Continuous manufacturing system and continuous manufacturing method of liquid crystal display element

A technology for liquid crystal display elements and manufacturing systems, applied in the direction of chemical instruments and methods, control lamination, and other household appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

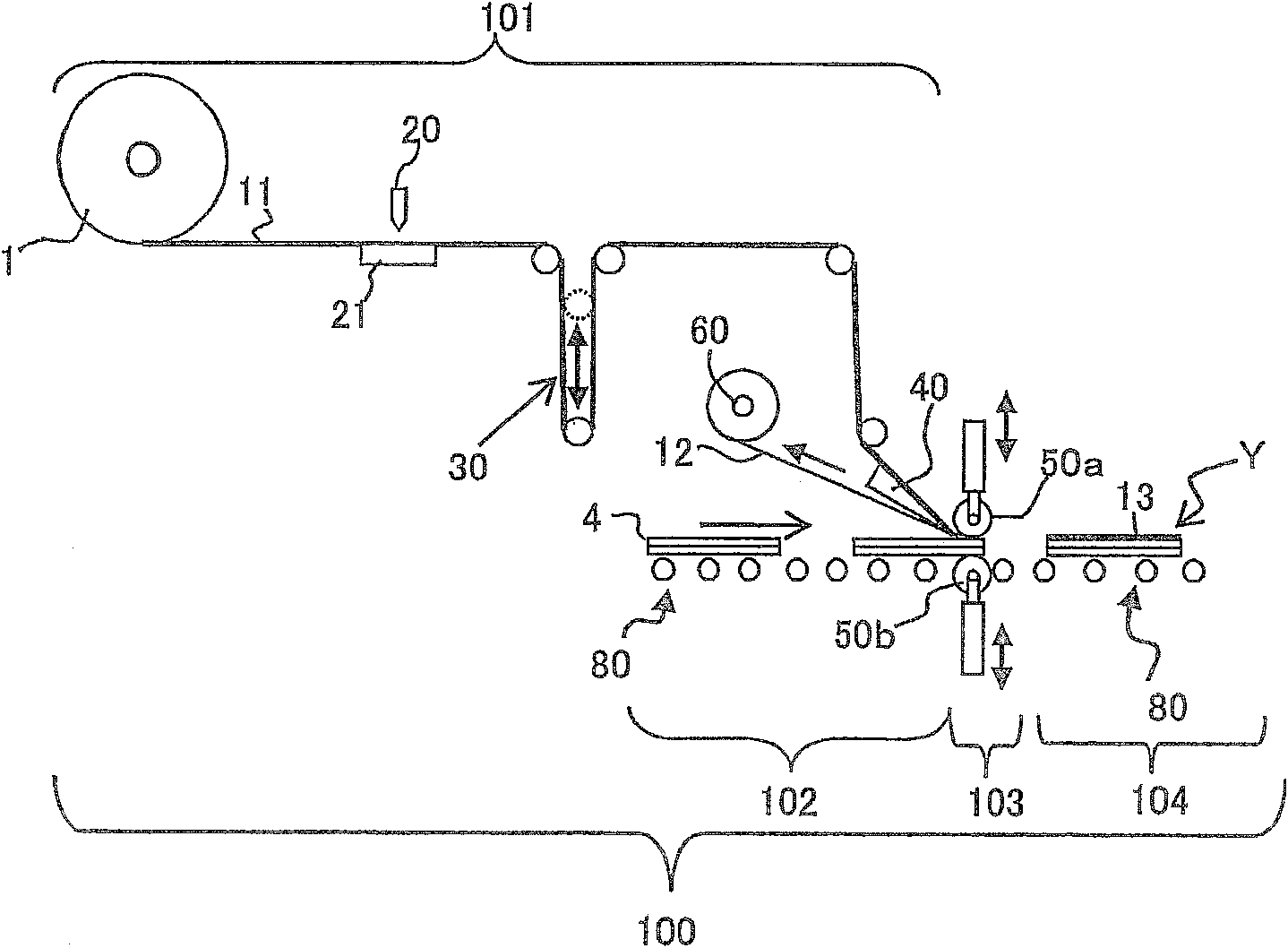

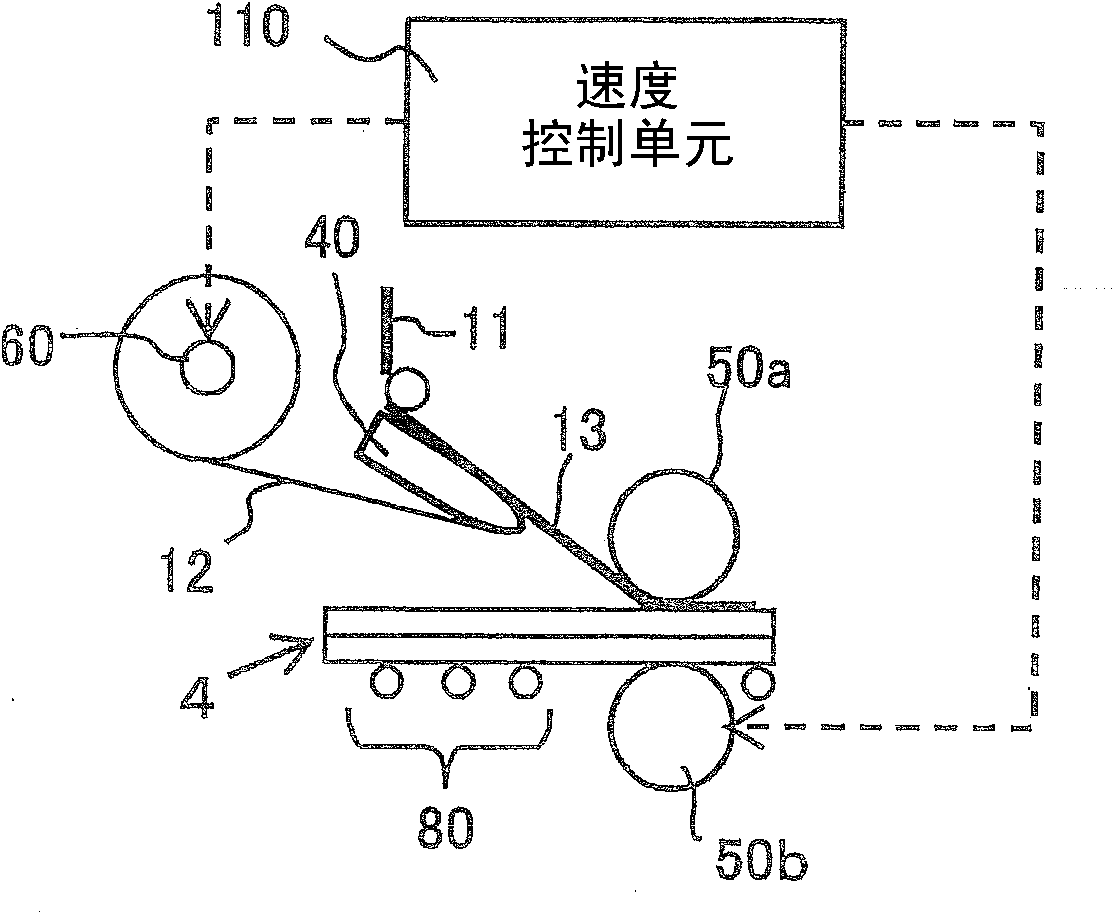

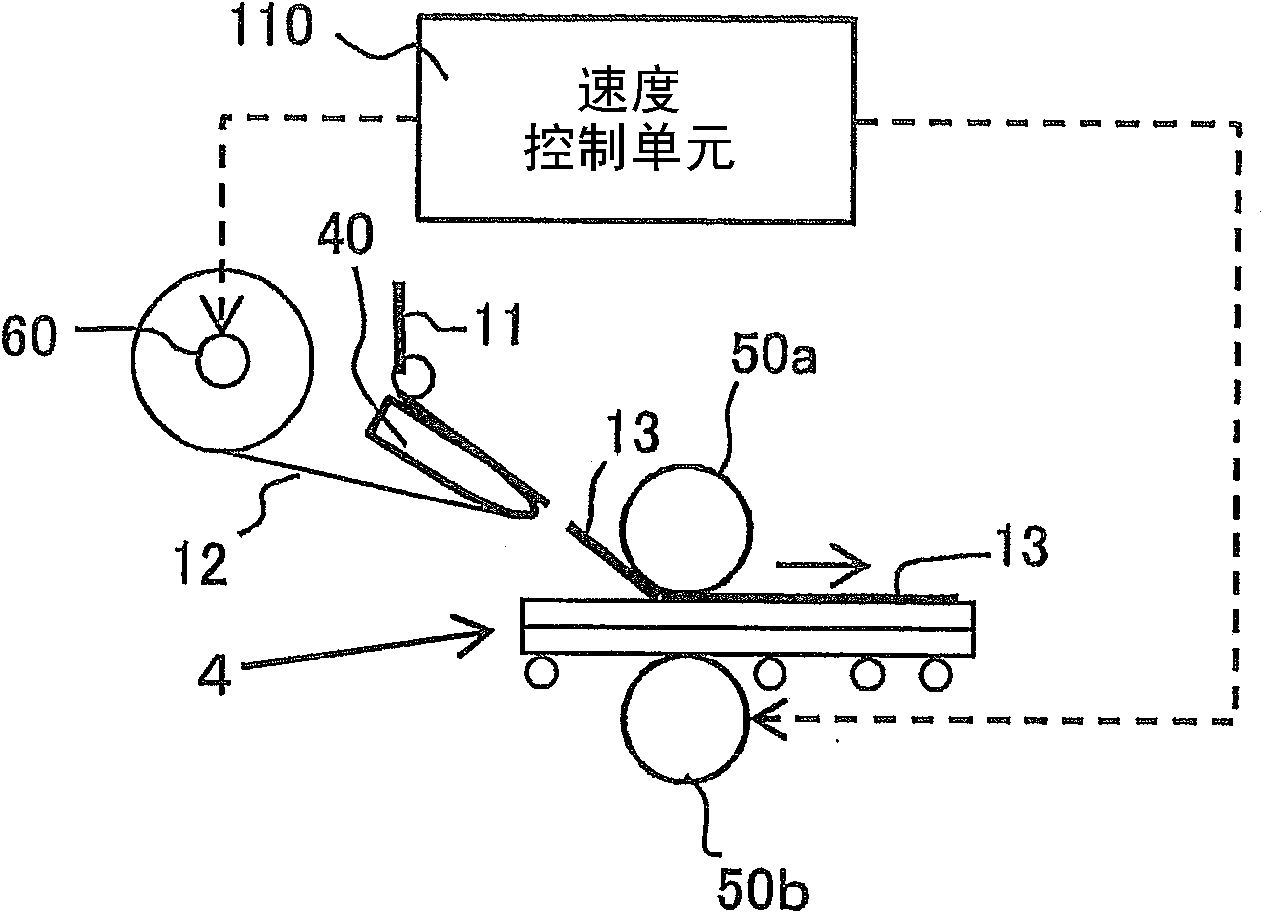

[0054] The continuous manufacturing system of the liquid crystal display element of the present embodiment has: a peeling unit that, when the film sheets of the polarizing film including the adhesive are adjacent to each other, uses the carrier film formed through the adhesive as the inner side. Turning over at the front end to peel off the film sheet from the carrier