Package-type rubber vibration isolation cushion with limit function

A rubber shock-isolating pad and assembled technology, which is applied in the direction of earthquake-proof, protective buildings/shelters, building components, etc., can solve the problems of not considering the diversity of structures or equipment types, etc., to achieve low cost and prevent oversize The effect of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

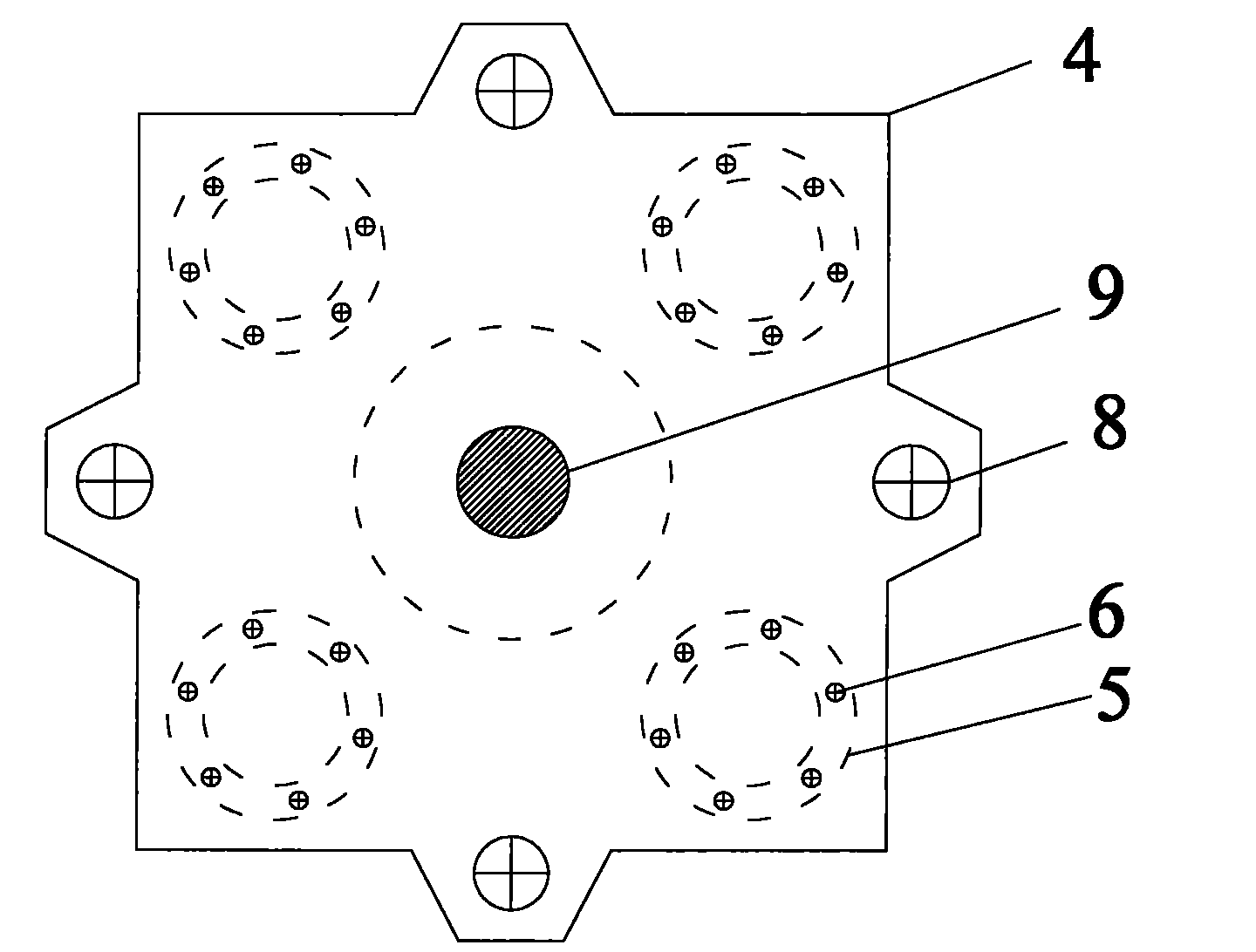

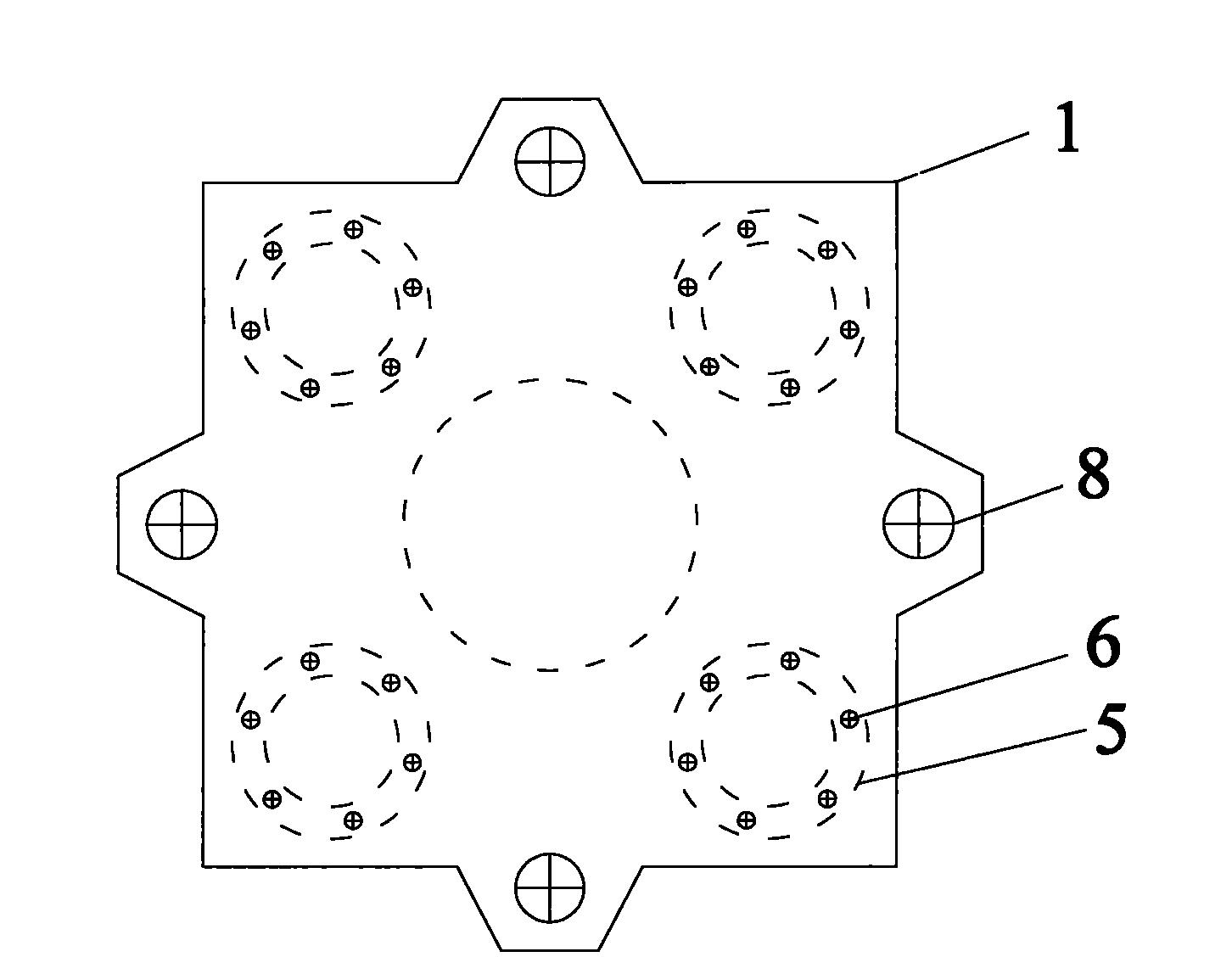

[0029] Embodiment 1: as figure 1 As shown, in the limitable assembled rubber shock-isolating pad, the lower end plate 4 has an octagonal structure, and four anchor bolt holes 6 are symmetrically distributed on its side for anchoring with the foundation; the other four groups are arranged according to the symmetrical center The distributed bolt holes are used to fix the rubber shock-isolation unit 5; there is a screw hole 9 at the center of the lower end plate, which is used to fix the limit rod 2, and the area of the screw hole 9 is consistent with the size of the bottom section of the limit rod 2.

