A fully superconducting primary excitation linear generator for direct drive wave power generation

A linear generator and wave power generation technology, applied in the usage of superconductor elements, electrical components, electromechanical devices, etc., can solve the problems of low power density, bulky volume, low speed, etc., reduce complexity and improve air gap magnetic density , the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

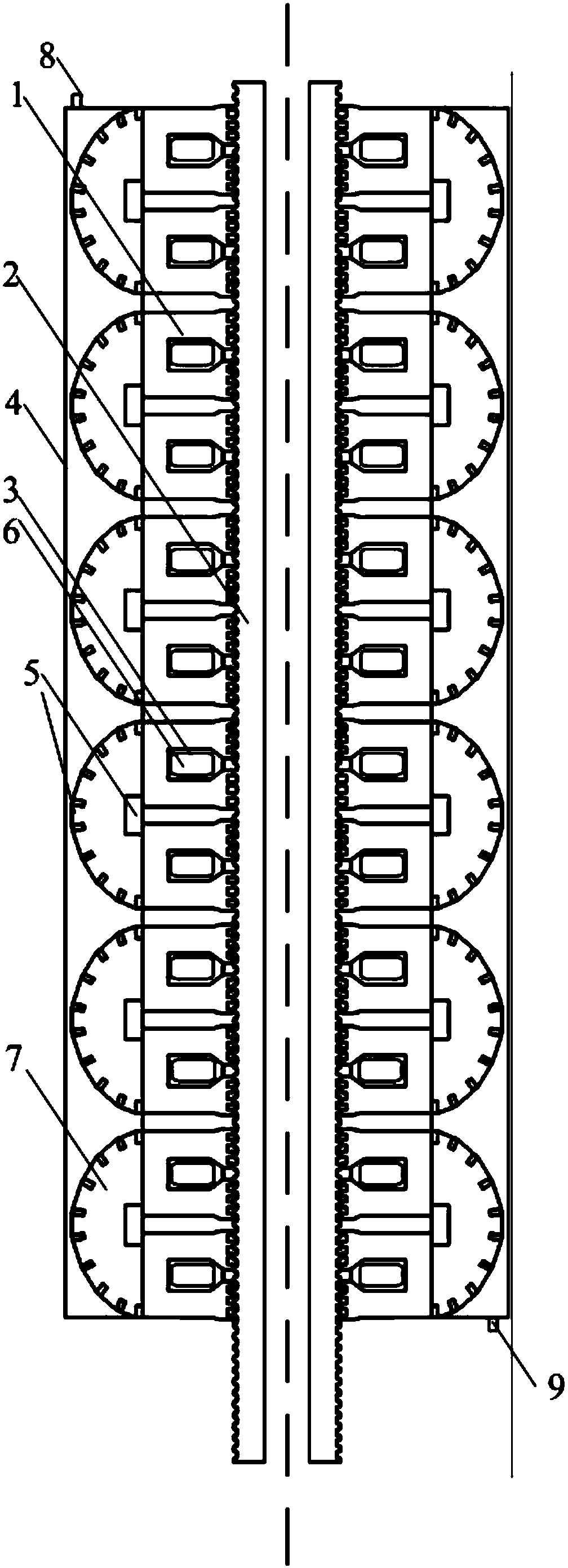

