Patents

Literature

39results about "Packaging cheese" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

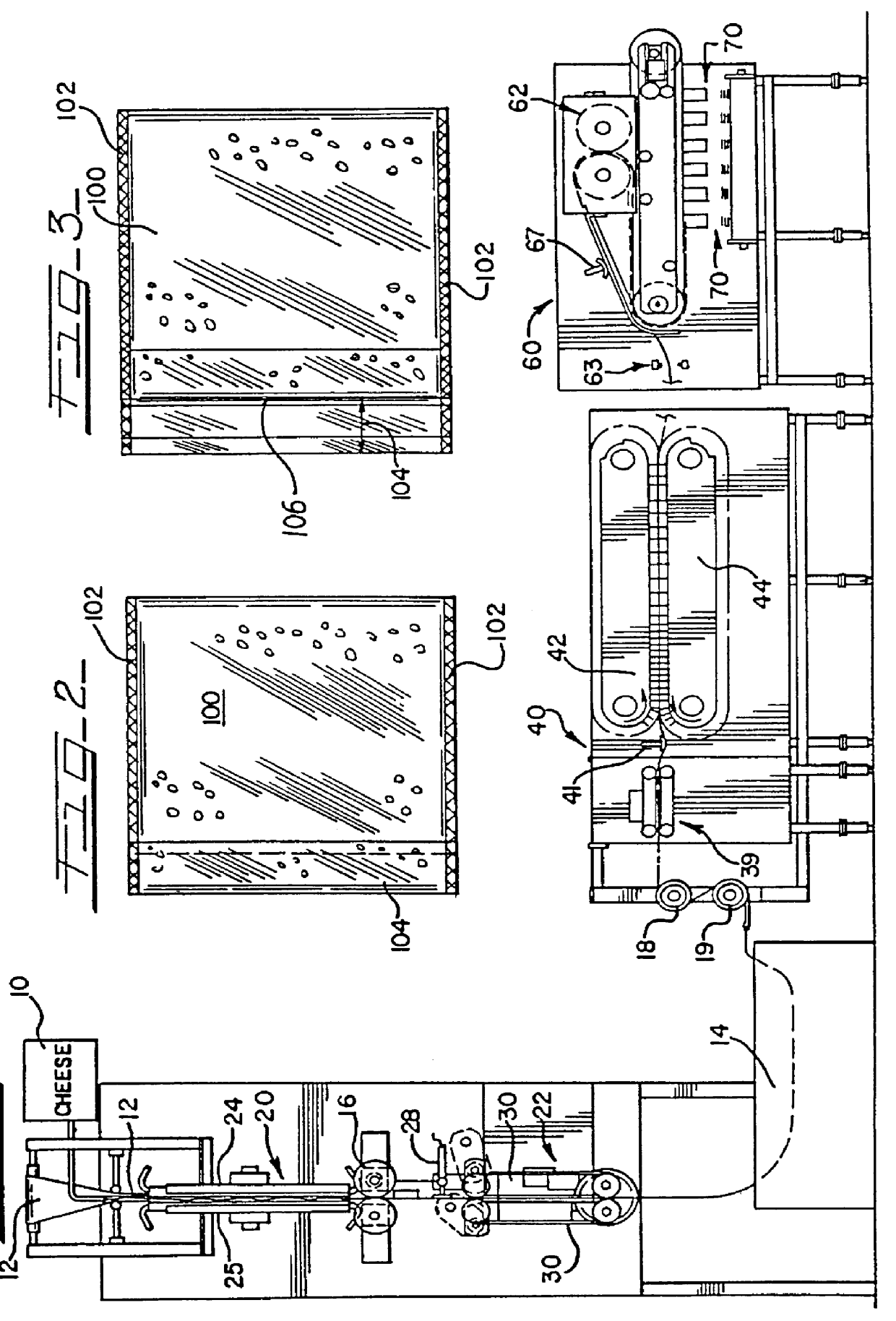

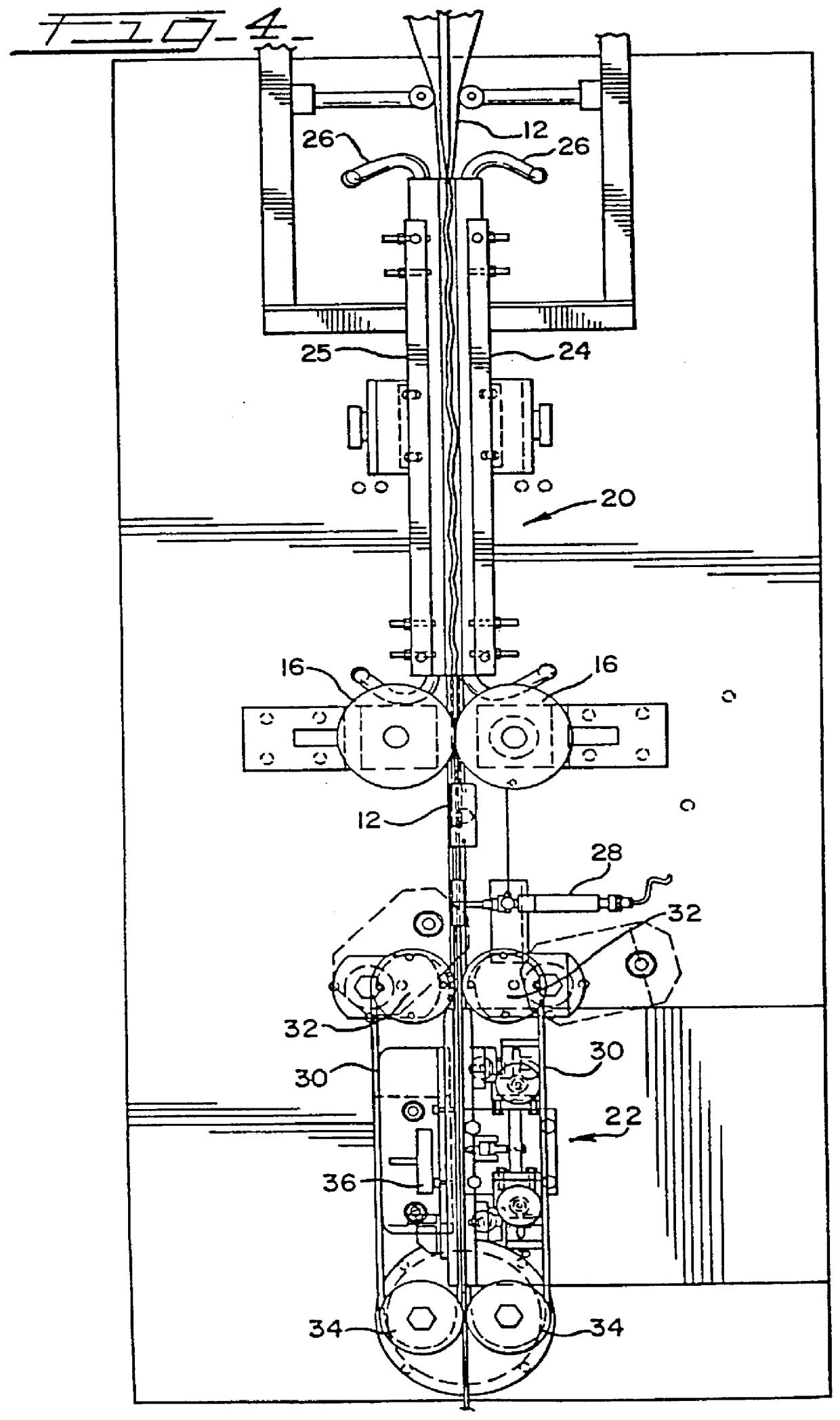

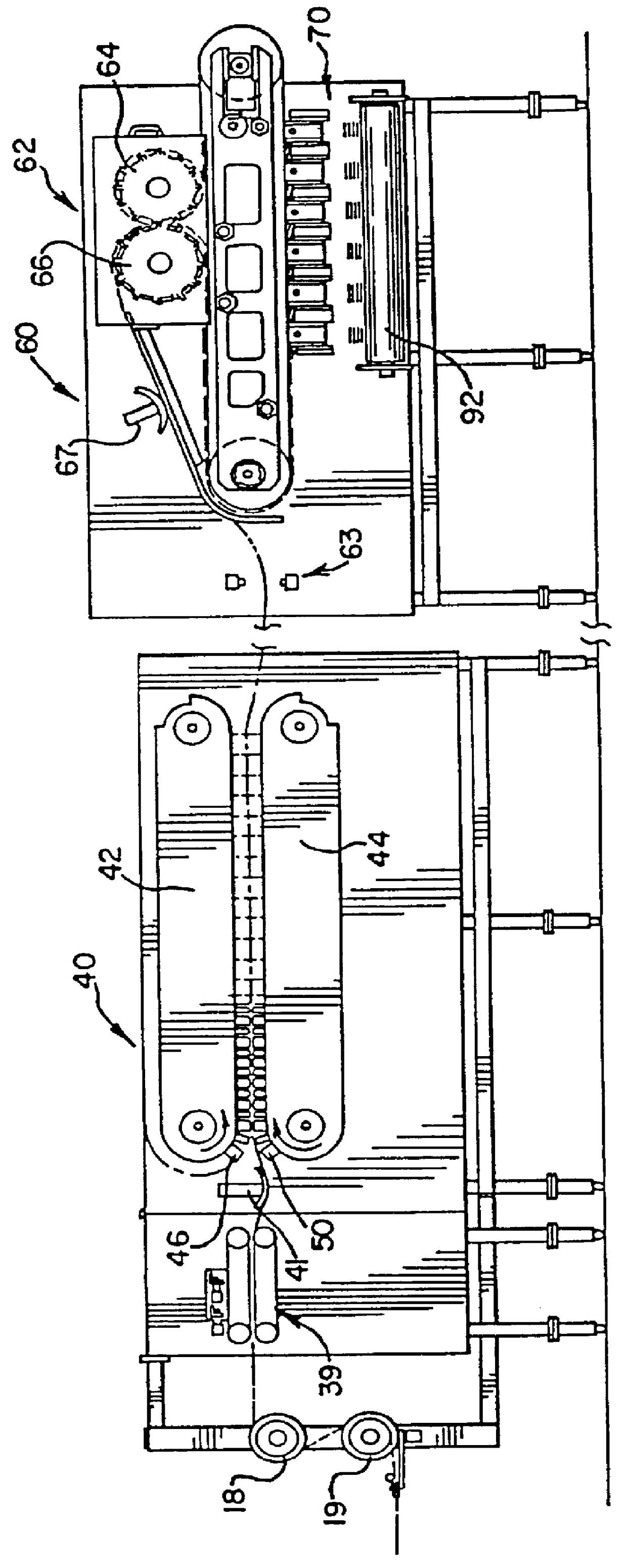

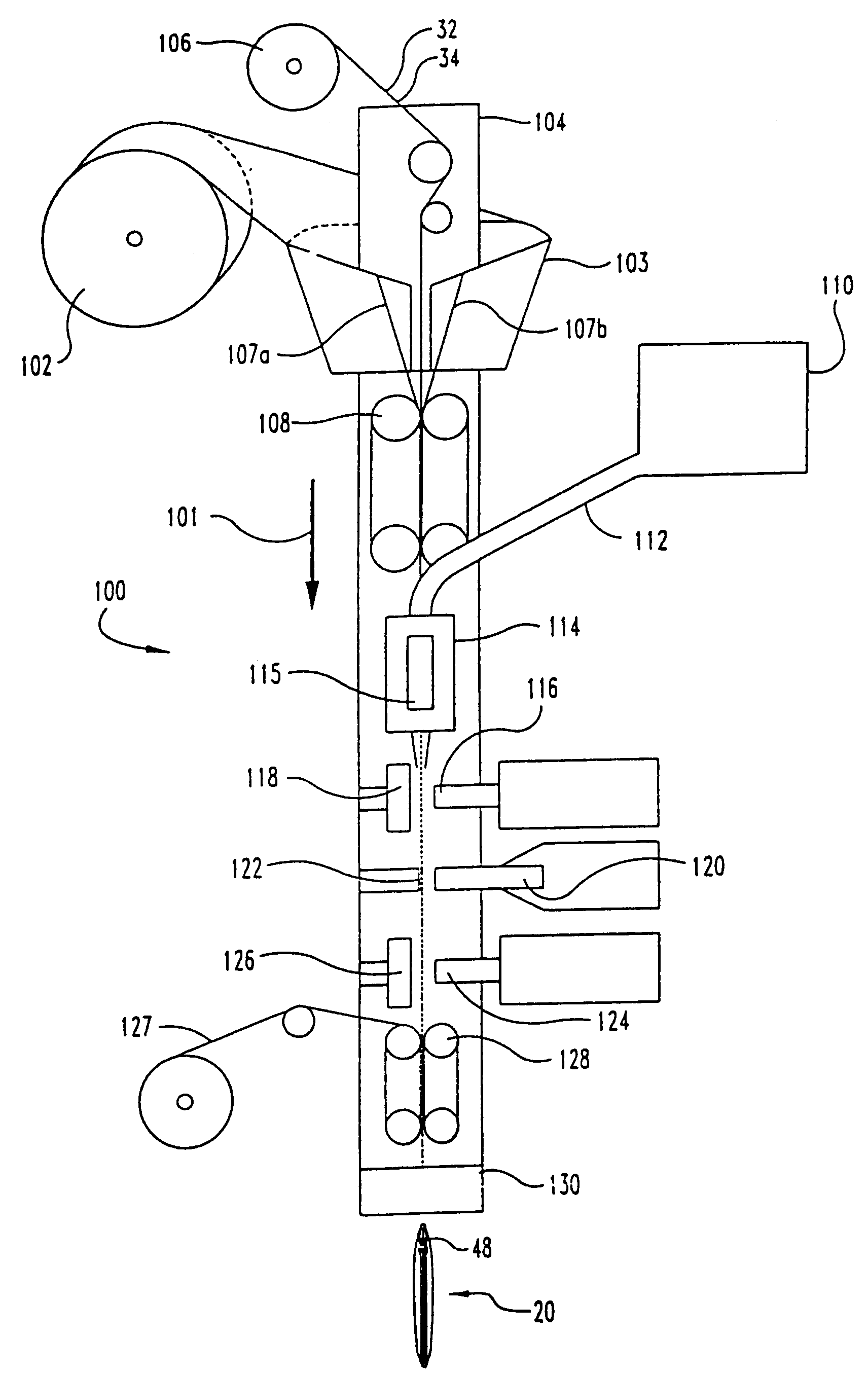

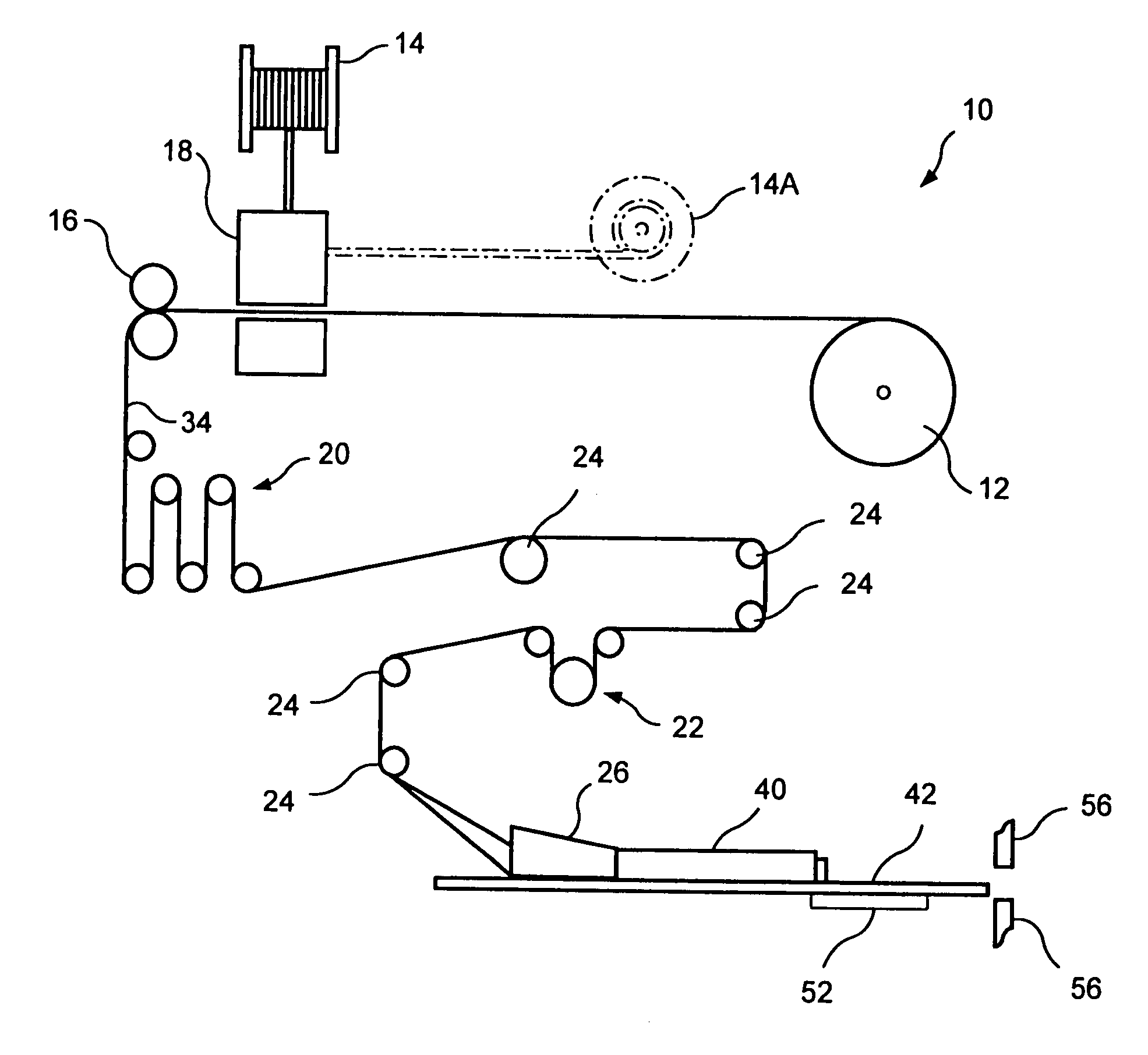

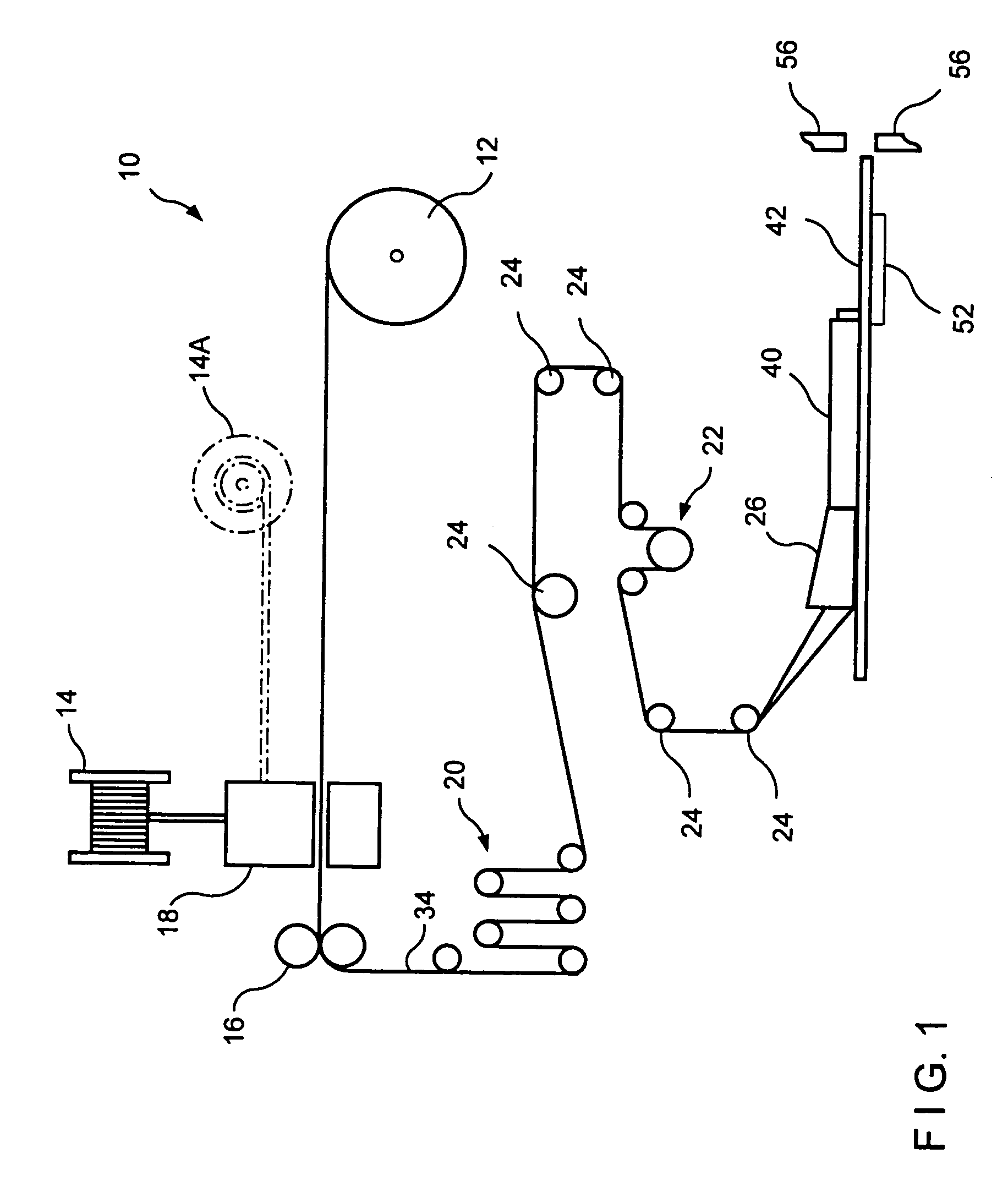

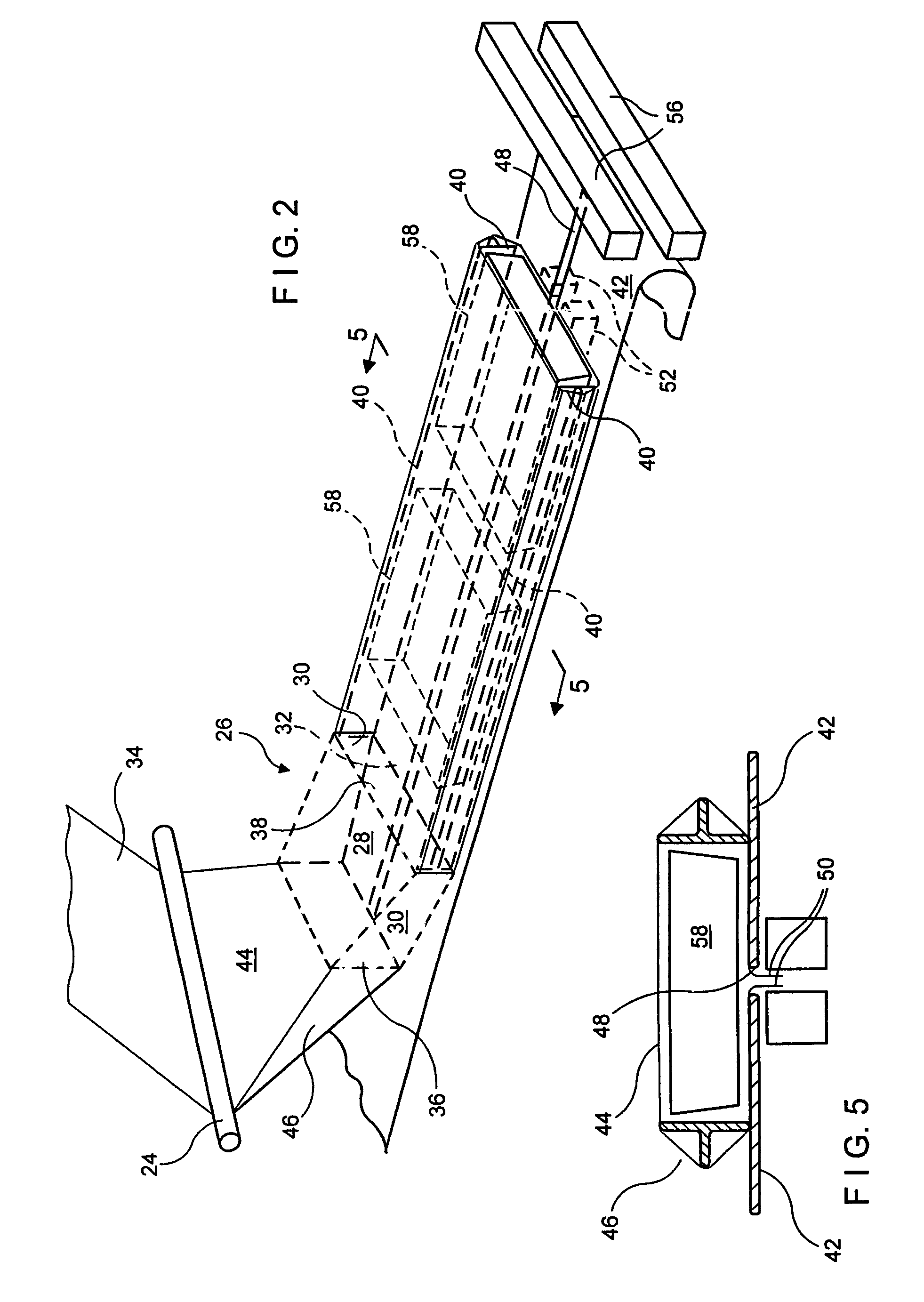

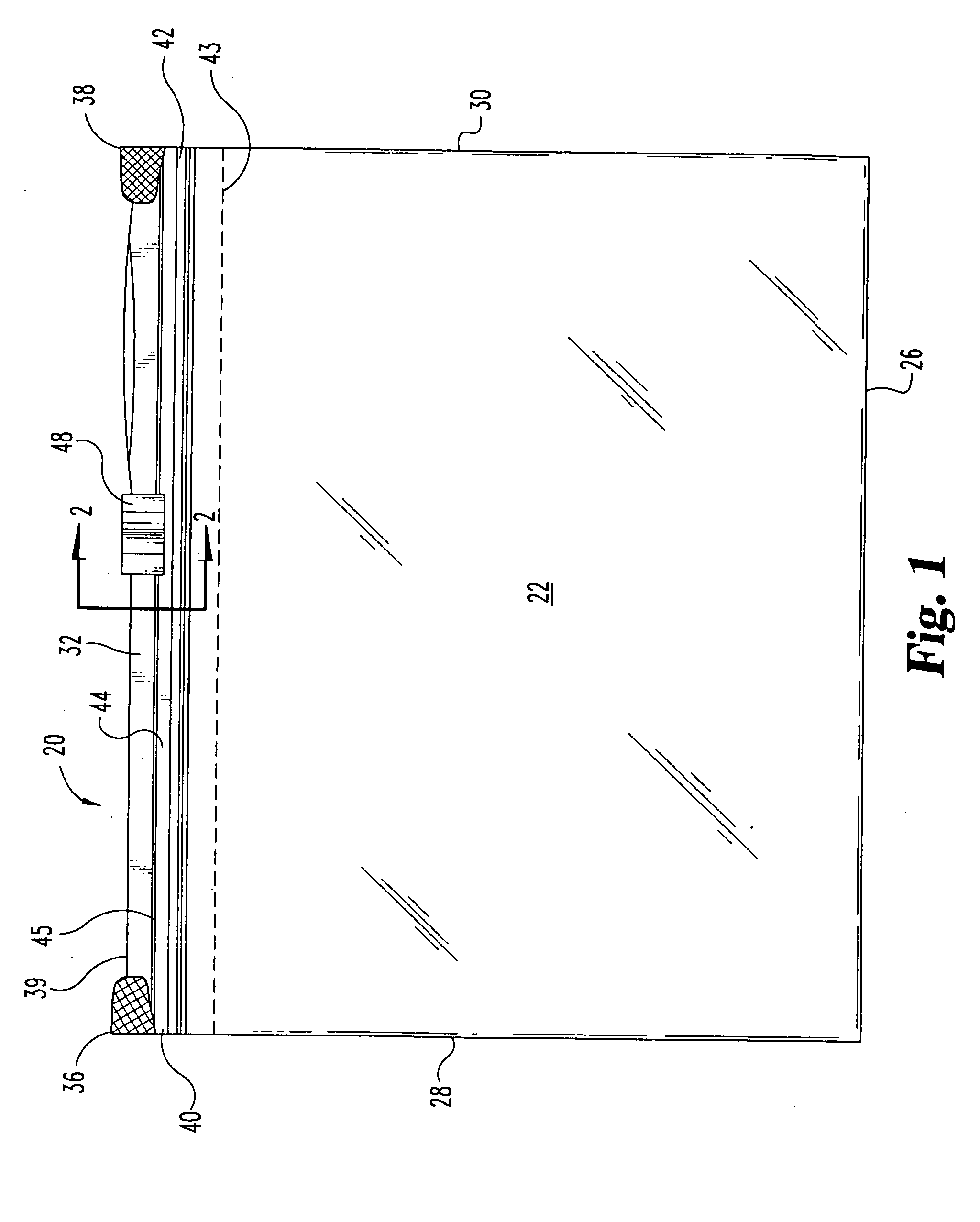

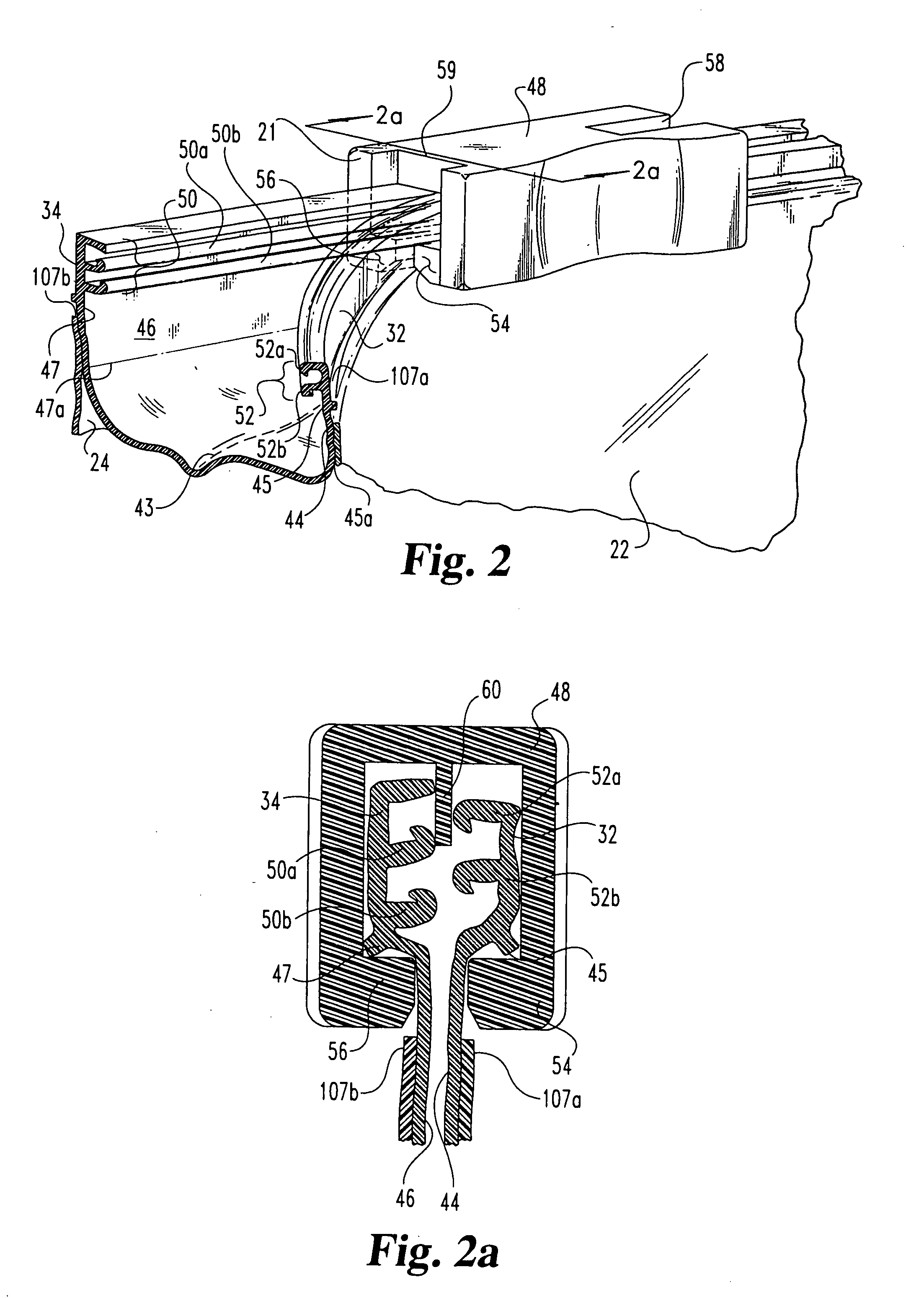

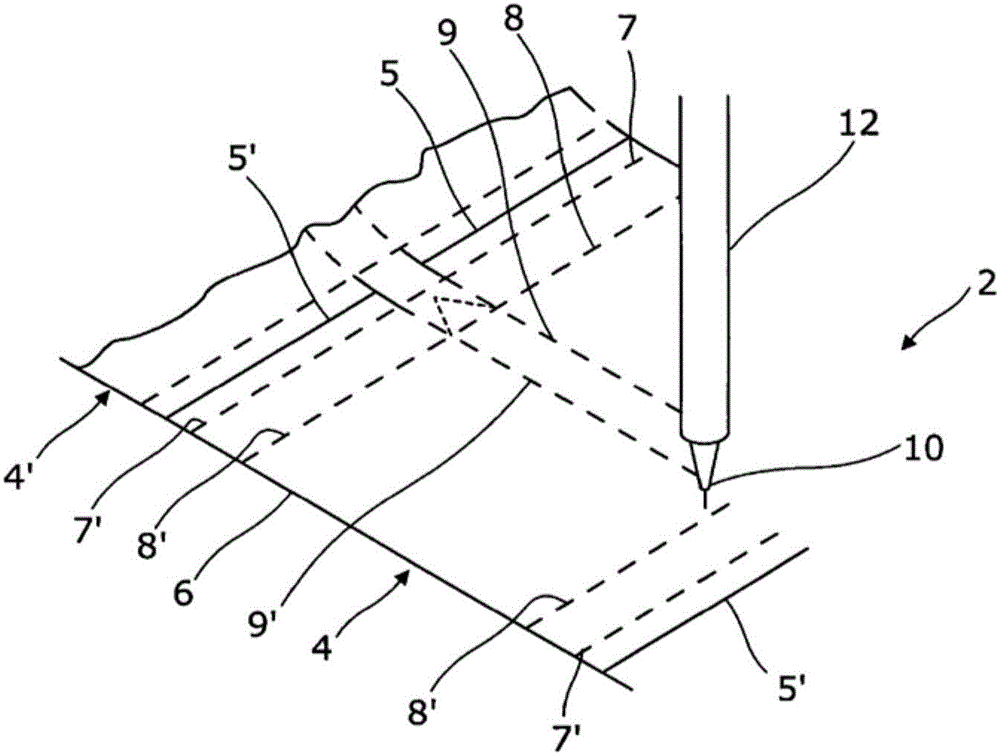

Method and apparatus for forming and hermetically sealing slices of food items

InactiveUS6058680AEfficient and rapid production rateExtended shelf lifePackaging cheeseReady-for-oven doughsHermetic sealThin membrane

An apparatus and method are provided for forming a hermetically sealed package for a slice of a food item. A web of thermoplastic material is first formed into a tubular arrangement with a hermetic longitudinal seal. To form the tubular arrangement, means are provided for folding a continuous web of thermoplastic material into V-folded condition and for continuously forming a hermetic seal along the open longitudinal edge of the V-folded web. The hermetic seal is formed between the inner surfaces of the front and rear faces of the web to define a tubular web member. The food item which has been formed into a soft mass, is then inserted into the tubular member and the tubular member is flattened to form a thin film tube. Means are provided for forming a hermetically sealed cross-seal which are disposed substantially transverse to the longitudinal forward moving direction of the web.

Owner:SCHREIBER FOODS

Process for triggering, storing, and distributing an oxygen scavenger, and a stored oxygen scavenger

ActiveUS6942821B2Package sterilisationWater/sewage treatment by substance additionScavengerOxygen barrier

A method includes triggering an oxygen scavenger; and storing the scavenger in a container configured such that the oxygen scavenger exhibits no substantial oxygen scavenging activity while inside the container. The triggered oxygen scavenger can later be removed from the container, and used in packaging oxygen sensitive products. A stored oxygen scavenger, triggered, is also disclosed. A method of distributing an oxygen scavenger film includes providing a tubular film at a first location, the film having oxygen barrier and oxygen scavenger layers; triggering the oxygen scavenger; collapsing the film; rolling up the film; transporting the film to a second location; and triggering the oxygen scavenger. Another method of distributing an oxygen scavenger film includes providing an oxygen scavenger film at a first location; transporting the film to a second location; triggering the oxygen scavenger; storing the oxygen scavenger film in a container; and transporting the film to a third location.

