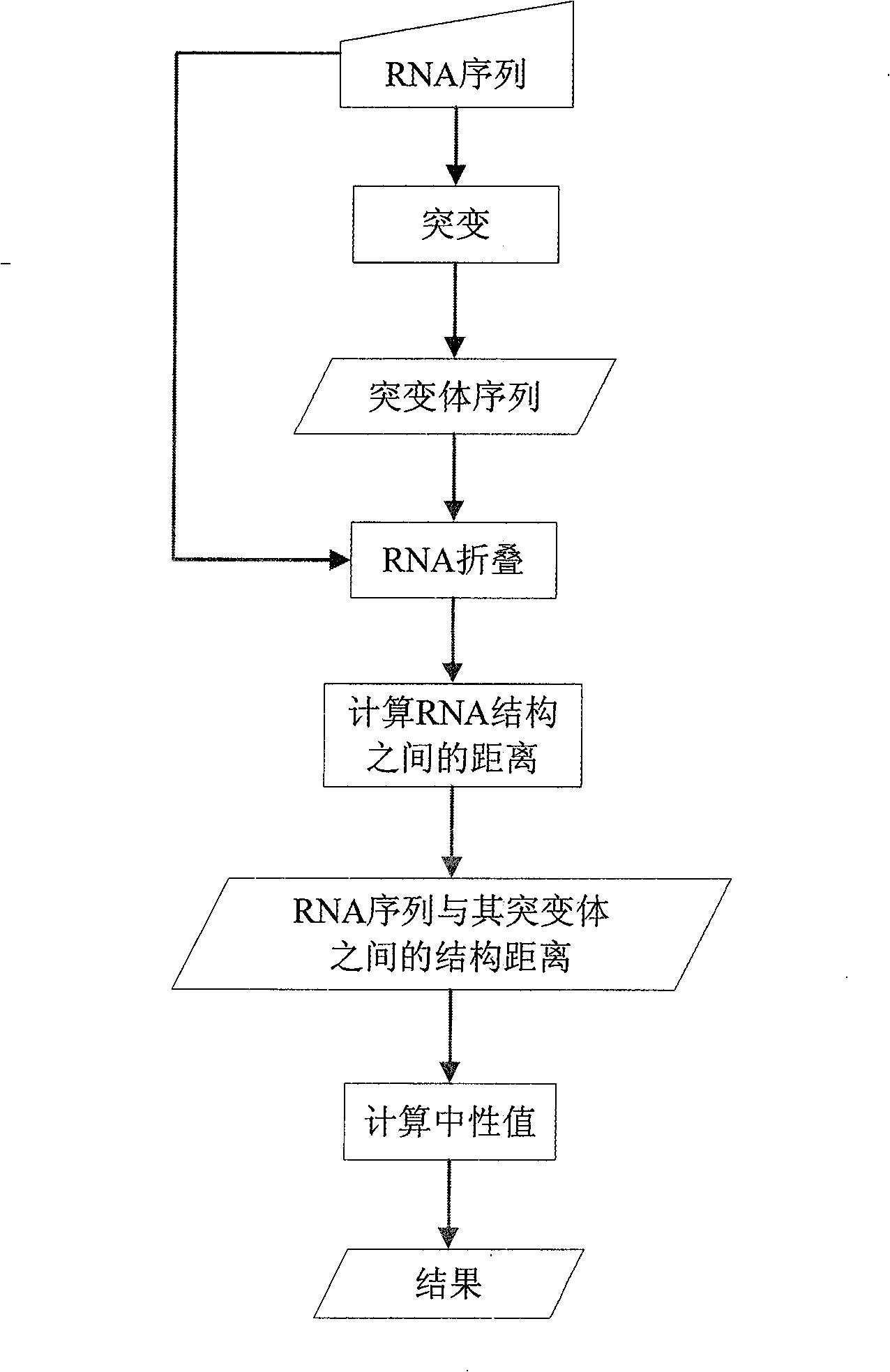

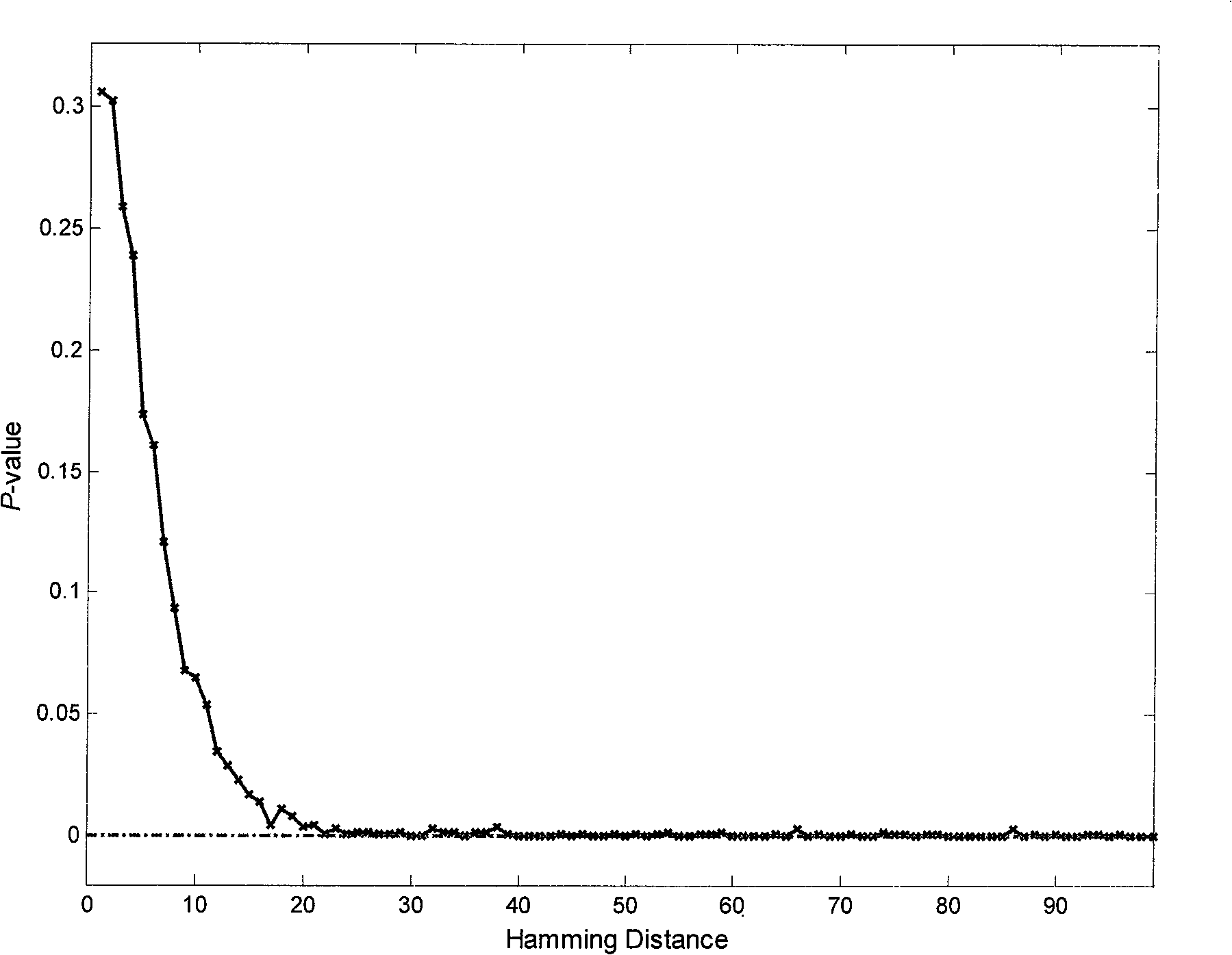

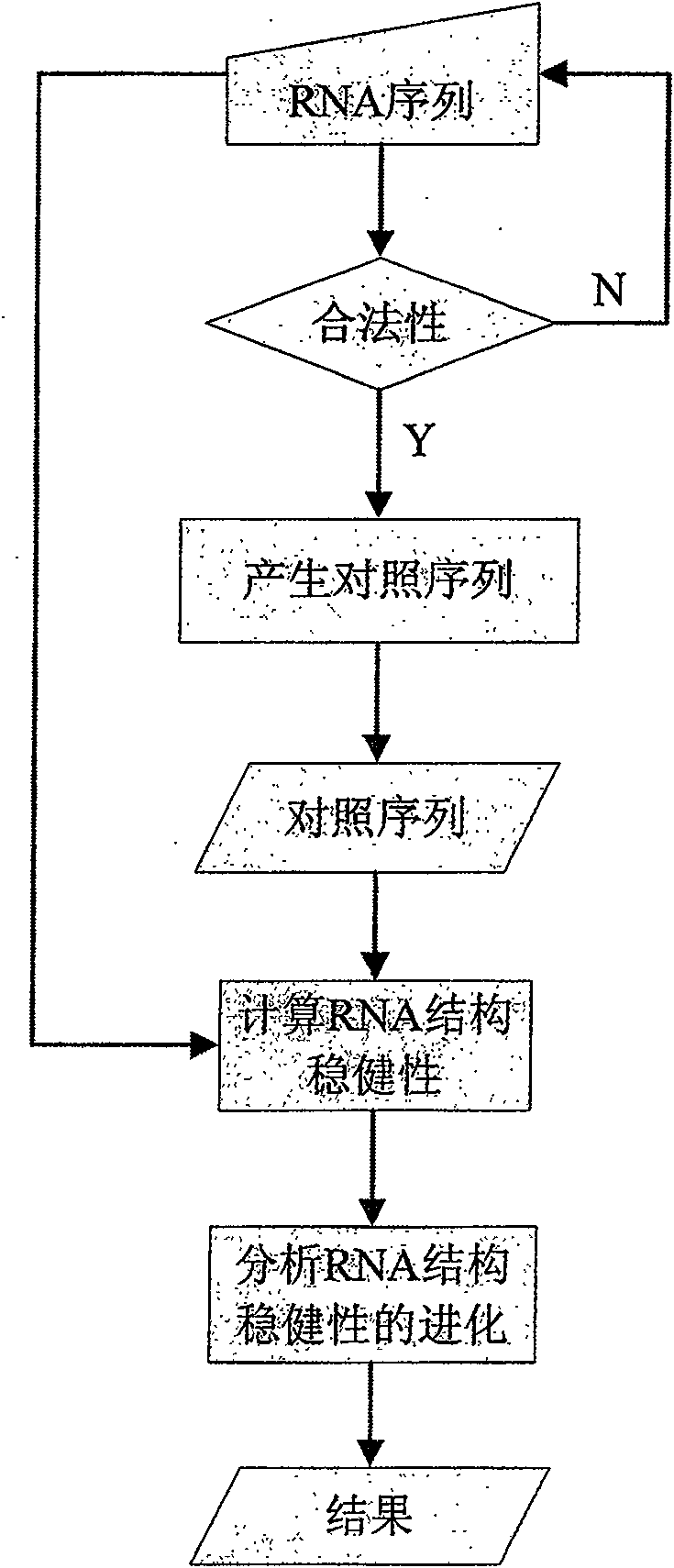

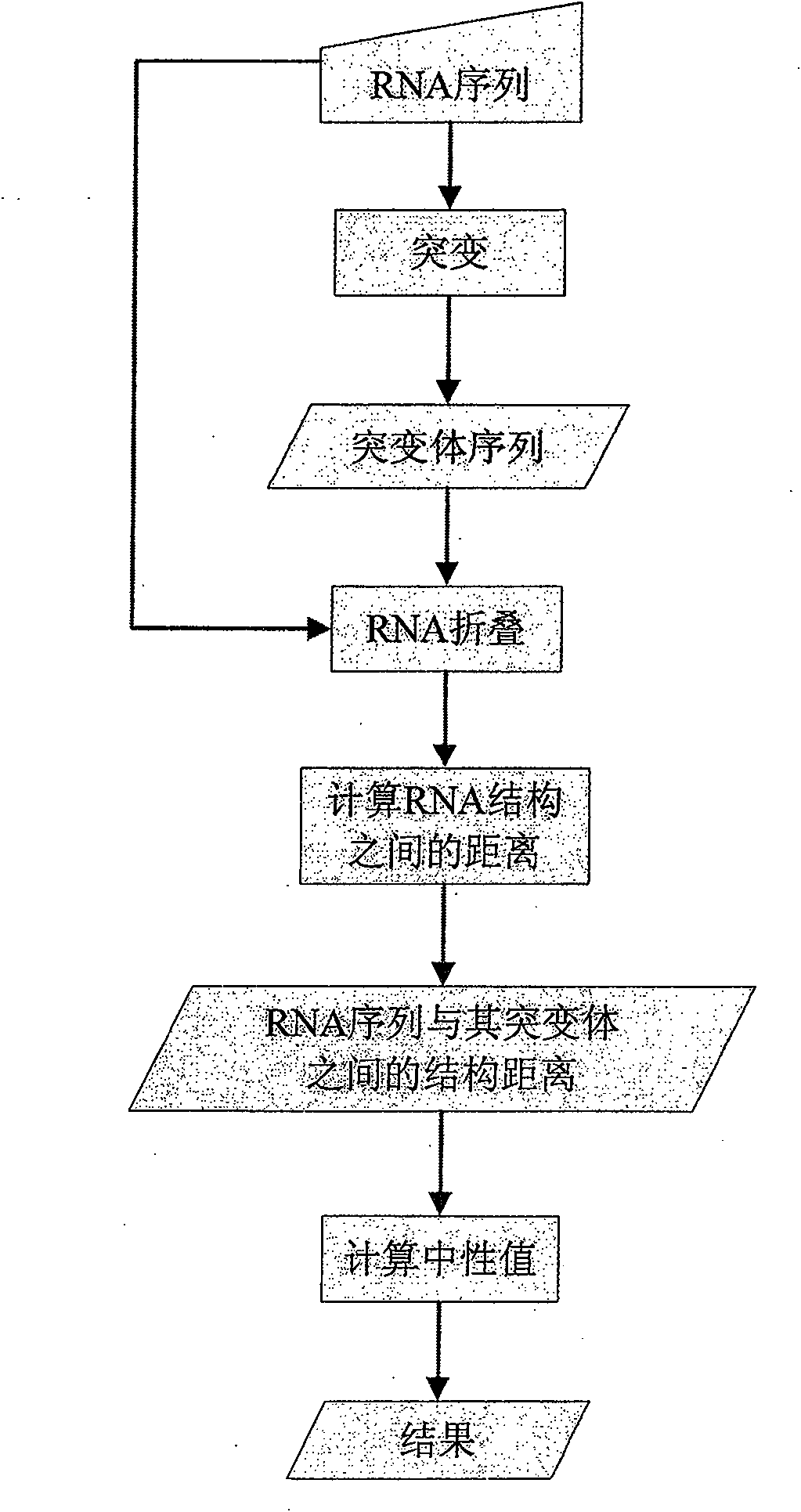

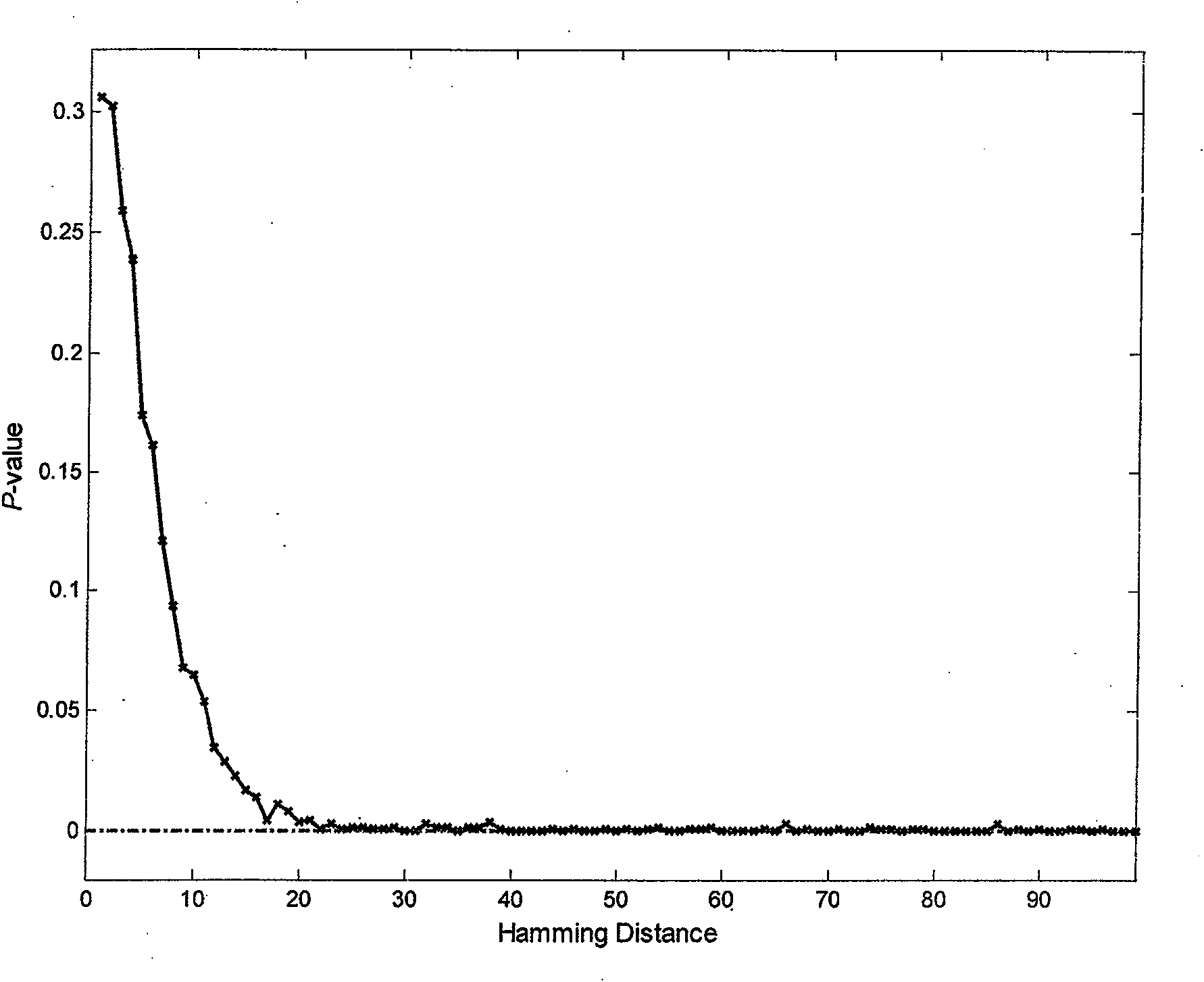

Method for quantitative analyzing evolution of RNA structure steadiness

InactiveCN101281561ASpecial data processing applicationsEvolutionary biologyComputerized systemRNA Sequence

The invention relates to a computer program, more specifically to a method for quantitatively analyzing the evolution of RNA structural robustness. The invention aims to provide a quantitative analytical method capable of analyzing RNA structural robustness simply, conveniently and quickly, solves the problem that RNA structural robustness is difficult to evaluate and quantify, reaches the objective of analysis of biological robustness origin and evolution thereof, thus improving the understanding of biological evolution. The invention is based on a RNA secondary structure as the research platform, provides a method for quantitatively analyzing the evolution of RNA structural robustness. The method comprises the steps of checking the validity of a RNA sequence inputted from a computer terminal, generating a control sequence, calculating RNA structural robustness, and quantitatively analyzing the evolution of the RNA structural robustness.

