Pull rod type tooth jump inspection tool

An inspection tool and tie-rod technology, which is applied to measuring devices, instruments, and mechanical devices, etc., can solve the problems of increasing working time, equipment loss, hindering production efficiency, etc., and achieve the effect of saving working time, convenient operation and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be described completely and clearly below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, not all of them.

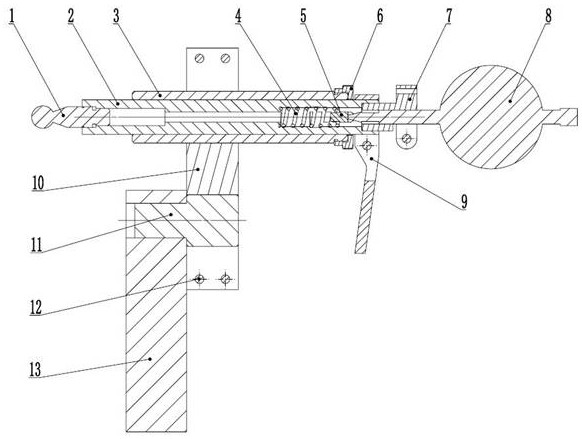

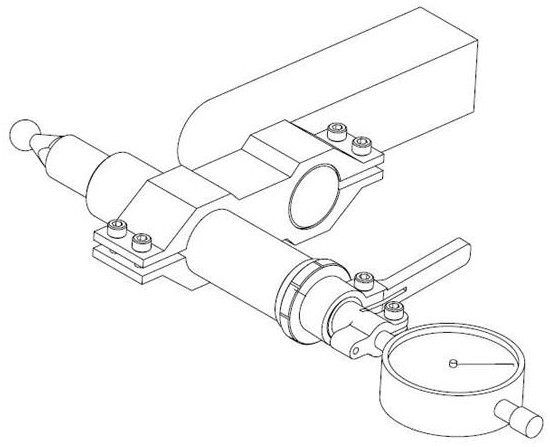

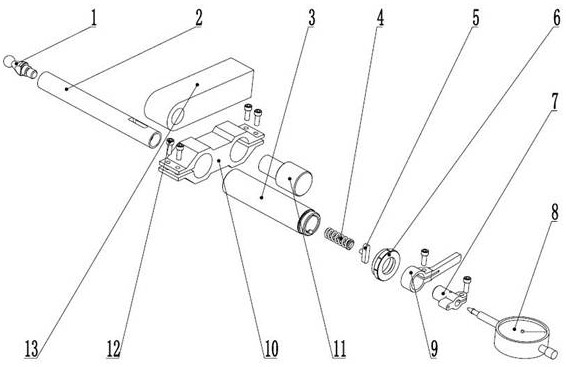

[0015] Such as Figure 1 ~ Figure 4 As shown, a pull rod type tooth jump inspection tool consists of a measuring head 1, an inner pull rod 2, an outer rod 3, a spring 4, a spring positioning key 5, a locking nut 6, a dial gauge fixing sleeve 7, a dial gauge 8, The handle 9, the frame body 10, the connecting bolt 11, the locking screw 12, and the support 13 are composed; the gear shaft 15 of the workpiece to be inspected is clamped on the machine tool, and the two ends are positioned by the top 14, and the pull-rod type tooth jump inspection tool is installed. Clamped on the tool table of the machine tool, the clamping part is the support 13, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com