Owner:CRYOVAC ILLC

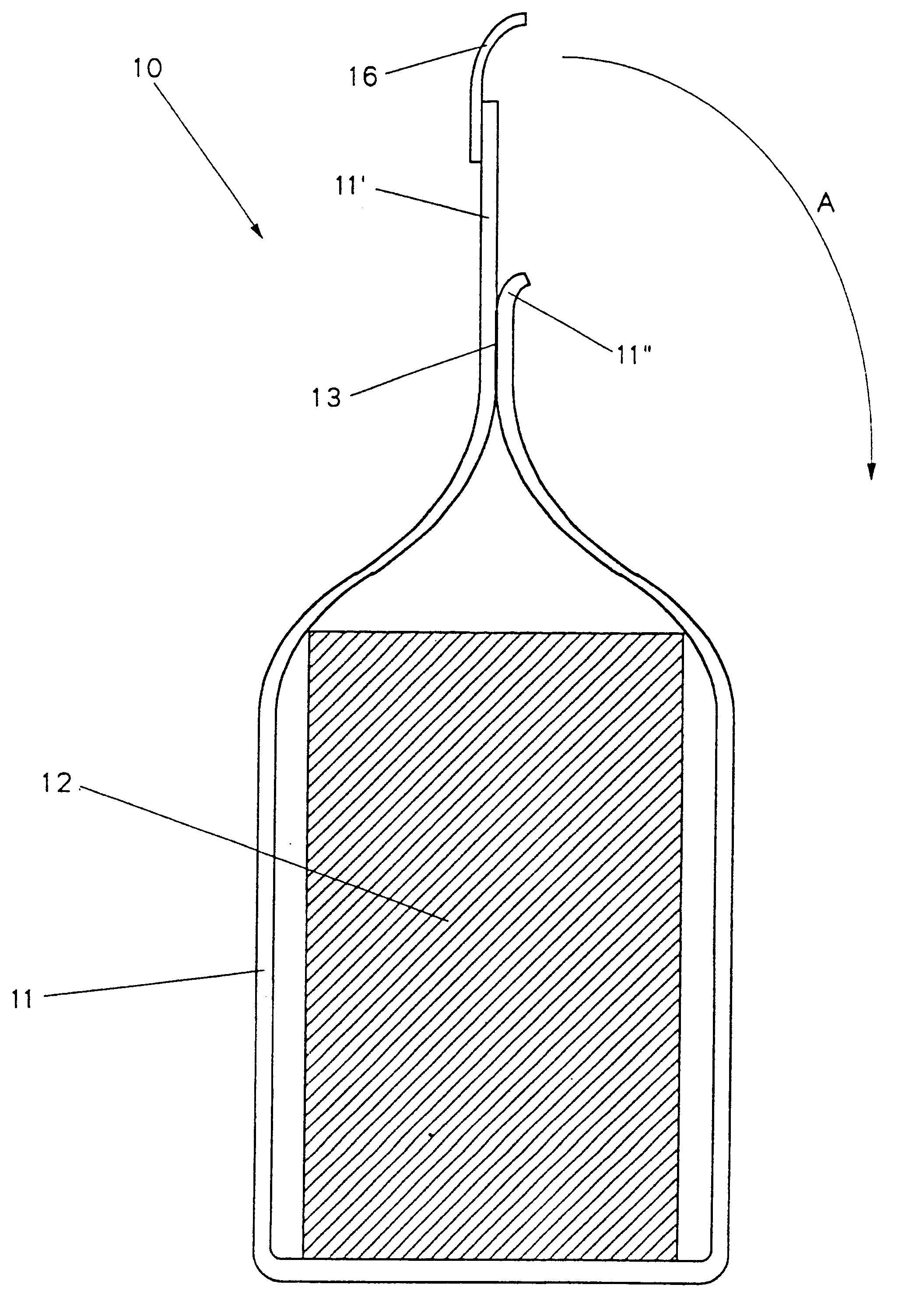

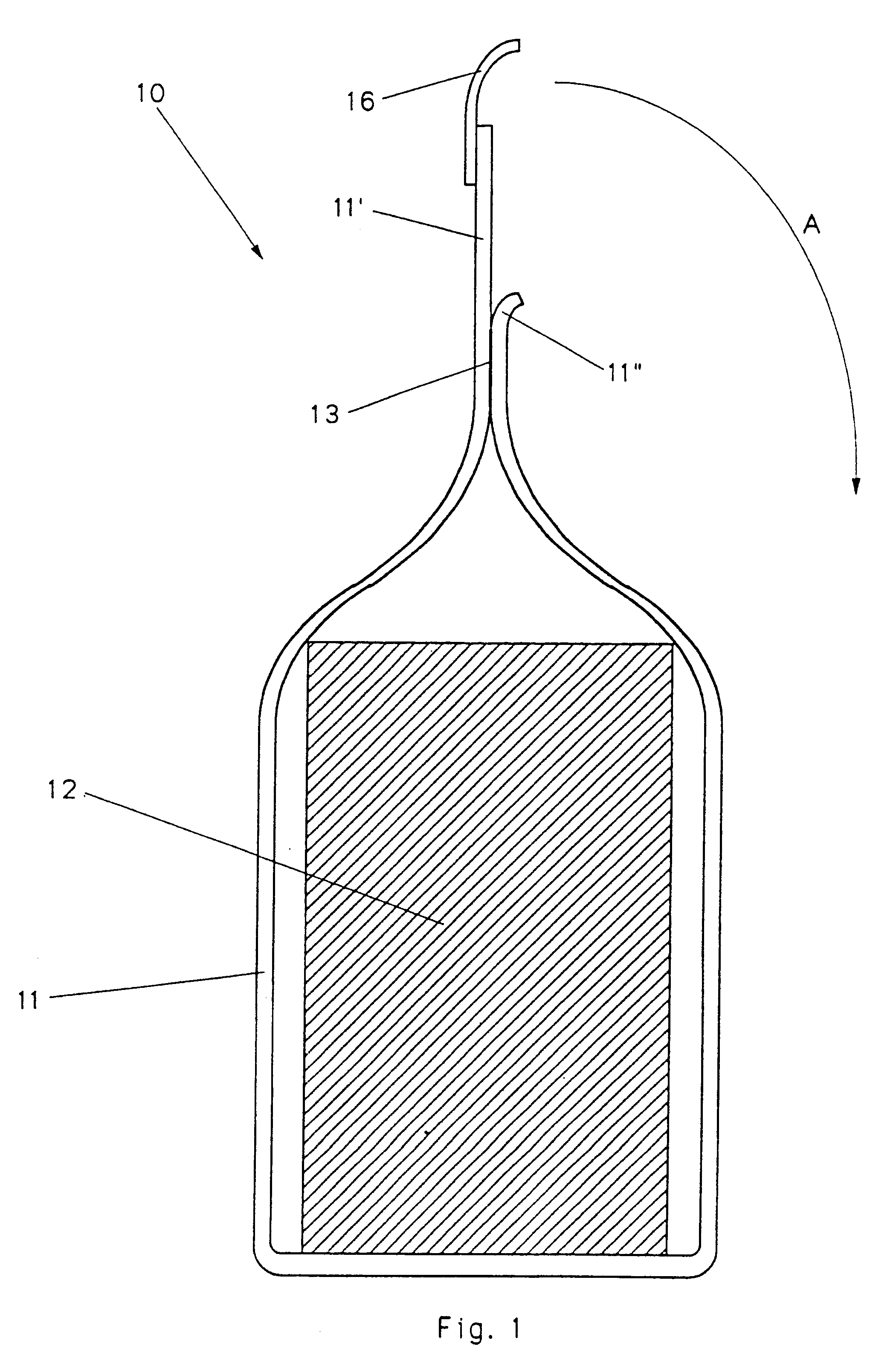

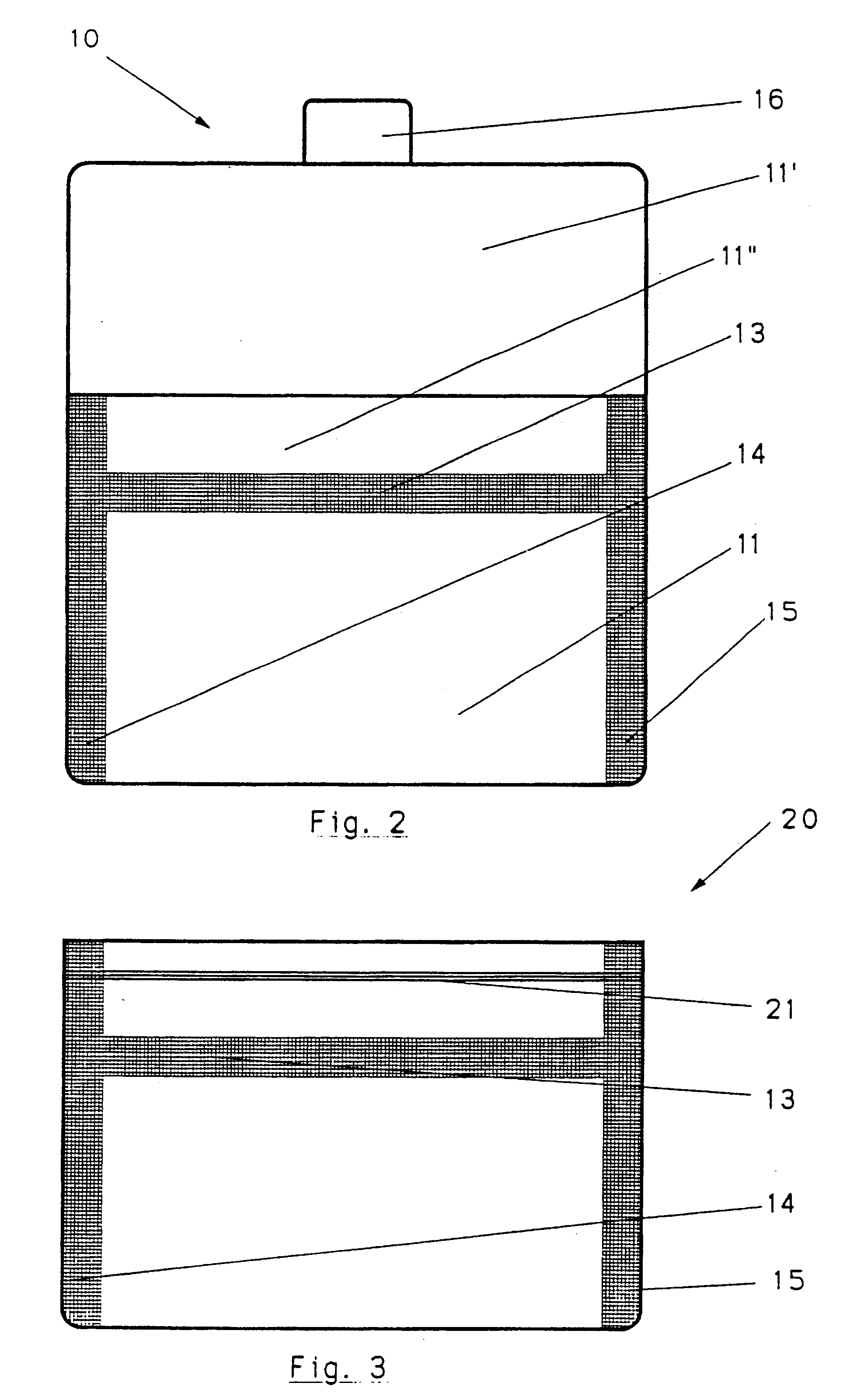

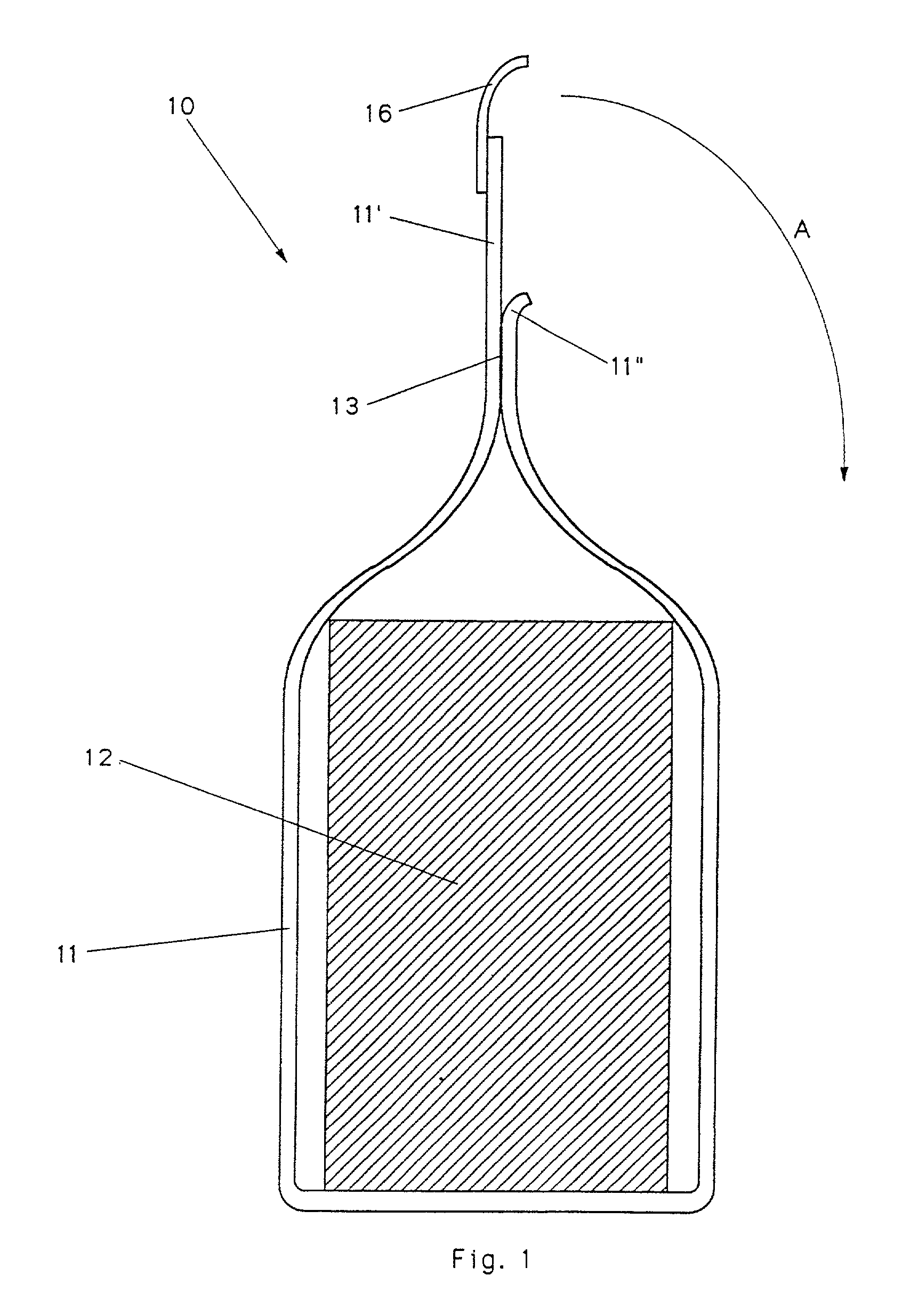

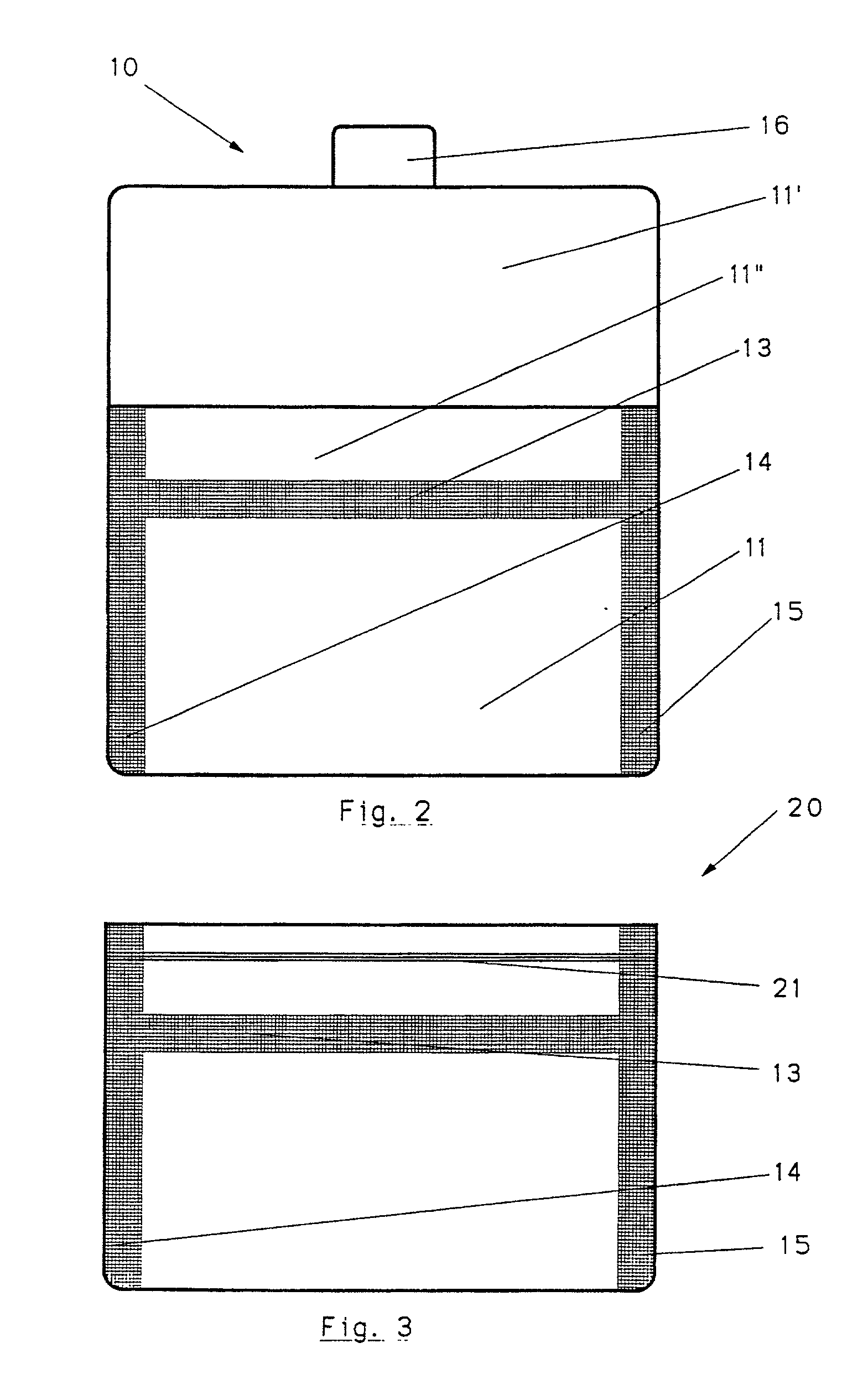

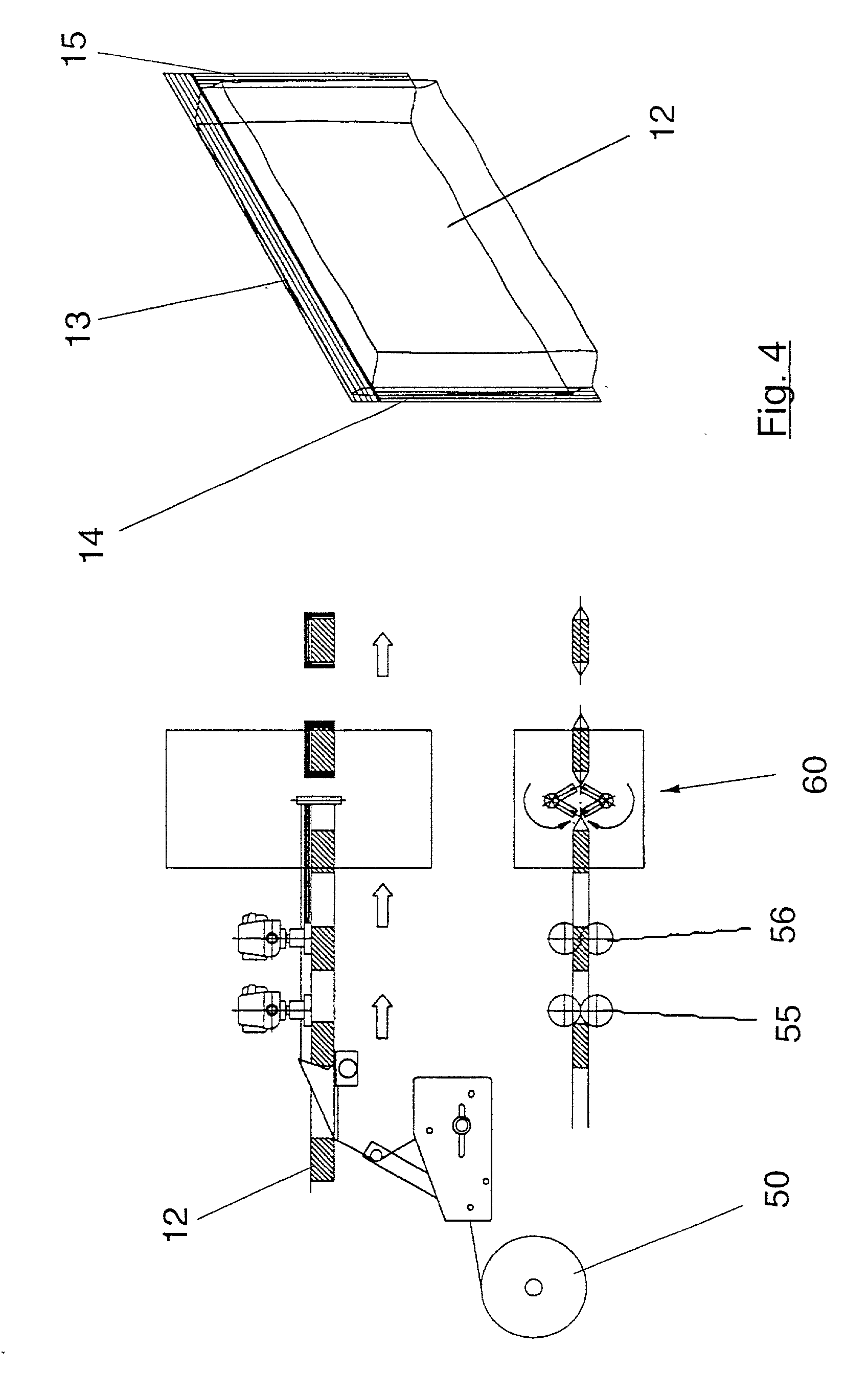

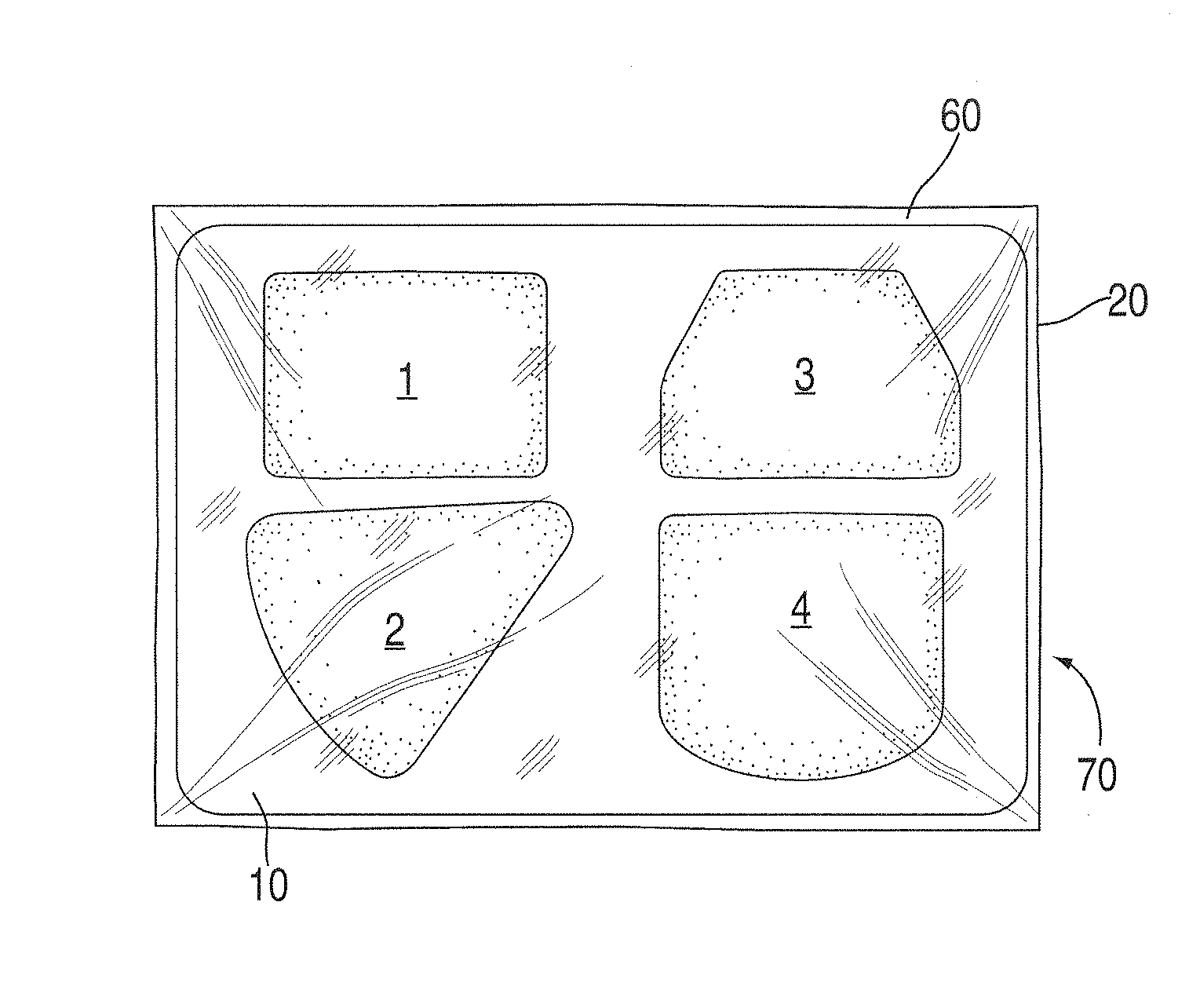

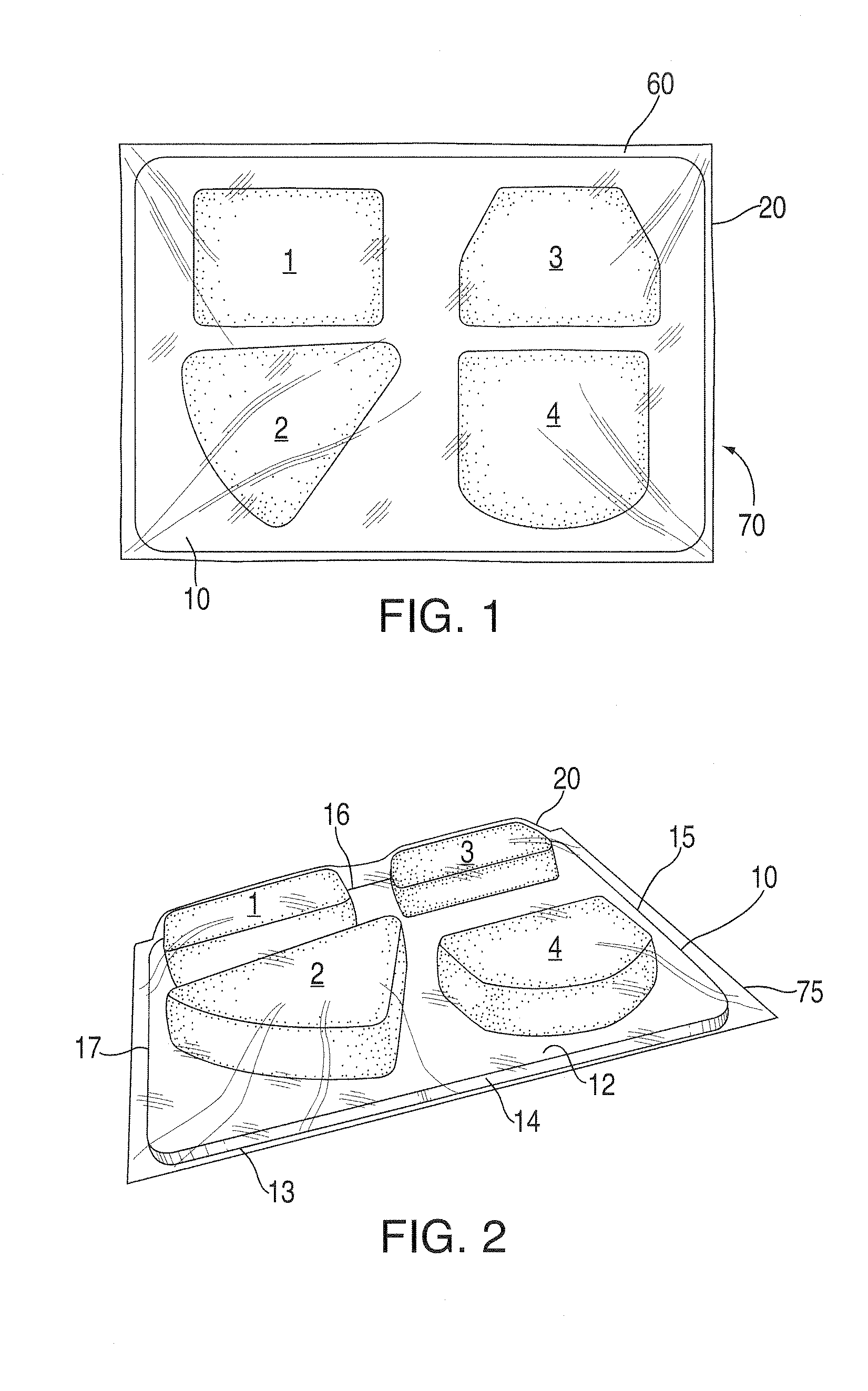

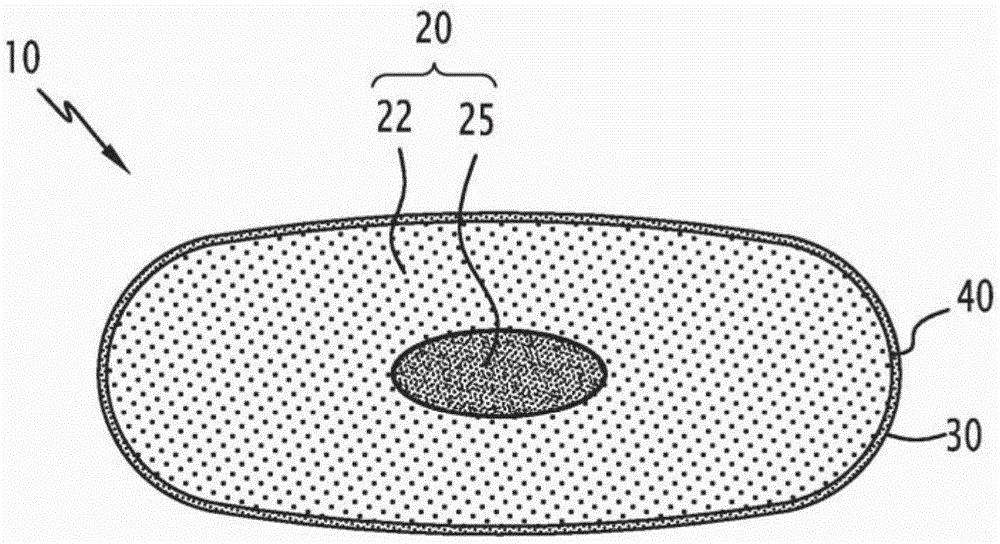

Pouch or packaging for foodstuffs made of a peelable film and process for the production thereof

An airtight pouch or packaging (10,20) made of synthetic material for the preservation of food products (12) is obtained by sealing (13, 14, 15) and cutting said synthetic material by an automatic packaging machine with a horizontal or vertical motioning of the product. The packaging (10,20) is constituted by a single peelable type film (11) consisting of an oriented polyamide layer coupled with a coextruded peelable polyethylene layer, the film being folded once on the polyethylene layer side in order to form the inner part of the packaging.