Owner:INST OF RADIATION MEDICINE ACAD OF MILITARY MEDICAL SCI OF THE PLA

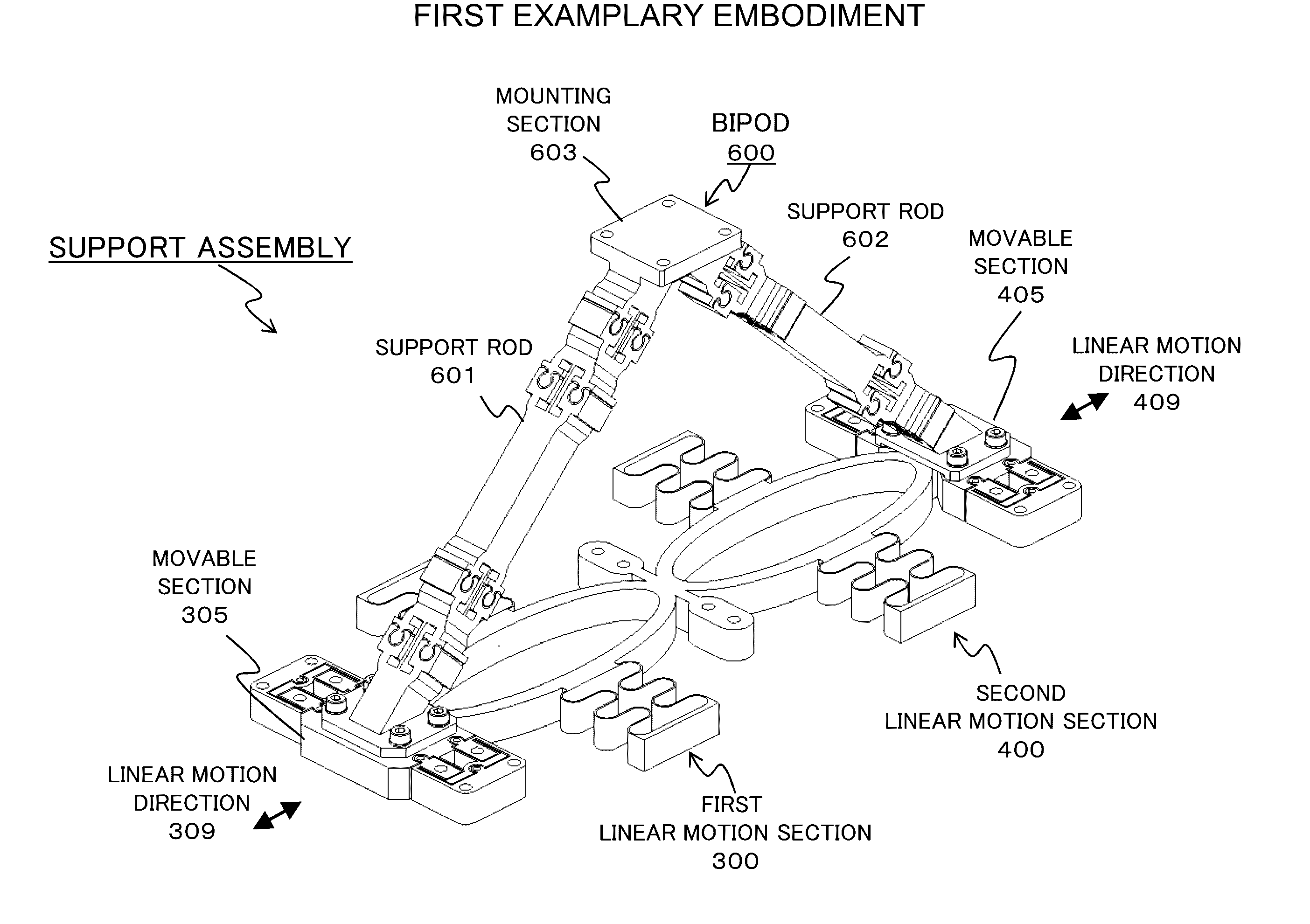

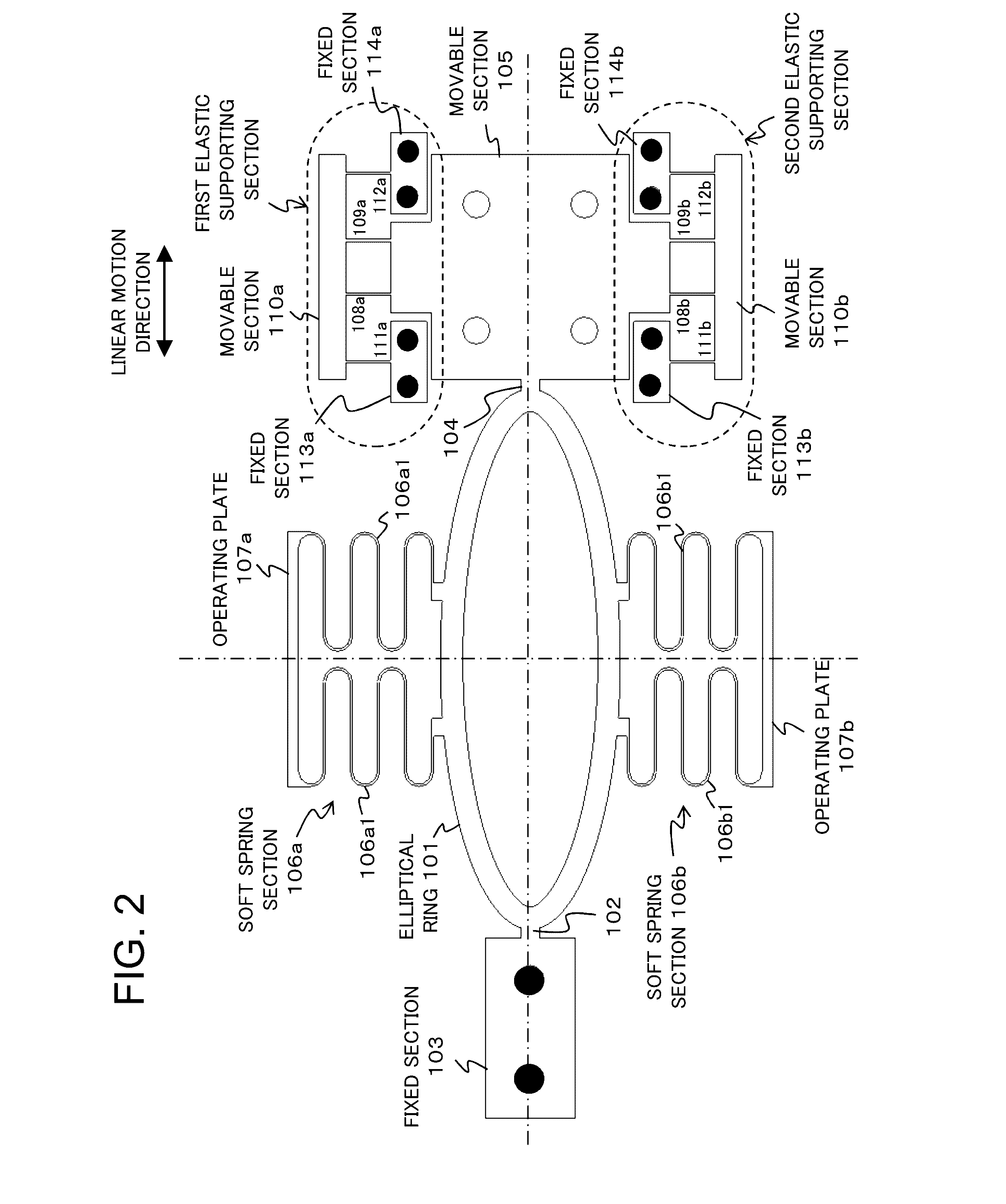

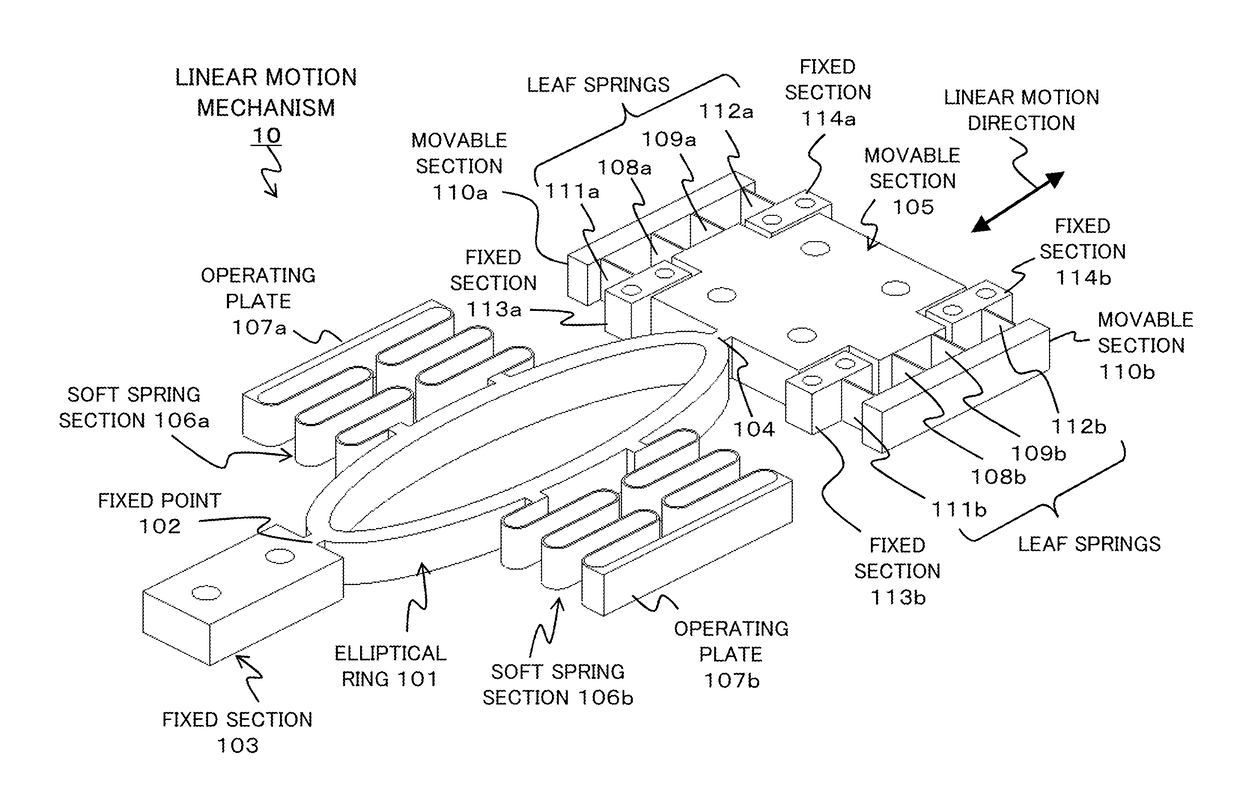

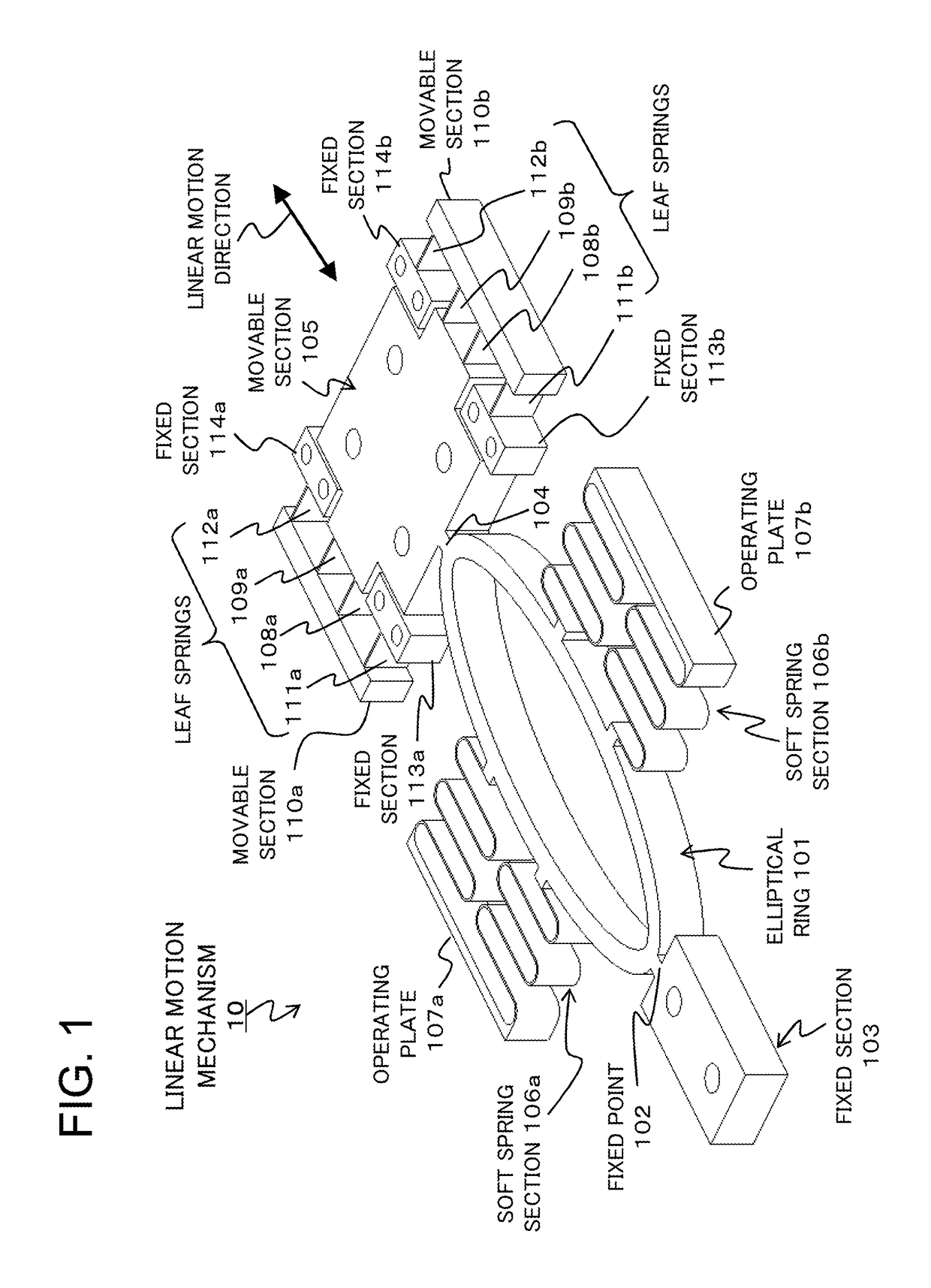

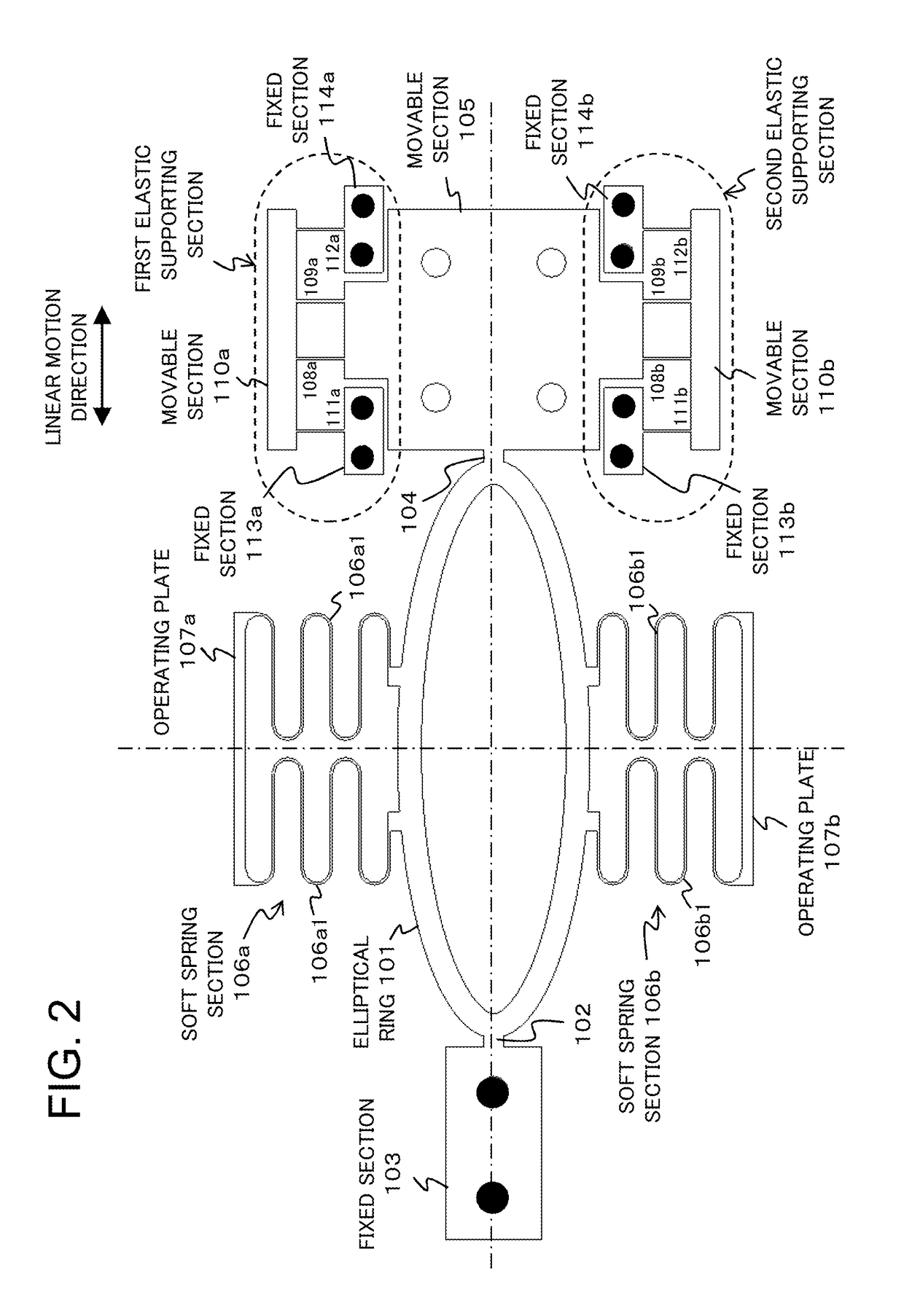

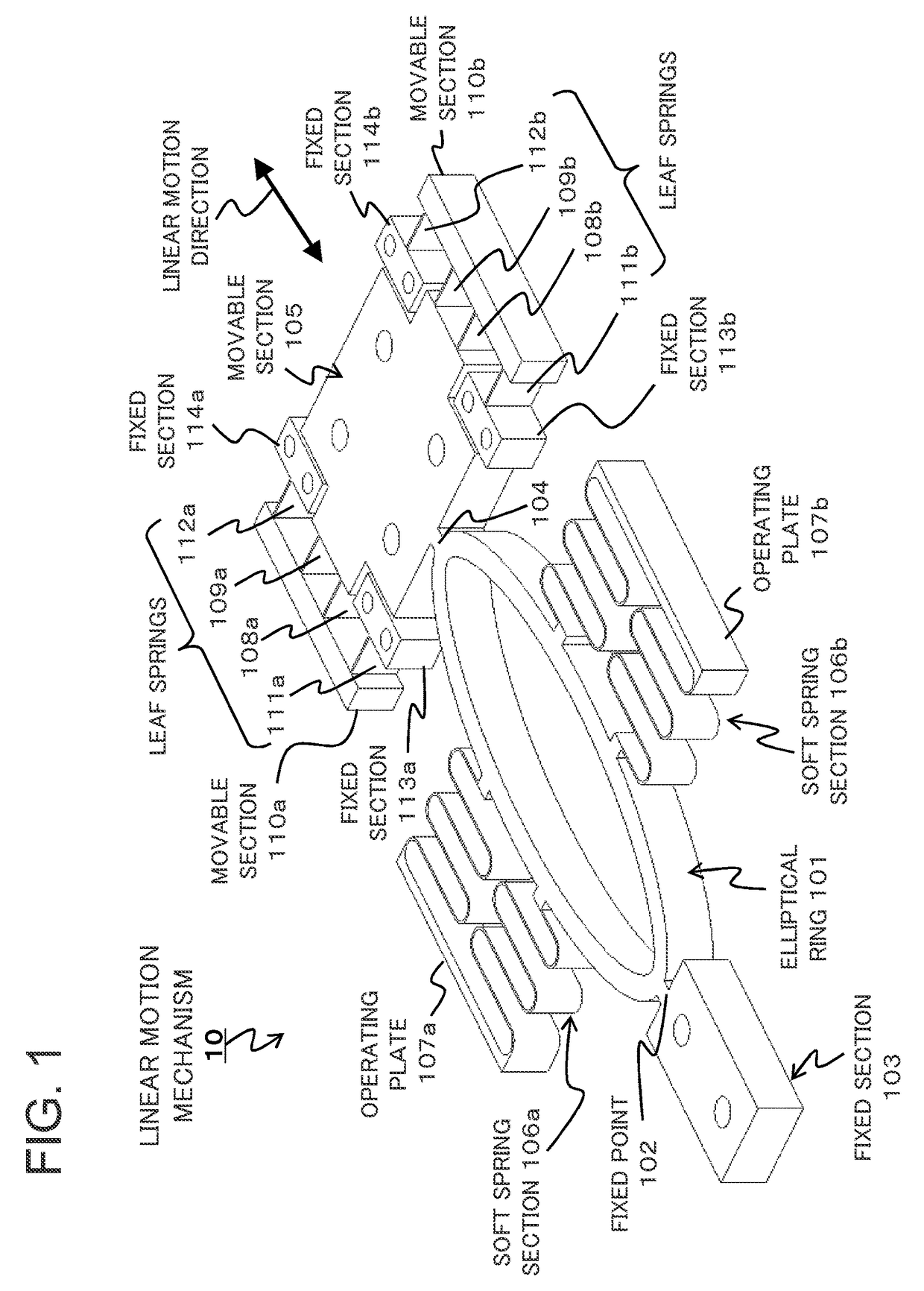

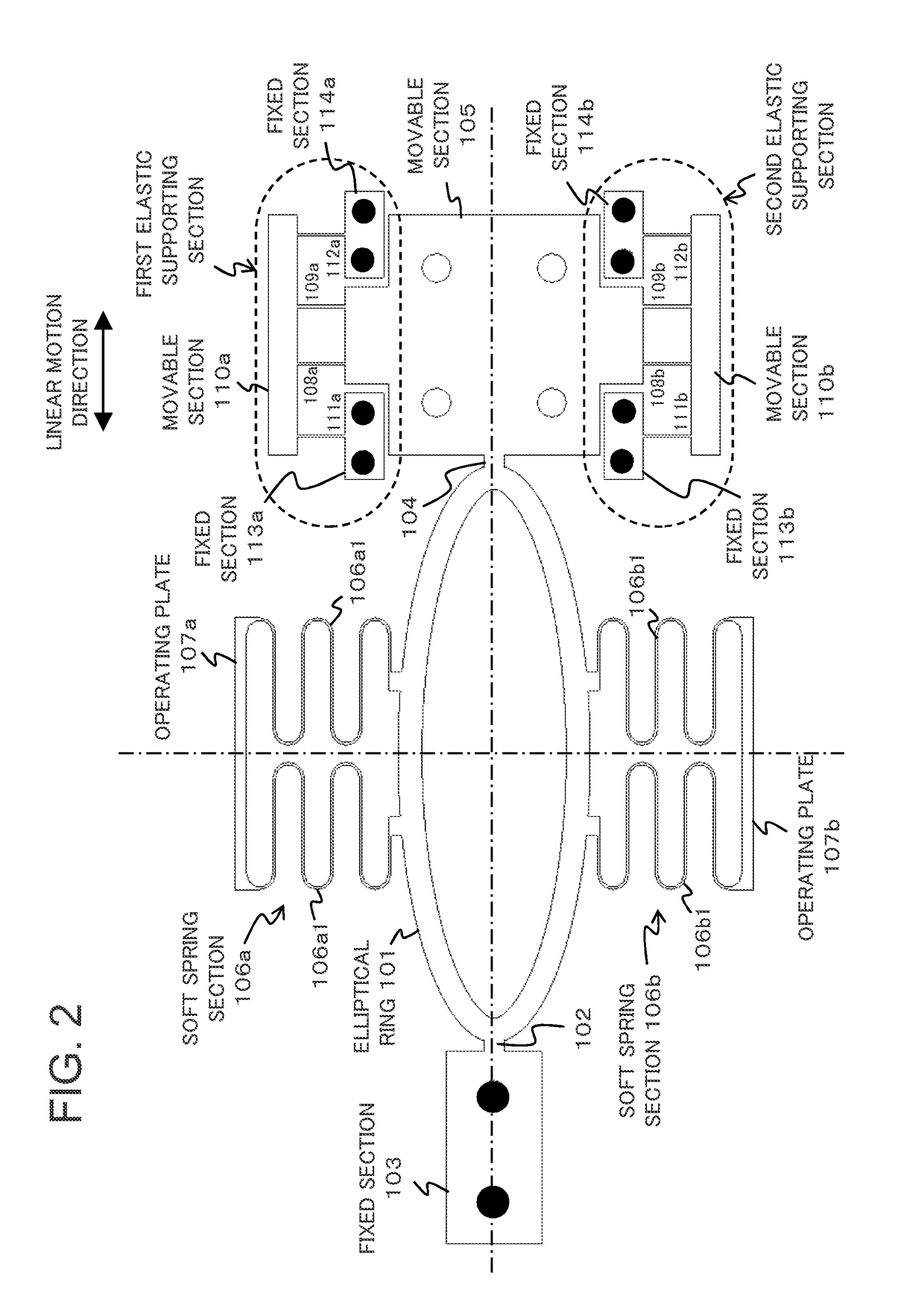

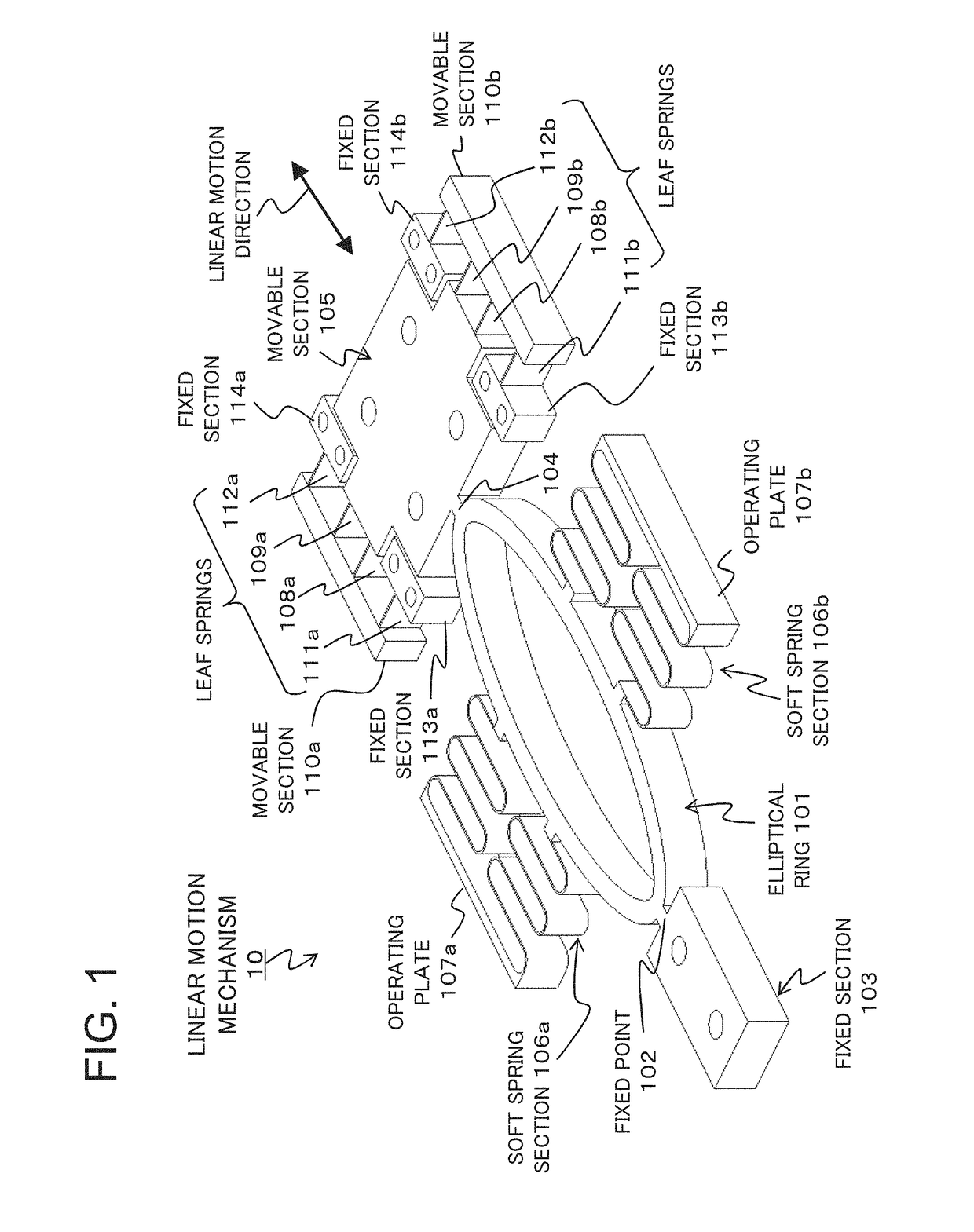