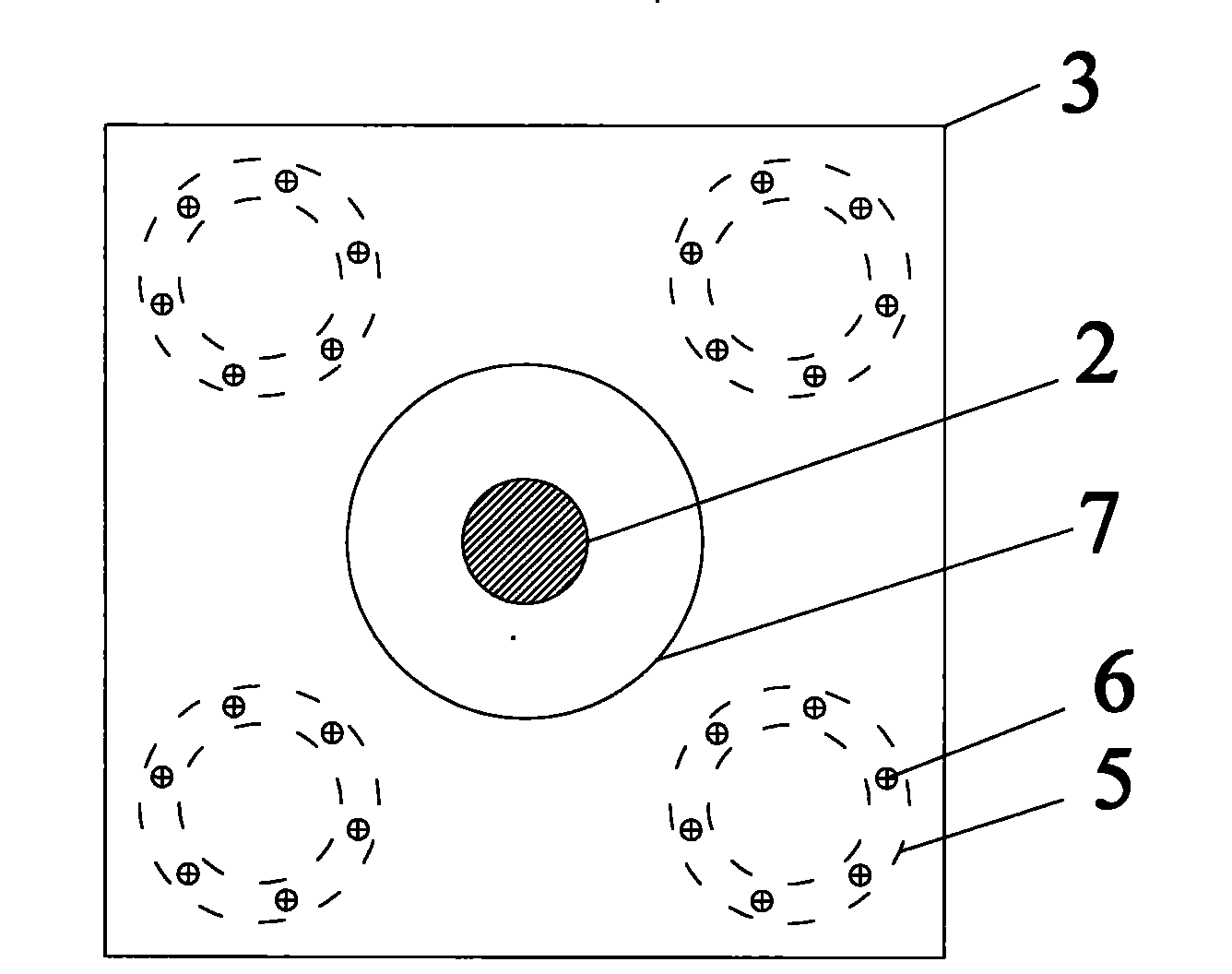

[0030] Such as figure 2 As shown, in the limitable assembled rubber shock-isolating pad, the middle laminated steel plate is formed by stacking several steel plates 3 in sequence, and a rubber shock-isolating unit 5 is installed between every two layers of steel plates 3, and each steel plate 3 is There are four groups of bolt holes for fixing the high-damping rubber shock-iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com