Liquid cooled reductant delivery unit for automotive selective catalytic reduction systems

a technology of automotive selective catalytic reduction and reductant, which is applied in the direction of engines, mechanical equipment, machines/engines, etc., can solve the problems of difficult treatment, long light-off times, and high nitrogen oxide emissions of lean-burn engines, and achieves sufficient structural robustness and improves assembly corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The following description of the preferred embodiment(s) is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

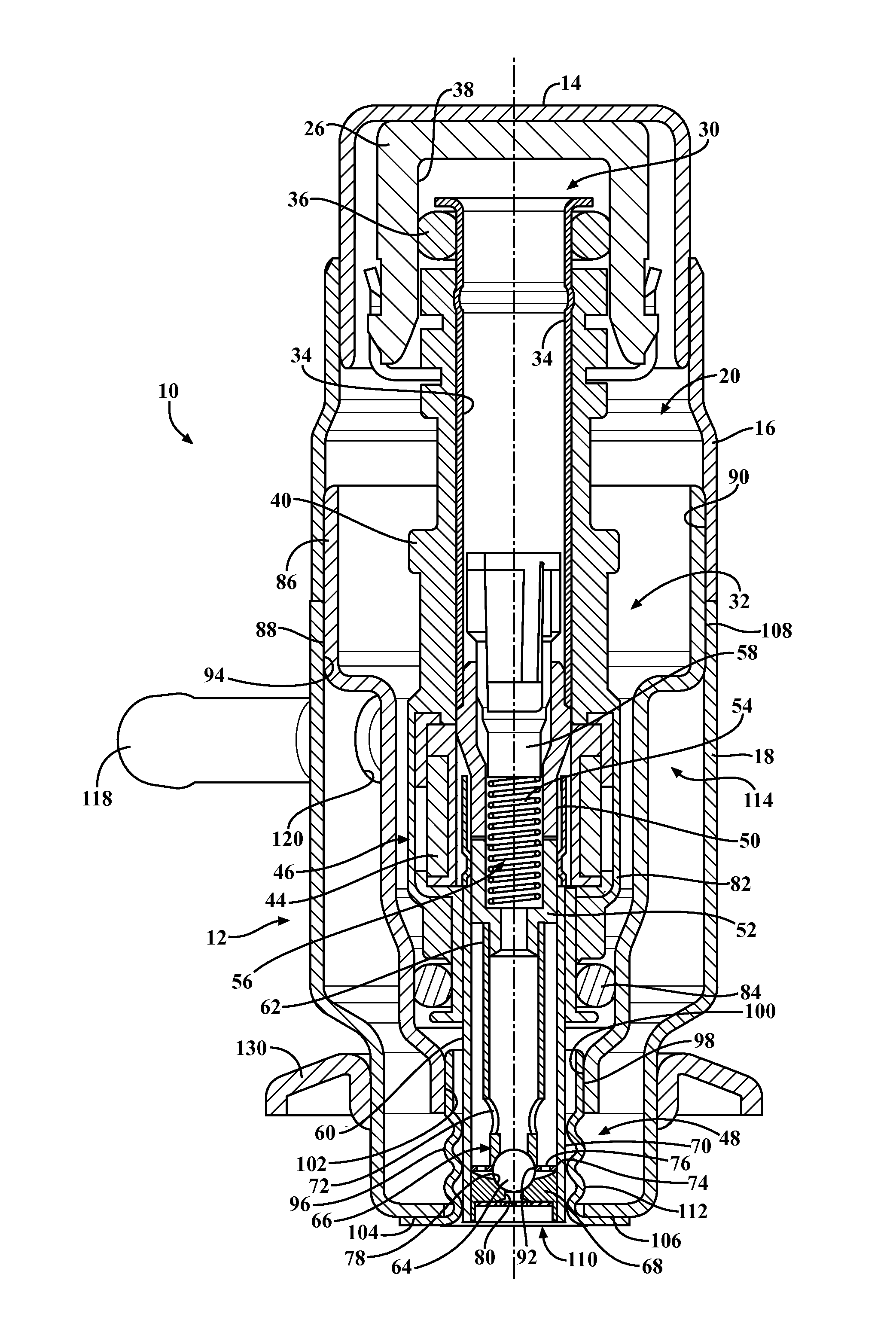

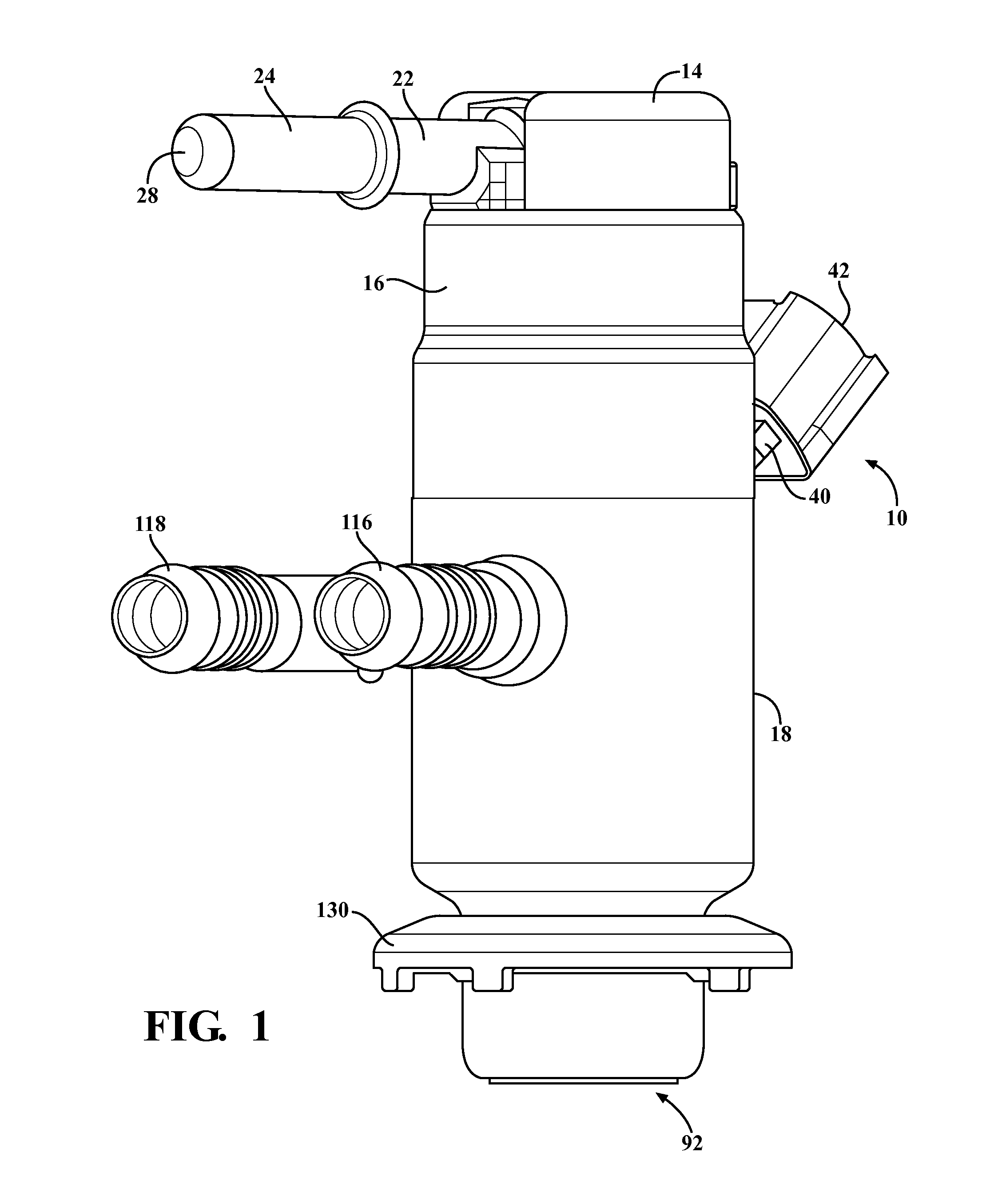

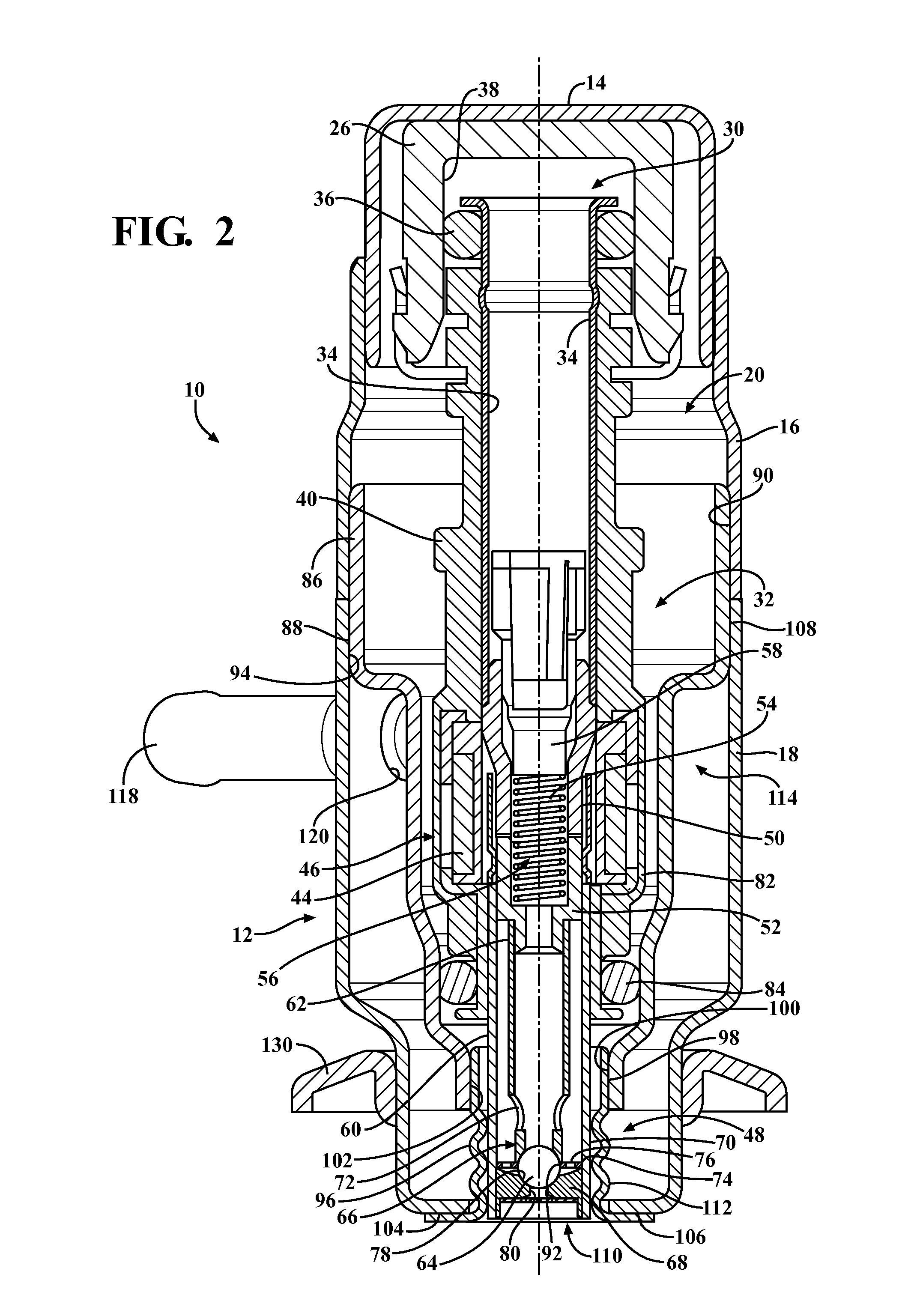

[0019]Referring to the FIGS. 1-3, an embodiment of a reductant delivery unit for an automotive selective catalytic reduction (SCR) system with active cooling is shown generally at 10. The reductant delivery unit 10 includes an outer shell or casing, shown generally at 12, and the shell 12 includes a retaining cap 14, which is connected to an upper shield 16, and a lower shield 18, which is also connected to the upper shield 16. The retaining cap 14 and the shields 16,18 when connected together form a cavity, shown generally at 20, in which various components are disposed.

[0020]The cap 14 at least partially surrounds a hydraulic connector 22. The hydraulic connector 22 has an inlet pipe 24, and an inlet cup 26, which in this embodiment are integrally formed together, but it is within the scope of the invention that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com