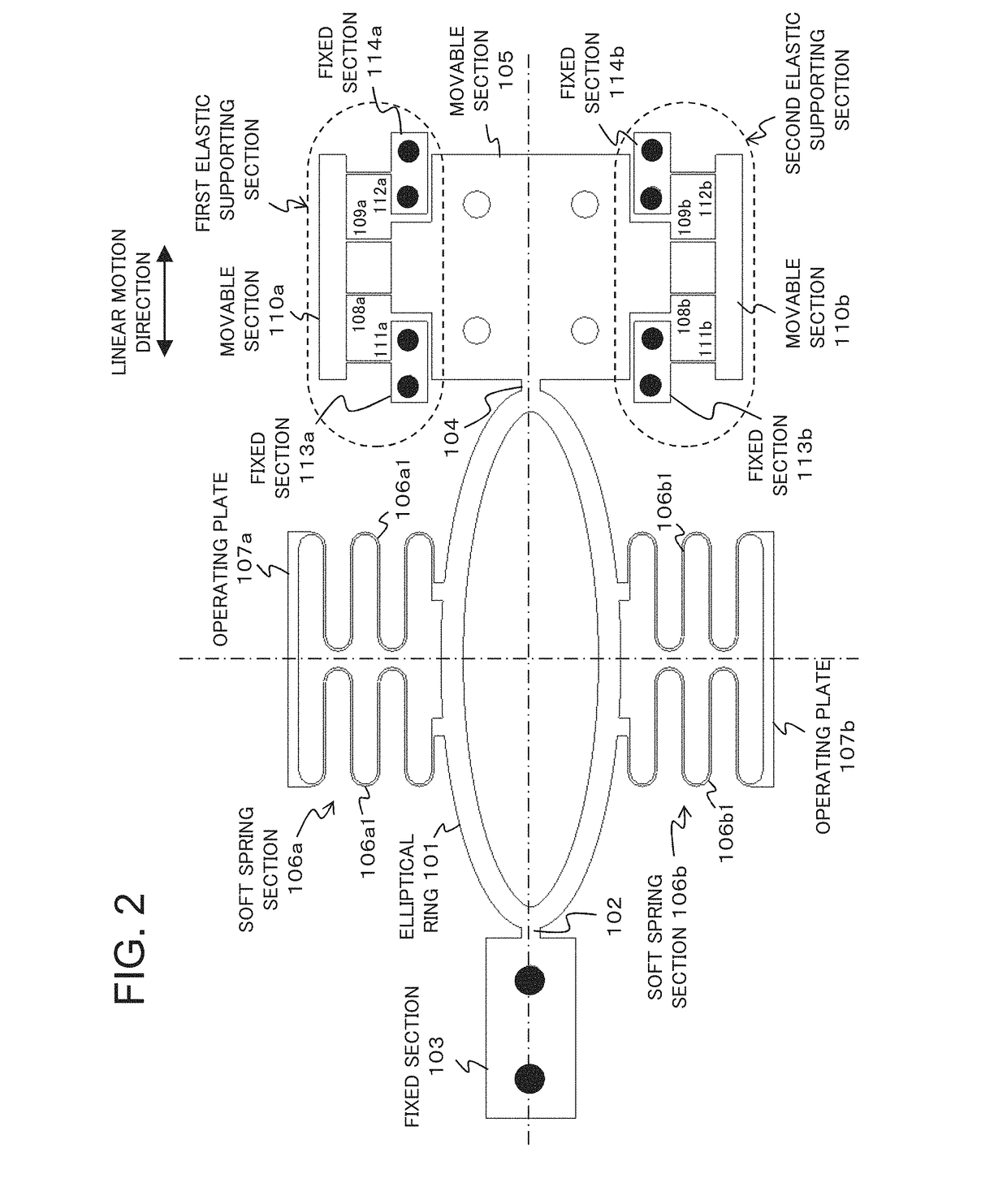

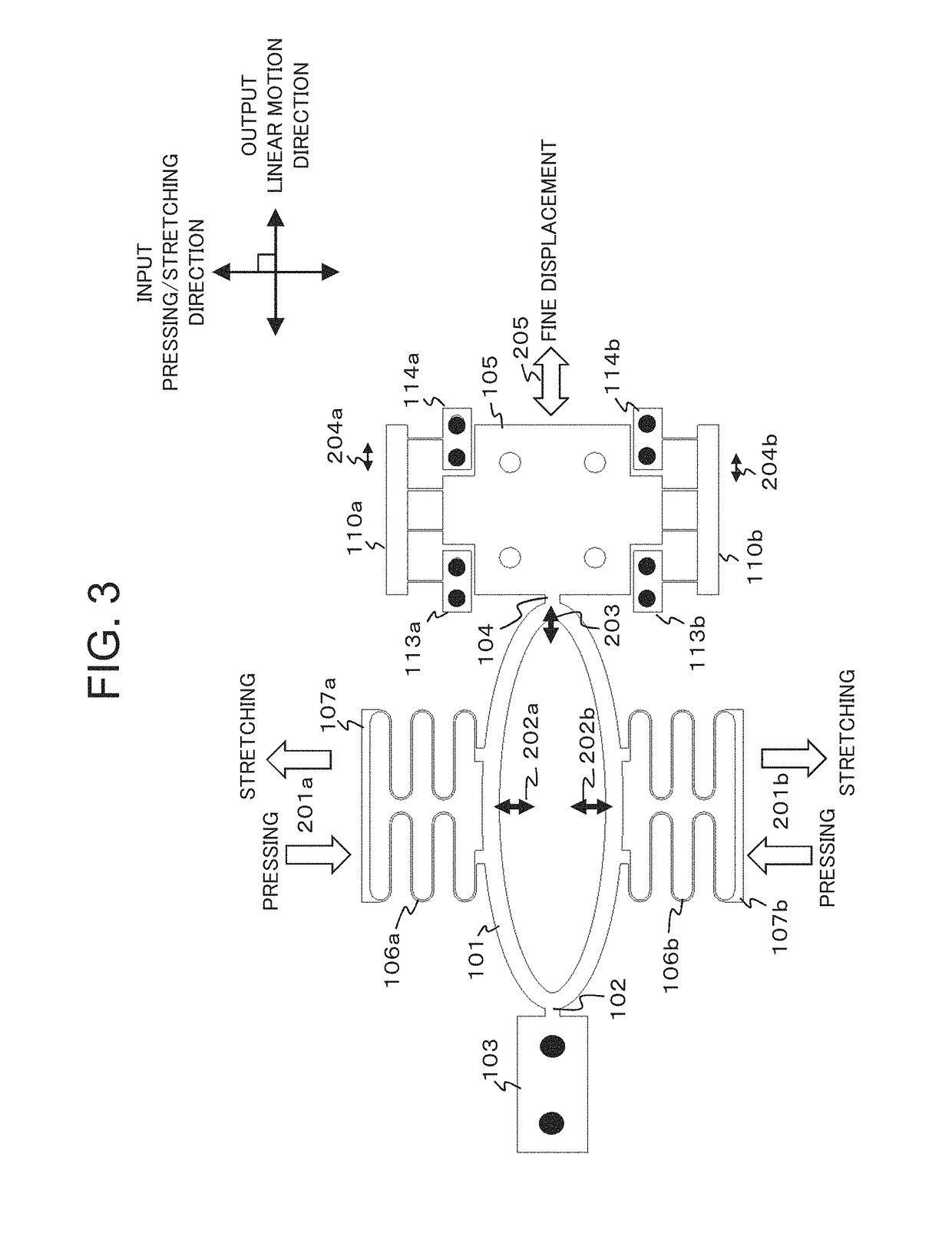

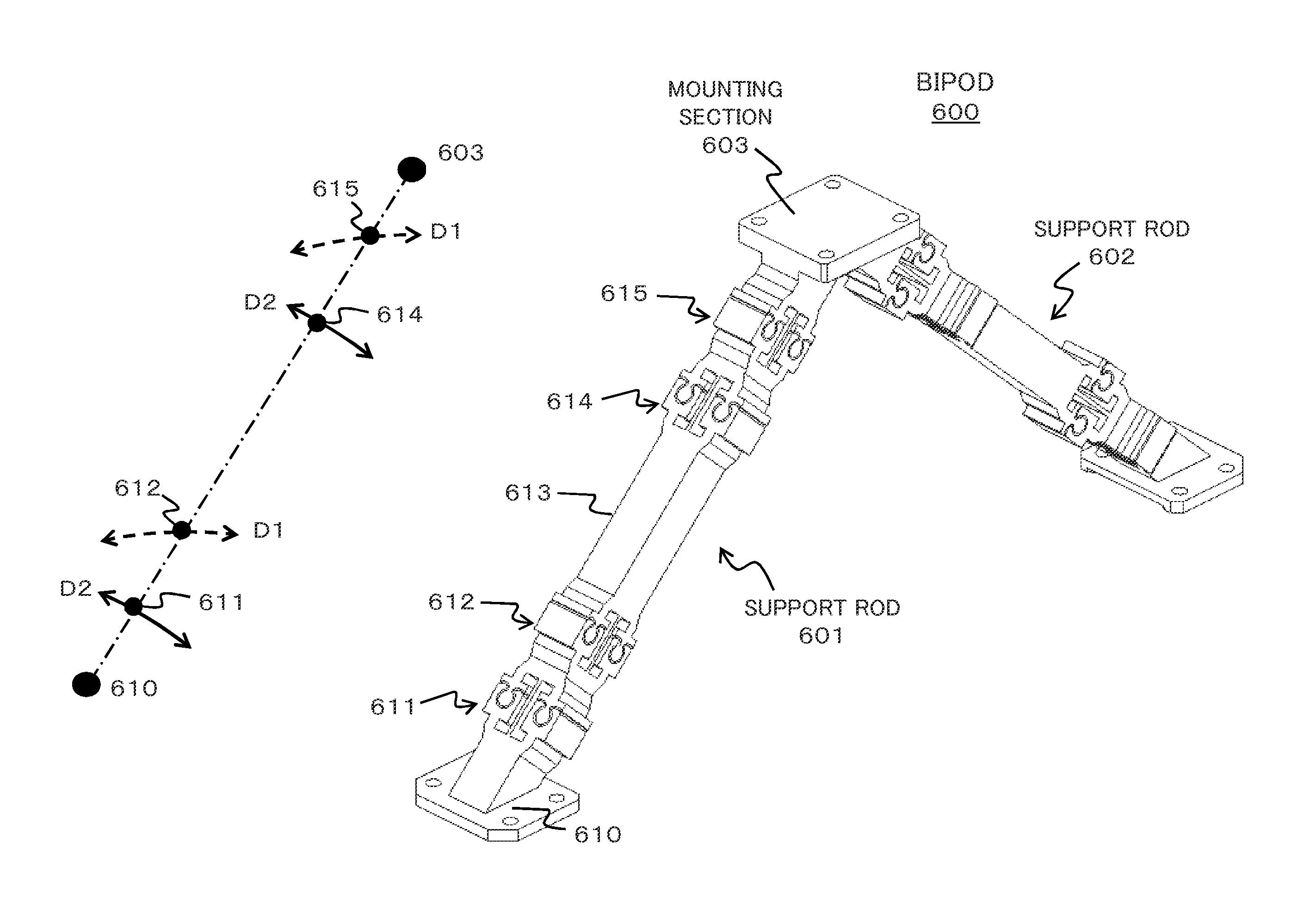

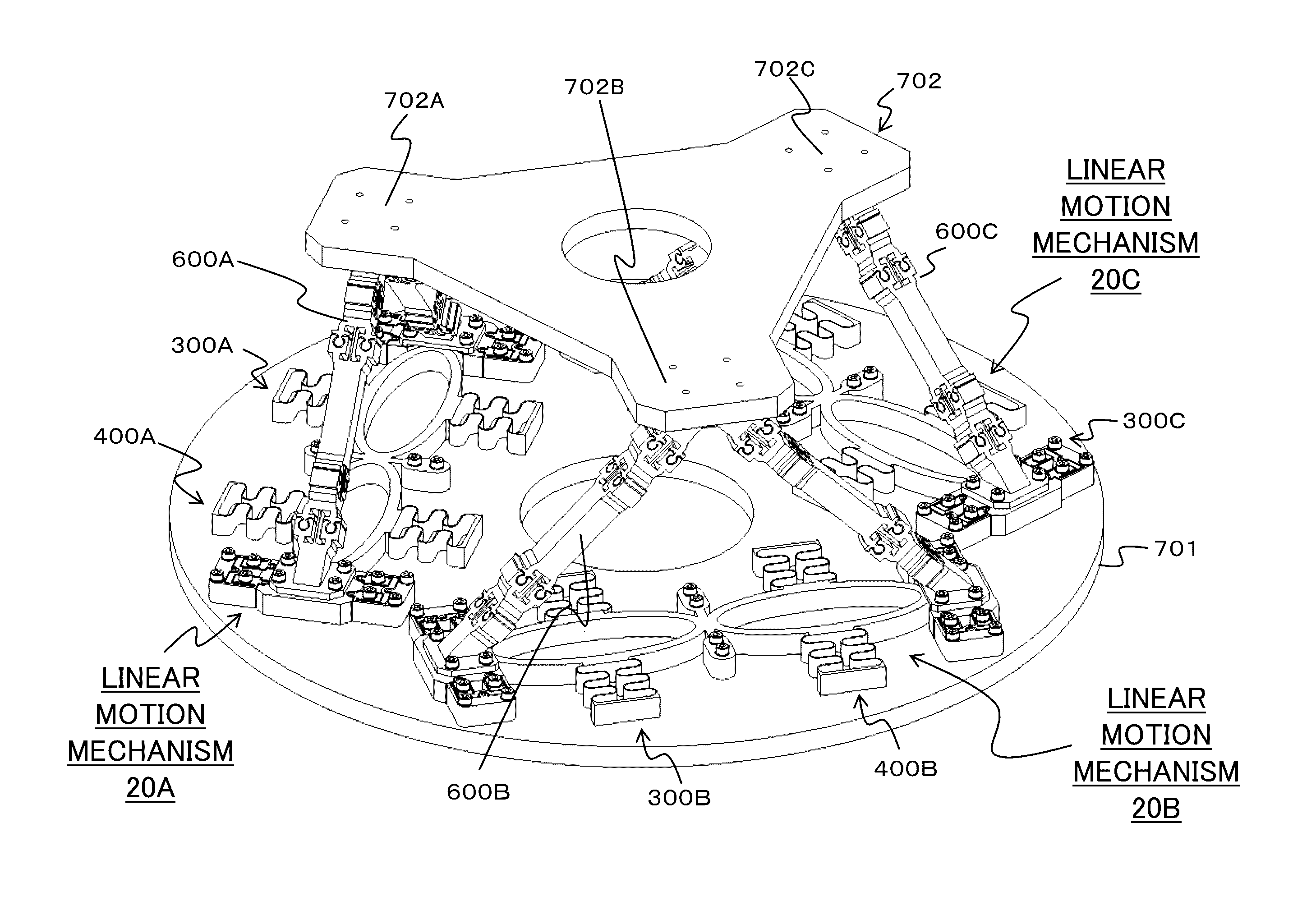

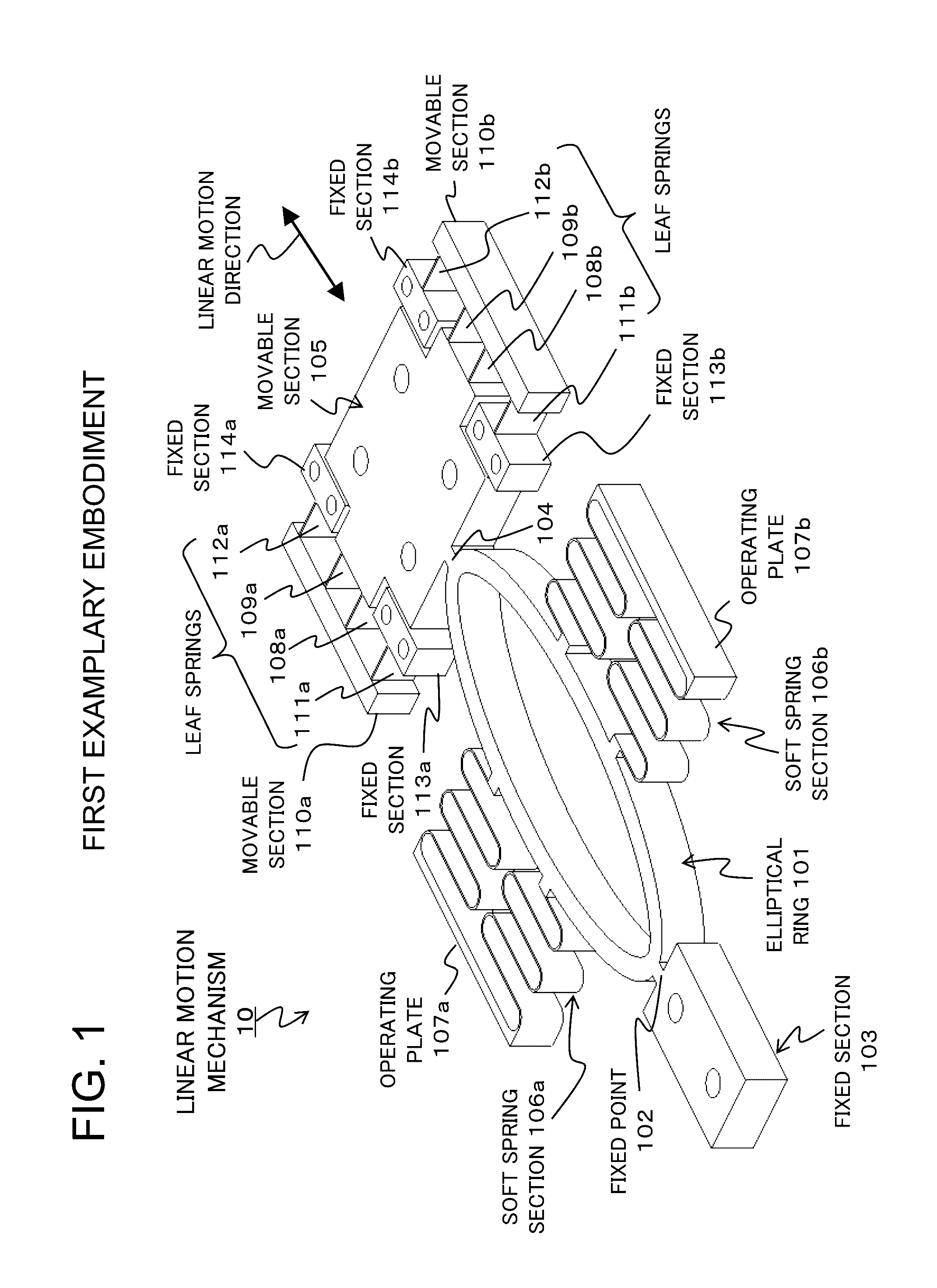

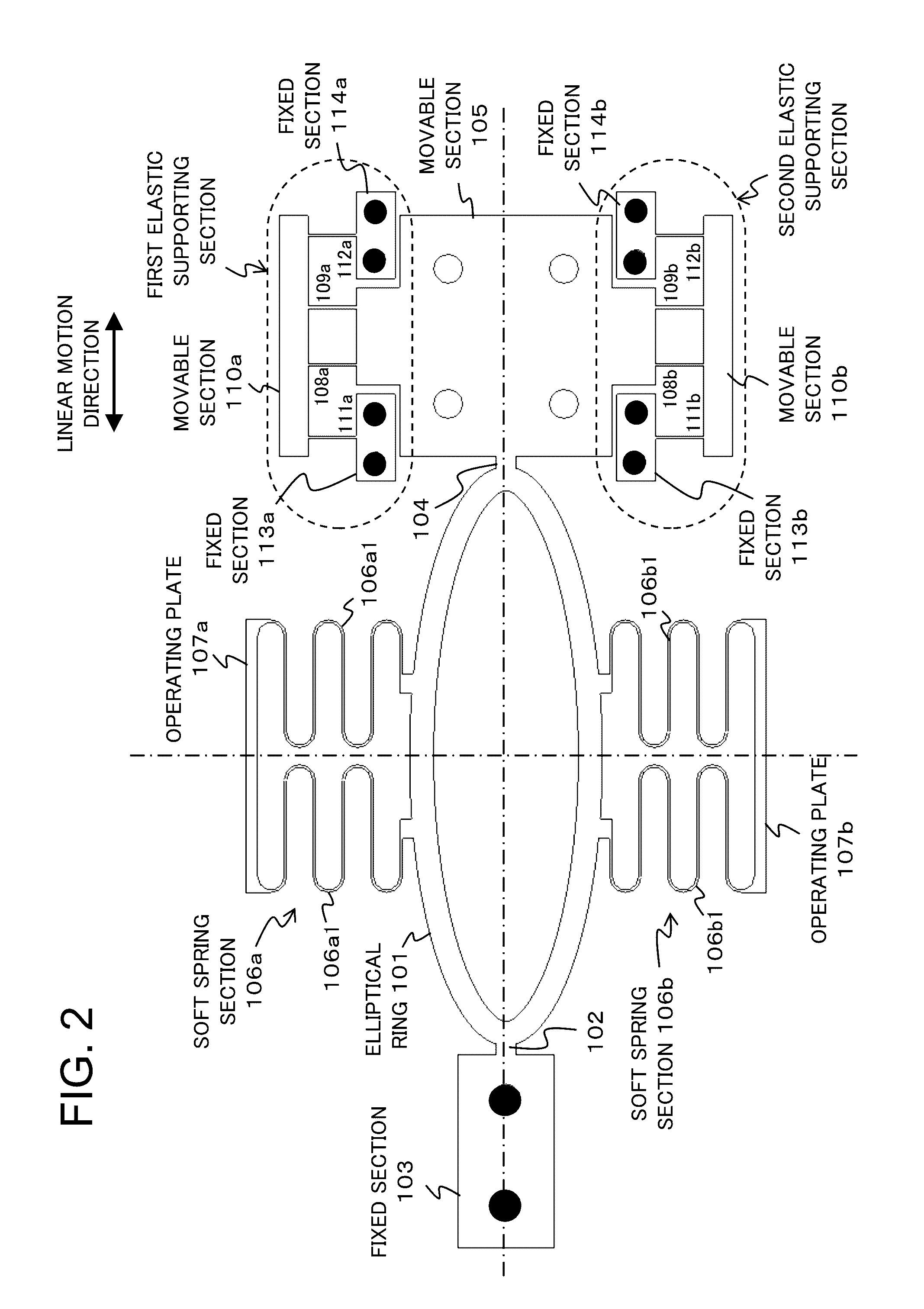

Multi-degree-of-freedom adjustment mechanism

ActiveUS10030695B2Improve accuracyEasy to manufactureProgramme-controlled manipulatorMicromanipulatorLinear motionMulti degree of freedom

A multiple-degree-of-freedom adjustment mechanism with precise linear motion has structural robustness and allows easy reduction in weight and size, simple production and easy operation. The multiple-degree-of-freedom adjustment mechanism includes: at least one support assembly; and a plate supported by the at least one support assembly, wherein the at least one support assembly includes: a bipod having a first rod and a second rod, one ends of which are fixed to each other at a top provided with a support section; and a linear motion arrangement having a first movable member and a second movable member which are fixed to the other ends of the first rod and the second rod respectively, wherein the first movable member and the second movable member independently move in a linear motion direction.