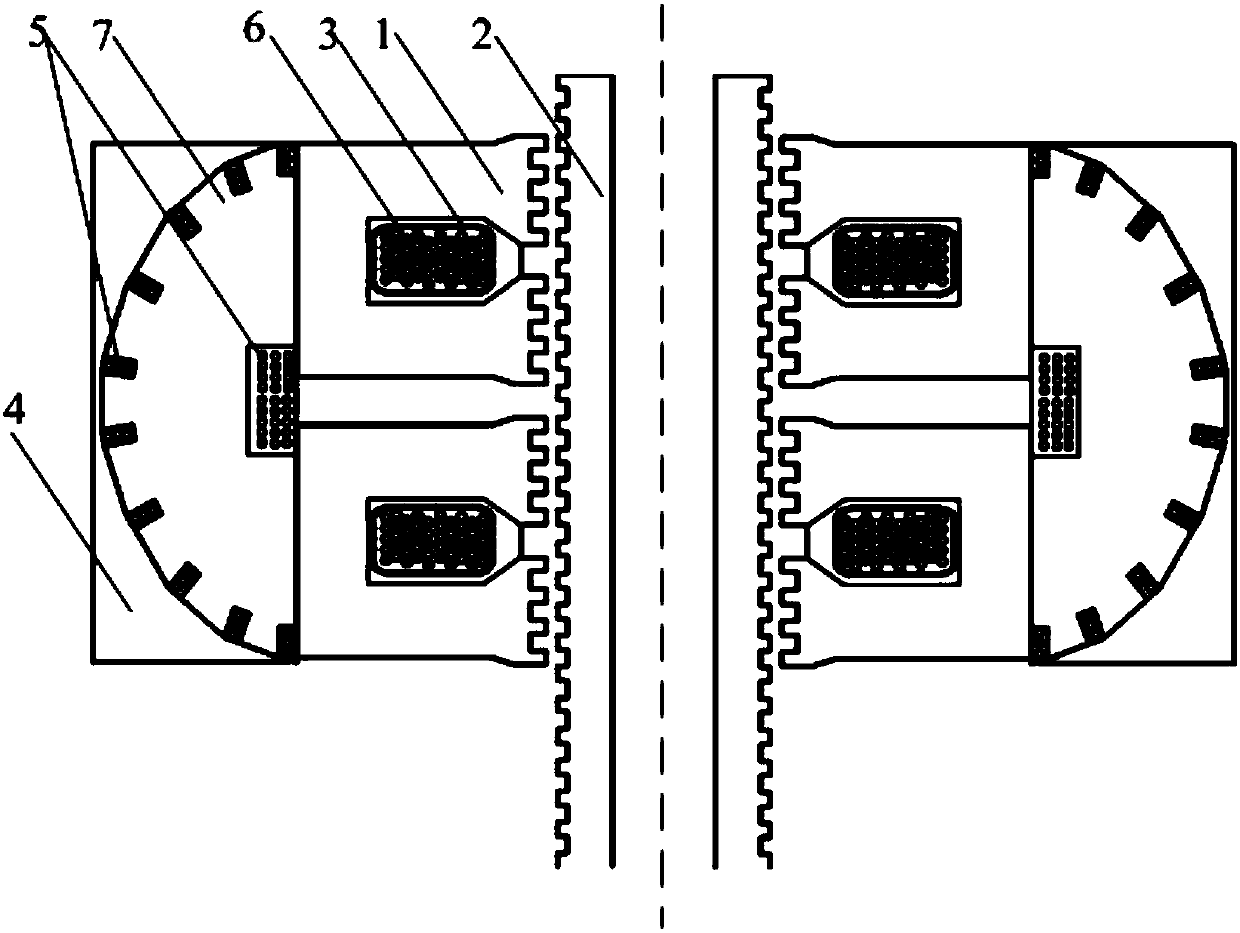

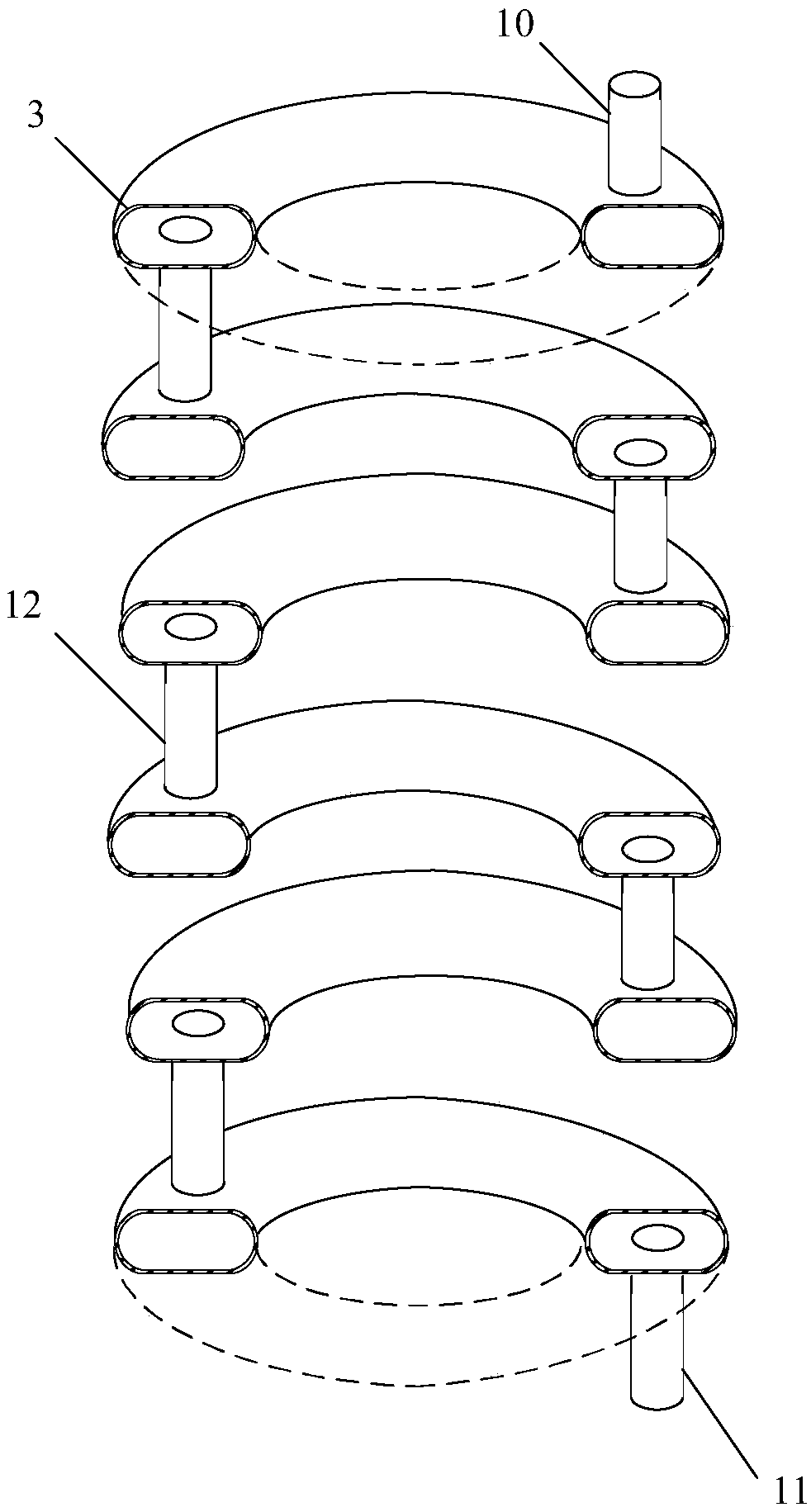

[0022] Combine below Figure 1-Figure 4 This embodiment will be described. This embodiment includes primary and secondary. The primary is composed of primary iron core 1 , primary field winding 5 , primary armature winding 6 , field winding cooling Dewar 4 , armature winding cooling Dewar 5 and field winding support 7 . The secondary is composed of secondary sections 13, 14 and 15 with different tooth-tooth ratios, and epoxy resin is filled in the secondary grooves to realize secondary movement. The primary and secondary iron cores use iron-cobalt alloys to increase the magnetic saturation point of the motor core. The excitation winding is supported by the excitation winding bracket 7, and the excitation winding outside the bracket and the excitation winding 5 inside the bracket adopt a pie-shaped winding structure, and the current in the winding is a dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com