Owner:PFM

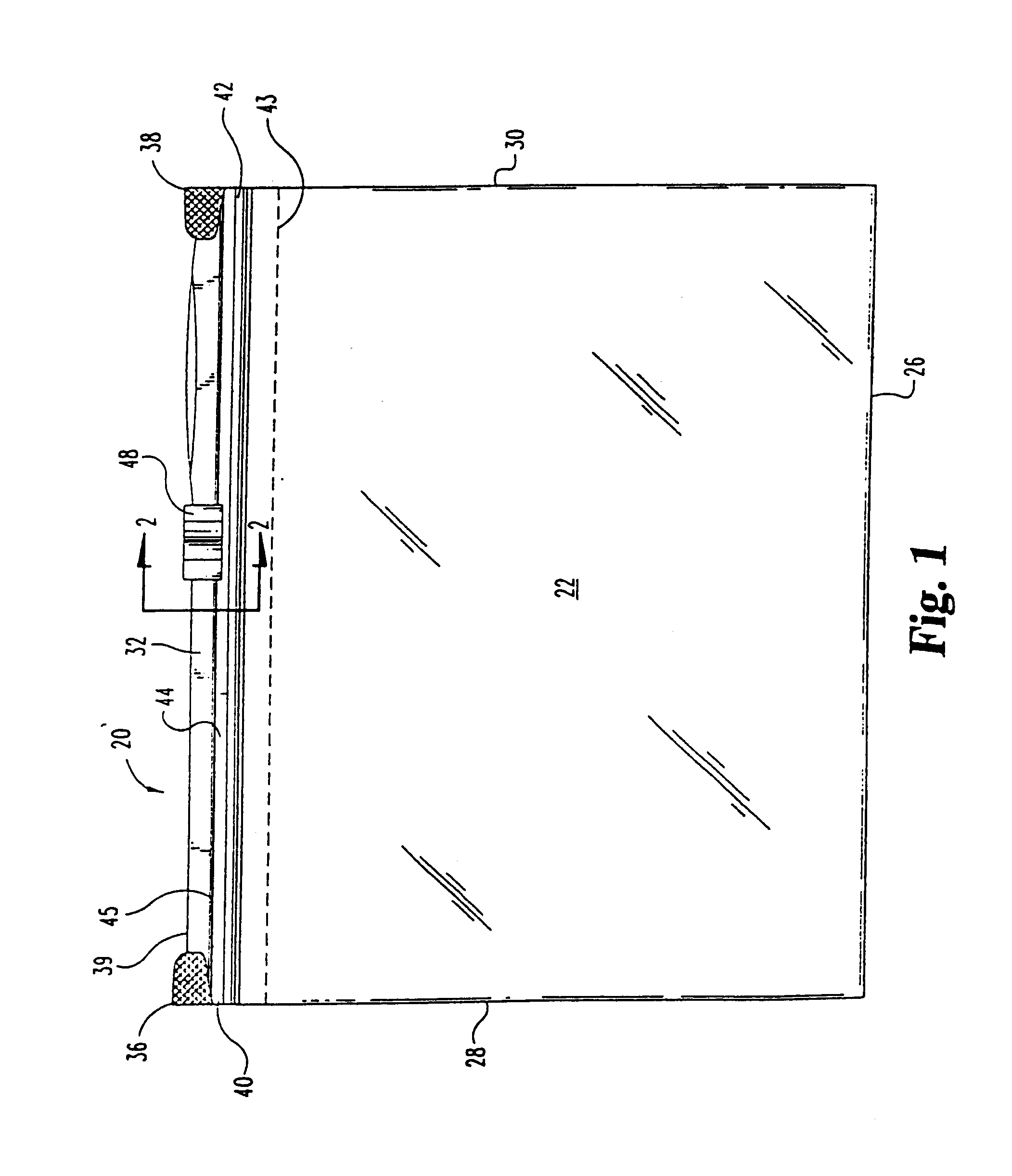

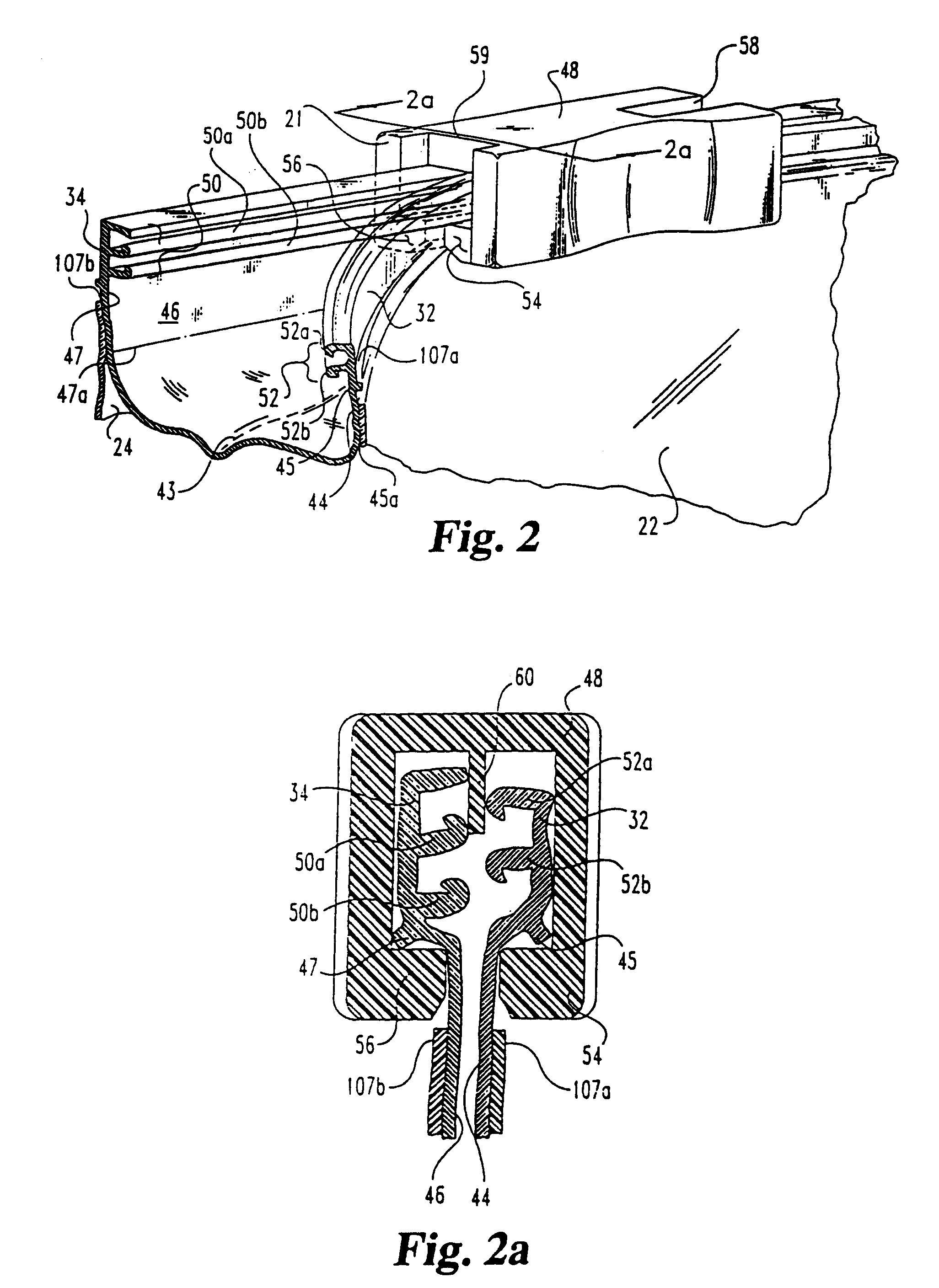

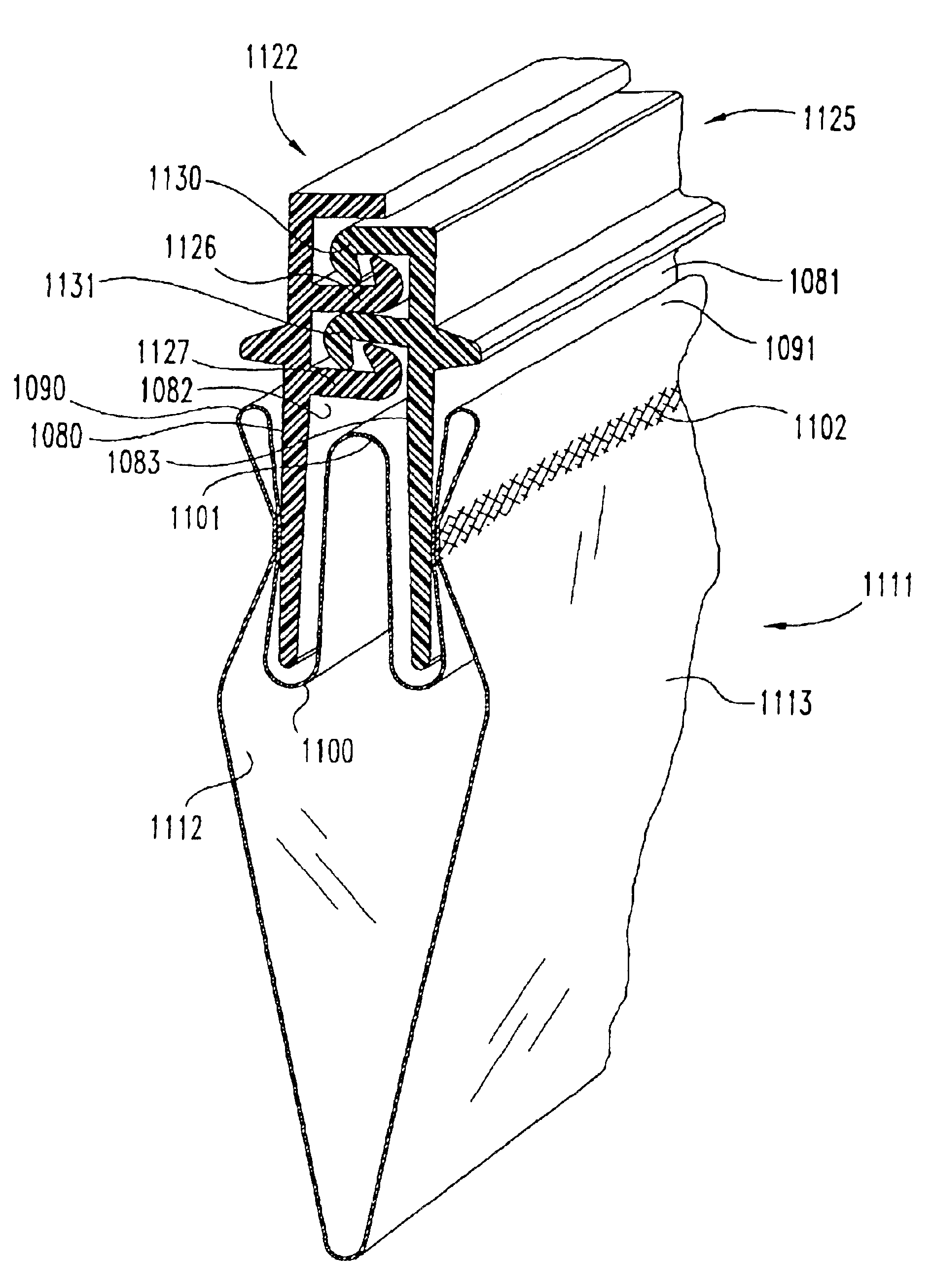

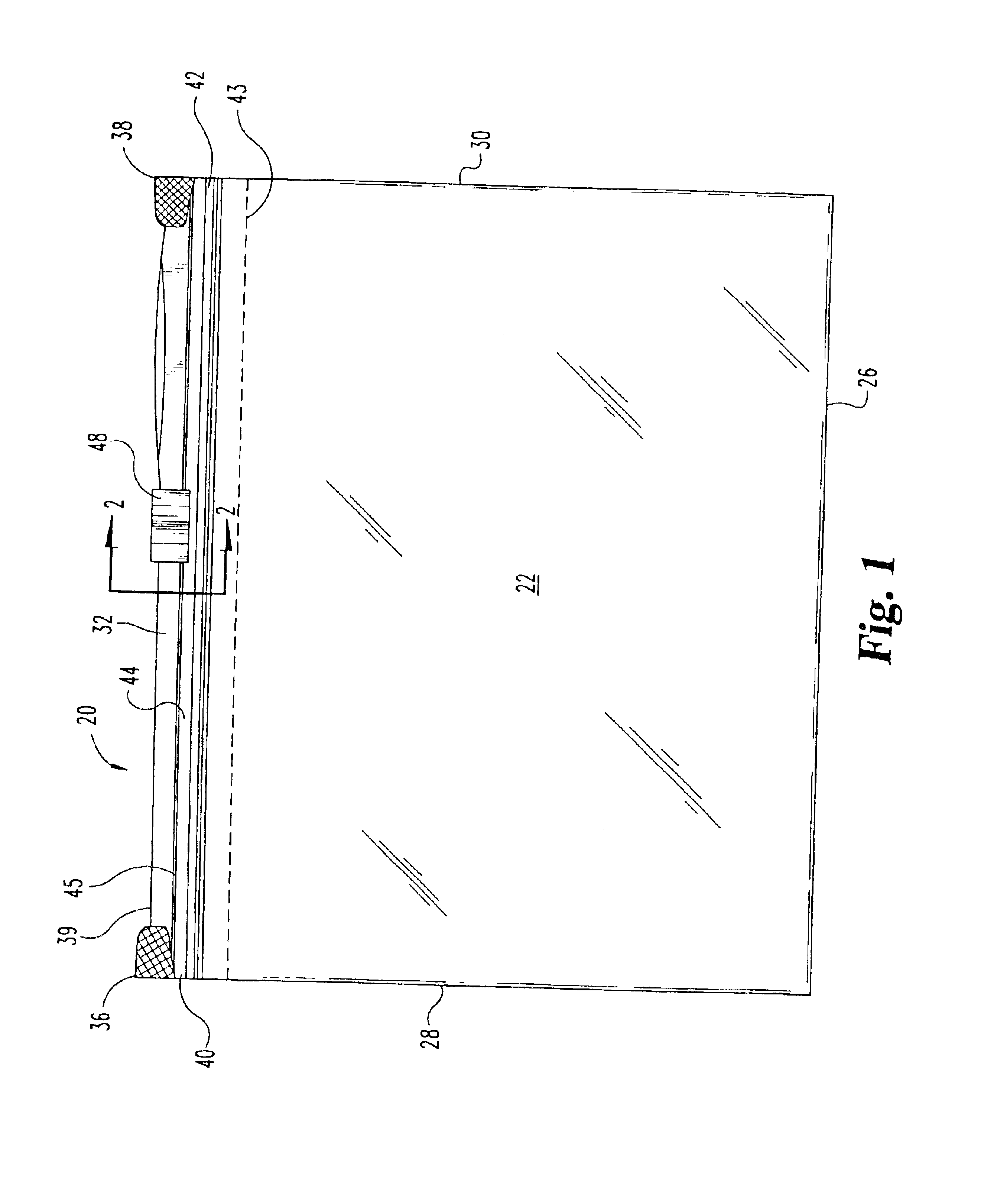

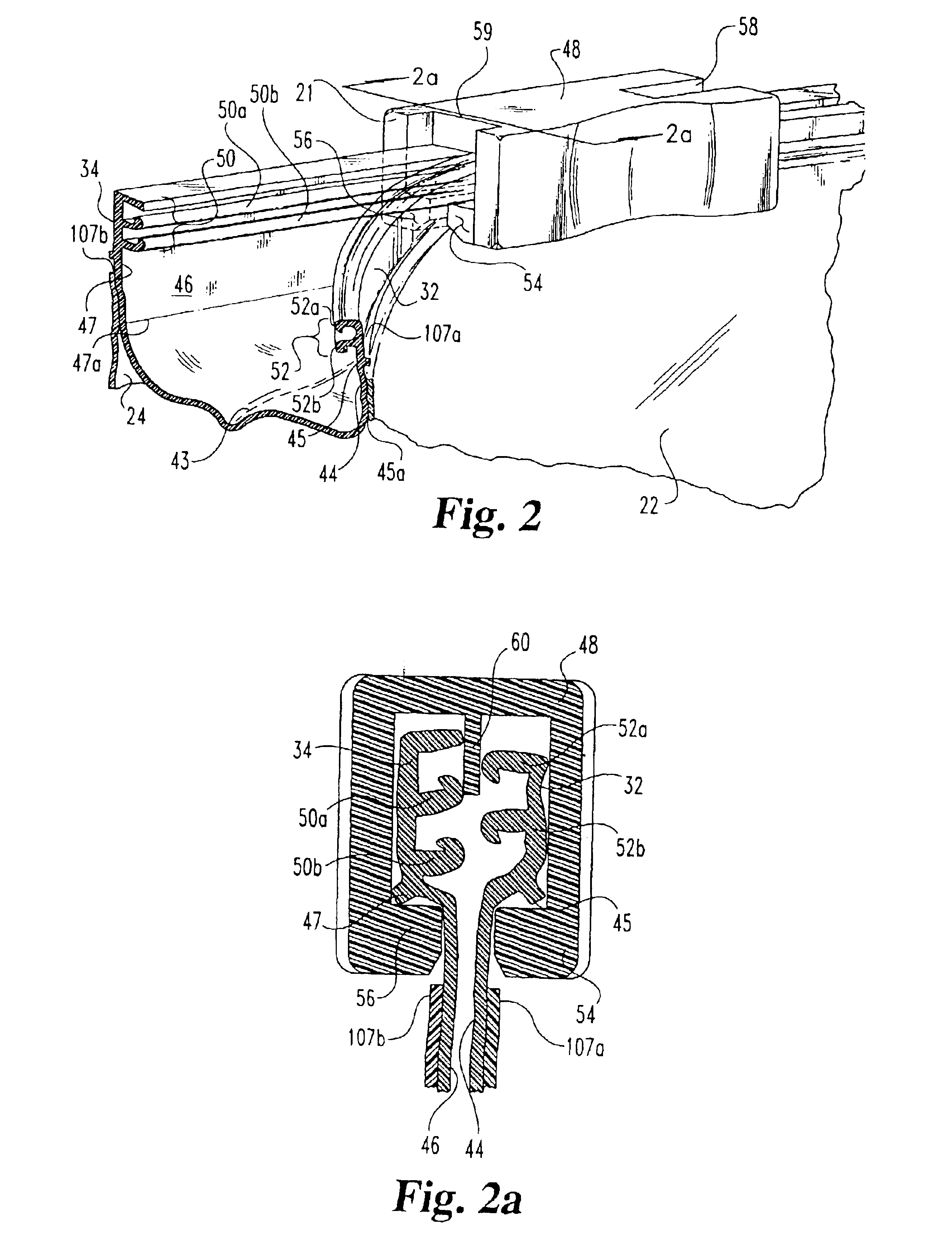

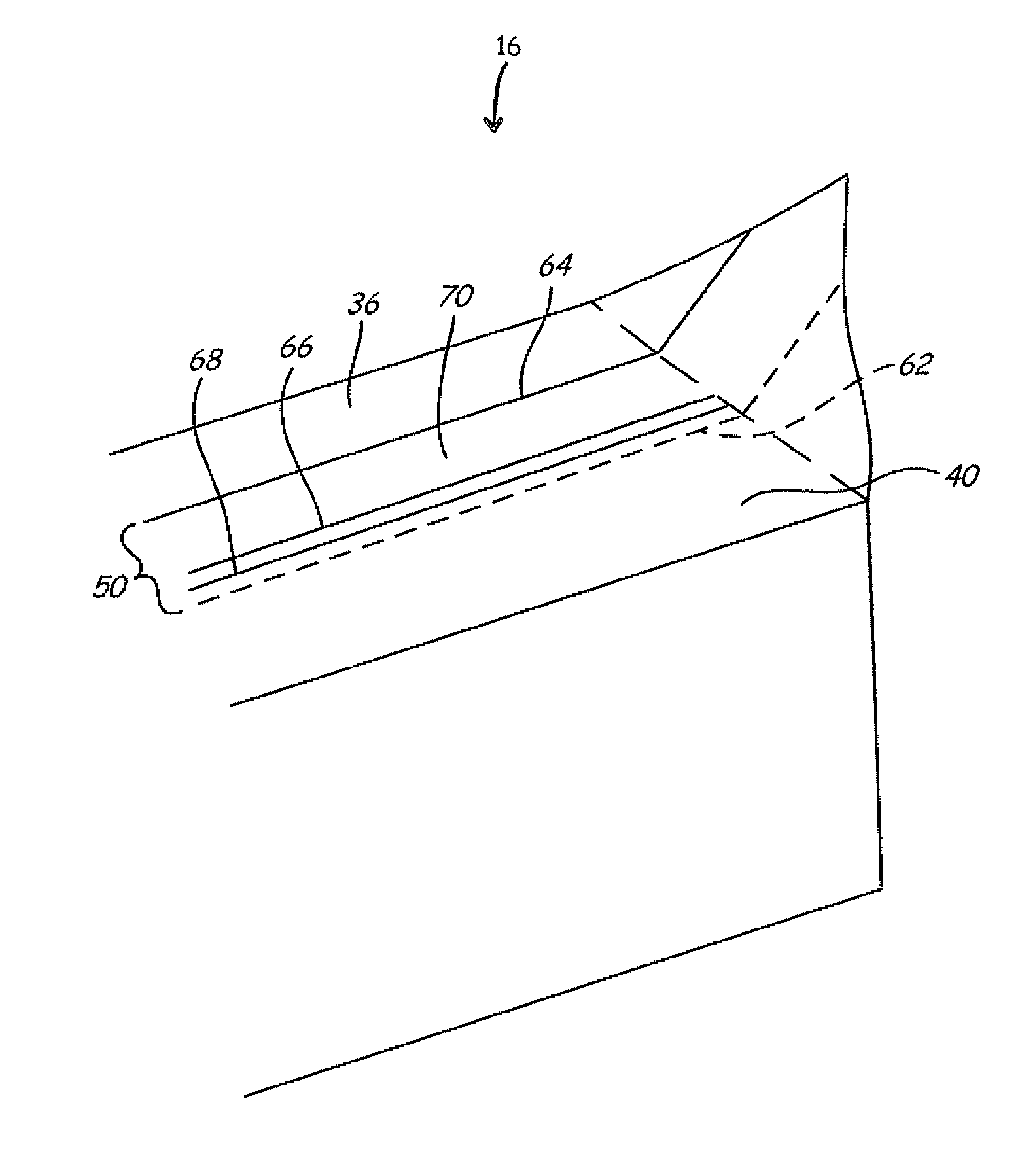

Method and apparatus for placing a product in a flexible recloseable container

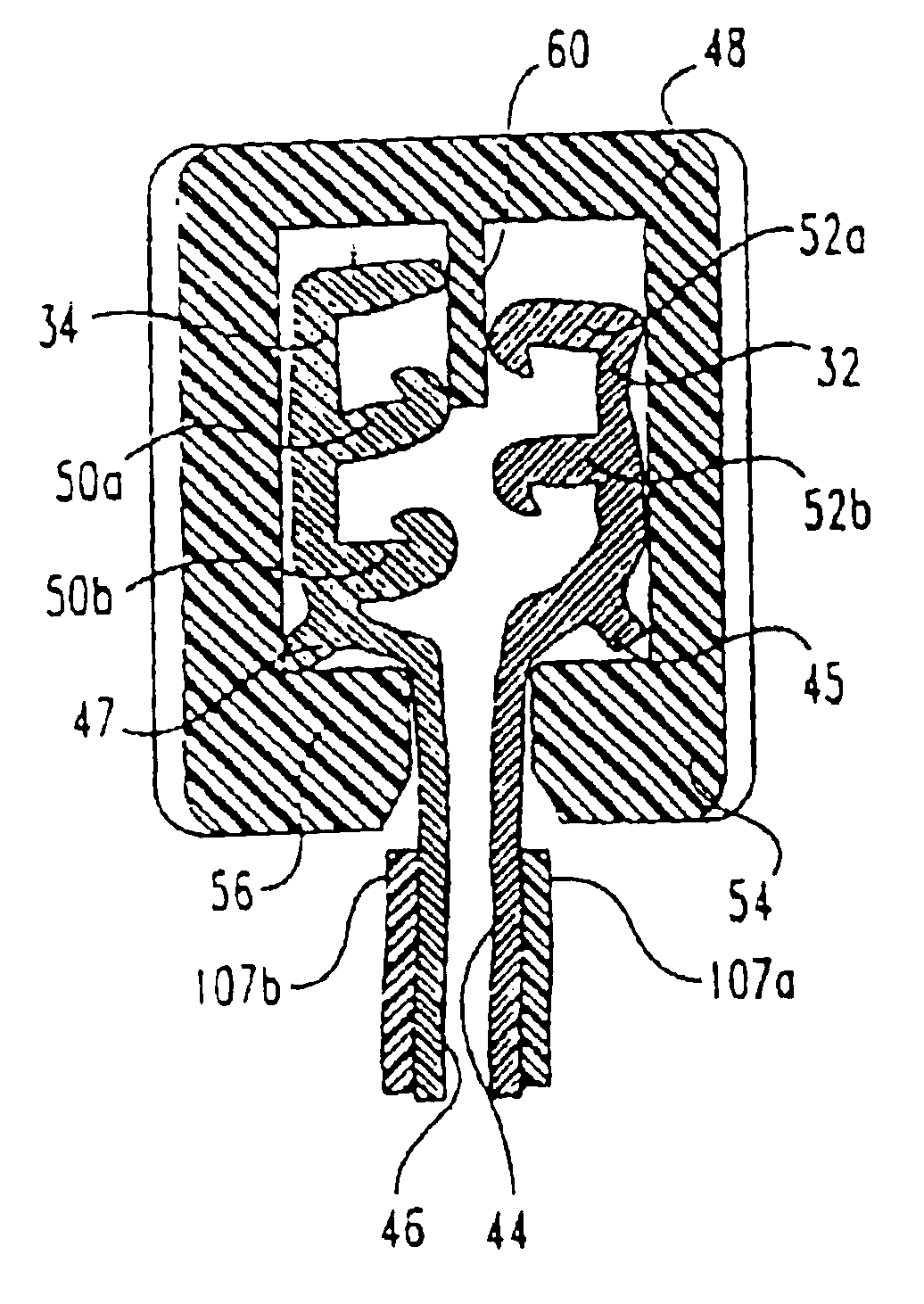

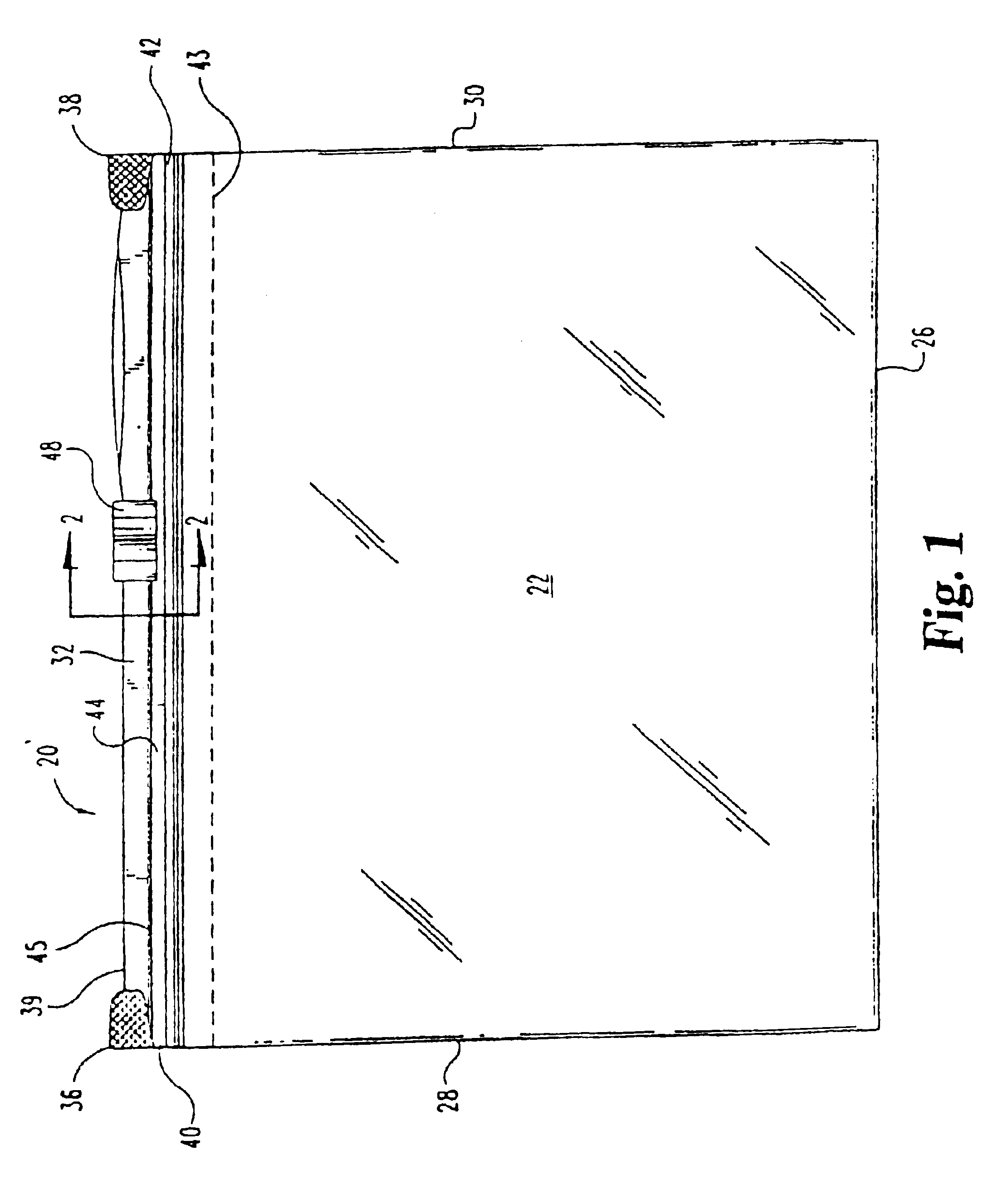

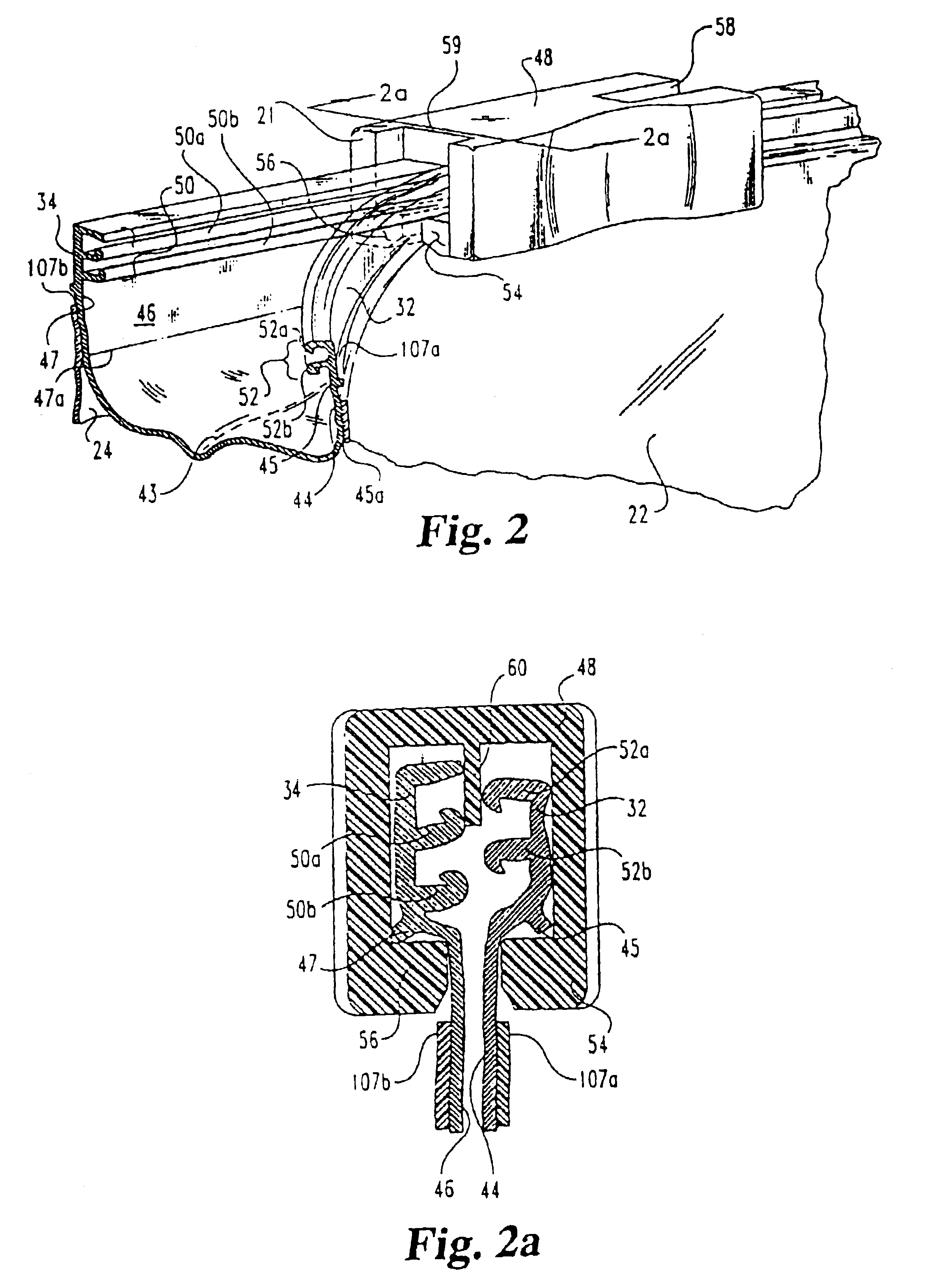

InactiveUS6925779B2Easy to placePackaging cheeseEnvelopes/bags making machineryDocking stationThin membrane

An invention for forming, filling, and sealing a flexible recloseable container. Both vertical and horizontal methods for placing product within the container are disclosed. The invention includes guiding a web of film which has interlocking fastener strips sealed to the web. A slider for locking and unlocking the fastener strips is placed in the correct orientation, spread apart at a pair of inner feet, and inserted over the fastener strips. The slider is positioned to close a substantial portion of the strips, and then an end stop, docking station, and corner seal are formed against a sealing plate. The slider is then repositioned, and a tamper evident seal may be placed over the fastener strips.

Owner:ILLINOIS TOOL WORKS INC

Method and apparatus for placing a product in a flexible recloseable container

Apparatus and methods for forming, filling, and sealing a flexible recloseable container. Both vertical and horizontal methods for placing product within the container are disclosed. The invention includes guiding a web of film which has interlocking fastener strips sealed to the web. A slider for locking and unlocking the fastener strips is placed in the correct orientation, spread apart at a pair of inner feet, and inserted over the fastener strips. The slider is positioned to close a substantial portion of the strips, and then an end stop, docking station, and corner seal are formed against a sealing plate. The slider is then repositioned, and a tamper evident seal may be placed over the fastener strip.Apparatus and methods for placing a product in a flexible recloseable container, and also for manufacturing an empty, flexible recloseable container. One method includes providing a pair of interlockable fastener strips, a web of flexible film, and a plurality of sliders, placing the sliders on the pair of interlockable fastener strips, subsequently attaching the interlockable fastener strips with attached sliders to the web of flexible film, and either placing a product within the web or providing the empty container to the consumer.

Owner:ILLINOIS TOOL WORKS INC

Method for producing a dairy product and system for packaging the same

InactiveUS20080305209A1Conducive to preservationMore manoeuvrablePackaging cheeseMilk preparationMozzarella cheeseEngineering

The present invention relates to a method for producing and packaging a dairy product, particularly mozzarella cheese, and a packaging method therefor which is studied to facilitate the handling and improve preservability of the latter.Particularly, the present invention relates to a method for preparing and packaging a pasta filata cheese, comprising a step of substantially dry packaging, i.e. without preserving liquid, and heat packaging of said pasta filata cheese.

Owner:EGIDIO GALBANI SRL

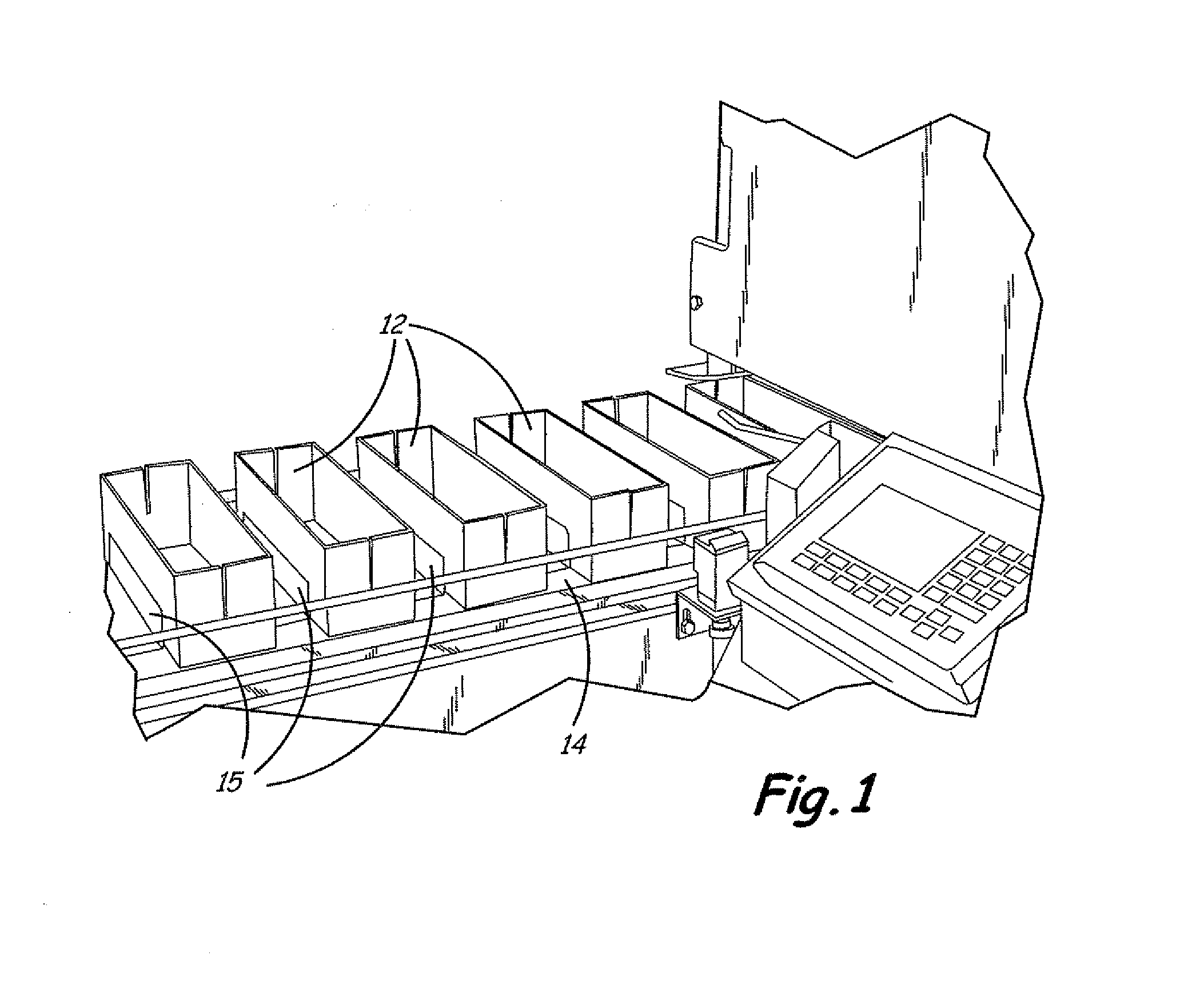

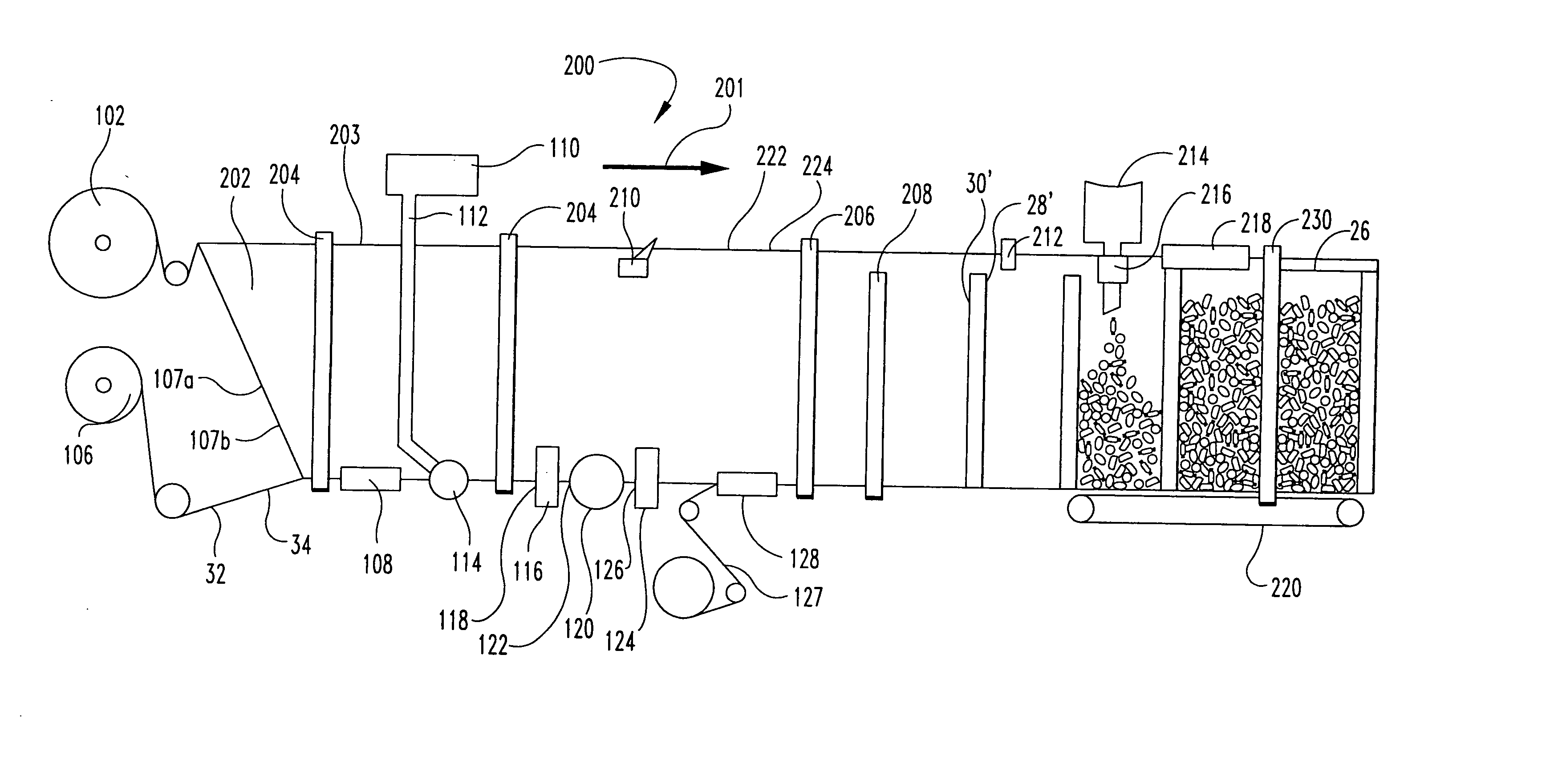

Horizontal form, fill and seal machine for loose fitting packages

A horizontal form, fill and seal machine has a hollow forming box into which a continuous film is longitudinally fed from a packaging film supply. The forming box has a top, sides and open inlet and outlet ends. A pair of guide bars extend from the outlet end of the forming box adjacent the forming box sides and extending away from the inlet end. The forming box transforms the flat packaging film into a film envelope that extends about the guide bars and has a product-receiving surface that rests on a conveyor between the guide bars. Sealing bars are provided to join the longitudinal edges of the packaging film together and to form seals across the envelope at package length intervals after each deposit of product onto the product-receiving surface. A zipper attaching mechanism applies zipper to the film upstream of the forming box.

Owner:ILLINOIS TOOL WORKS INC

Pouch or packaging for foodstuffs made of a peelable film and process for the production thereof

An airtight pouch or packaging (10, 20) made of synthetic material for the preservation of food products (12) is obtained by sealing (13, 14, 15) and cutting said synthetic material by an automatic packaging machine with a horizontal or vertical motioning of the product. The packaging (10, 20) is constituted by a single peelable type film (11) consisting of an oriented polyamide layer coupled with a coextruded peelable polyethylene layer, said film being folded once on the polyethylene layer side in order to form the inner part of said packaging.