Owner:NEC CORP

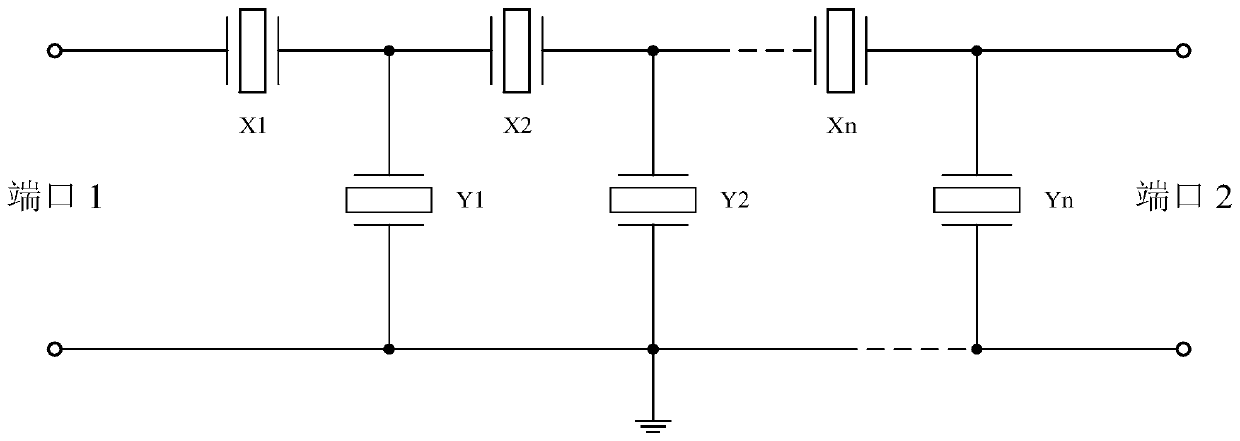

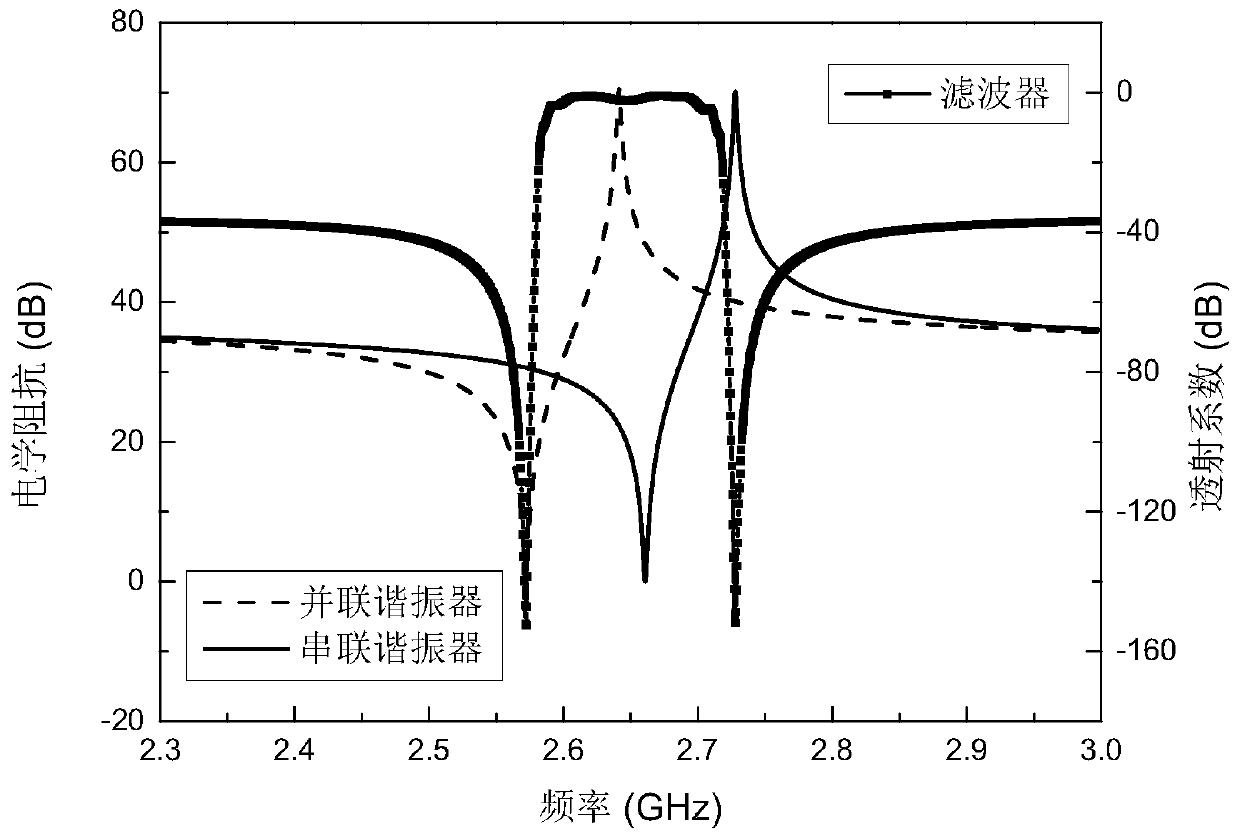

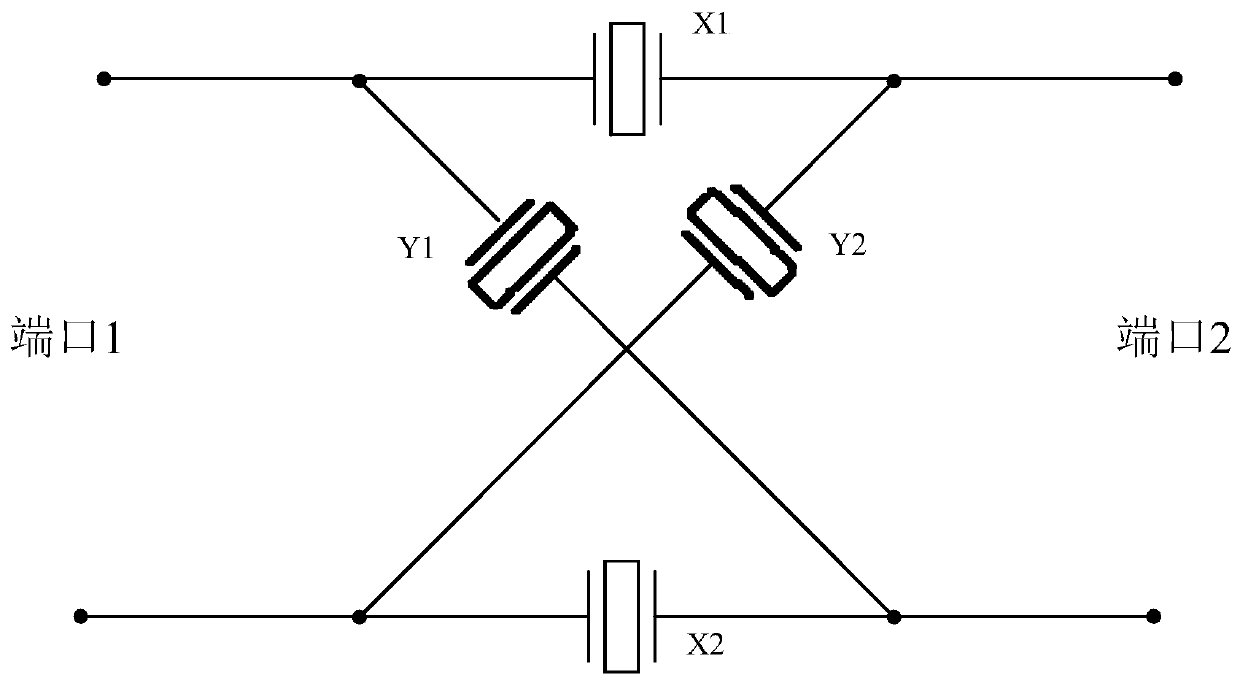

Flexible bulk acoustic wave filter

The invention provides a flexible bulk acoustic wave filter, which comprises a flexible substrate, a plurality of resonators, a port electrode and a connecting band. The materials of the flexible substrate comprise but are not limited to polyterephthalic acid plastics, polyacetylenimine, polyethylene naphthalate, polyetherimide, metal or inorganic materials. The pattern of the resonator is polygonal, oval or special-shaped and is composed of a plurality of arc lines and straight lines, and the conditions that any two edges are not parallel to each other, the inner angle in the pattern is larger than or equal to 60 degrees, and the number of resonance groups of the series resonator and the parallel resonator is larger than or equal to 2 are met. The flexible bulk acoustic wave filter can beapplied to a transfer process to a flexible substrate, and has structural robustness after transfer. In the invention, the structure of the working area is stable by adding an edge constraint structure, and the adhesion capability of the filter on a flexible substrate is increased by adding an additional adhesion area.

Owner:TIANJIN UNIV +1

Linkage rod including limited-displacement flexible mechanism

ActiveUS9920874B2Easy to fallEasy to manufactureProgramme-controlled manipulatorMicromanipulatorFlexible MechanismsMechanical engineering

A linkage rod including a limited-displacement flexible mechanism has structural robustness and allows easy reduction in weight and size, simple production and easy operation. The linkage rod including at least one limited-displacement flexible mechanism, wherein the limited-displacement flexible mechanism comprises at least one limited-displacement flexible joint which comprises: a flexible member; and at least one bend limitation section which is arranged in parallel with the flexible member so that the bend limitation section limits a bend of the flexible member.

Owner:NEC CORP

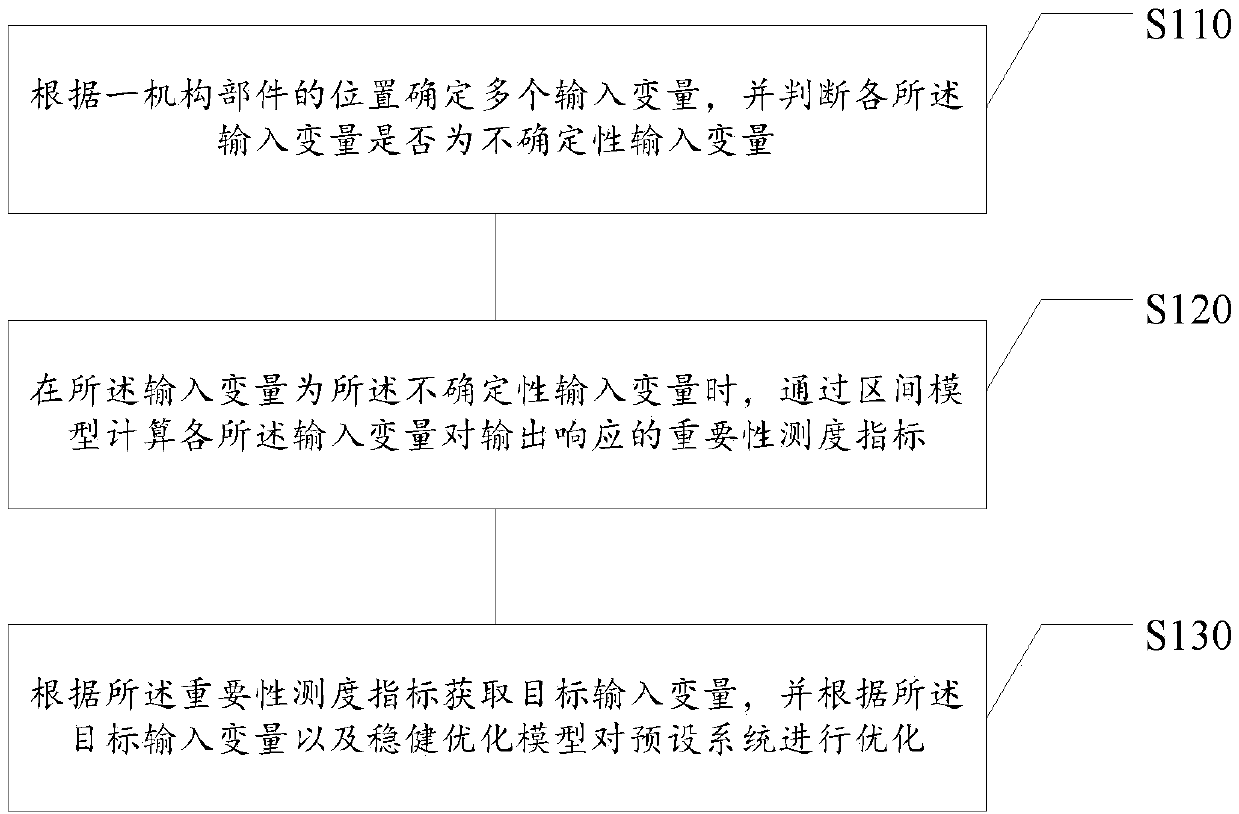

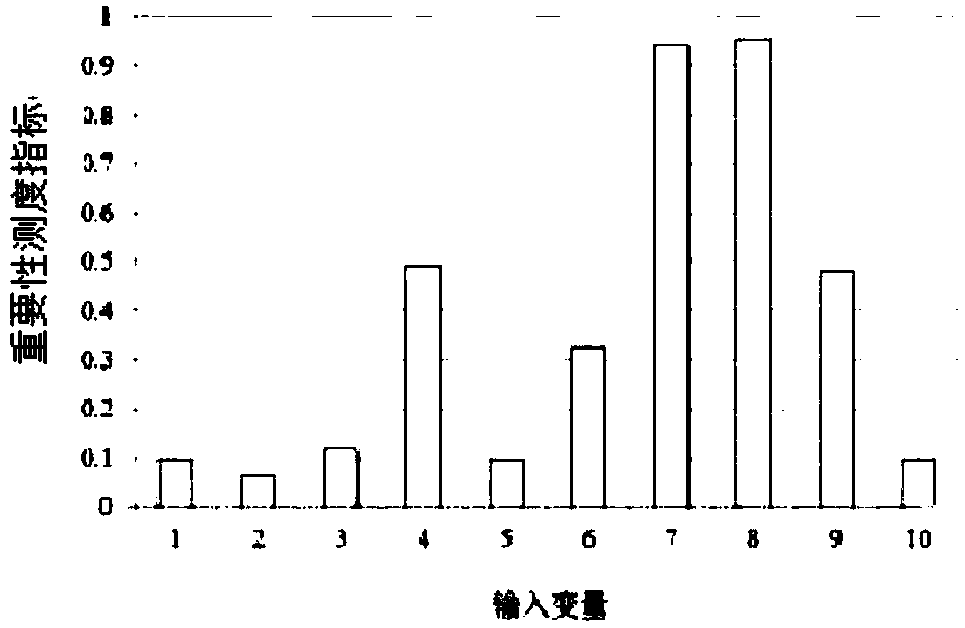

Uncertainty-based robustness analysis method and system

ActiveCN107609234AAchieve dimensionality reductionAchieve precise optimizationSpecial data processing applicationsAnalysis methodComputer science

The invention provides an uncertainty-based robustness analysis method and system. The method comprises the following steps of: determining a plurality of input variables according to position of a mechanism component and judging whether each input variable is an uncertainty input variable or not; when the input variables are uncertainty input variables, calculating a significance measurement index, to output response, of each input variable through an internal model; and obtaining a target input variable according to the significance measurement indexes, and carrying out robustness analysis on a preset system according to the target input variable and a robustness optimization model. According to the method and system, the input variables can be decreased through the significance measurement indexes, and the optimization model can be simplified, so that the efficiency of structural robustness analysis is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Linkage rod including limited-displacement flexible mechanism

ActiveUS10161561B2Easy to fallEasy to manufactureMicromanipulatorDoor/window protective devicesCompliant mechanismFlexible Mechanisms

A linkage rod including a limited-displacement flexible mechanism has structural robustness and allows easy reduction in weight and size, simple production and easy operation. The linkage rod including at least one limited-displacement flexible mechanism, wherein the limited-displacement flexible mechanism comprises at least one limited-displacement flexible joint which comprises: a flexible member; and at least one bend limitation section which is arranged in parallel with the flexible member so that the bend limitation section limits a bend of the flexible member.

Owner:NEC CORP

Linkage rod including limited-displacement flexible mechanism

ActiveUS20170030513A1Easy to fallEasy to manufactureProgramme-controlled manipulatorMicromanipulatorFlexible MechanismsCompliant mechanism

A linkage rod including a limited-displacement flexible mechanism has structural robustness and allows easy reduction in weight and size, simple production and easy operation. The linkage rod including at least one limited-displacement flexible mechanism, wherein the limited-displacement flexible mechanism comprises at least one limited-displacement flexible joint which comprises: a flexible member; and at least one bend limitation section which is arranged in parallel with the flexible member so that the bend limitation section limits a bend of the flexible member.

