A positioning and tightening device for high-speed machining of cycloidal gears

A cycloidal gear, high-speed technology, applied in the direction of positioning device, gear tooth manufacturing device, metal processing equipment, etc., can solve the problem of restricting the processing speed and processing efficiency of parts, is not conducive to ensuring the consistency of parts size, and has not retrieved technical solutions, etc. problems, to achieve the effect of improving processing efficiency, easy disassembly, and reducing the number of clamping times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

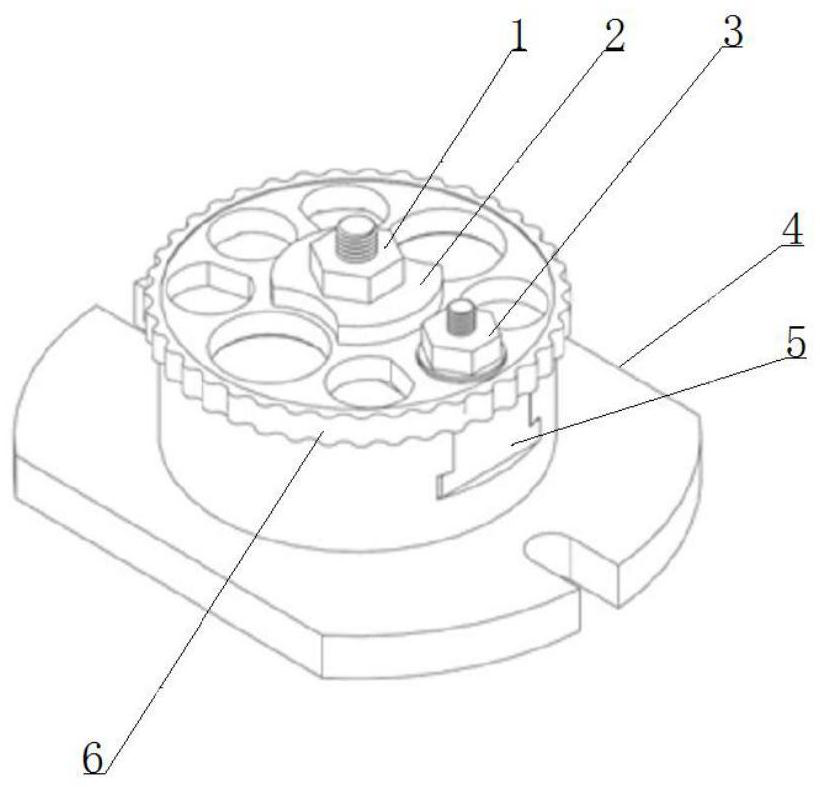

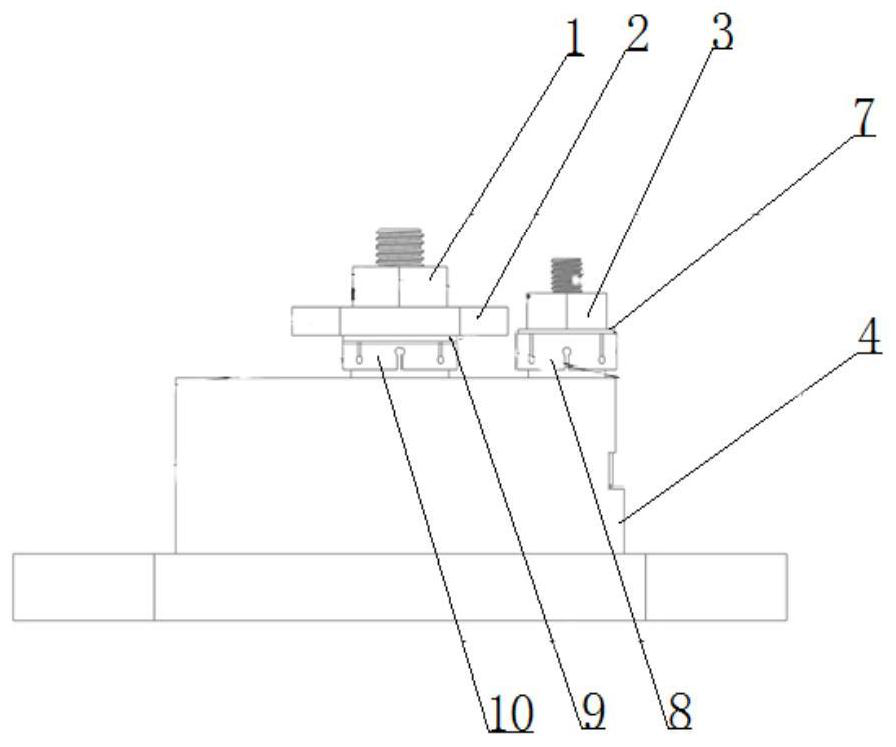

[0026] A positioning tightening device for high-speed machining of cycloidal gears, see Figure 1-6 , its invention point is:

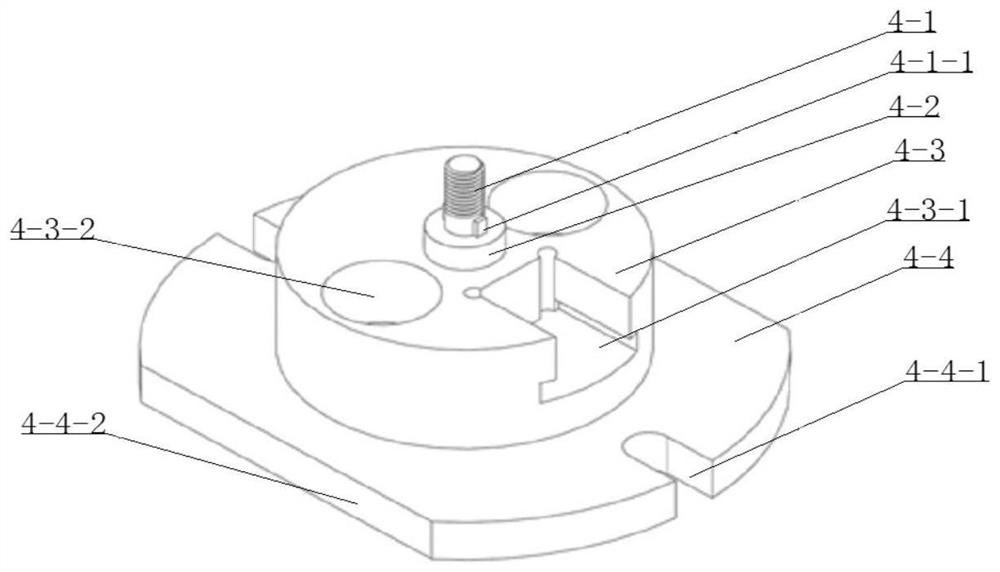

[0027] It includes a supporting base 4, which is composed of four parts: a first screw rod 4-1, a first tensioning mandrel 4-2, a supporting round table 4-3 and a bottom plate 4-4 arranged coaxially up and down in sequence. The upper end surface of the support round table is parallel to the lower end surface of the base plate and perpendicular to the axial direction of the first screw rod and the first tensioning mandrel, and parallel end surfaces 4-4-2 for alignment are symmetrically provided on the front and rear sides of the base plate. On the right side of the supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com