Owner:PFM

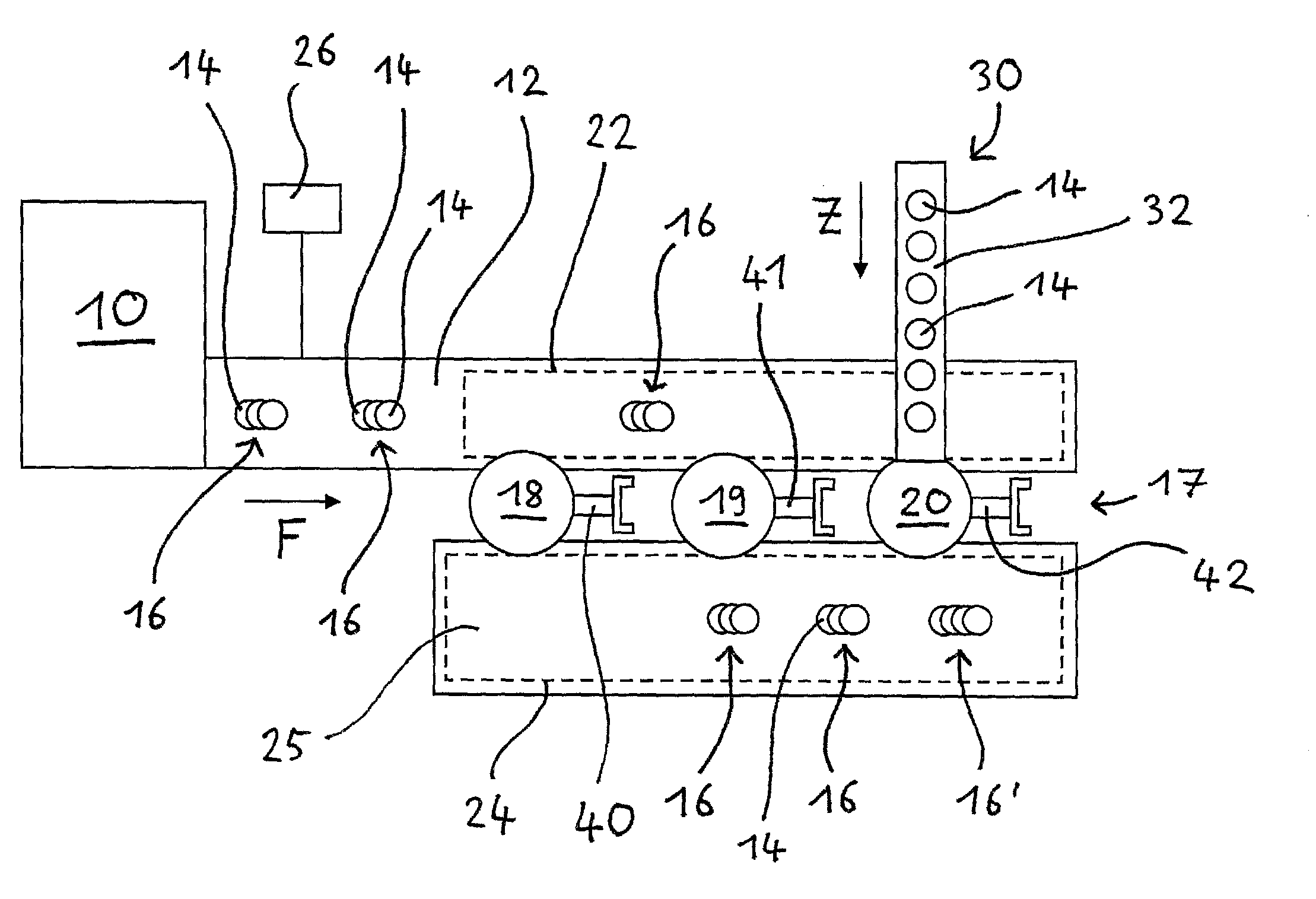

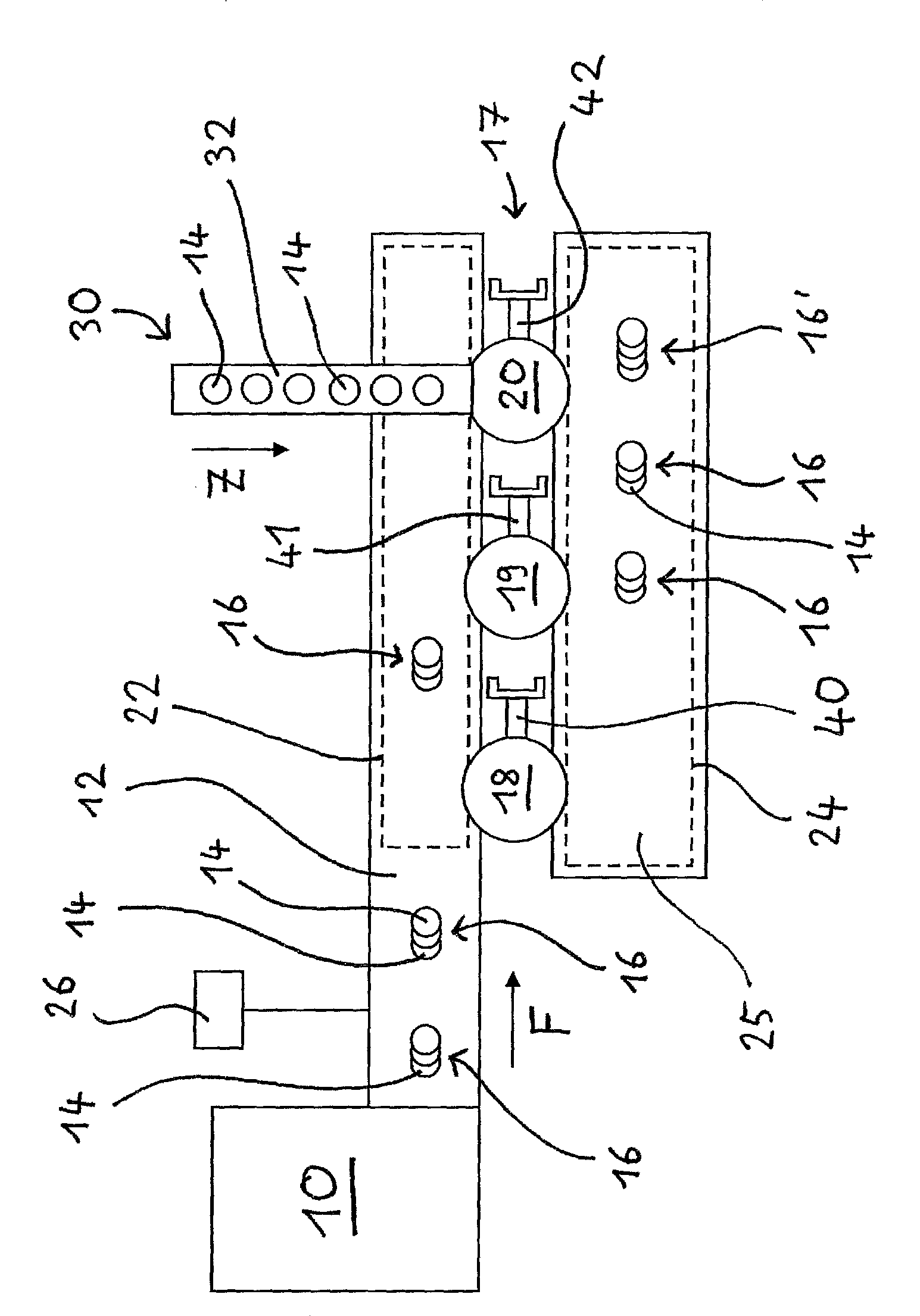

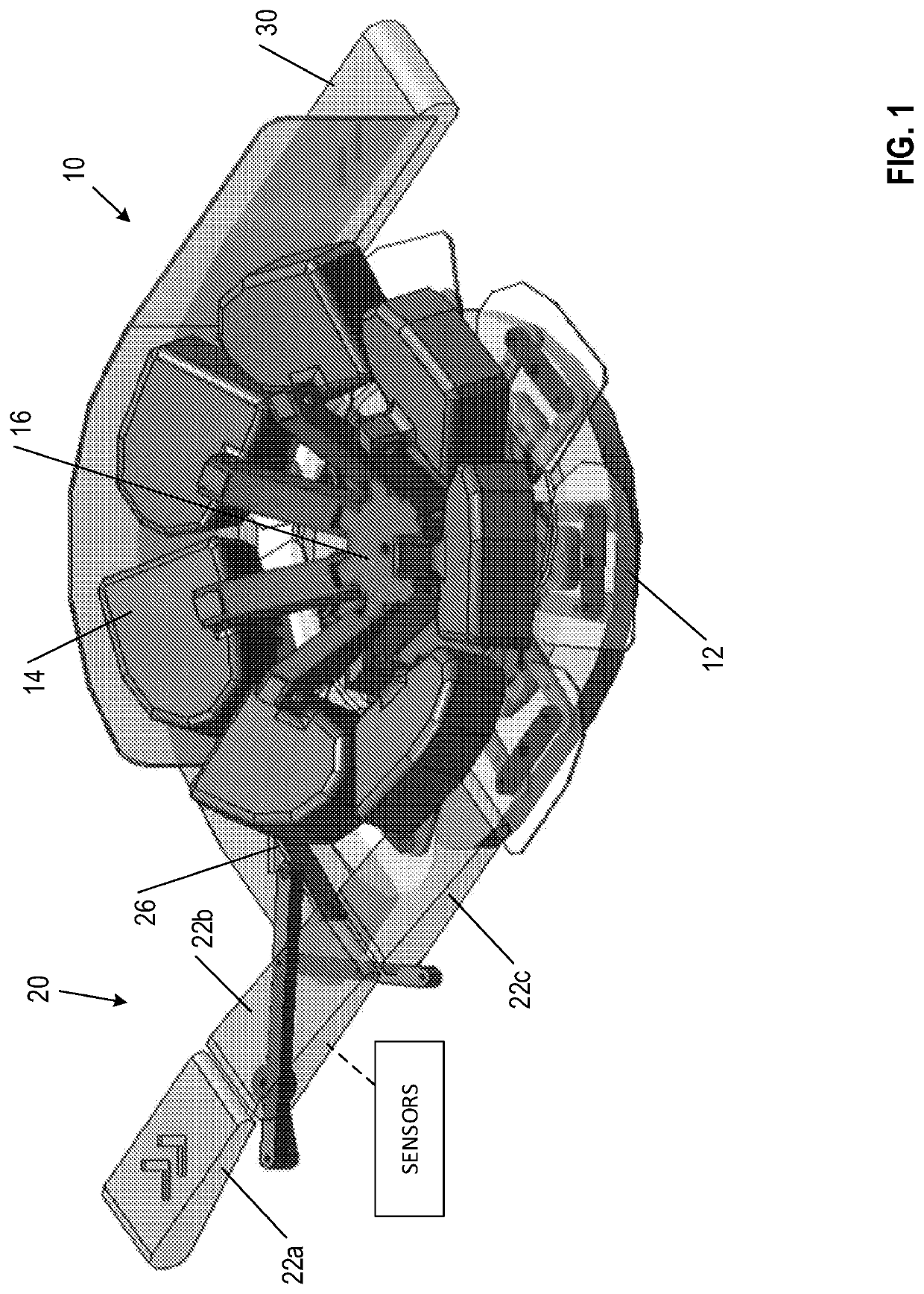

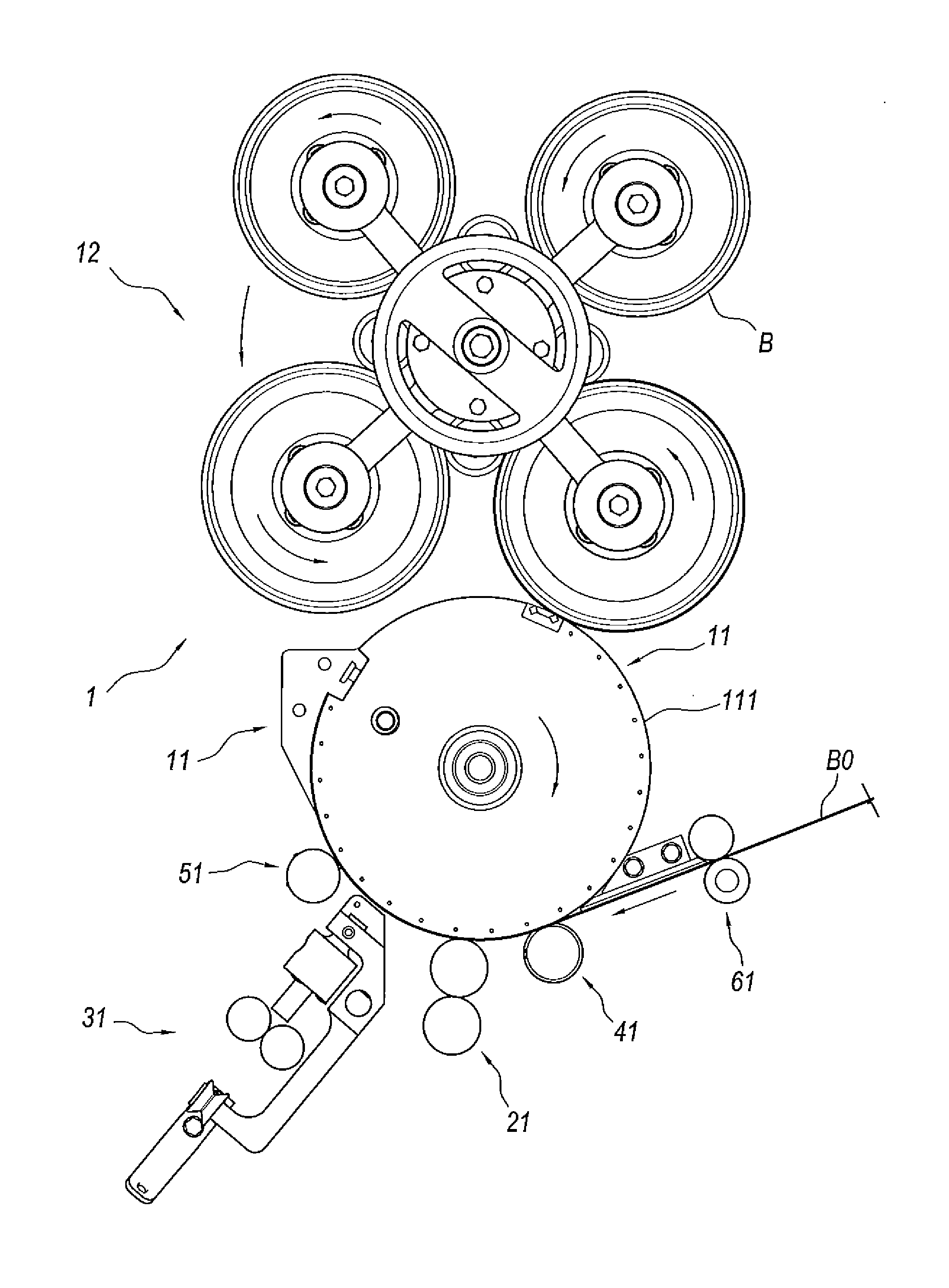

Apparatus and method for vacuumizing and sealing a package

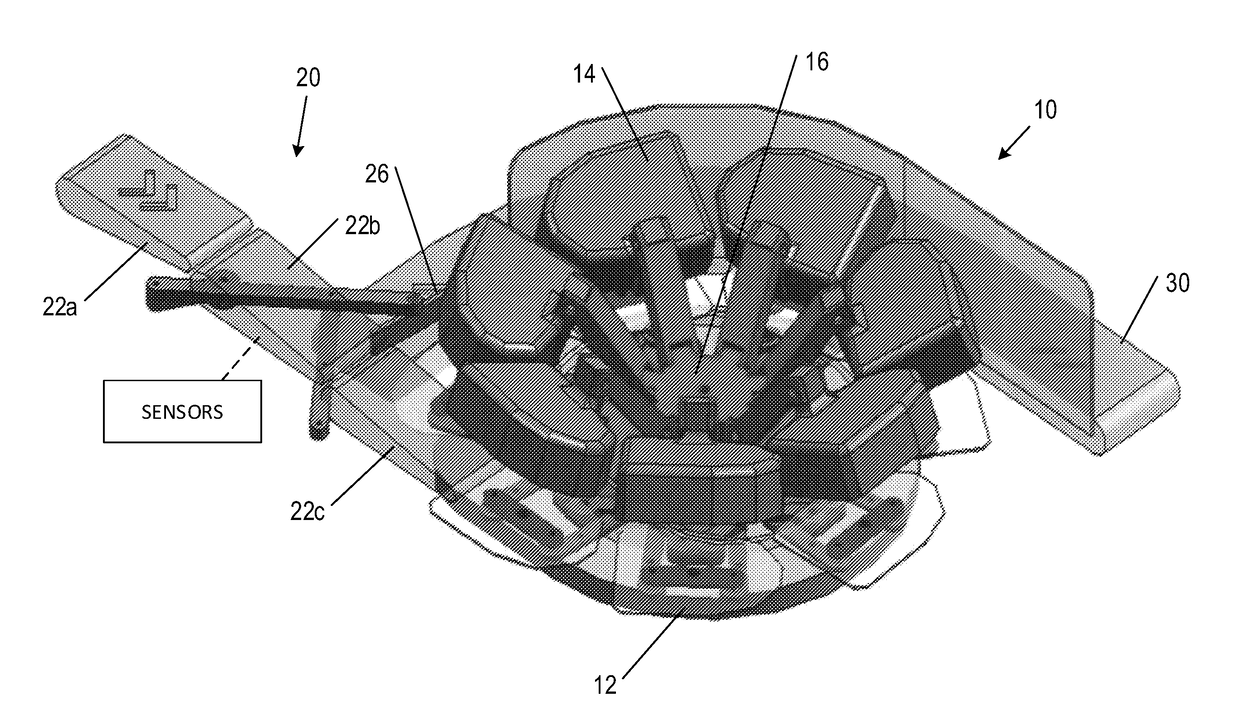

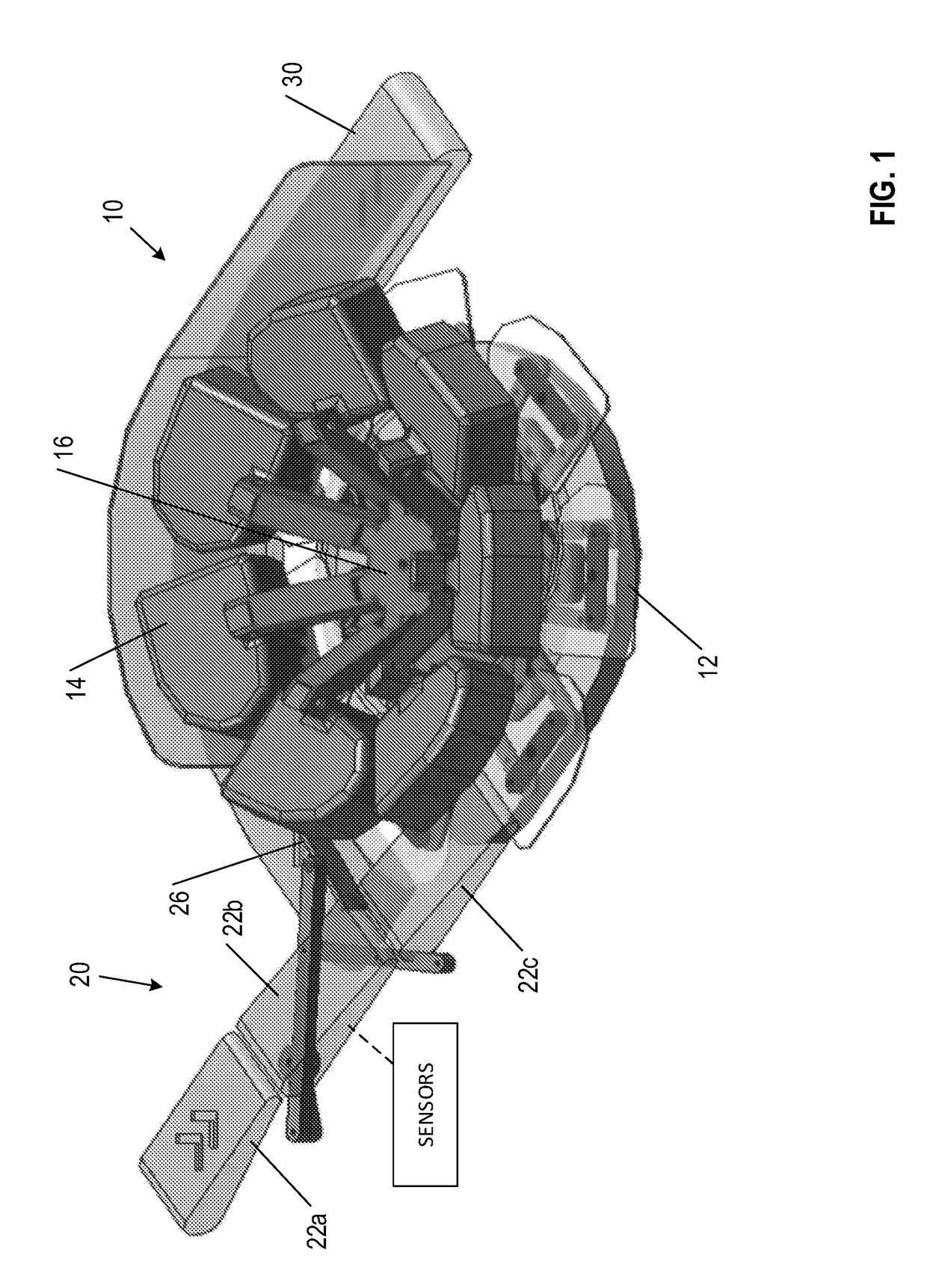

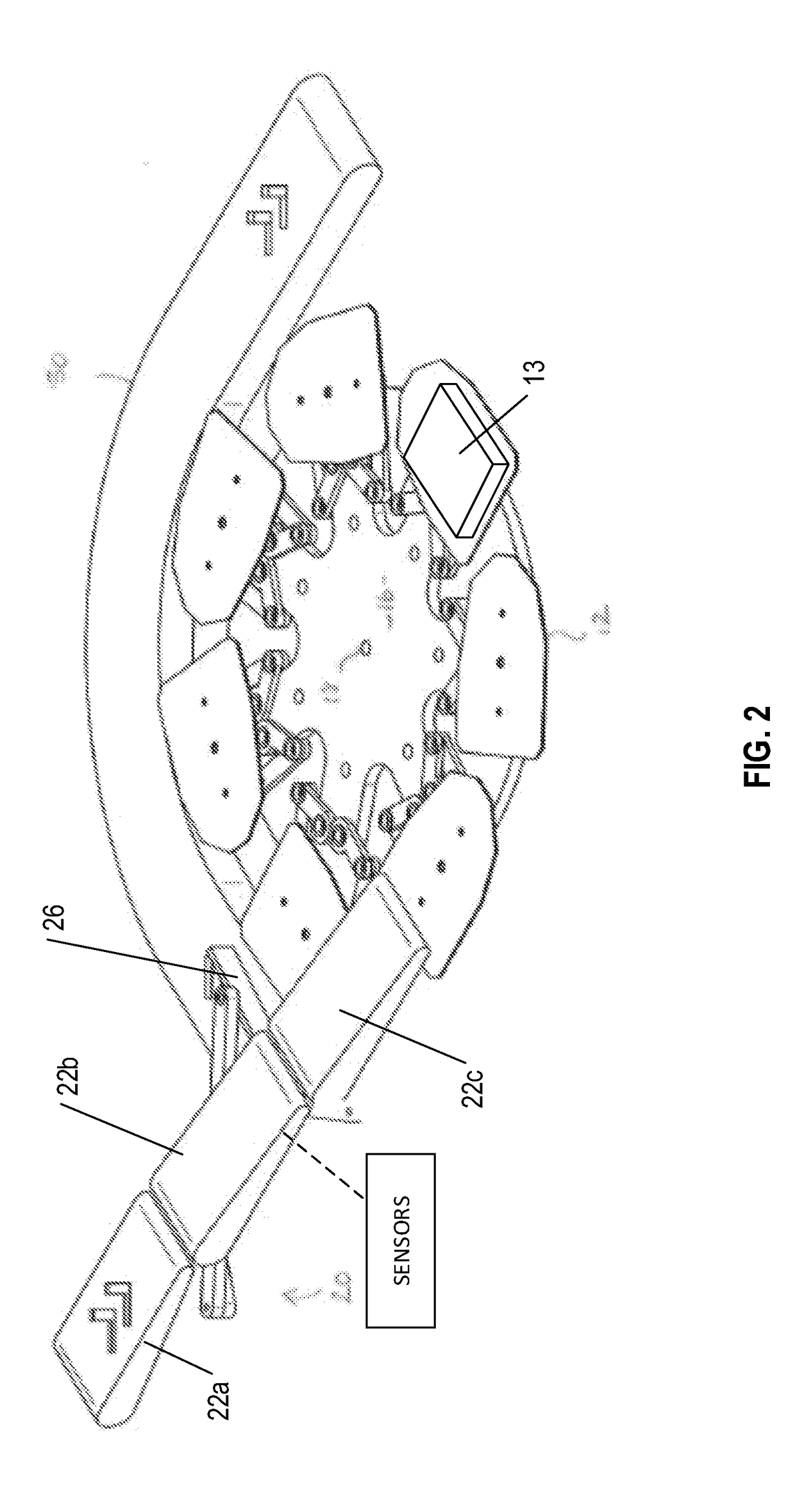

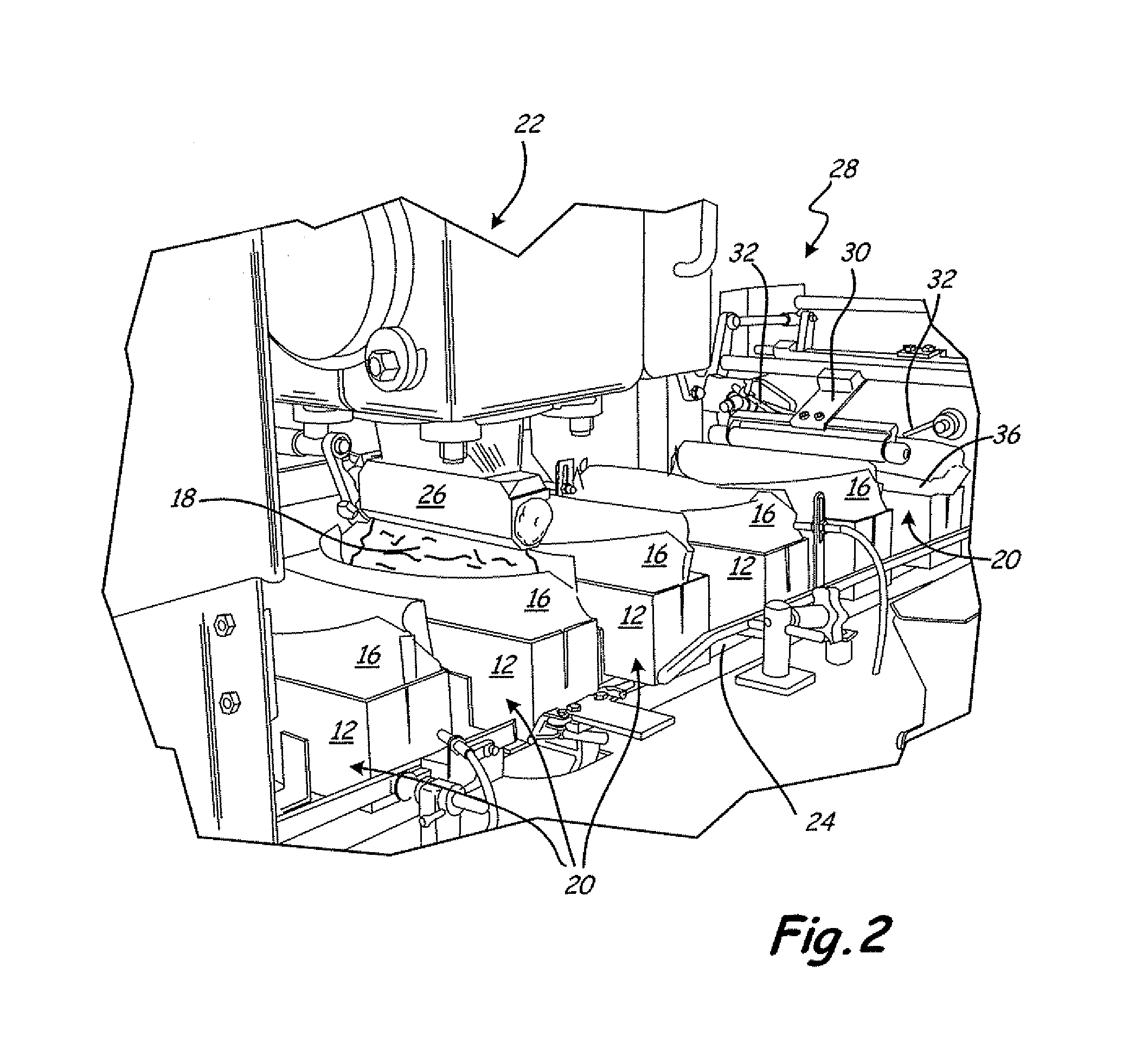

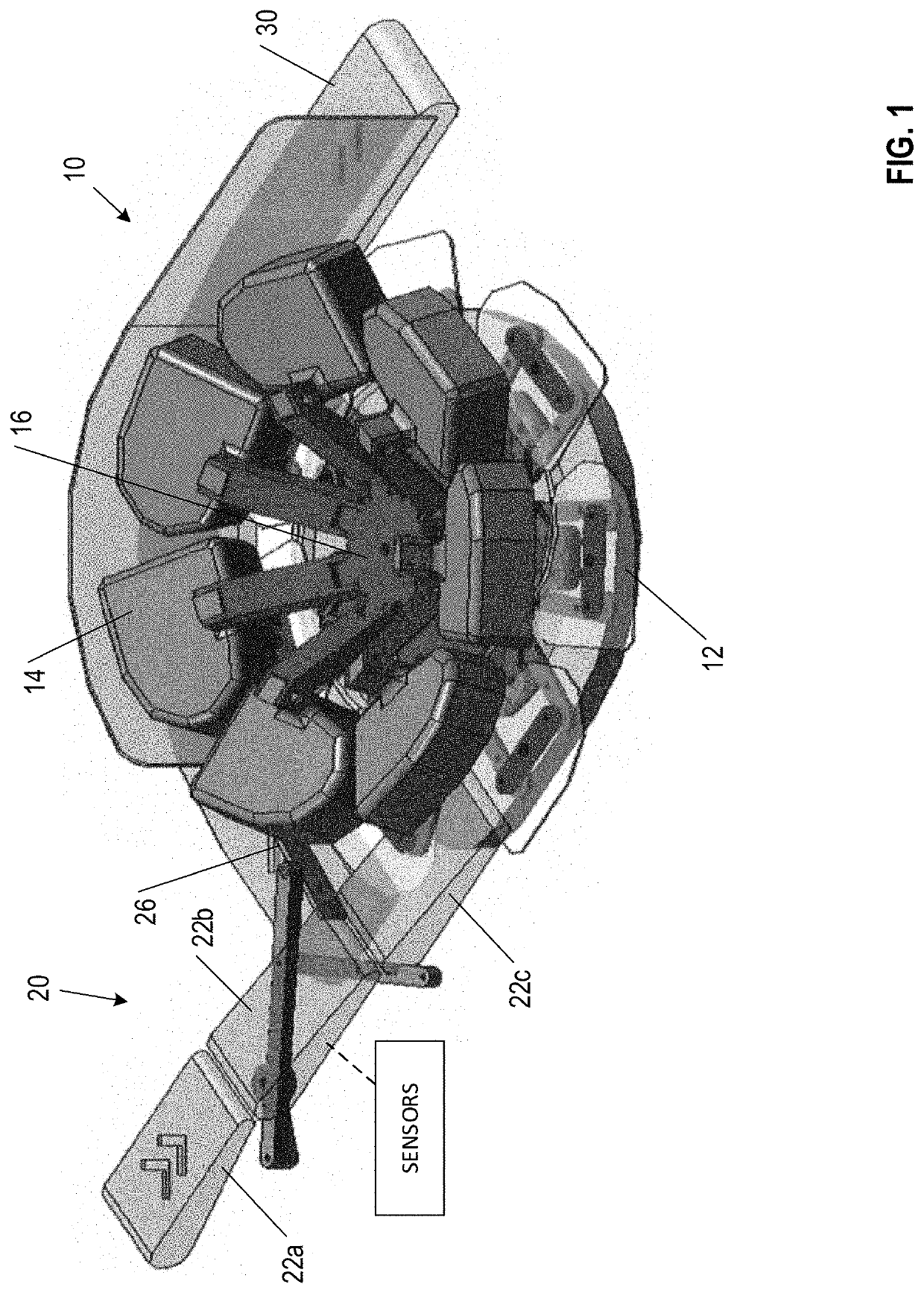

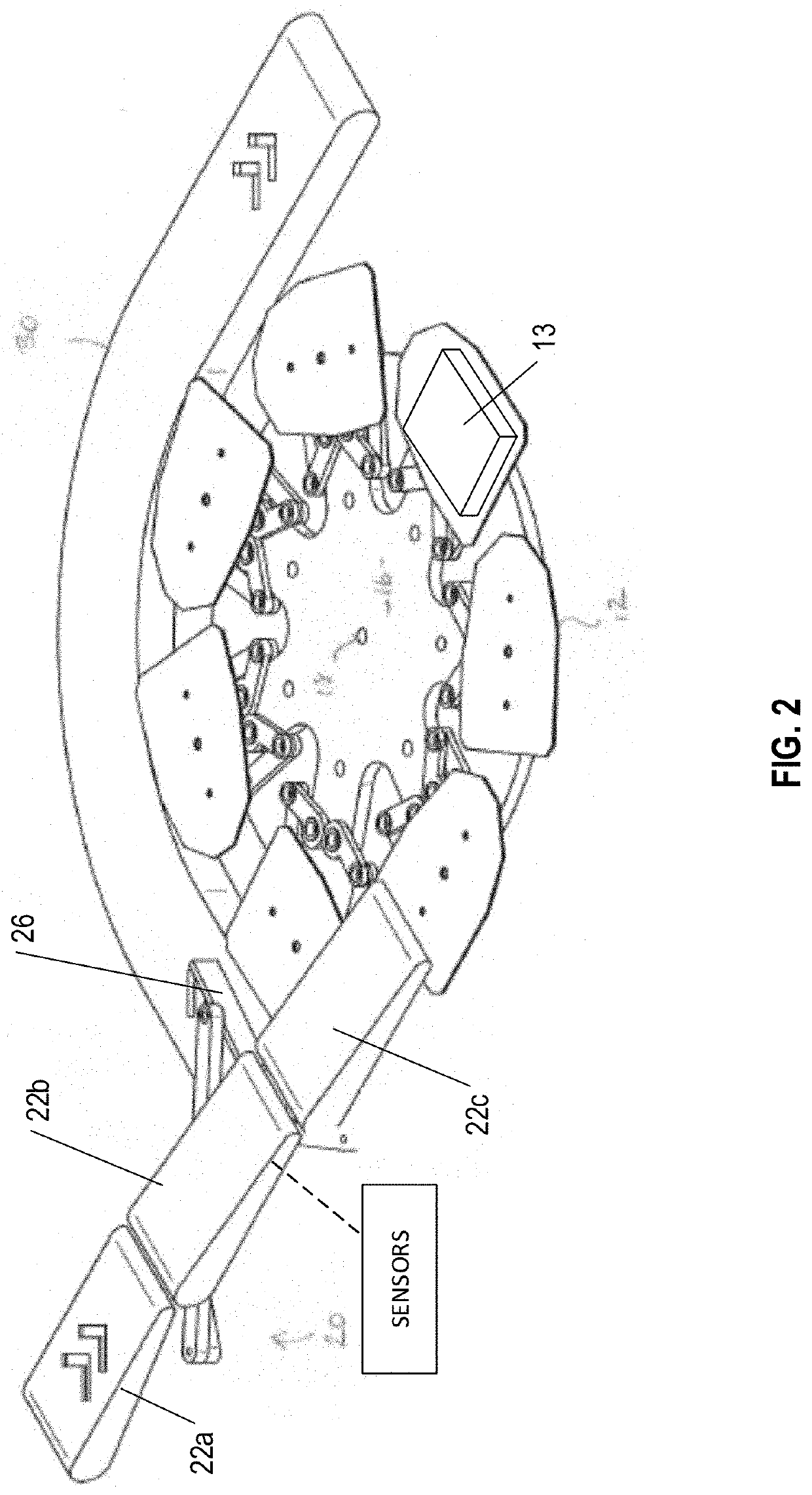

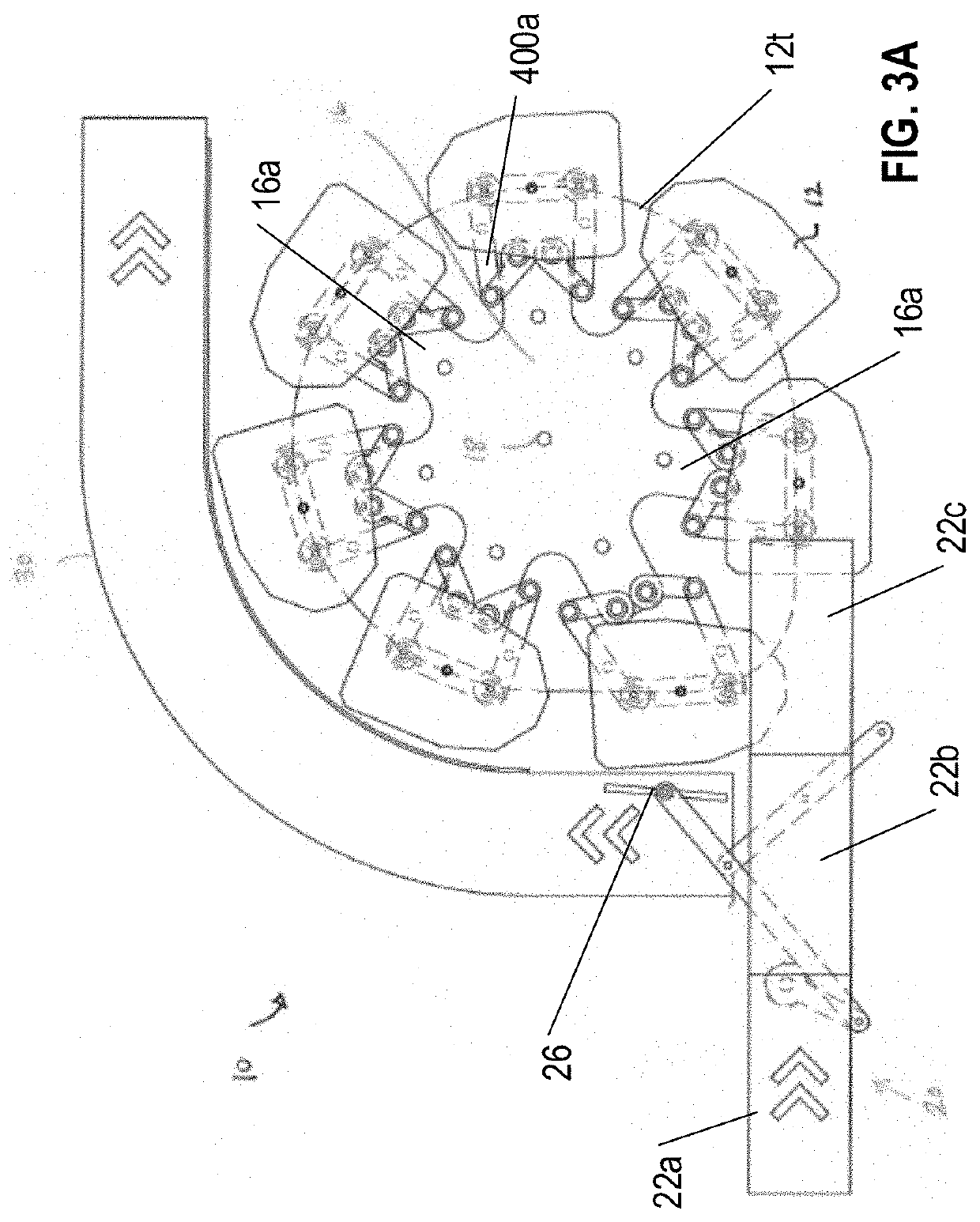

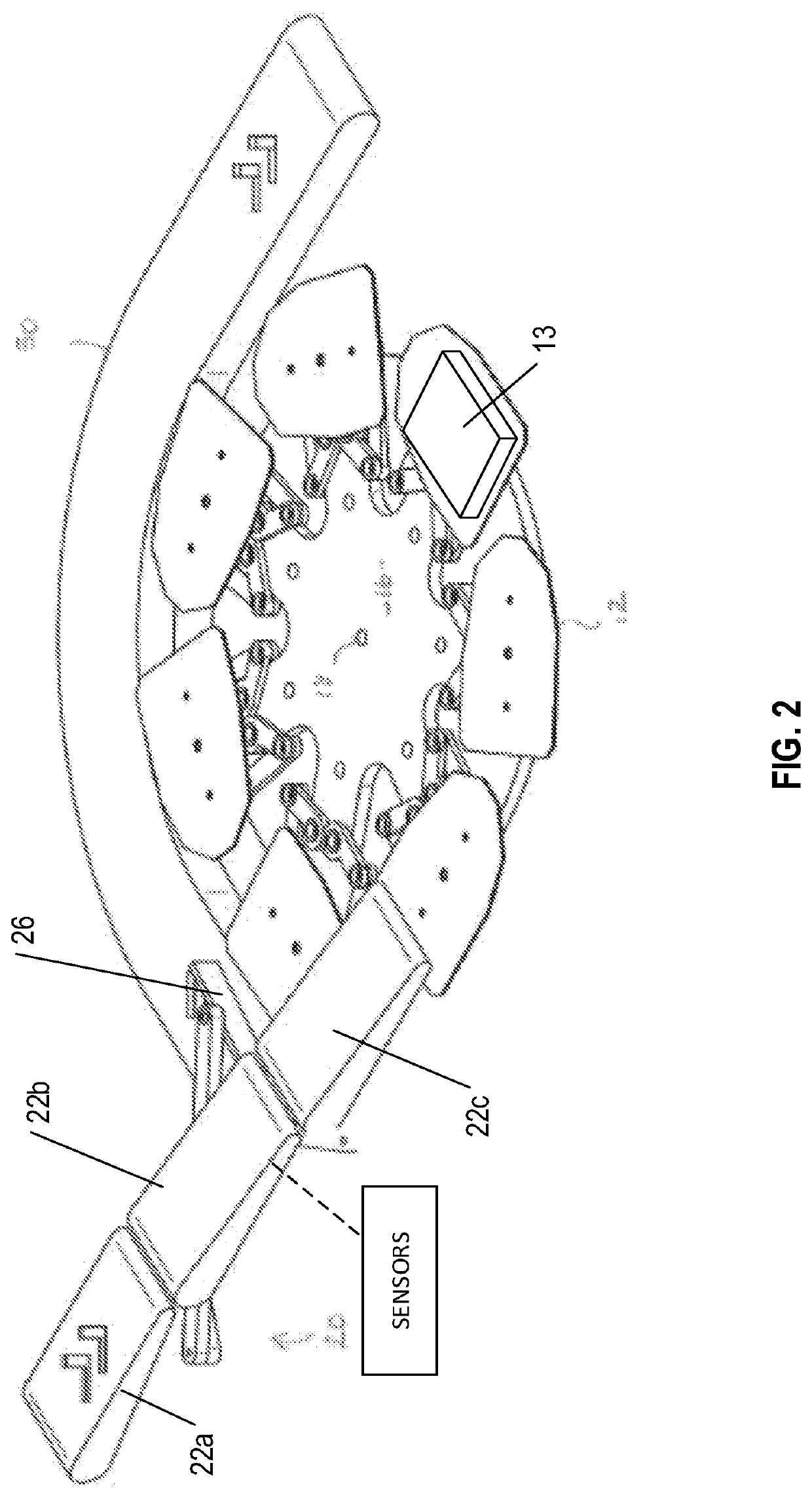

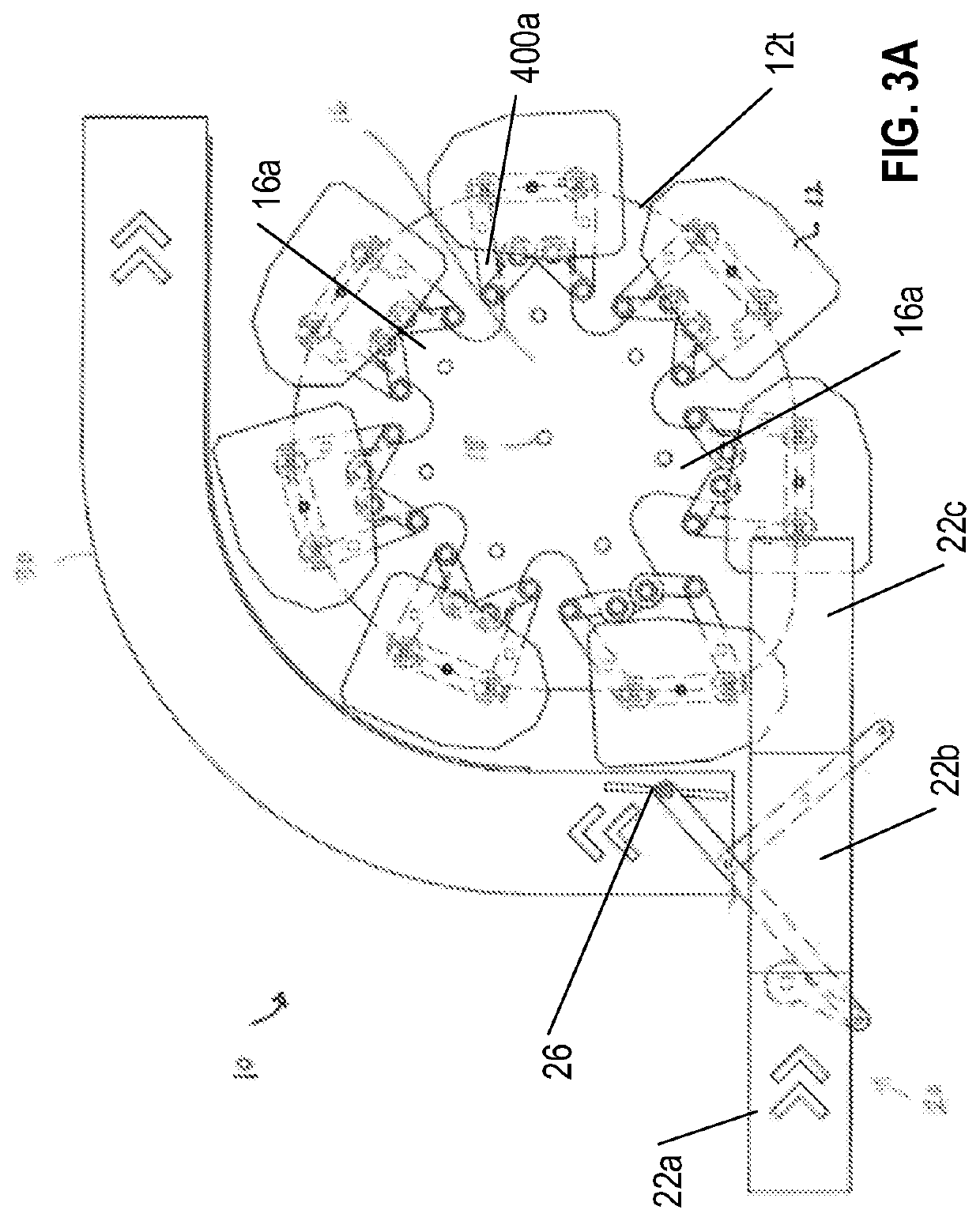

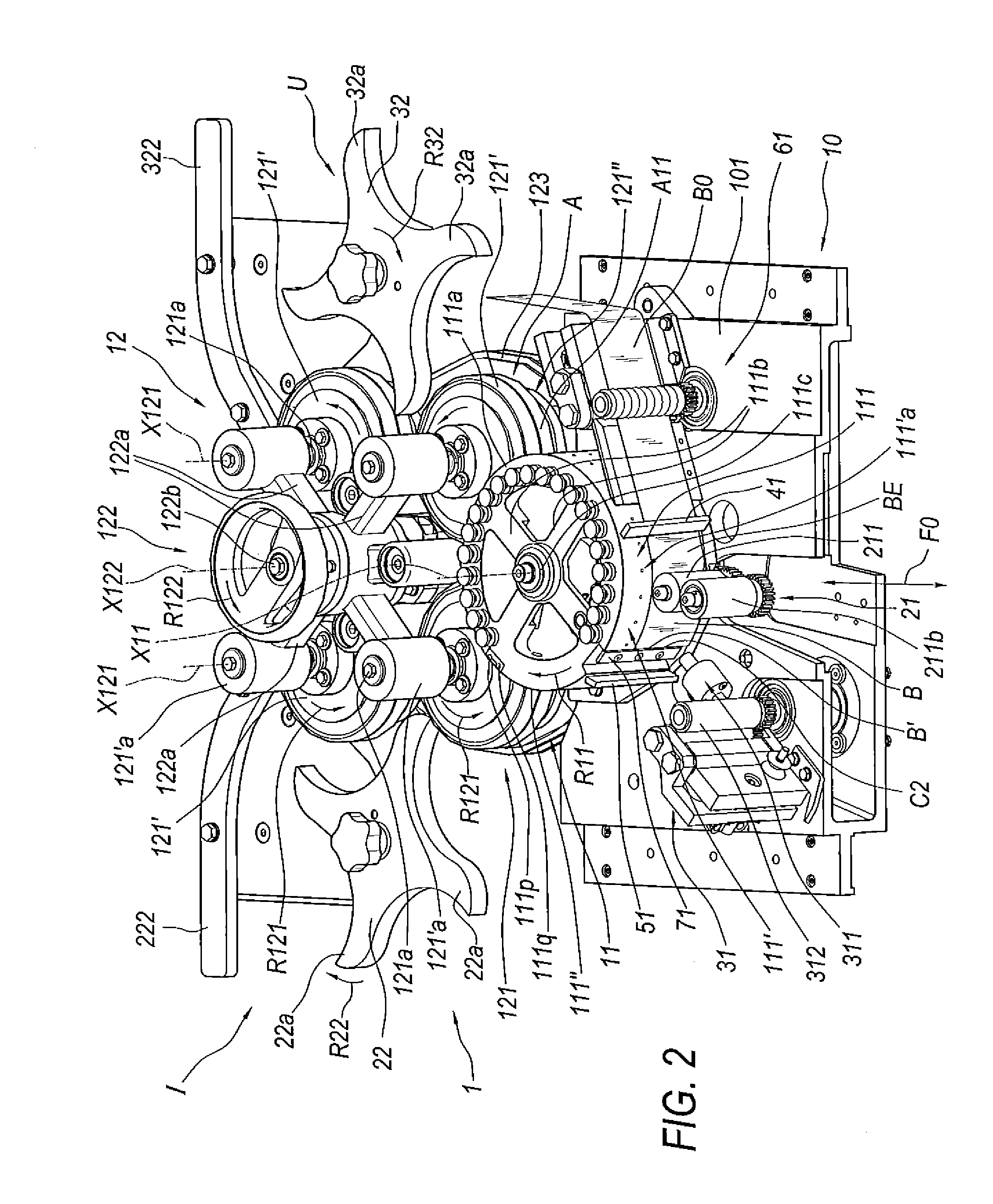

ActiveUS20180259092A1Reduced operating footprintEasy to unloadWrappers shrinkagePackaging cheeseLinear componentEngineering

An apparatus (10) for vacuumizing and sealing a package (322) includes a plurality of platens (12) and vacuum chambers (14), each chamber (14) adapted to mate with a dedicated one of the platens (12); a conveying system (16) for conveying the platens (12) and chambers (14) along a generally angular path having a single axis of rotation (18); an automated loading assembly (20) having a linear component (22c) and configured to load a package (322) onto each of the platens (12); an automated unloading assembly (26) having a linear portion and configured to unload a vacuumized, sealed package (322) from each loaded platen (12) onto an outfeed conveyor (30); and a vacuumizing / sealing system configured to cause relative movement of each chamber (14) / platen (12) pair, along a portion of the angular path, to form therebetween an air-tight enclosure accommodating the package (322) and effect vacuumization and sealing of the package (322).

Owner:FURUKAWA MFG +1

Method and apparatus for placing a product in a flexible recloseable container