Owner:NEC CORP

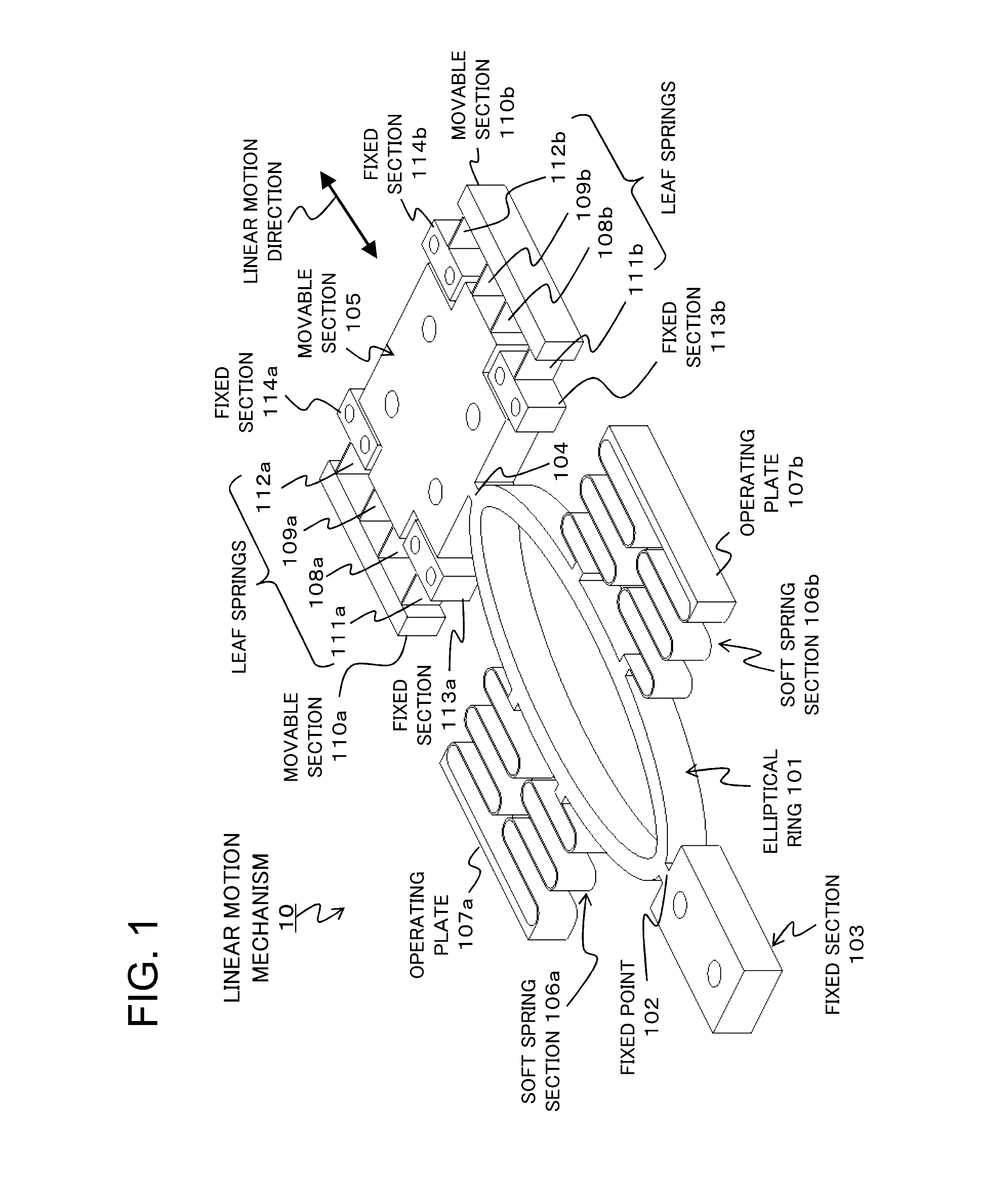

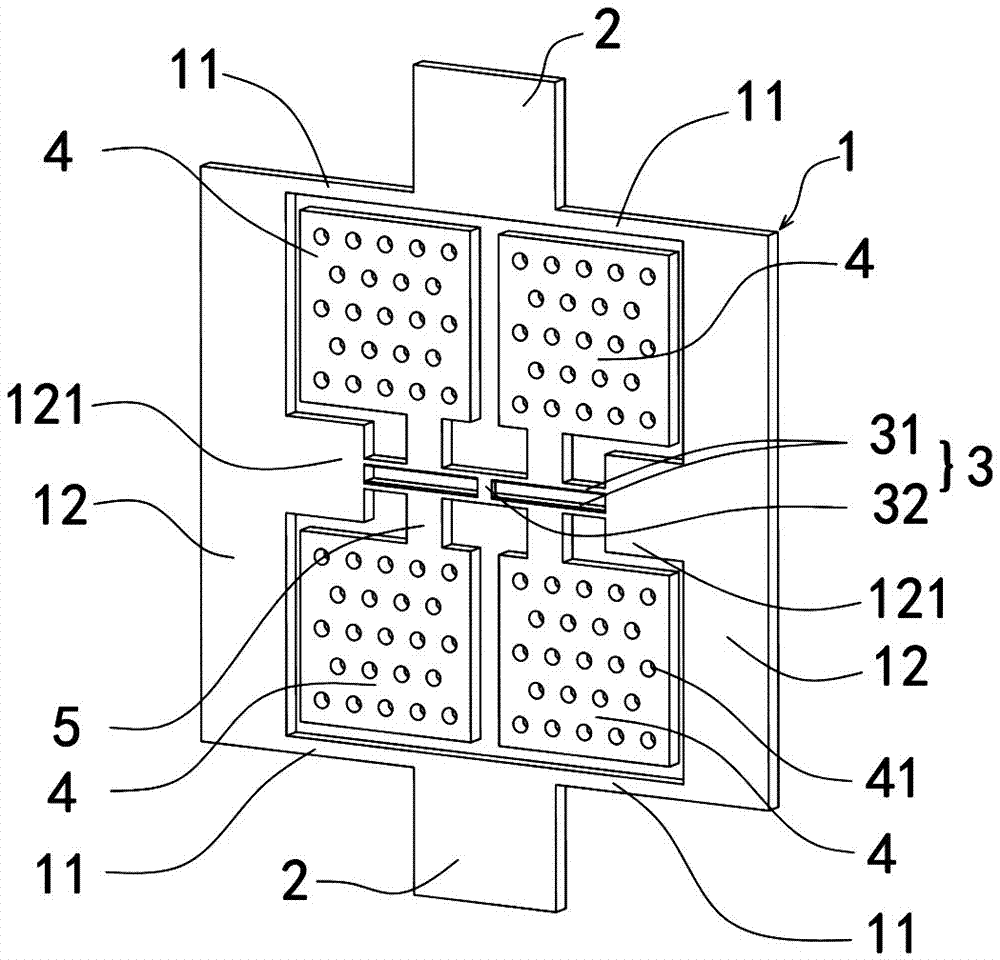

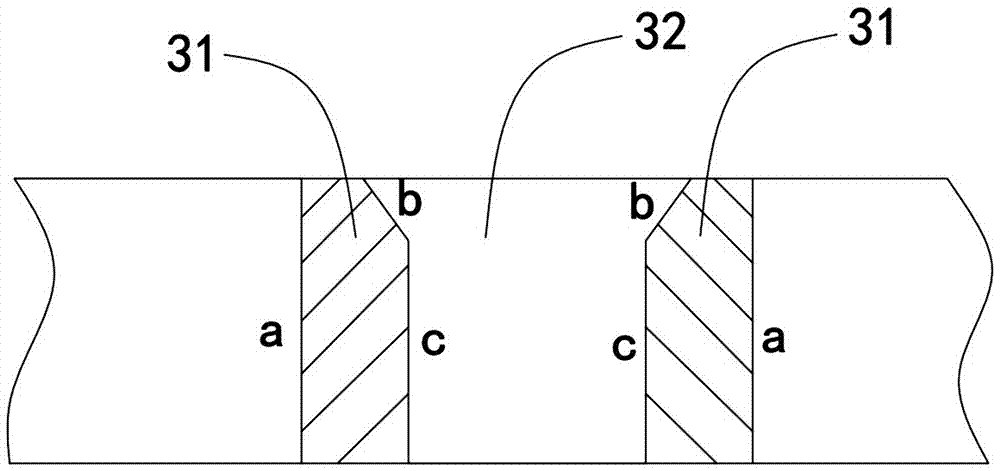

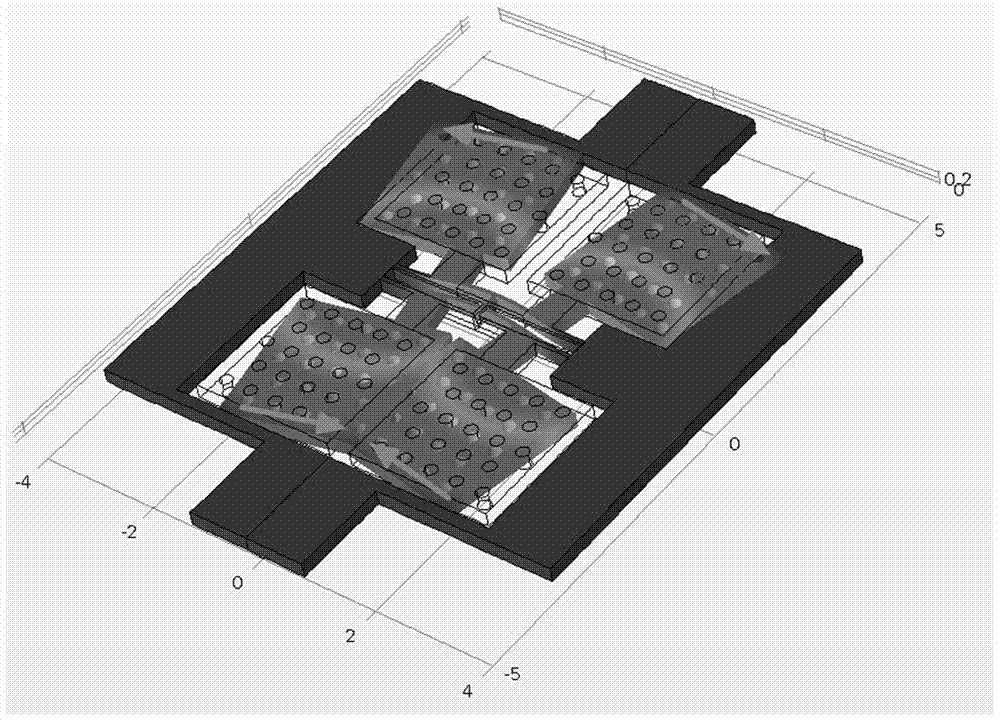

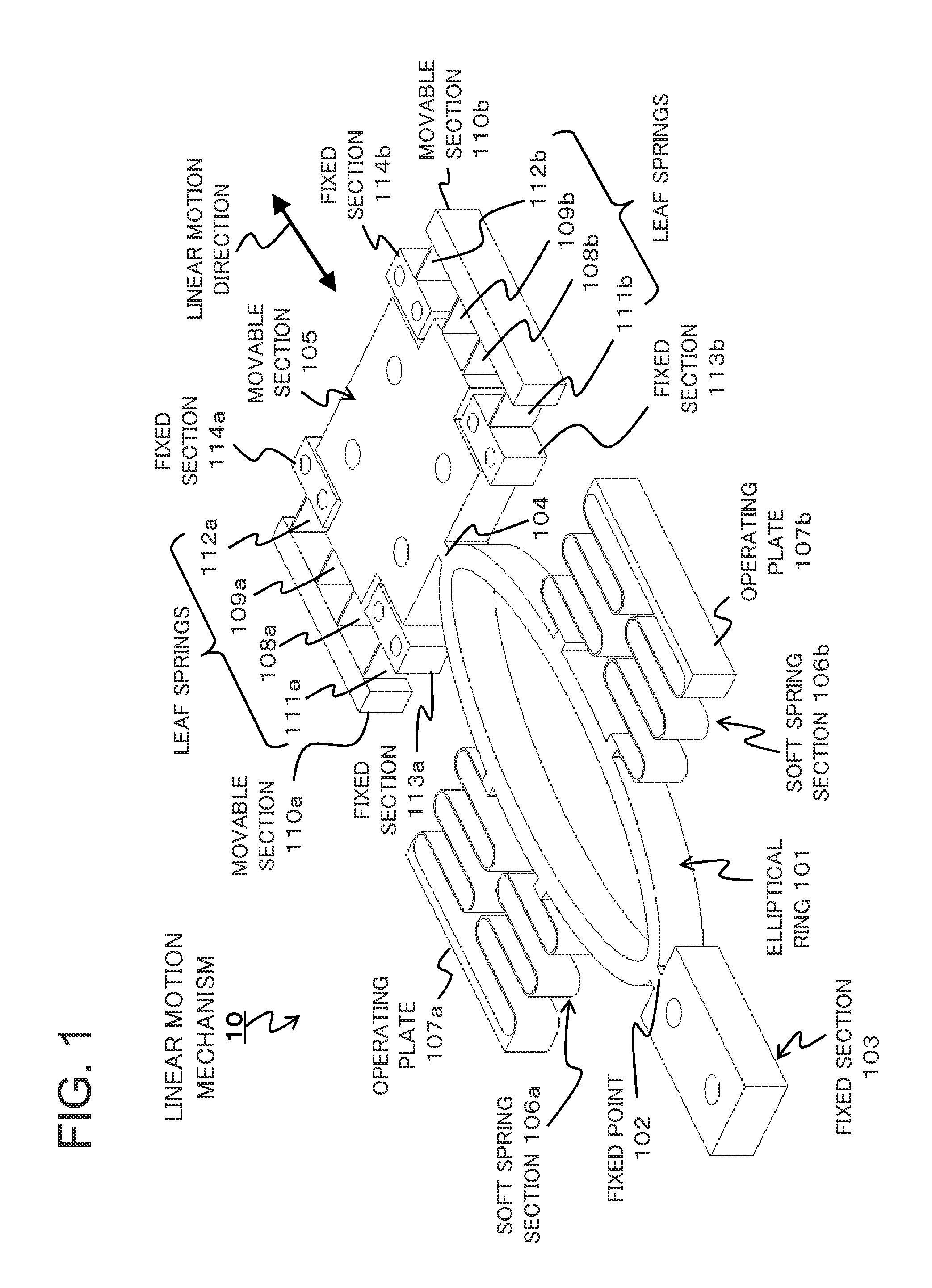

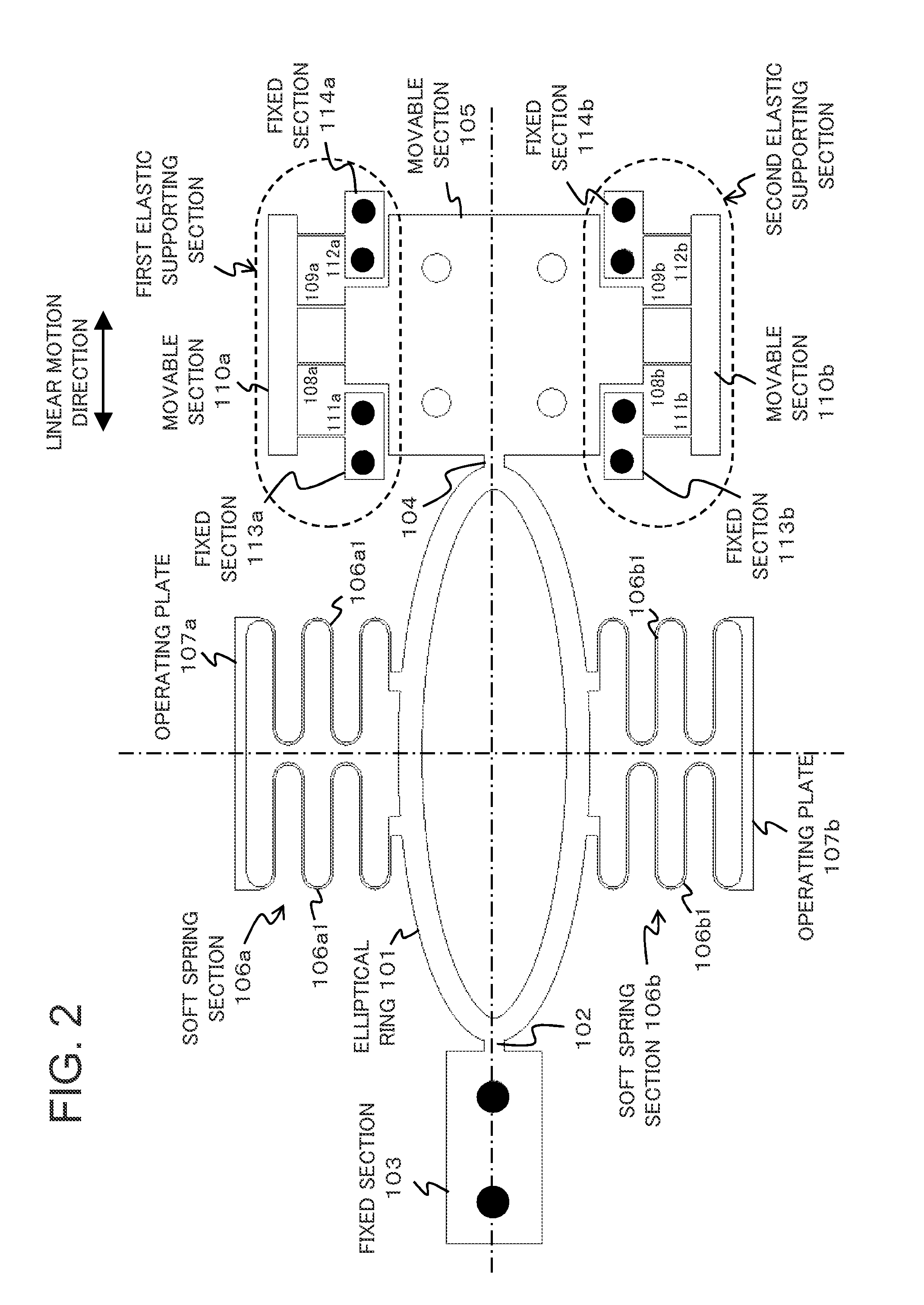

Linear motion mechanism formed integrally

ActiveUS20170030444A1Small sizeReduce weightProgramme-controlled manipulatorMicromanipulatorLinear motionEngineering

A linear motion mechanism with precise linear motion has structural robustness and allows easy reduction in weight and size, simple production and easy operation. The linear motion mechanism includes: an elastic arrangement which is arranged to transform an input direction and an input displacement to an output direction and an output displacement, wherein the output direction is orthogonal to the input direction; an operating member which is arranged to deform the elastic arrangement in the input direction by the input displacement; and a movable member fixed to the elastic arrangement to move in the output direction by the output displacement.

Owner:NEC CORP

10KV cold-shrinkable cable indoor terminal

ActiveCN110429553AImprove structural stabilityImprove sealingCable terminationsEngineeringStructural stability

The invention discloses a 10KV cold-shrinkable cable indoor terminal comprising a cold-shrinkable sheath and a support tube, wherein the support tube is located inside the cold-shrinkable sheath; thetwo ends of the cold-shrinkable sheath are provided with end covers; each end cover comprises a cover wall and a cover surface; the cover wall extends into the support tube; the cover surfaces cover the two end surfaces of the cold-shrinkable sheath; convex rings are disposed on the two ends of the support tube at positions close to the end portions of the cover walls, and have an internal diameter larger than that of other parts of the support tube; ring grooves are disposed on the cold-shrinkable sheath at positions corresponding to the convex rings. The sealing effect and the waterproof performance of the cold-shrinkable sheath are improved by the structure in which the support tube having the convex rings matches the ring grooves of the shrink-shrinkable sheath. The end covers improvesthe structural stability of the support tube, prolongs the service life of a product, and improves structural robustness of the product.

