Bottom separation plate microsensor capable of being used for measuring wall shear stress in high temperature environment and manufacturing method thereof

A micro-sensor and high-temperature environment technology, applied in the field of sensors, can solve problems such as the impact of the force conduction performance of the actuating diaphragm and microspheres, and the damage of the internal structure of the sensor, so as to achieve the effect of improving work reliability and reducing failure problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

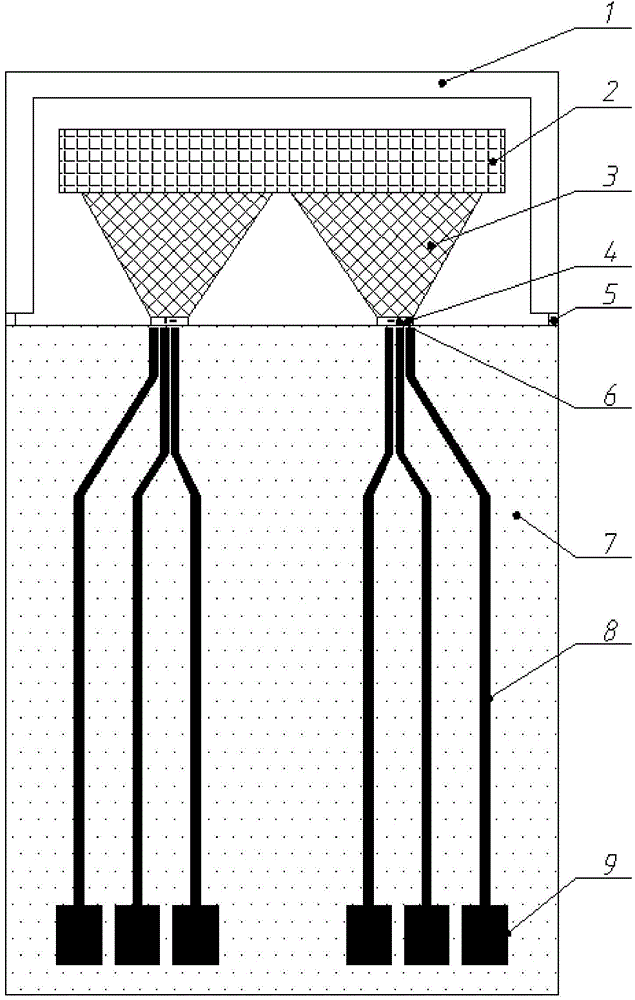

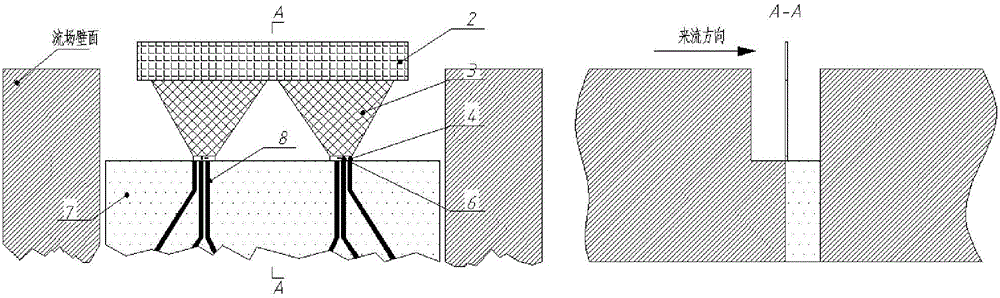

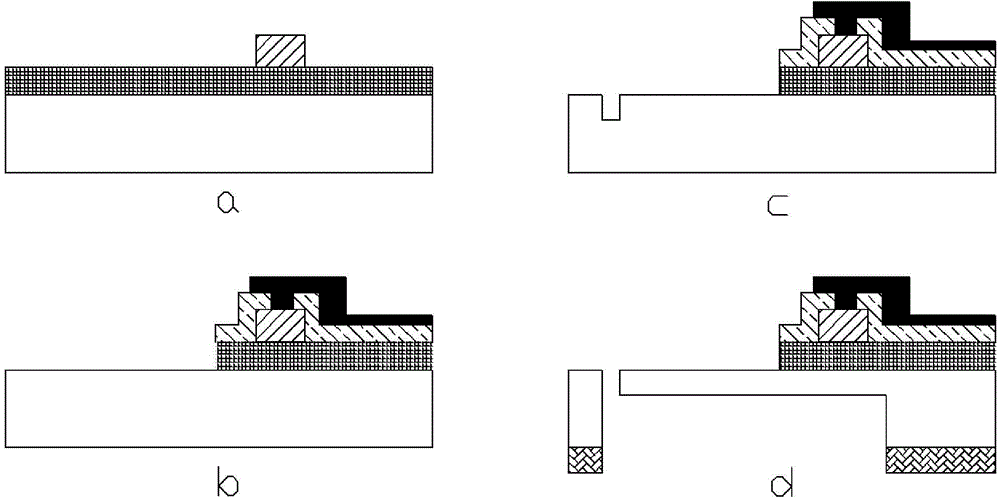

[0033] refer to figure 1 , figure 2 , the present invention includes a U-shaped ring 1, a protruding partition 2, a cantilever beam 3, a beam root 4, a U-shaped ring groove 5, a force sensitive resistor 6, a substrate 7, a wire 8 and a pad 9; the protruding partition The plate 2 is supported on the base 7 by two cantilever beams 3 and their beam roots 4; the protruding partition 2 is perpendicular to the incoming flow direction, and part of the protruding partition 2 protrudes from the wall surface of the flow field to be measured; the base 7, the convex The material of the partition plate 2, the cantilever beam 3, and the beam root 4 is the base layer silicon of the SOI silicon wafer; and the silicon material surface of the substrate 7 is deposited with a silicon dioxide layer and a silicon nitride layer;

[0034] The force sensitive resistor 6 is placed on the surface of the beam root 4 at the lowermost end of the cantilever beam 3 through an insulating material;

[0035] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com