Manufacturing process of false eyelashes

A production process and technology of false eyelashes, applied in the direction of bald wigs, clothing, hair accessories, etc., can solve the problem that it is difficult to achieve the customer's aesthetic stereotype effect and comfort, wool intersection points are not on the same horizontal line, false eyelashes stereotype effect is not good, etc. problems, to achieve the effect of improving the efficiency of viscose, not easy to return to straight deformation, and beautiful curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

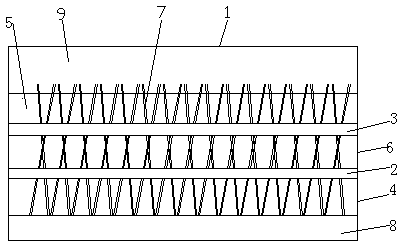

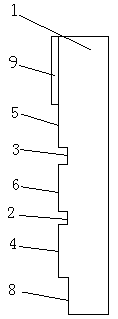

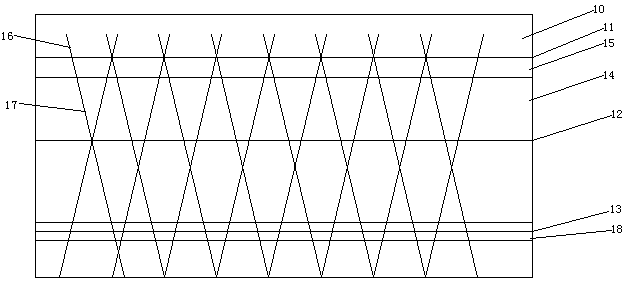

[0025] A kind of false eyelash production technology, comprises the following steps:

[0026] a. Wool glue: Take a rectangular working panel a1, and set up the first groove 2 for adjusting the wool and the second groove for placing the wool single-sided adhesive tape 15 along the length direction of the rectangular working panel a1 3. The first groove 2 and the second groove 3 separate the rectangular work panel a1 into two sides: the hand stall wool table top 4 and the wool tip shaping table 5 located on both sides of the rectangle work panel a1 respectively, and the hand stall wool table 4 and the wool The ruler between the tip shaped table tops 5 is placed on the table top 6, and then a plurality of third grooves 7 for positioning the wool are opened on the hand stall wool table top 4, the wool tip shaped table top 5 and the ruler placement table 6, and on the hand stall wool table top 4 Set up a fourth groove 8 on the side close to the end of the rectangular work panel a1 ...

Embodiment 2

[0034] A kind of false eyelash production technology, comprises the following steps:

[0035] a. Wool glue: Take a rectangular working panel a1, and set up the first groove 2 for adjusting the wool and the second groove for placing the wool single-sided adhesive tape 15 along the length direction of the rectangular working panel a1 3. The first groove 2 and the second groove 3 separate the rectangular work panel a1 into two sides: the hand stall wool table top 4 and the wool tip shaping table 5 located on both sides of the rectangle work panel a1 respectively, and the hand stall wool table 4 and the wool The ruler between the tip shaped table tops 5 is placed on the table top 6, and then a plurality of third grooves 7 for positioning the wool are opened on the hand stall wool table top 4, the wool tip shaped table top 5 and the ruler placement table 6, and on the hand stall wool table top 4 Set up a fourth groove 8 on the side close to the end of the rectangular work panel a1 ...

Embodiment 3

[0043] A kind of false eyelash production technology, comprises the following steps:

[0044] a. Wool glue: Take a rectangular working panel a1, and set up the first groove 2 for adjusting the wool and the second groove for placing the wool single-sided adhesive tape 15 along the length direction of the rectangular working panel a1 3. The first groove 2 and the second groove 3 separate the rectangular work panel a1 into two sides: the hand stall wool table top 4 and the wool tip shaping table 5 located on both sides of the rectangle work panel a1 respectively, and the hand stall wool table 4 and the wool The ruler between the tip shaped table tops 5 is placed on the table top 6, and then a plurality of third grooves 7 for positioning the wool are opened on the hand stall wool table top 4, the wool tip shaped table top 5 and the ruler placement table 6, and on the hand stall wool table top 4 Set up a fourth groove 8 on the side close to the end of the rectangular work panel a1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com