Owner:ANHUI YIFALA ELECTRICAL CO LTD

Graphene enhanced elastomeric stator

ActiveUS10012230B2Improved polymerSimple structureMaterial nanotechnologySpecific nanostructure formationElastomerCross-link

An enhanced elastomeric stator assembly and method of making the same is disclosed. The elastomeric stator may be structurally, thermally, and / or chemically enhanced through the incorporation of graphene particles, cross-linkable polymers, coupling agents that extend cross-links, and by the reduction of filler material. The graphene particles can be incorporated in functionalized or non-functionalized form or in a combination thereof, the functionalized graphene increasing the number of cross-links in the overall structure, thereby enhancing the structural robustness of the elastomeric stator. The compound can be formulated to have a relatively low viscosity and other characteristics that allow the material to flow through a mold cavity.

Owner:REMY TECHNOLOGIES LLC

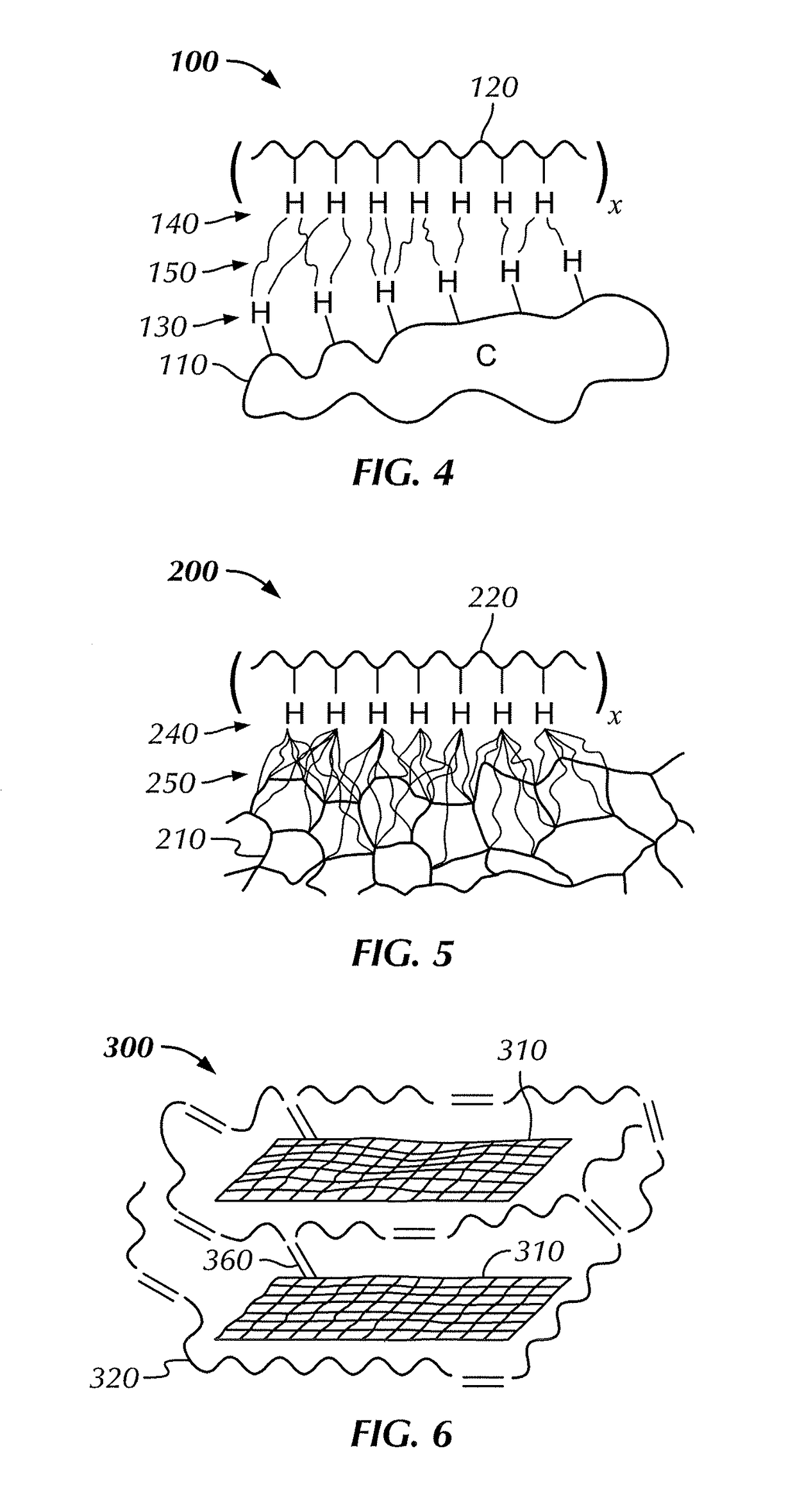

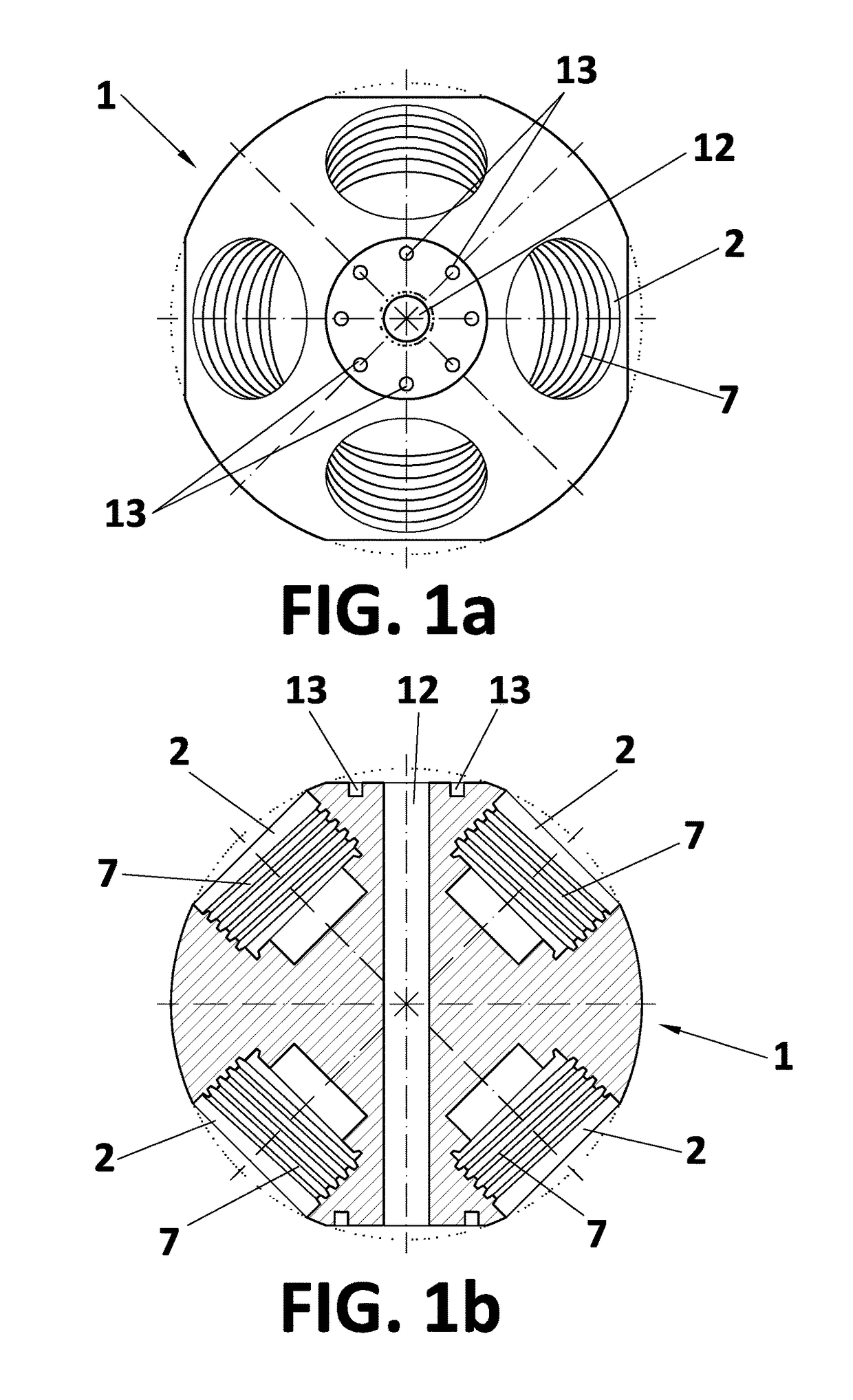

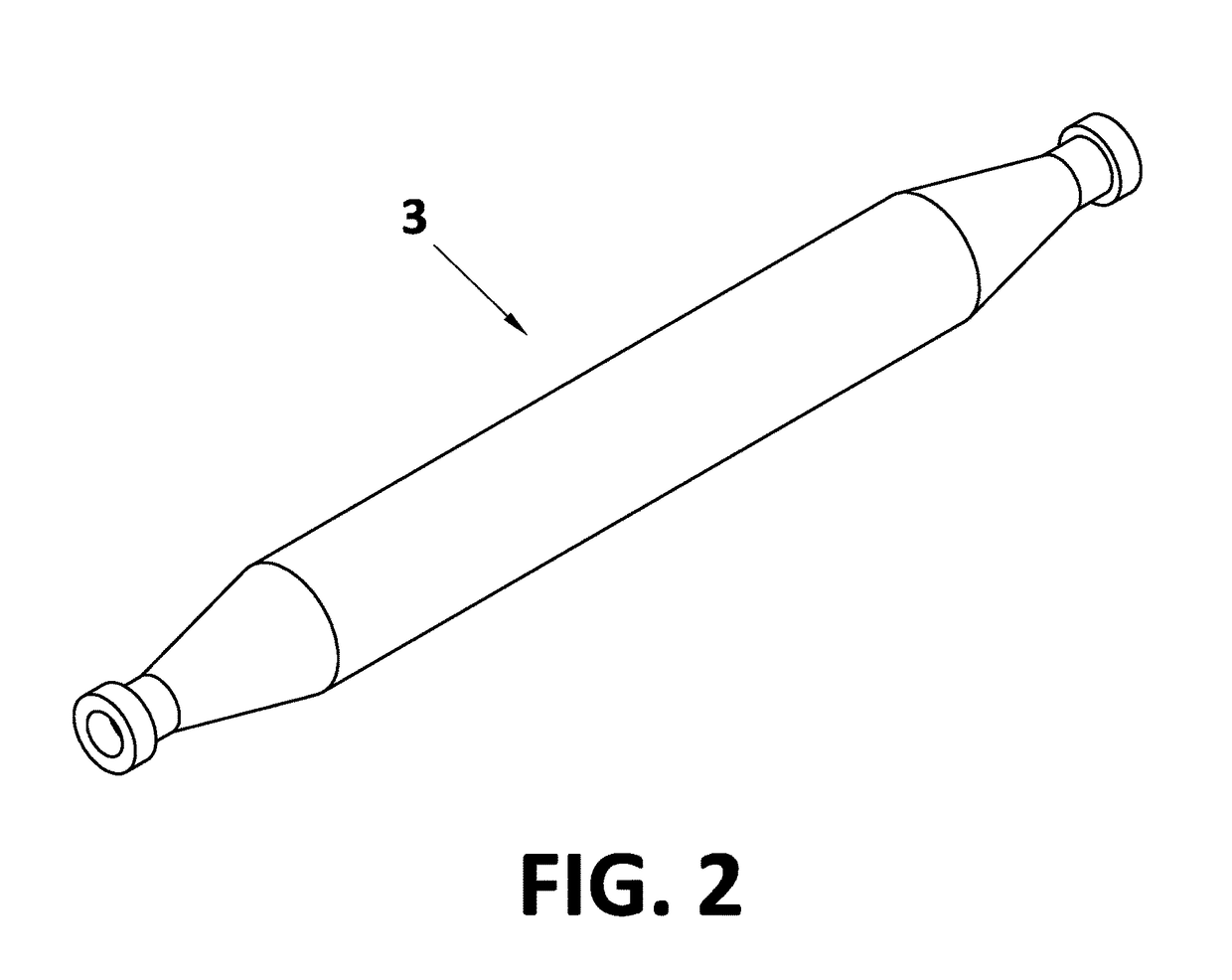

Spatial structure

InactiveUS20180023284A1Creation of light and resistant architectural elements quickly and easilyBuilding constructionsSpatial structureEngineering

A spatial structure that enables the assembly and disassembly of architectural elements quickly and easily, ensuring the necessary structural robustness and which basically comprises a node (1) with a plurality of sockets (2), a bar (3) intended for insertion at either of the two ends thereof in said sockets (2), a perforated screw (5) whose inner surface (6) allows the insertion of the end of the bar (3) and whose outer surface is coupled to the sockets (2), and a portion of flexible washer (8) suitable for insertion into the socket (2) of the node (1) and closing by compression as a result of the thrust exerted by the perforated screw (5) to adopt the shape of a substantially closed washer such that said bar (3) is locked inside the perforated screw (5), preventing the disassembly of the structure but not the rotation of the bar (3) inside the socket (2).

Owner:HERREZUELO DE LA SIERRA EDUARDO +1

A kind of micro-sensor of the bottom diaphragm that can be used for the measurement of wall shear stress in high temperature environment and its manufacturing method

ActiveCN103954383BAvoid defects that cannot withstand high temperaturesHigh working reliabilityDecorative surface effectsForce measurementElectrical resistance and conductanceWall shear

The invention discloses a bottom separation plate microsensor capable of being used for measuring wall shear stress in a high temperature environment and a manufacturing method of the bottom separation plate microsensor, and belongs to the technical field of sensors. The microsensor mainly comprises a protruding separation plate 2, cantilever beams 3, beam roots 4, a U-shaped annular groove 5, force-sensitive resistors 6, a substrate 7, wires 8 and bonding pads 9. The bottom separation plate microsensor is made of SOI silicon wafers with the thickness of a device layer smaller than one micron, the sensitive resistors of the microsensor are manufactured on an insulation layer, the resistors are kept independent from one another and are connected through high temperature resisting metal films, the problem that the sensitive resistors and metal leads are out of effect due to high temperature can be effectively solved, and the wall shear stress in the cold flow high temperature environment such as an engine air inlet channel and a combustion chamber can be measured. The measuring range of the microsensor is not limited by the thickness of the device layer of the SOI silicon wafers. The process is simplified, and the difficulty level is lowered. The output consistency of the microsensor is high when the cantilever sensitive beams carry out forward and reverse bending, and high structural robustness is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for quantitative analyzing evolution of RNA structure steadiness

InactiveCN100559381CSpecial data processing applicationsEvolutionary biologyComputerized systemRNA Sequence

The present invention relates to a computer program, and more particularly, to a method for the quantitative analysis of the evolution of the robustness of RNA structures. The present invention aims to provide a quantitative analysis method that can simply, conveniently and quickly measure the evolution of RNA structural robustness, solve the problems of difficult evolution evaluation and quantification of robustness, and achieve the goal of analyzing the origin and evolution of biological robustness purpose, thereby improving the understanding of biological evolution. In order to achieve the above object, the present invention uses the RNA secondary structure as a research platform, and provides a method for quantitatively analyzing the evolution of the robustness of the RNA structure in a computer system. The method includes checking the legitimacy of the RNA sequence imported from the computer terminal, Steps to generate control sequences, calculate RNA structural robustness, and quantify the evolution of RNA structural robustness.

Owner:INST OF RADIATION MEDICINE ACAD OF MILITARY MEDICAL SCI OF THE PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com