Reinforcement anchorage and mounting method thereof

A technology of steel bar anchorage and steel bar, applied in the processing of building materials, structural elements, building components, etc., can solve the problems of large rework workload, difficult construction quality control, construction quality limitation, etc., to achieve simple construction and easy construction quality control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

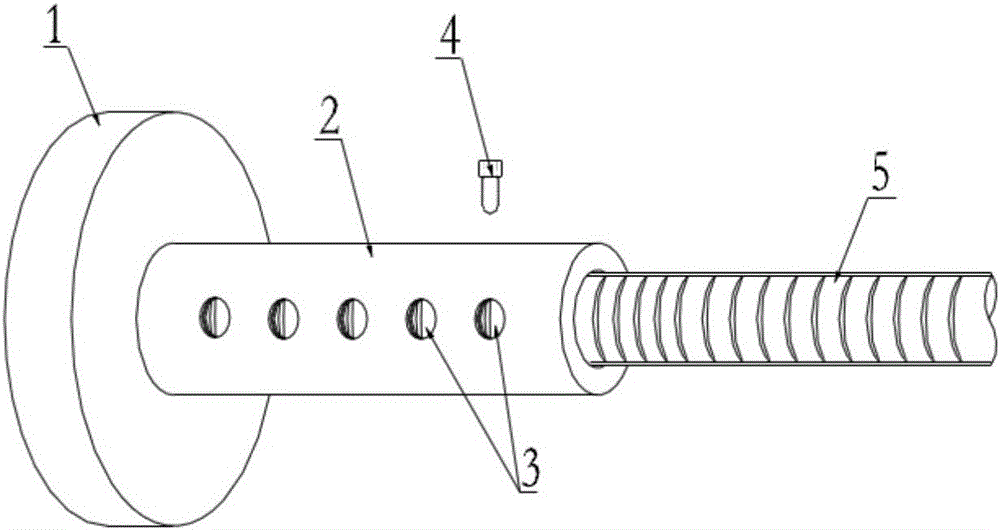

[0038] Such as Figure 4 As shown, insert the steel bar 5 into the self-contained sleeve 2 on the end anchor plate, the end of the steel bar goes deep into the bottom of the sleeve, and turn the anchor plate sleeve 2 properly so that the rib side of the steel bar 5 is aligned with the sleeve 2. threaded hole 3; several pointed screws 4 are screwed into the threaded hole 3 and tightened successively; tighten the pointed screw 4 with an electric wrench until the nut on the screw is broken to form an anchoring device for the tensile steel bar 5, such as Figure 5 shown.

[0039] The specifications of the anchoring device components in this embodiment are as follows:

[0040] Anchor plate: thickness 32mm, diameter 96mm.

[0041] Sleeve: wall thickness 6mm, outer diameter 54mm, inner diameter 42mm, length 160mm, the surface of the inner wall is sandblasted or scored.

[0042] Threaded holes: Select 5 threaded holes with an inner diameter of 8mm and arrange them at equal interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com