film; a winding unit that winds up the carrier film from which the film sheet has been peeled off by the peeling unit; and a sticking unit that, while transporting the liquid crystal panel, A liquid crystal display element is formed by affixing the film sheet peeled by the peeling unit to the liquid crystal panel via the adhesive. Moreover, it also has a speed control unit, which controls the winding unit and the pasting unit so that: in the pasting process of pasting the film sheet to the liquid crystal panel, the film sheet is moved toward the During the period from the sticking start time when the sticking of ...

Embodiment

[0080] use figure 1 In the production system of , a film sheet of a polarizing film was attached to a liquid crystal panel (40 inches) on both sides from the long side, and the presence or absence of air bubbles was evaluated.

[0081] When the rear end of the film sheet being pasted is located at any one of the upstream position in the conveying direction (comparative example) or the downstream position in the conveying direction (embodiment) with respect to the front end of the peeling unit, when the take-up speed V1 of the carrier film is In the case of decelerating from the sticking speed V2, the state of bubble generation in the liquid crystal panel after sticking the film sheet was evaluated.

[0082] exist Figure 6 In the shown embodiment 1, the deceleration is carried out on the premise of making the winding speed V1 and the sticking speed V2 the same speed from the highest speed. After the front end of the coil, only the winding speed V1 is further decelerated so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com