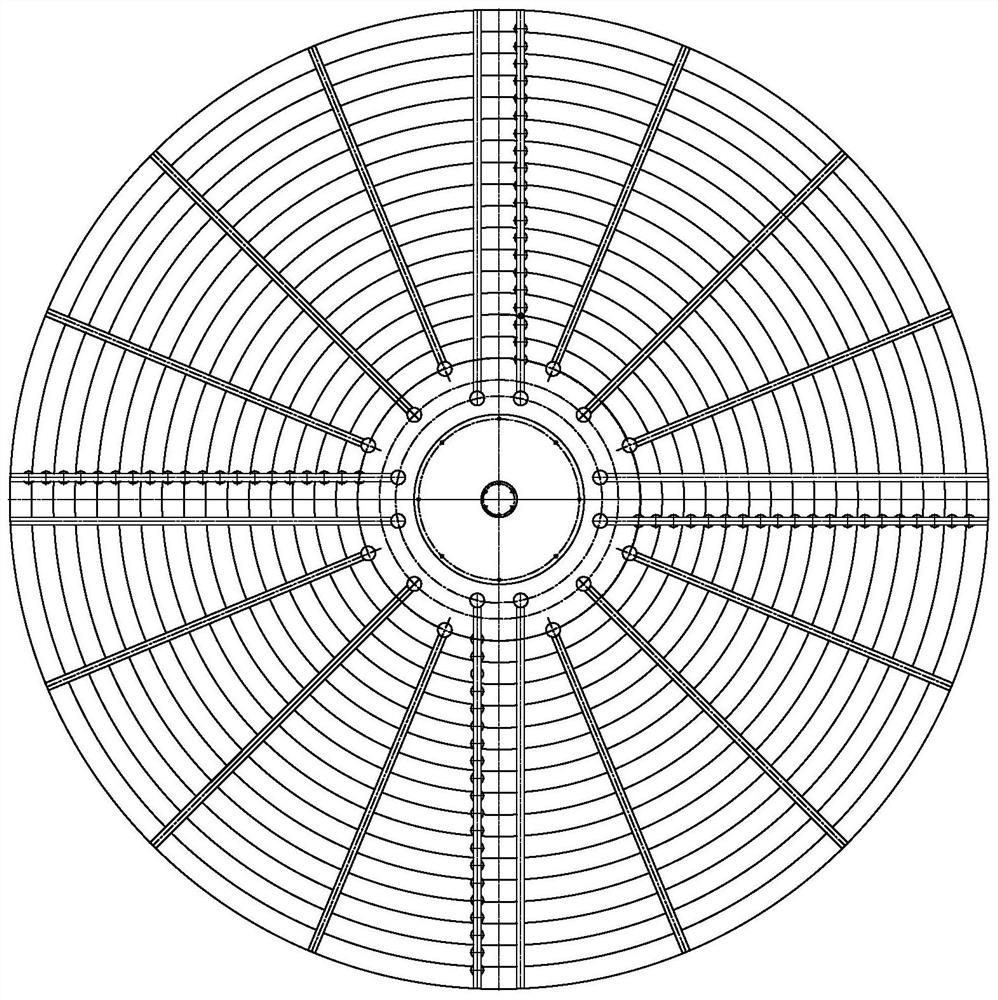

Three-axis milling mechanism for machining T-shaped slot of vertical lathe rotary table

A technology of rotary table and vertical lathe, which is applied in the field of machine tools, can solve the problems of high manufacturing cost, large diameter of vertical lathe rotary table, time-consuming and labor-intensive problems, and achieve the effect of reducing the number of clamping times, reducing man-hours, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

