A kind of l-shaped support for the measurement of cabin quality characteristics

A technology of quality characteristics and compartments, applied in the direction of measuring devices, machine/structural component testing, static/dynamic balance testing, etc., can solve problems such as low measurement accuracy, poor measurement accuracy, multiple hoisting, etc., to improve The effects of measuring accuracy, reducing measurement time, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

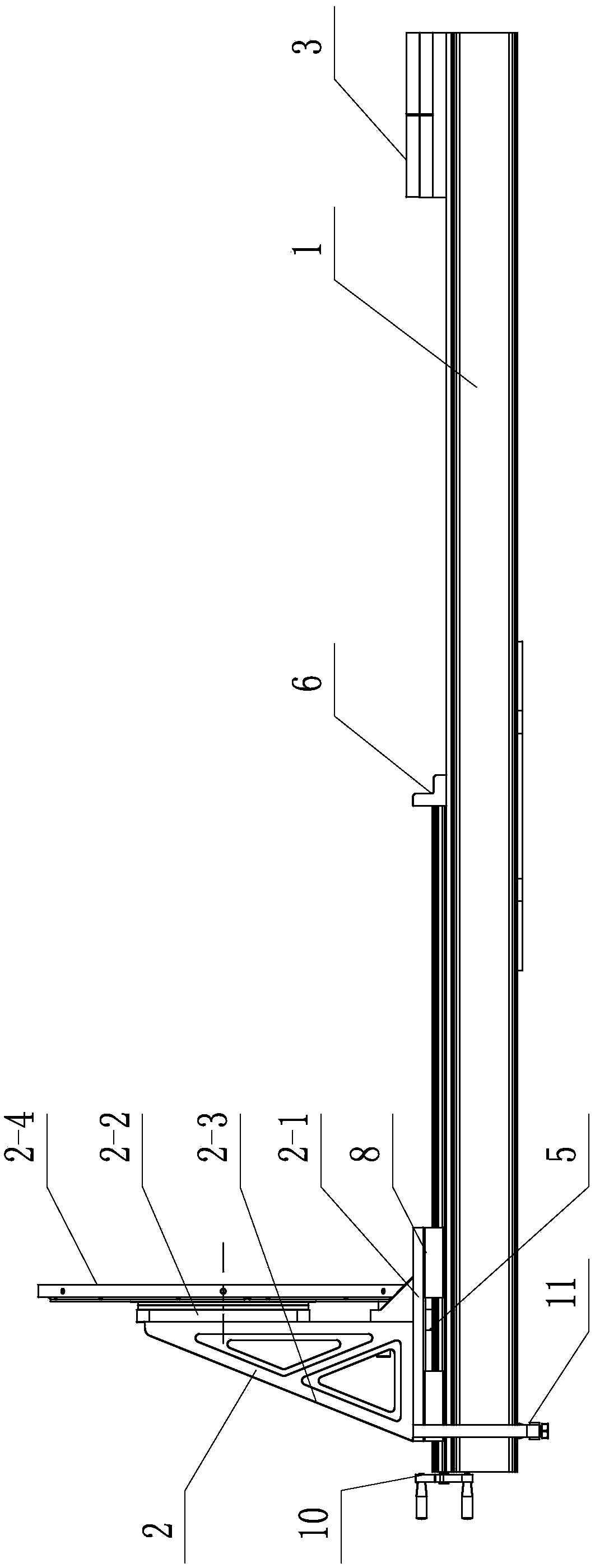

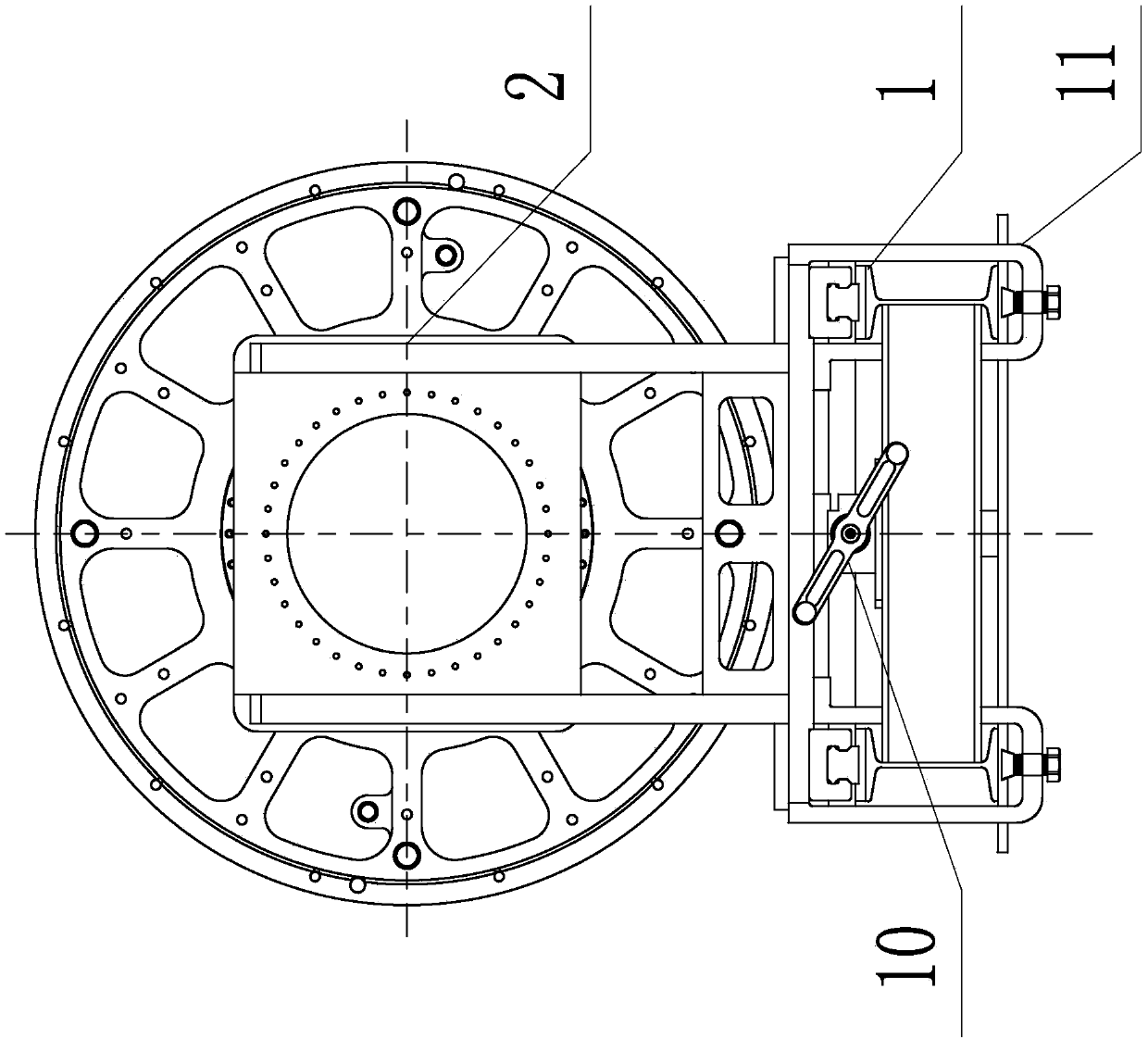

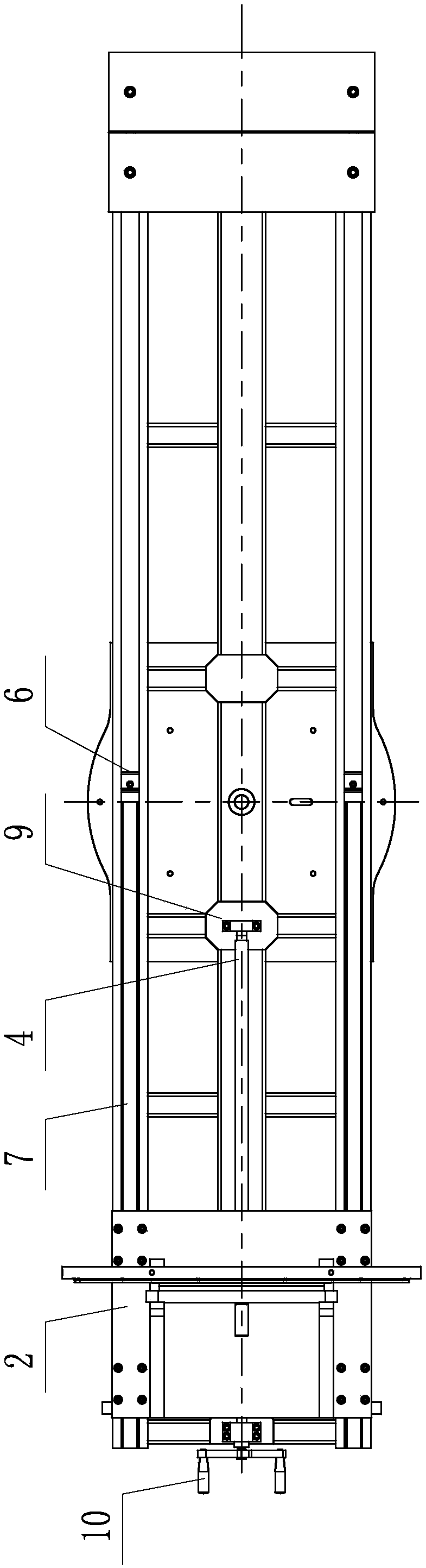

[0008] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, an L-shaped bracket used for cabin quality characteristic measurement described in this embodiment, it includes base 1, bracket 2, lead screw 4, screw nut 5, handle 10, two positioning blocks 6, two A linear guide rail 7, two bearing housings 9 and four sliders 8, the base 1 is a rectangular frame body, a plurality of beams are fixedly installed on the rectangular frame body, and the plurality of beams are