InactiveUS6907713B2Easy to placePackaging cheeseEnvelopes/bags making machineryThin membraneFastener

An invention for forming, filling, and sealing a flexible recloseable container. Both vertical and horizontal methods for placing product within the container are disclosed. The invention includes guiding a web of film which has interlocking fastener strips sealed to the web. A slider for locking and unlocking the fastener strips is placed in the correct orientation, spread apart at a pair of inner feet and inserted over the fastener strips. The slider is positioned to close a substantial portion of the strips, and then an end stop, docking station, and corner seal are formed against a sealing plate. The slider is then repositioned, and a tamper evident seal may be placed over the fastener strips.

Owner:ILLINOIS TOOL WORKS INC

Methods for sealing overlapped flexible packaging material using an electrical impulse through a conductive element

ActiveUS8484937B1Improve sealingEasy to openPackaging cheeseWrapper twisting/gatheringHermetic sealElectrical impulse

This disclosure relates to foiiuing food packages with a lap seal. A continuous, peelable hermetic seal is formed by activating a conductive element to emit an electrical impulse while contacting the overlap region of a pouch. The overlap is sealed by the heat generated from the activation of the conductive element, for example a wire. The conductive element is placed longitudinally along the overlap area of the pouch, which results in a sealed line. A second parallel sealed line may also be made to add redundancy, thereby better sealing the pouch. The disclosed method results in a package with an unsealed flap between first seal line and the film edge that allows for easy opening of the pouch.

