Combined oil press with stander shared by punching and stretching

A combined hydraulic press technology, which is applied in the field of mechanical punching and drawing equipment, can solve the problems of long blank transmission distance, large heat loss, and large floor space, so as to avoid heat loss, reduce processing errors, and reduce clamping The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

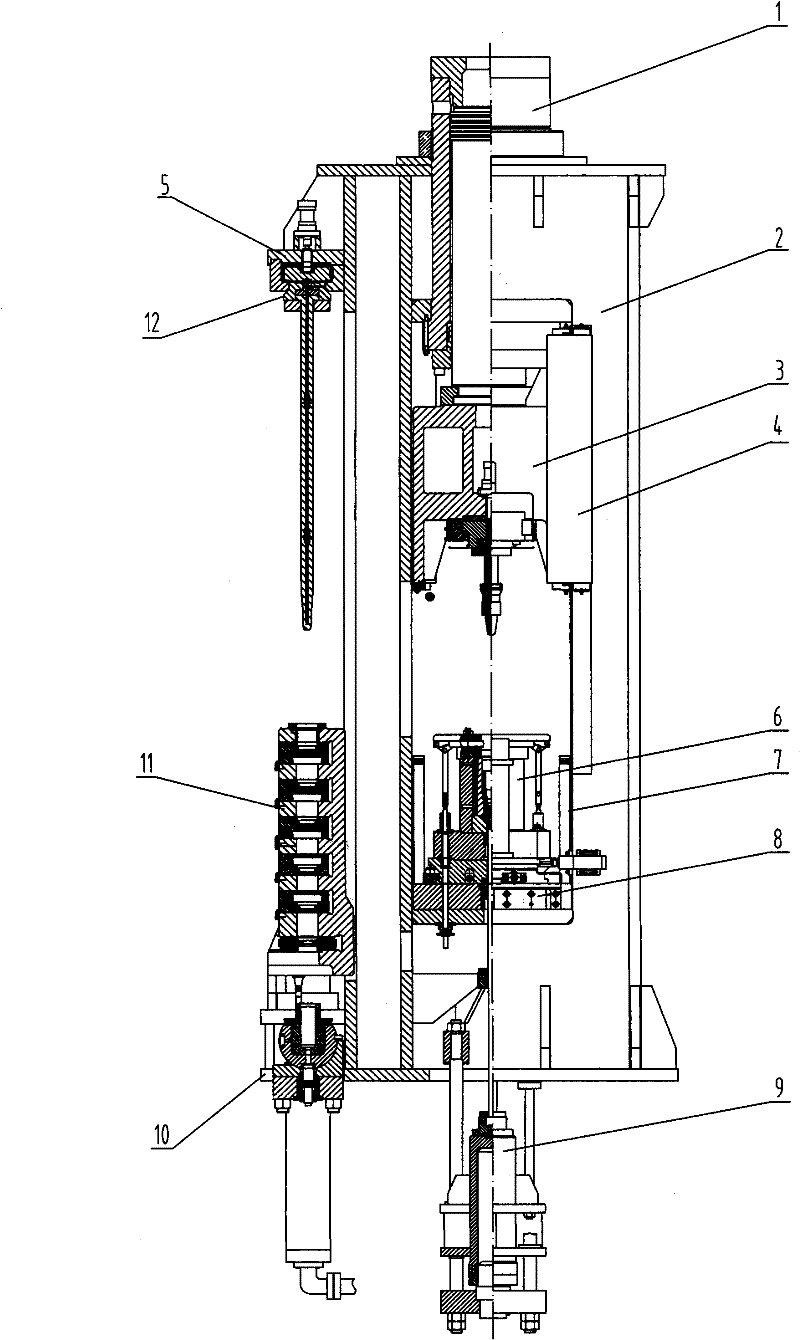

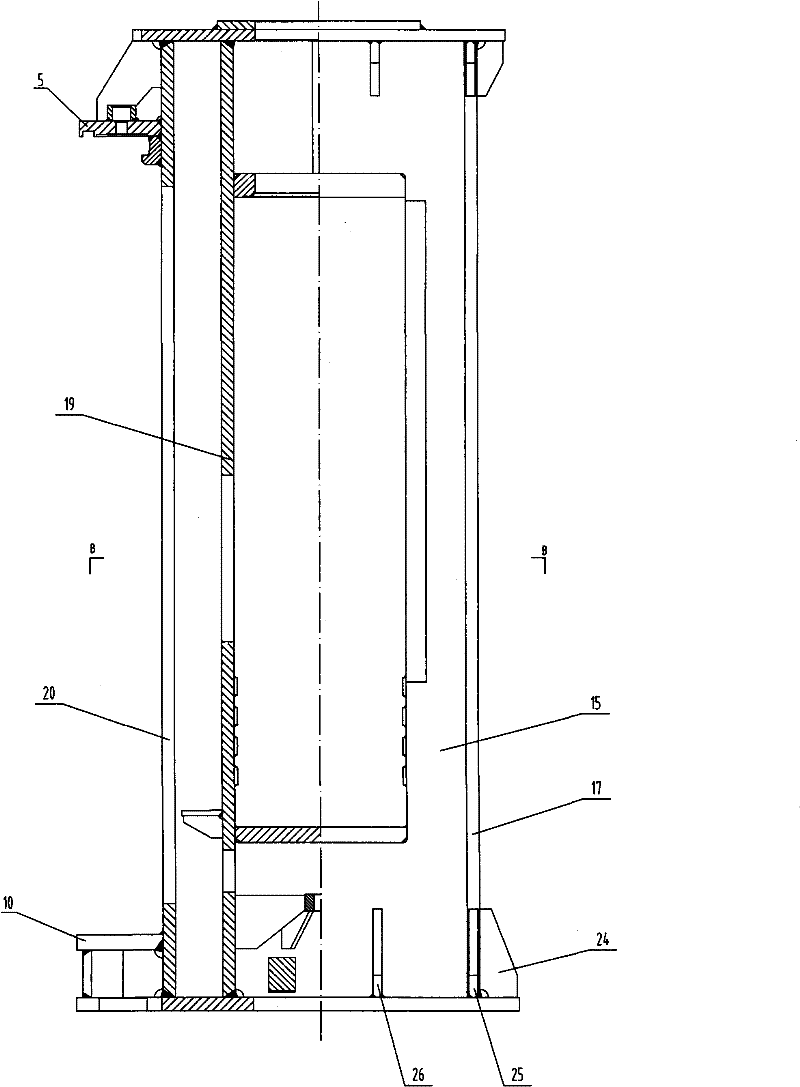

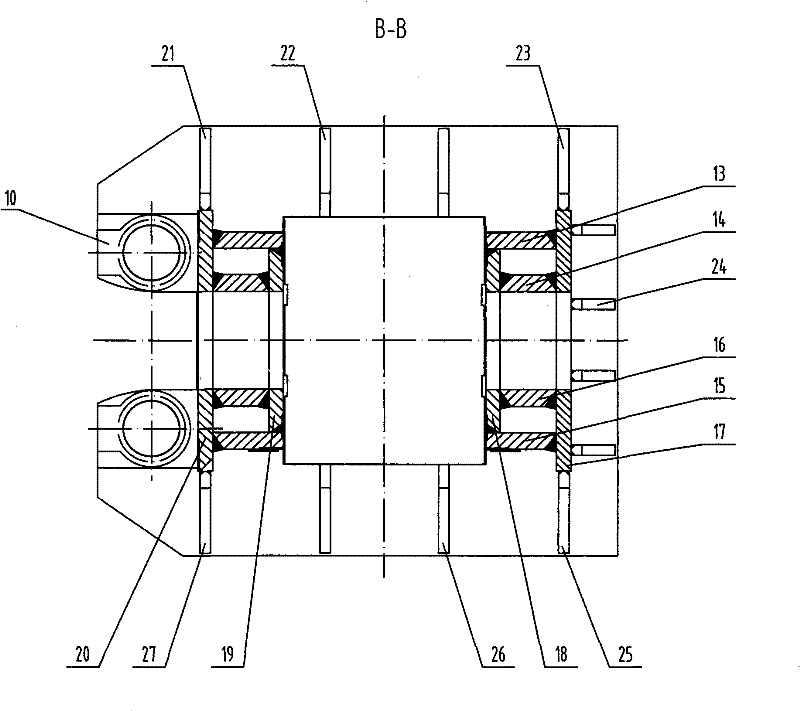

[0011] The combined hydraulic press with a common frame for punching and drawing includes a frame 2, a main working cylinder 1 fixed on the upper part of the frame 2, a punching beam 3, and a guide device 4, and a punching machine fixed Hole die base 6, limit mechanism 7 and punching workbench 8, the ejector 9 that is arranged below frame 2, described frame 2 is welded into the box body of rectangle by steel plate, the concrete of this box body It is configured to be fixedly welded with the left box plate 20 and the right box plate 17 arranged parallel to each other between the upper box plate and the lower box plate arranged in parallel, and between the left box plate 20 and the right box plate 17 to be fixedly welded with parallel to each other. The rear box plate 13 and the front box plate 15 are fixedly welded with the left rib plate 19 and the right rib plate 18 arranged parallel to each other between the rear box plate 13 and the front box plate 15, and between the left b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com