arranged in parallel, and the two linear guide rails 7 are arranged on On the base 1, the left end of each linear guide 7 is fixed on the left end of the rectangular frame, the right end of each linear guide 7 is fixed on the rectangular frame of the base 1, and the two linear guides 7 are arranged in parallel, and close to each straight line The right end of guide rail 7 is provided with a positioning block 6, and positioning block 6 is fixedly installed on the rectangular frame bo...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Figure 1-Figure 4 Describe the present embodiment, the L-shaped support for the measurement of cabin quality characteristics described in this embodiment, it also includes a plurality of counterweights 3, the plurality of counterweights 3 are arranged on the right end of the base 1, when measuring the product When counterweight is required, select counterweight 3 from multiple counterweights to adjust the eccentric load moment of the L bracket through the counterweight to prevent the overall tooling from shifting. Other components and connection relationships are the same as those in Embodiment 1 .

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 1-Figure 4 Describe this embodiment, a kind of L-shaped support that is used for cabin mass characteristic measurement described in this embodiment, support 2 comprises base plate 2-1, vertical plate 2-2, rib plate 2-3 and rotating ring 2-4, The base plate 2-1 is a rectangular plate, the vertical plate 2-2 is fixedly installed on the upper end surface of the base plate 2-1, the rotating ring 2-4 is installed on the vertical plate 2-2, and the rib plates 2-3 are fixedly installed on the On the bottom plate 2-1 and the vertical plate 2-2, the four corners of the bottom end surface of the bottom plate 2-1 are respectively fixedly connected with a slider 8 by bolts, and the bottom end surface of the bottom plate 2-1 is fixedly connected with the screw nut 5, each The sliders 8 all slide on the linear guide rail 7, and then drive the bottom plate 2-1 to move on the base 1, and the rotating ring 2-4 is connected to the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com