Owner:LAND O'LAKES

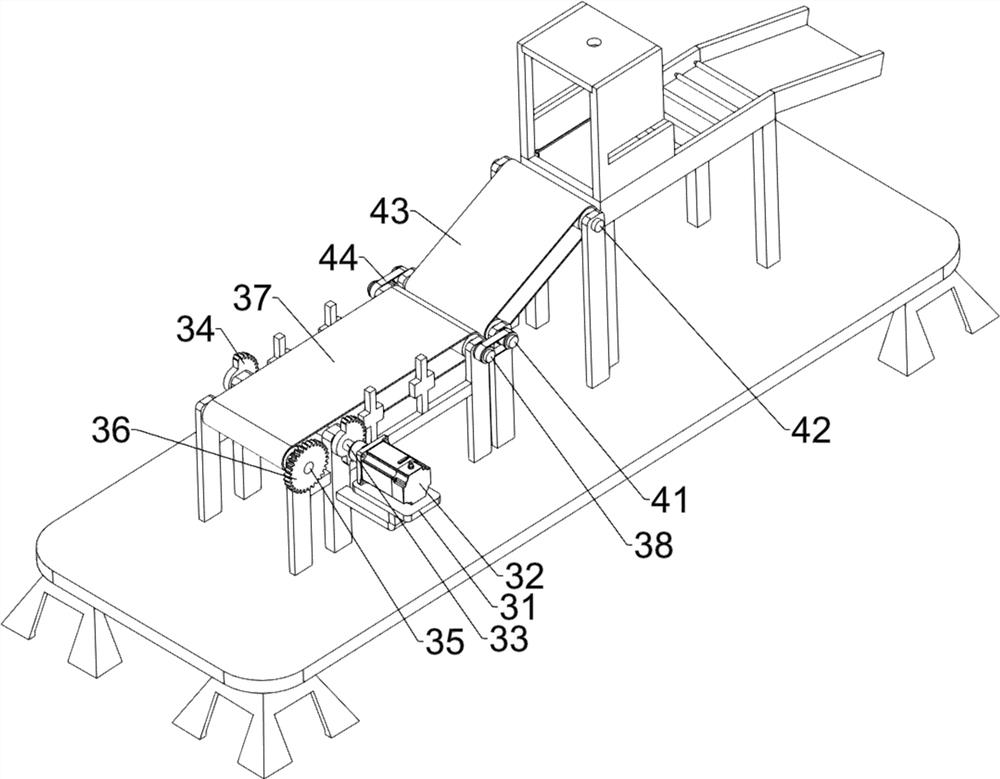

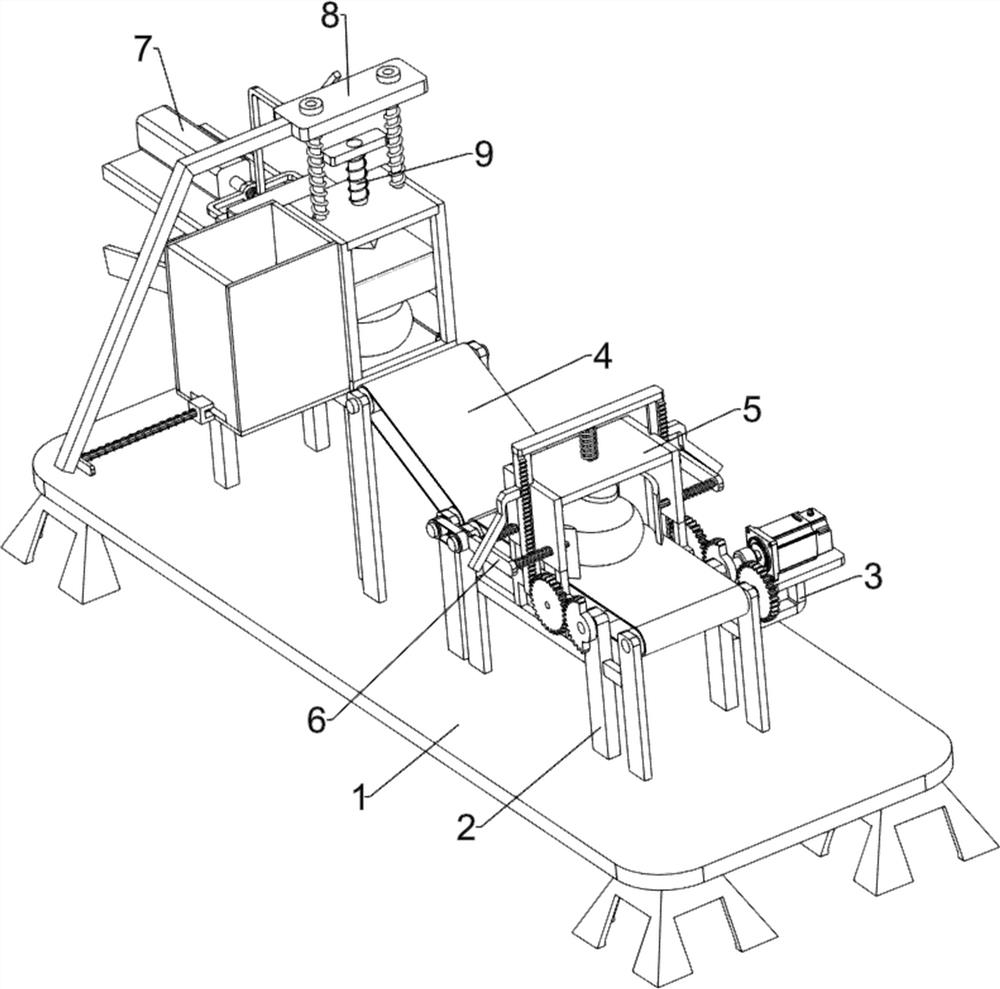

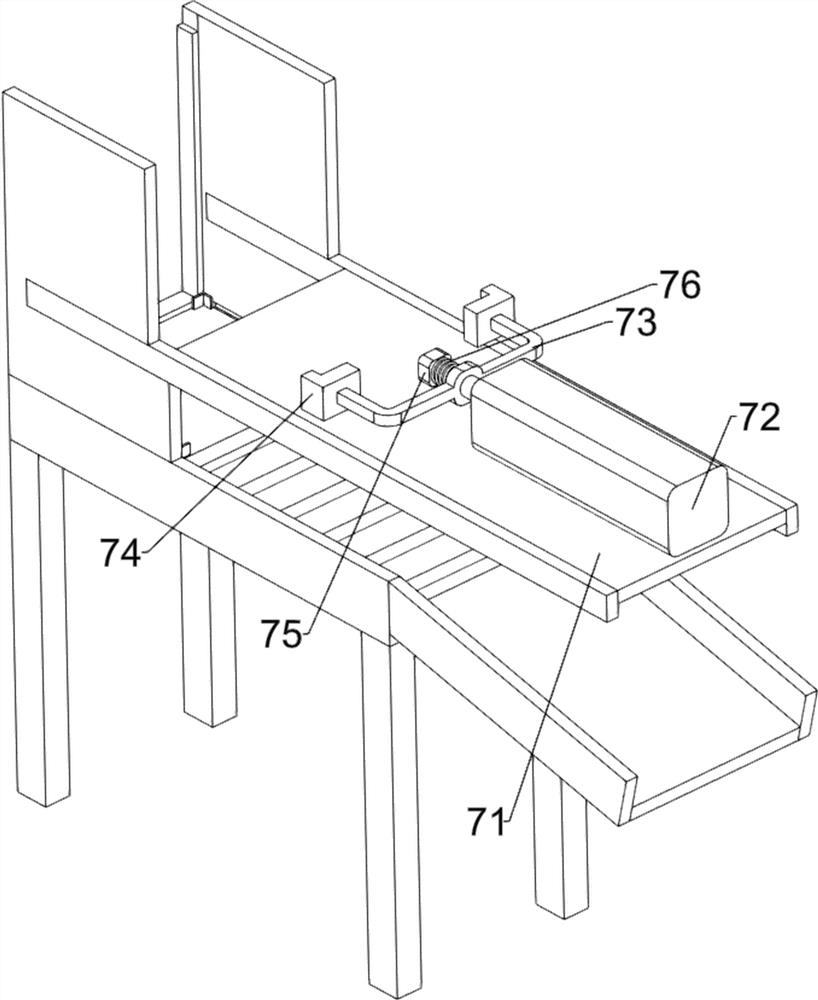

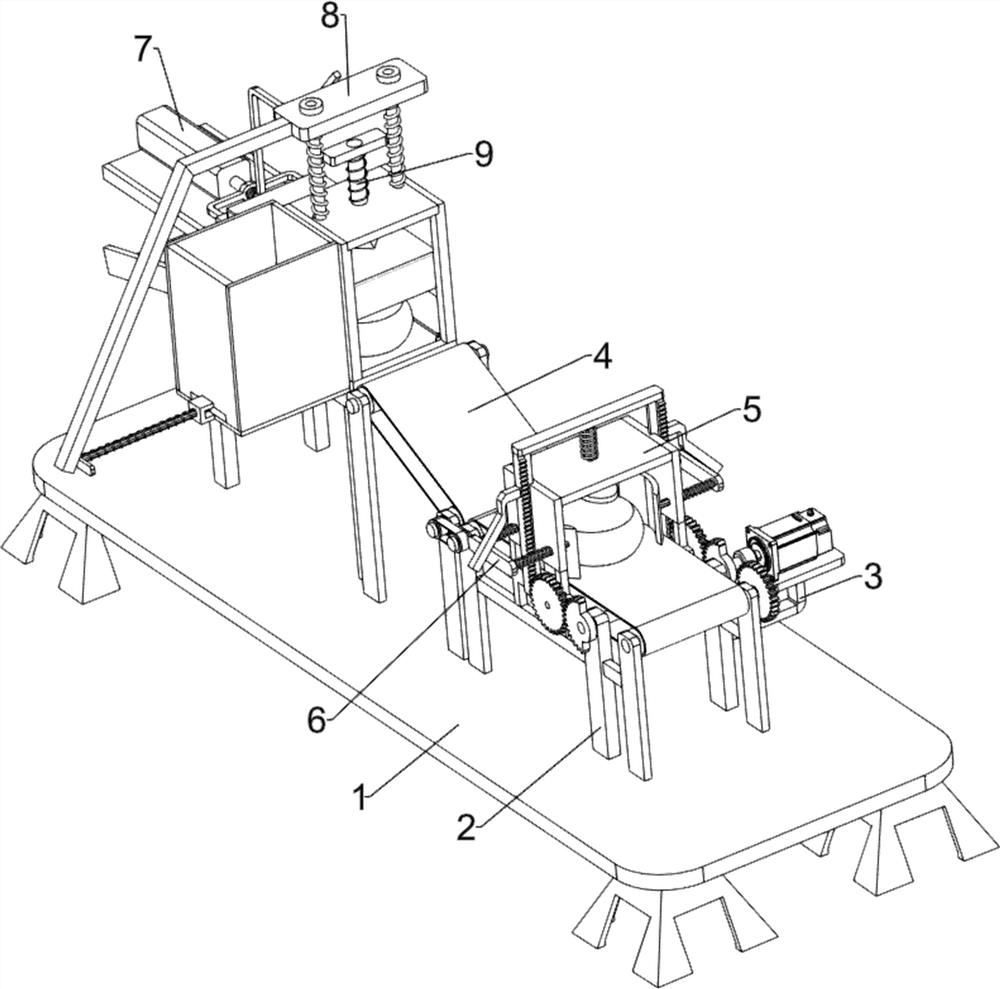

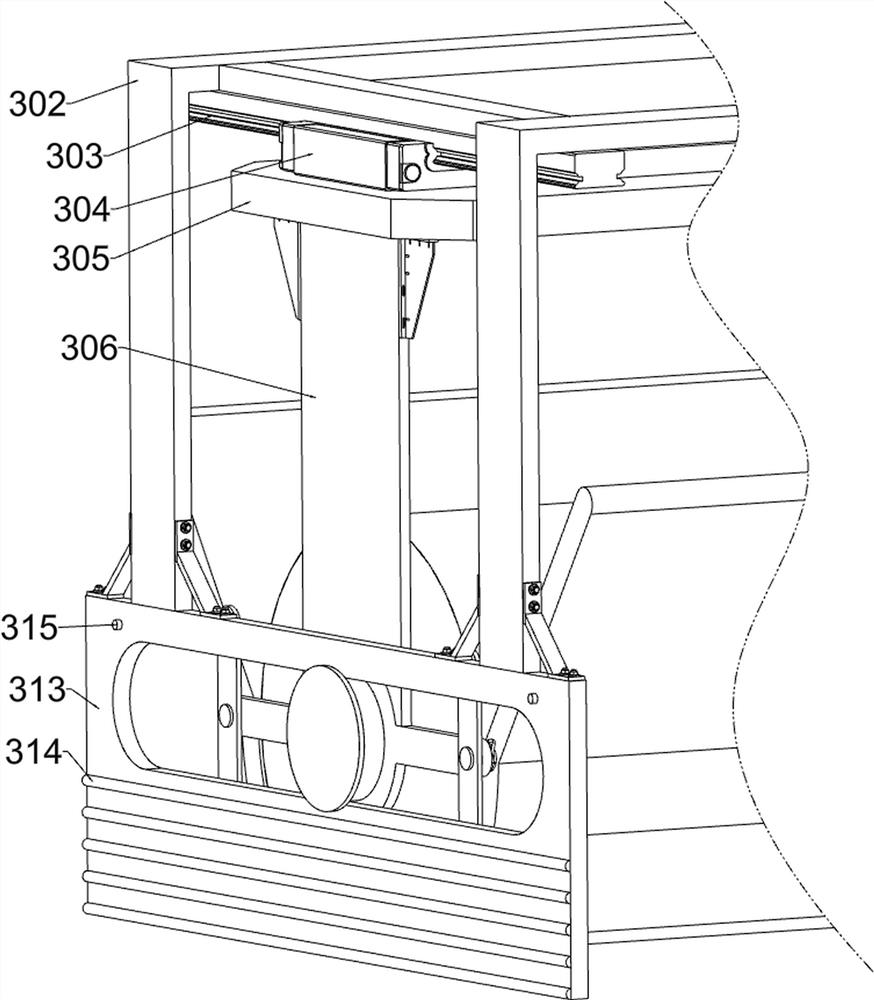

Cheese conveying equipment for food production

ActiveCN112429343AEasy to printPackaging cheeseRotary pressesProcess engineeringIndustrial engineering

The invention relates to conveying equipment, in particular to cheese conveying equipment for food production. The cheese conveying equipment for food production can convey cheese more automatically,print the production date of the cheese and pack the outer package of the cheese. The cheese conveying equipment for food production comprises a base, a rack, a primary transmission mechanism and a secondary transmission mechanism, wherein the rack is arranged at the top of the base; the primary transmission mechanism is arranged on the upper portion of one side of the rack; and the secondary transmission mechanism is arranged on the rack. According to the cheese conveying equipment for food production, a pressing mechanism is arranged, a pressing plate in the pressing mechanism moves downwards, thus a pressing rod is driven to move downwards to press a cover clamped above the cheese downwards, a sixth spring is extruded, and when the cover and a bottom plate are fixed, the cheese is completely packaged, and the effect of replacing manual cheese packaging is achieved.