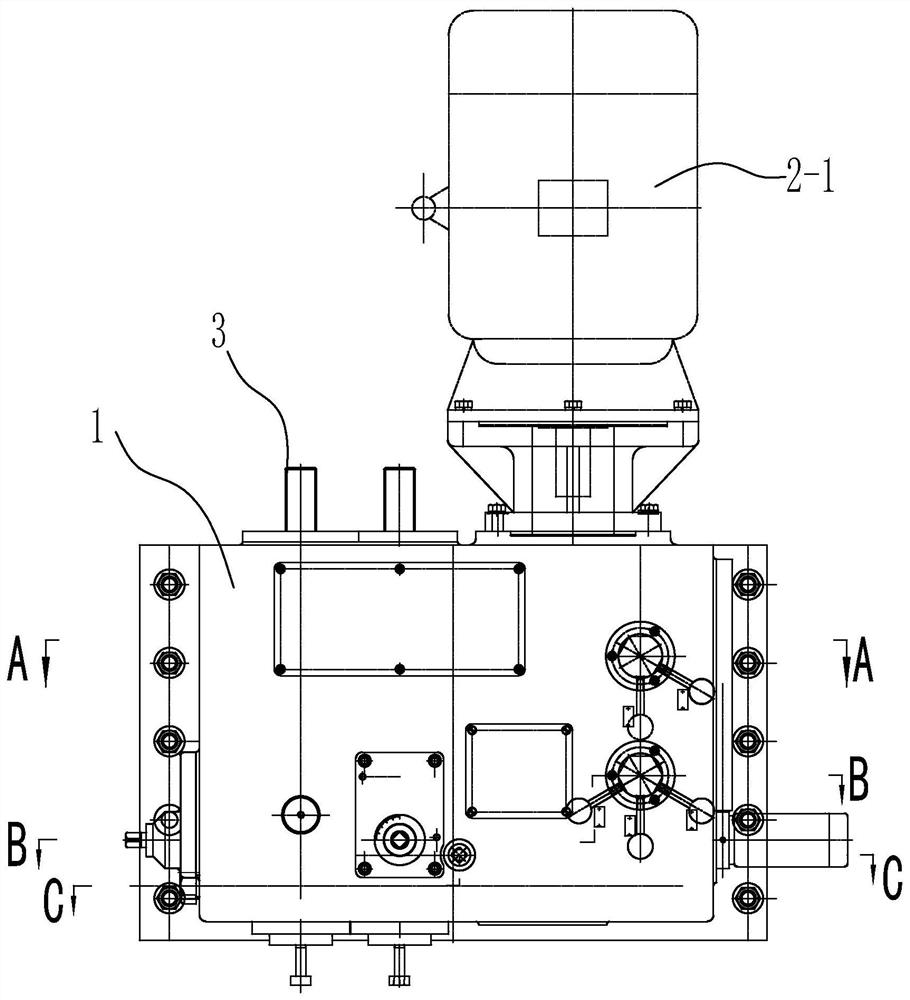

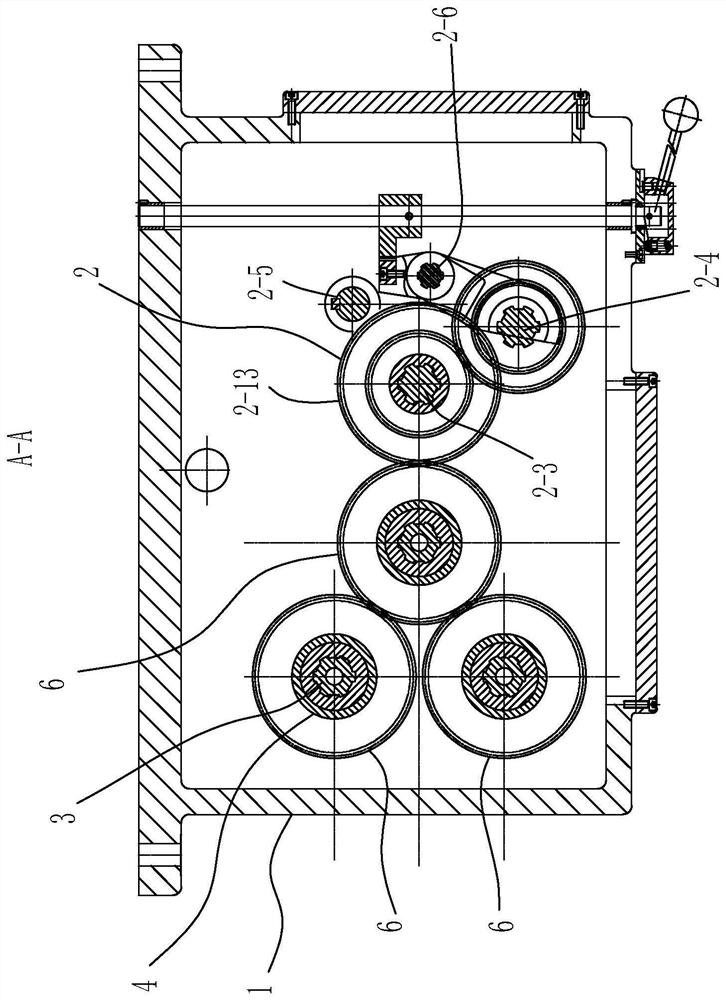

[0029] Embodiment 1: as Figure 2-Figure 4 As shown, this embodiment relates to a three-axis milling mechanism for machining T-shaped slots of a vertical lathe rotary table, including a spindle box 1, a speed-regulating drive mechanism 2, three spindles 3 and three spindle sleeves 4;

[0030] The main shaft box 1 is provided with three parallel spindle sleeves 4, and each main shaft sleeve 4 is provided with a main shaft 5 for rotation, and each main shaft 5 is provided with a gear 6, and each gear 6 passes through each main shaft 5. The gear 6 on one of the main shafts 5 meshes with the gears 6 on the other two main shafts 5 , and the gear 6 on one of the three main shafts 5 is driven by the speed-adjusting drive mechanism 2 .

[0031] Specifically, such as figure 2 , image 3 , Figure 4 and Image 6 As shown, the speed regulating drive mechanism 2 includes a motor 2-1, IV shaft 2-2, IVa shaft 2-3, V shaft 2-4, VI shaft 2-5 and two shift forks 2-7;

[0032] IV axis 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com