Owner:SHANDONG GAOTANGYONGWANG FOOD CO LTD

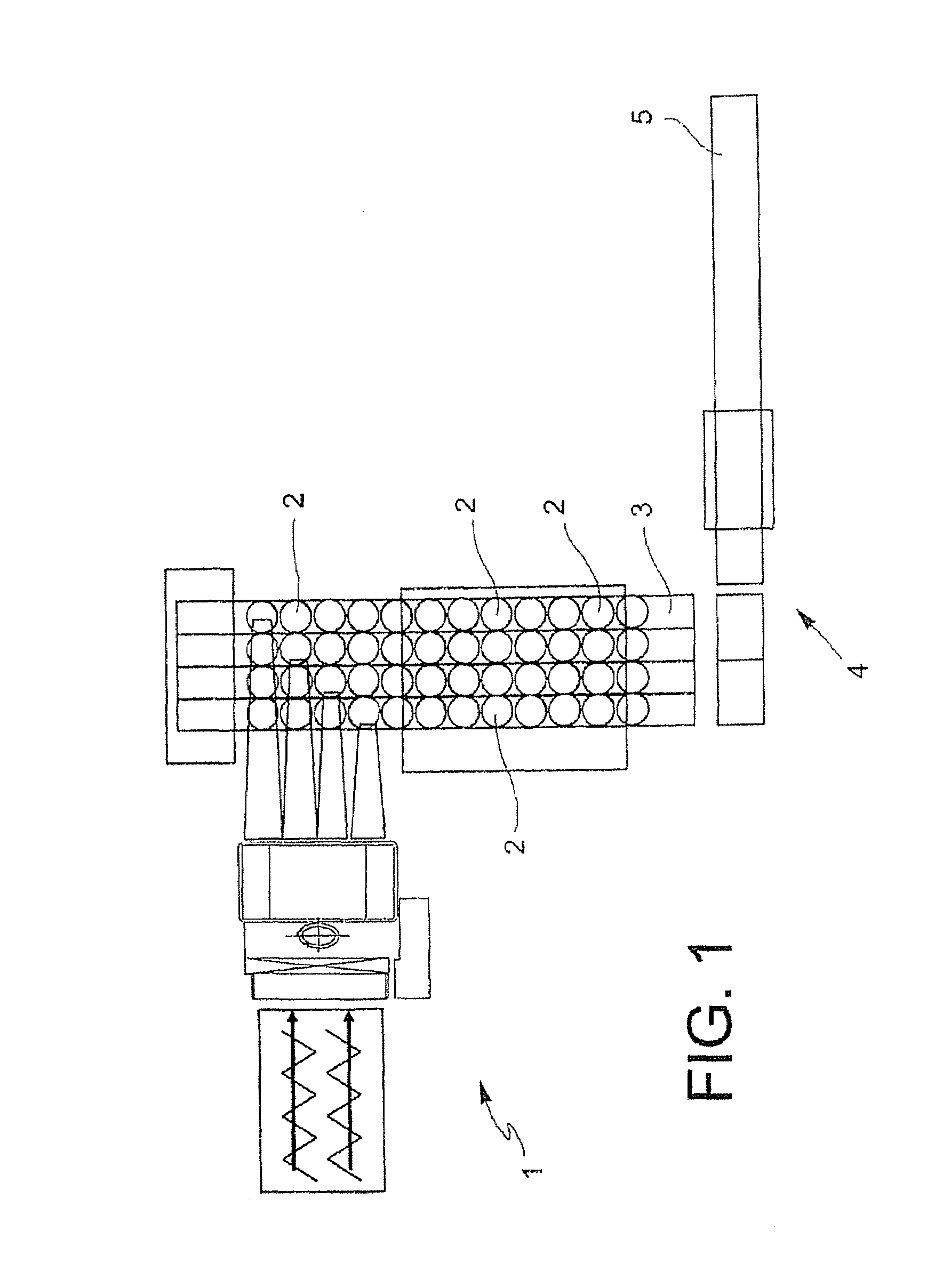

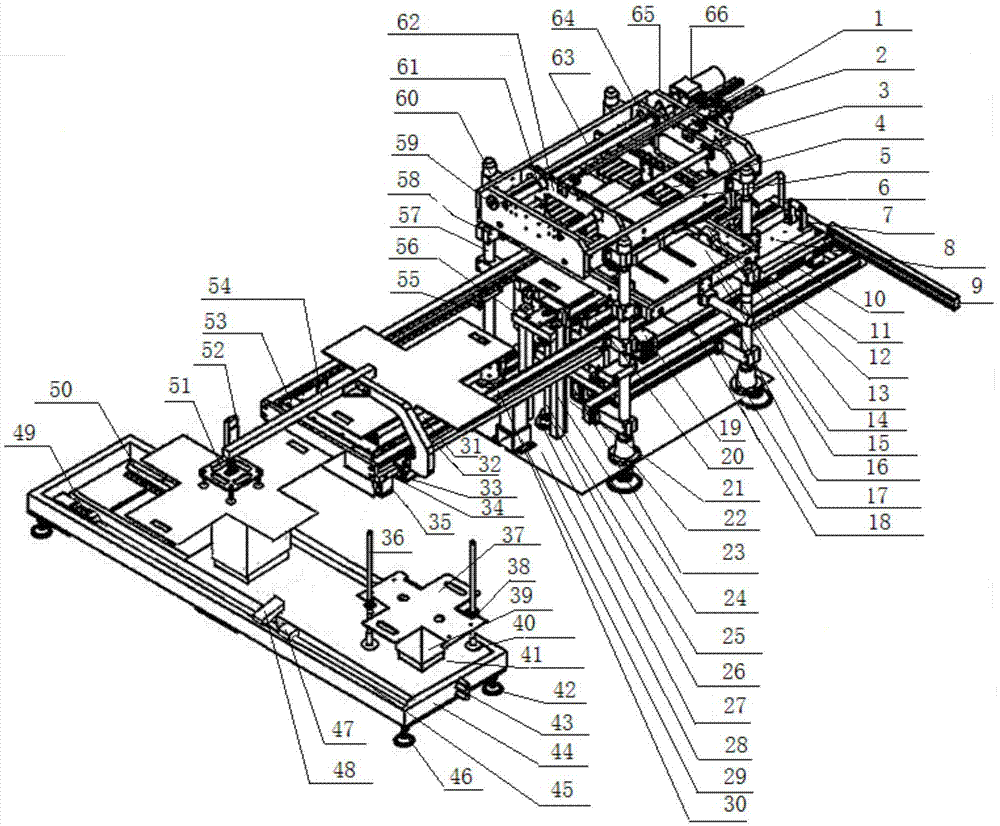

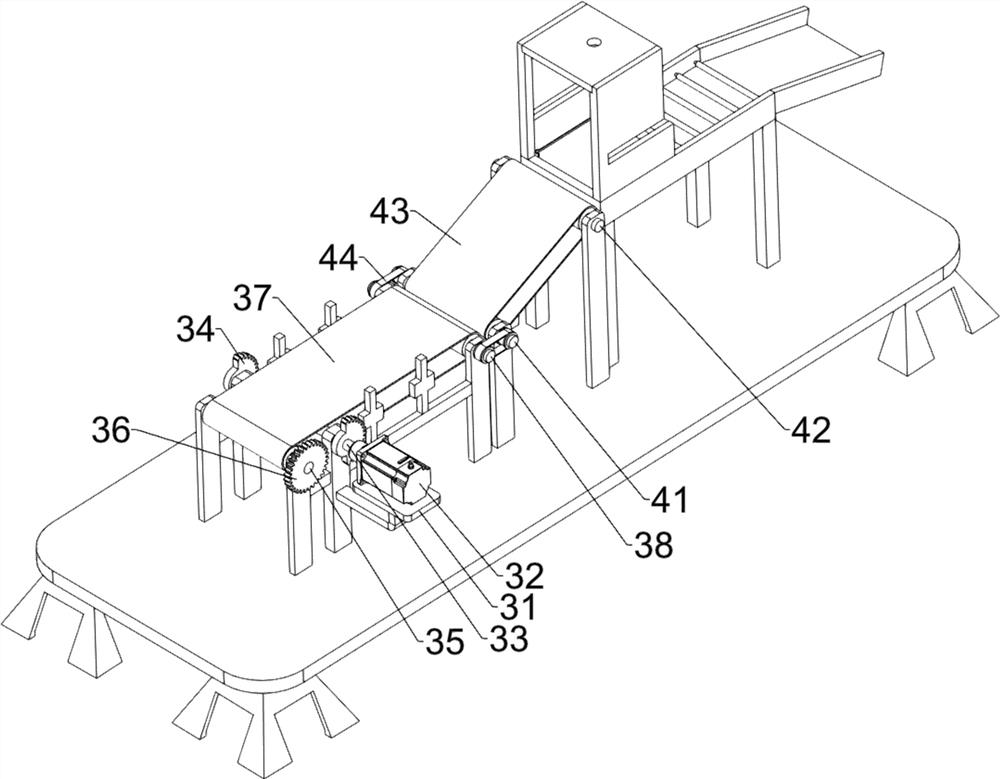

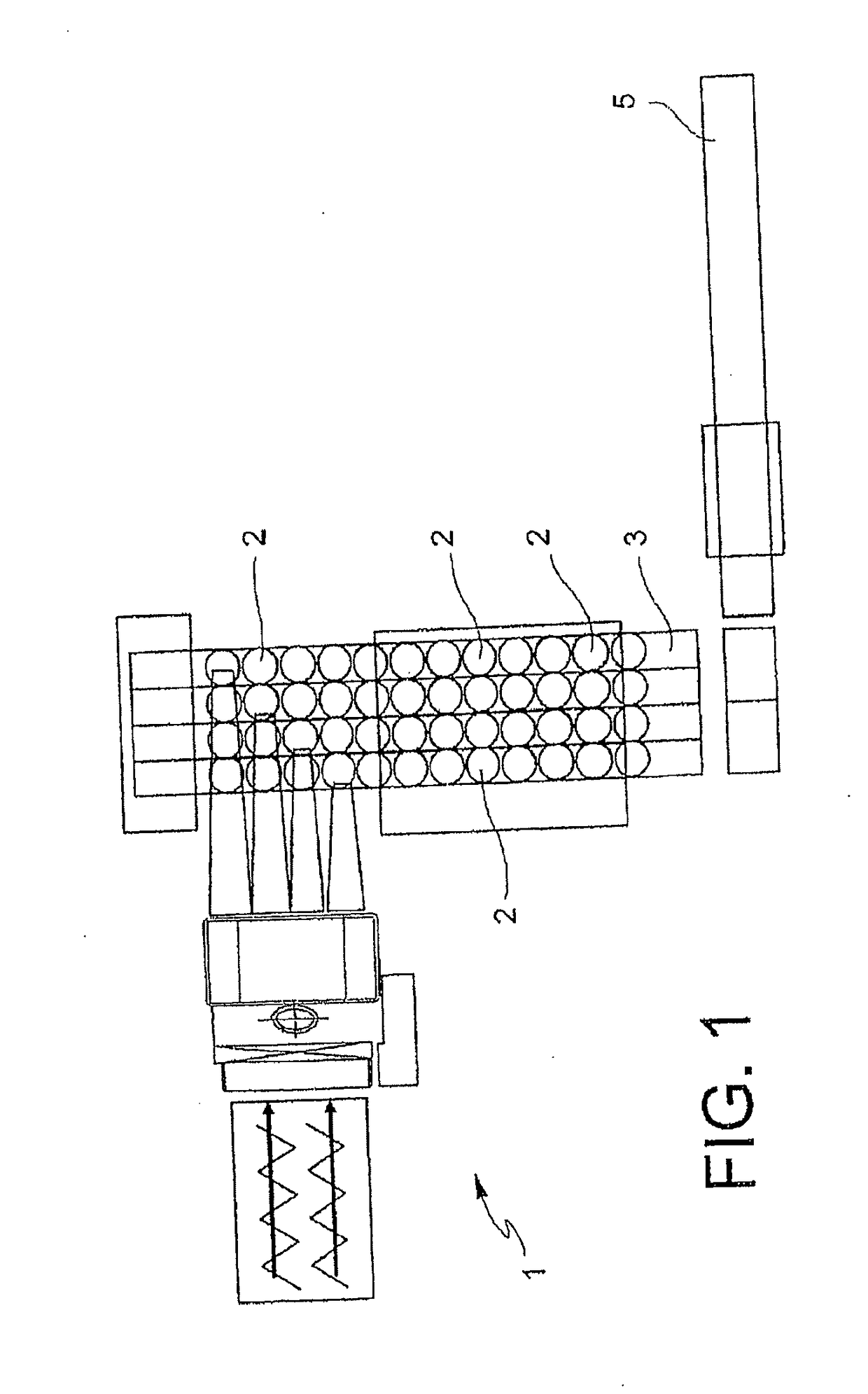

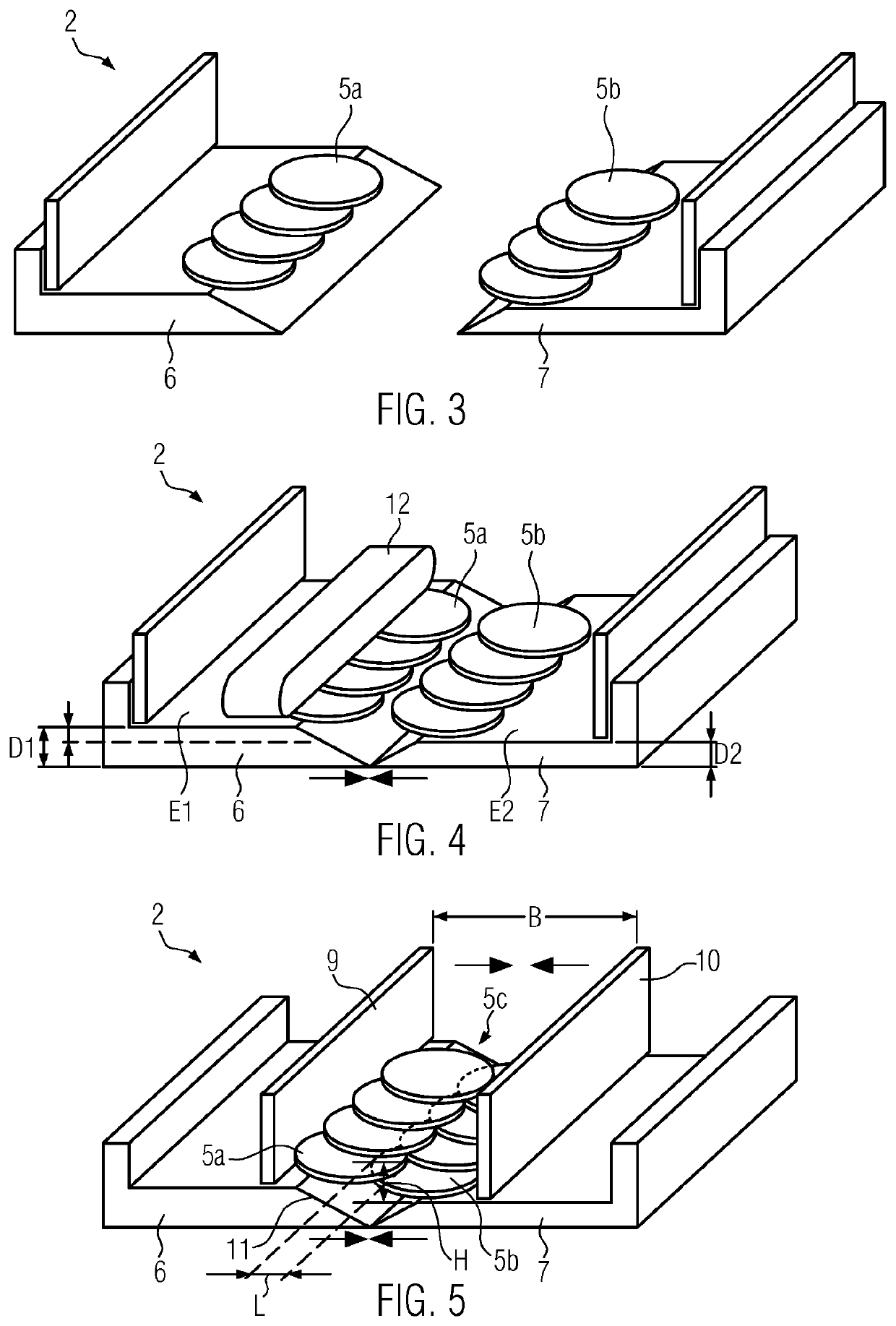

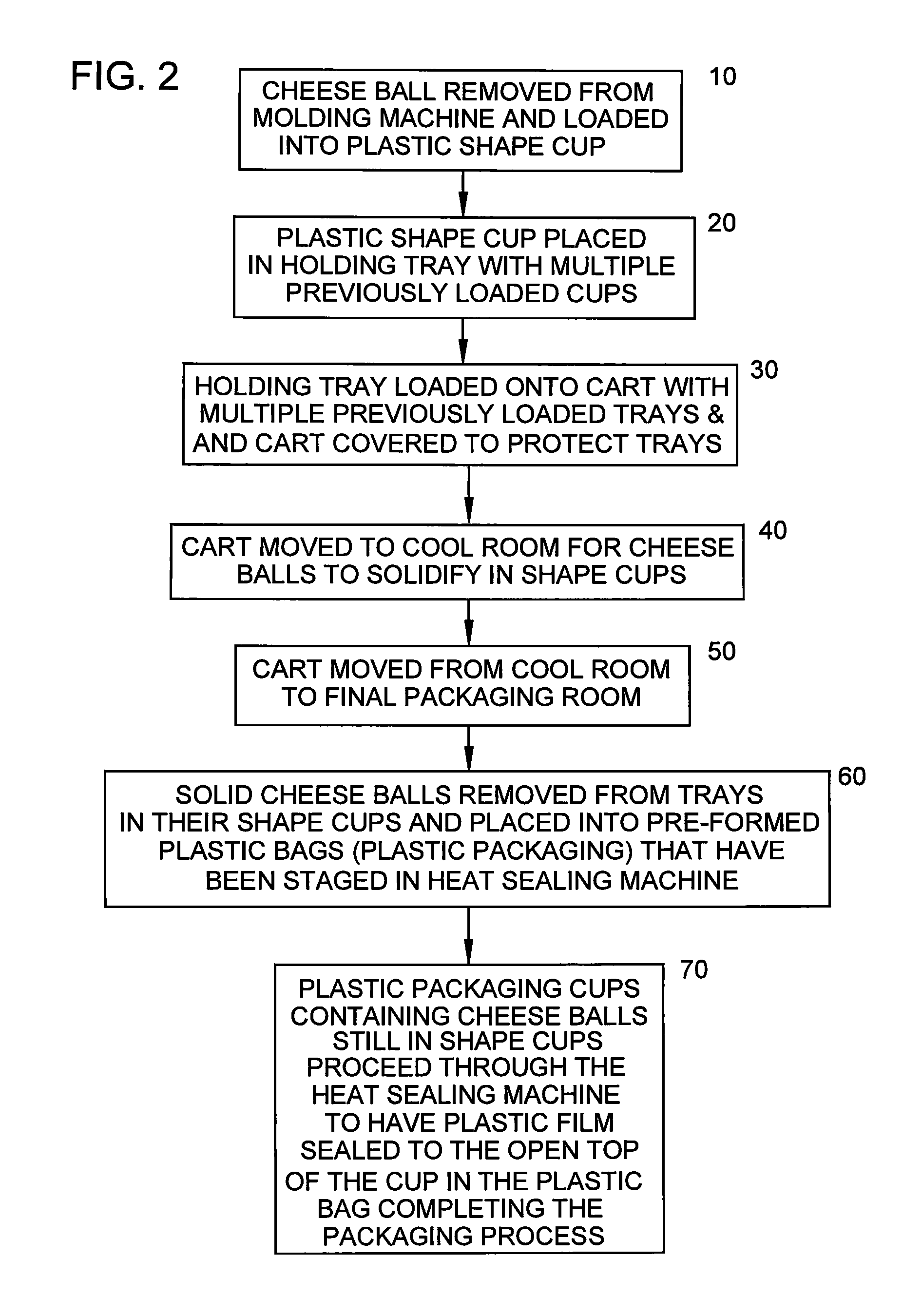

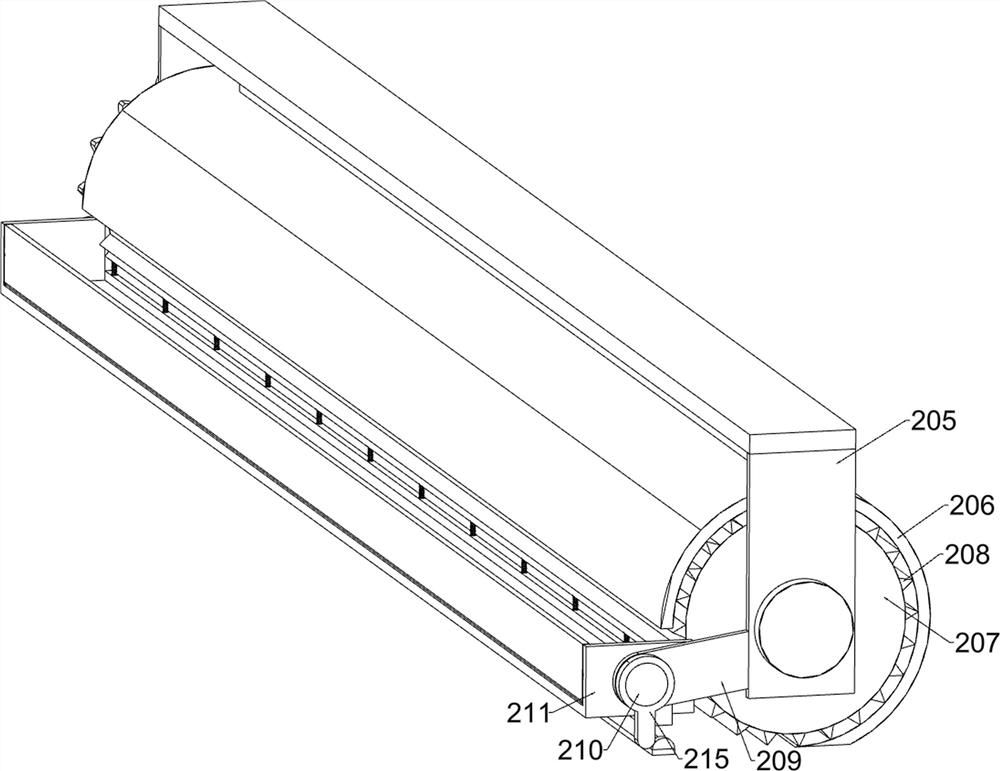

Automatic stacking device for flake cream

InactiveCN105438516AScientific and reasonable designEasy to operatePackaging cheeseStacking articlesCardboardBiochemical engineering

The invention relates to the field of food packaging machines, in particular to an automatic stacking device for flake cream. The automatic stacking device comprises four parts including a cross board supporting part, a cross paper board moving part, a cream flake automatic stacking part and a cream flake stacking finishing output part. The cross board supporting part and the cross paper board moving part are connected through a vacuum suction cup, and the cross paper board moving part and the cream flake automatic stacking part are connected through a long beam; and the cream flake automatic stacking part and the cream flake stacking finishing output part are connected through a carton lifting platform. Automatic stacking for flake cream can be achieved, manual operation is replaced, design is scientific and reasonable, production operation is convenient, hands of people can be effectively prevented from being in direct contact with cream flakes, and therefore the cream flakes can be prevented from deforming, going bad and being polluted, the production quality is ensured, time and labor are saved, and the production efficiency is improved.

Owner:LUDONG UNIVERSITY

Apparatus and method for vacuumizing and sealing a package

InactiveUS20210164586A1Reduced footprintEasy loading and unloadingWrappers shrinkagePackaging cheeseRotational axisRelative motion

An apparatus for vacuumizing and sealing a package includes a plurality of platens and vacuum chambers, each chamber adapted to mate with a dedicated one of the platens; a conveying system for conveying the platens and chambers along a generally angular path having a single axis of rotation; an automated loading assembly having a linear component and configured to load a package onto each of the platens; an automated unloading assembly having a linear portion and configured to unload a vacuumized, sealed package from each loaded platen onto an outfeed conveyor; and a vacuumizing / sealing system configured to cause relative movement of each chamber / platen pair, along a portion of the angular path, to form therebetween an air-tight enclosure accommodating the package and effect vacuumization and sealing of the package.

Owner:CRYOVAC ILLC +1

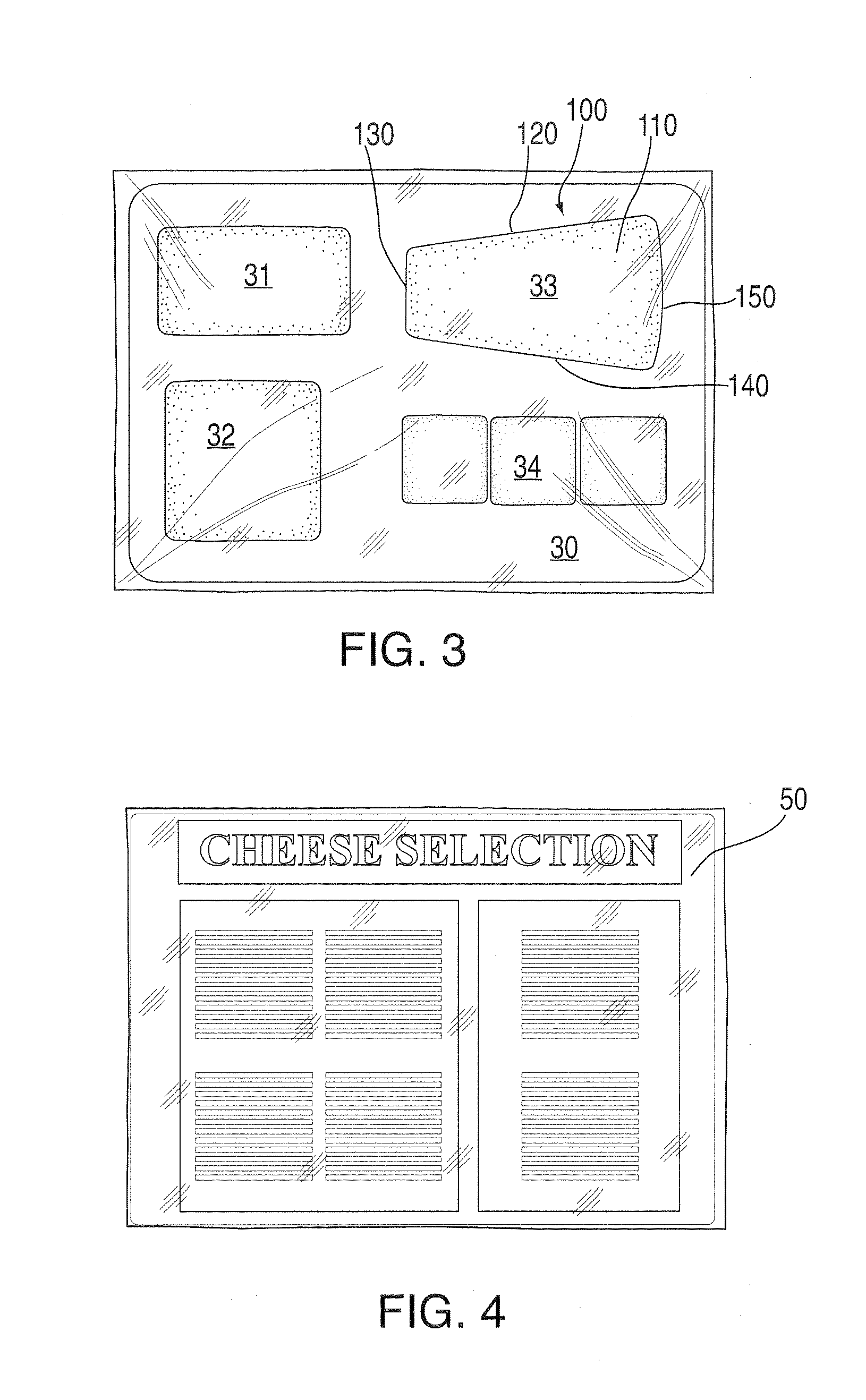

Cheese board

A cheese platter containing a variety of cheeses chosen with a common theme that blend well together. The cheeses are placed on a decorative platter on which the cheeses can also be cut. The entire platter is vacuum sealed in a clear plastic such that the cheese can be readily viewed. This seal also preserves the cheese for consumption.

Owner:SCHUMAN NEAL H

Method and apparatus for placing a product in a flexible recloseable container

Apparatus and methods for forming, filling, and sealing a flexible recloseable container. Both vertical and horizontal methods for placing product within the container are disclosed. The invention includes guiding a web of film which has interlocking fastener strips sealed to the web. A slider for locking and unlocking the fastener strips is placed in the correct orientation, spread apart at a pair of inner feet, and inserted over the fastener strips. The slider is positioned to close a substantial portion of the strips, and then an end stop, docking station, and corner seal are formed against a sealing plate. The slider is then repositioned, and a tamper evident seal may be placed over the fastener strip. Apparatus and methods for placing a product in a flexible recloseable container, and also for manufacturing an empty, flexible recloseable container. One method includes providing a pair of interlockable fastener strips, a web of flexible film, and a plurality of sliders, placing the sliders on the pair of interlockable fastener strips, subsequently attaching the interlockable fastener strips with attached sliders to the web of flexible film, and either placing a product within the web or providing the empty container to the consumer.

Owner:ILLINOIS TOOL WORKS INC

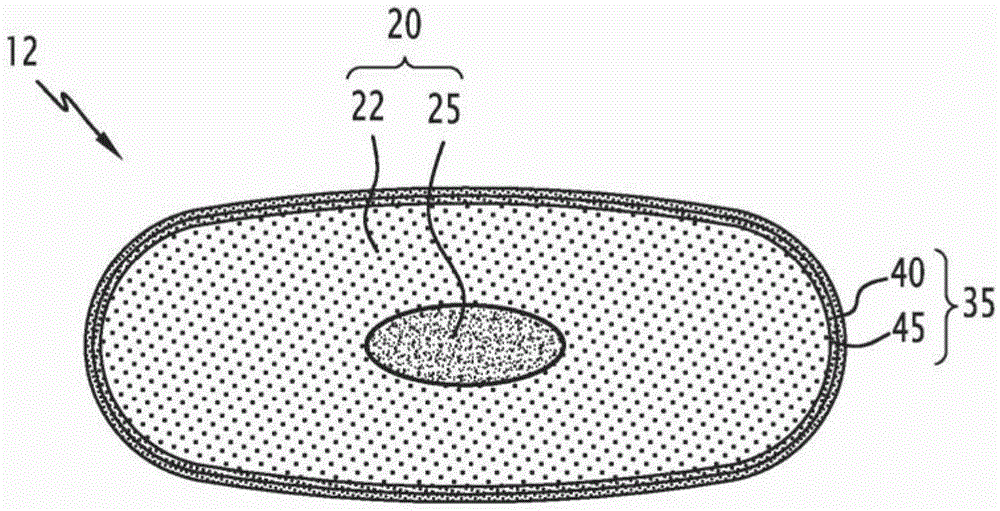

Method for coating cheese products

ActiveCN105246343AReduce the risk of contaminationPackaging cheeseCheese manufactureHydrophobic polymerMoisture

The present invention relates to a method for preparing a coated cheese product, said method including the steps of: a) injecting a cheese material in viscous state between two coating films and in contact with said films, said films being malleable at the storage temperature of said coated cheese product and each including, on the outer surface, at least one outer layer made of a coating composition C1 in a gelled state, said coating composition including at least one hydrophobic polymer, and b) shaping at least one coated cheese product, by pressing on the outer surface of each one of said two coating films, such as to obtain a coated cheese product including a core that includes said cheese material and a coating that is malleable at the storage temperature of said coated cheese product and sealed against moisture and microorganisms, completely surrounding the periphery of the core thereof, said coating consisting of the assembly by pressing said two coating films and including at least one outer layer made of said coating composition C1.

Owner:BELL SRO

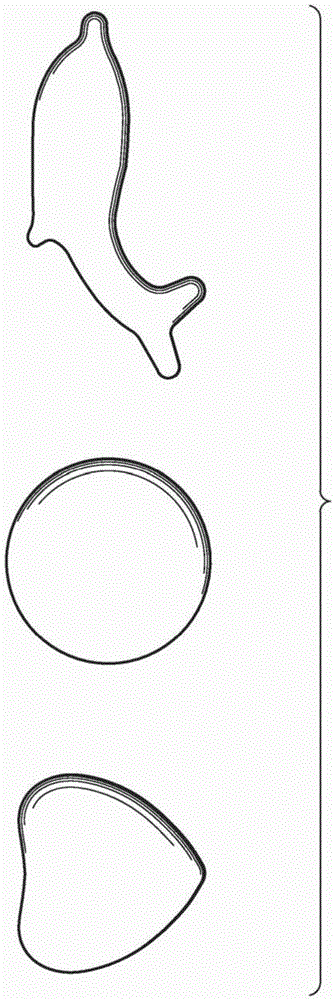

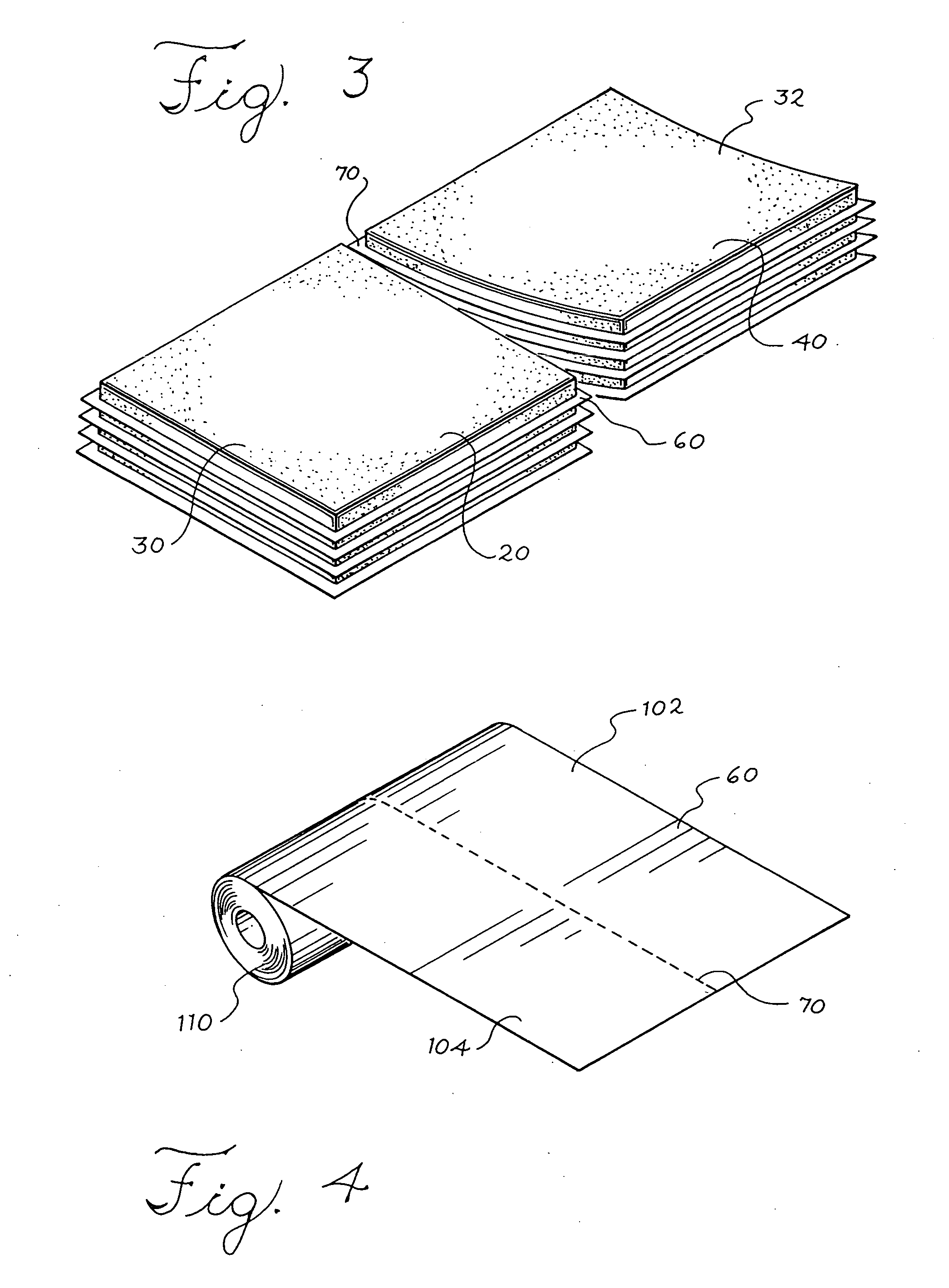

Apparatus and method for separating stacks of food products slices

A system for separating multiple stacked slices of food slices includes a plurality of overlying food slices that are arranged in at least two columns, with a first column having a side adjacent to a side of a second column. Each of the plurality of food slices are separated by a divider that includes a weakened region between the sides of the first and second columns of food slices. A method of separating multiple stacks of food slices includes stacking a plurality of food slices into at least two columns of food slices, placing a divider between each food slice in each of at least two columns, wherein the divider includes a weakened region located between the at least two columns of food slices, and separating the at least two columns of food slices by separating the plurality of dividers along the weakened region of each divider.

Owner:SCHREIBER FOODS

Cheese conveying equipment for food production

The invention relates to a conveying device, in particular to a cheese conveying device for food production. The invention provides a cheese conveying device for food production which can convey cheese more automatically, print the production date of the cheese, and package the cheese. Cheese conveying equipment for food production, including: a base and a frame, with a frame on the top of the base; a primary transmission mechanism, with a primary transmission mechanism on one side of the frame; a secondary transmission mechanism, with a secondary transmission on the frame mechanism. In the present invention, a pressing mechanism is provided, and the pressing plate in the pressing mechanism moves downward, thereby driving the pressing rod to move downward to press down the lid stuck above the cheese, the sixth spring is squeezed, and when the lid and the bottom plate are fixed The cheese is completely packaged, achieving the effect of replacing manual packaging of cheese.

Owner:SHANDONG GAOTANGYONGWANG FOOD CO LTD

Method for producing a dairy product and system for packaging the same

InactiveUS20180352825A1Conducive to preservationMore manoeuvrablePackaging cheeseBoxesMozzarella cheeseBiomedical engineering

A method for producing and packaging a dairy product, particularly mozzarella cheese, and a packaging method for facilitating the handling and improve preservability of the latter. Particularly, the present invention relates to a method for preparing and packaging a pasta filata cheese, comprising a step of substantially dry packaging, i.e. without preserving liquid, and heat packaging of the pasta filata cheese.

Owner:EGIDIO GALBANI SRL

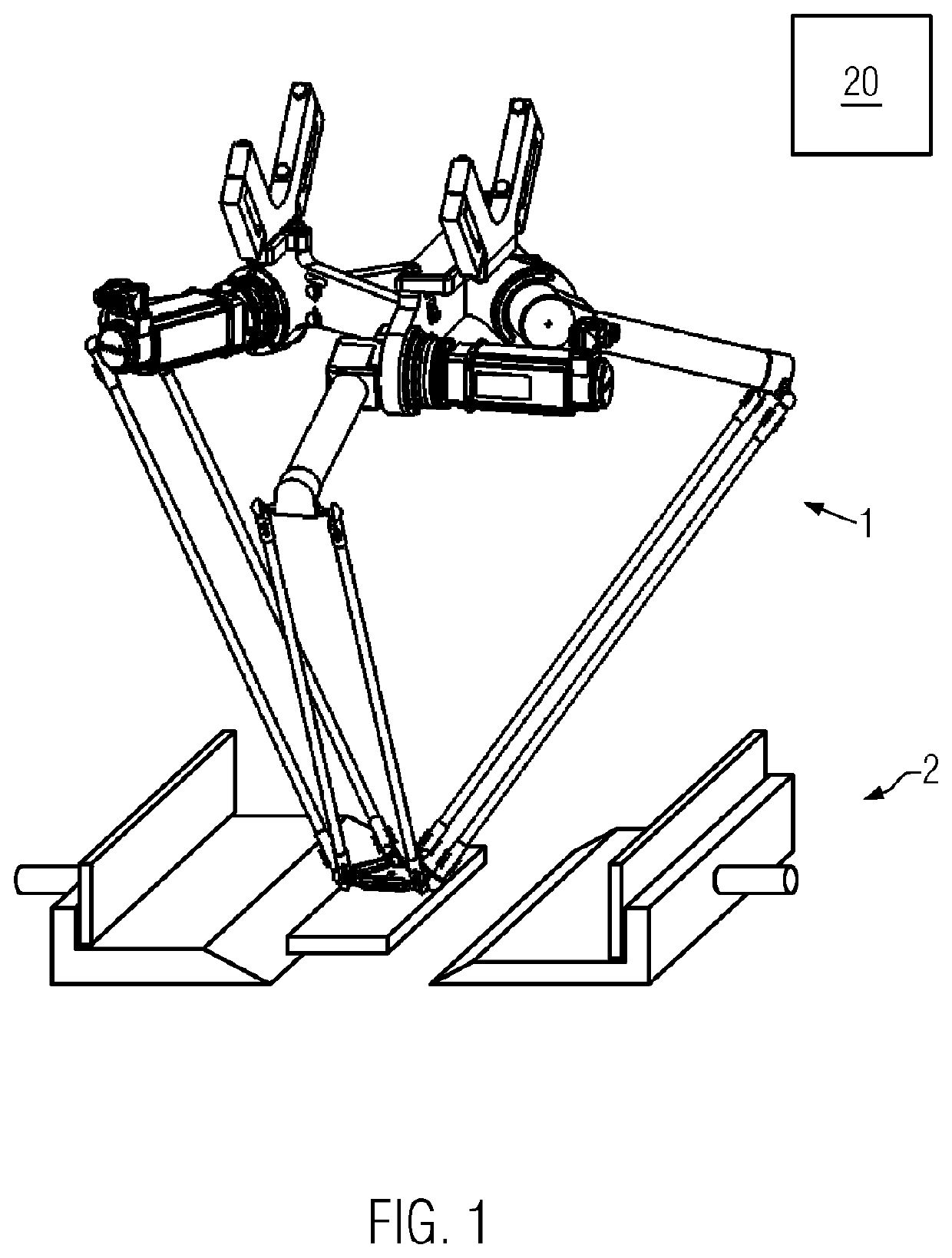

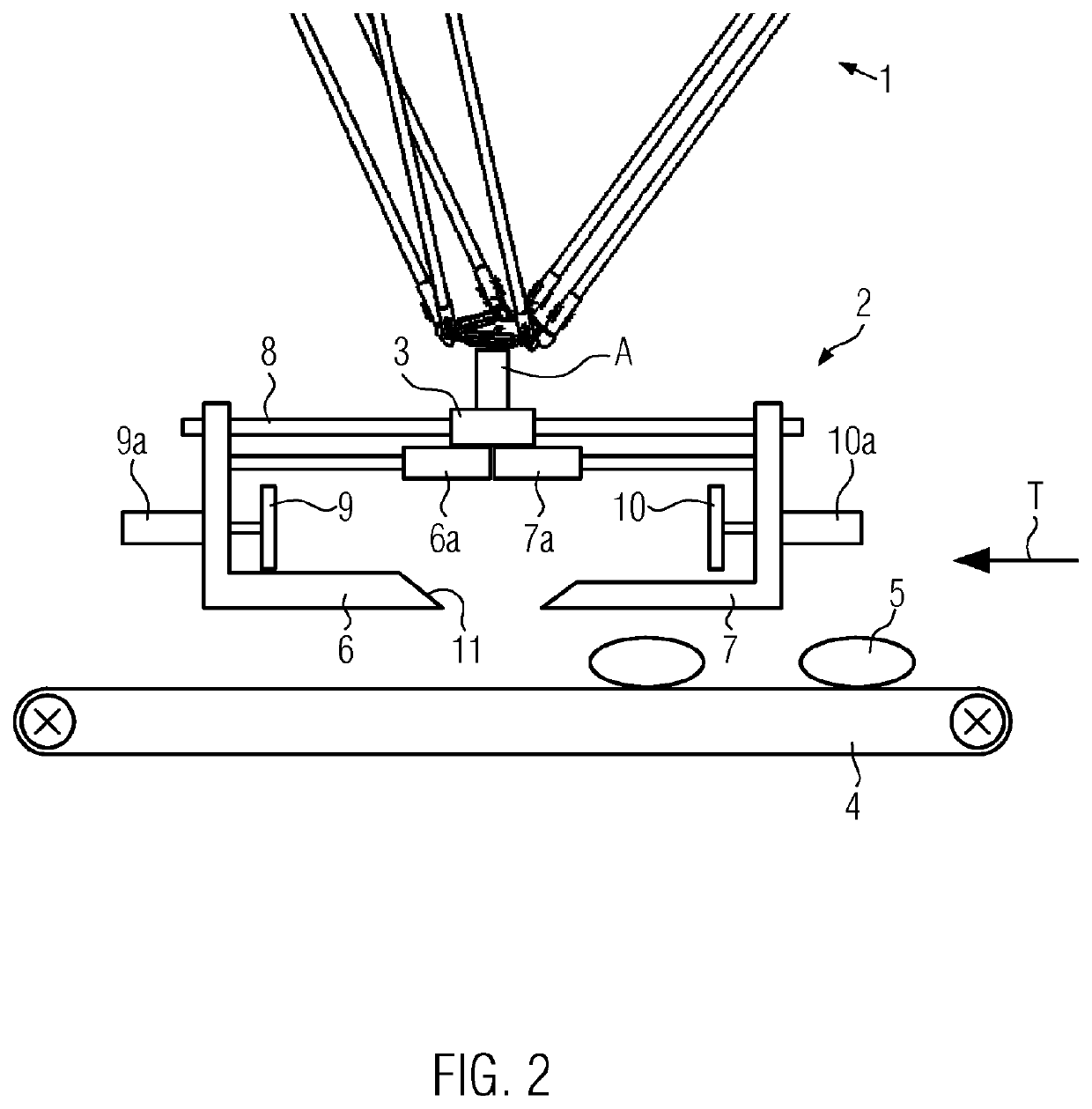

Apparatus for handling portions of products

ActiveUS8887602B2Easy to handleImprove efficiencyFeeding apparatusMaterial check-weighingProcess engineeringIndustrial engineering

An apparatus for handling portions of products, in particular food products, includes a product conveyor which conveys the portions sequentially along a conveying direction and at least one sensor which serves to determine the weight of the conveyed portions. The apparatus includes an automatic weight compensation unit which is arranged in the vicinity of the product conveyor and which serves additionally to place at least one single product on a portion in dependence on the determined weight of the portion.

Owner:WEBER MASCHENBAU

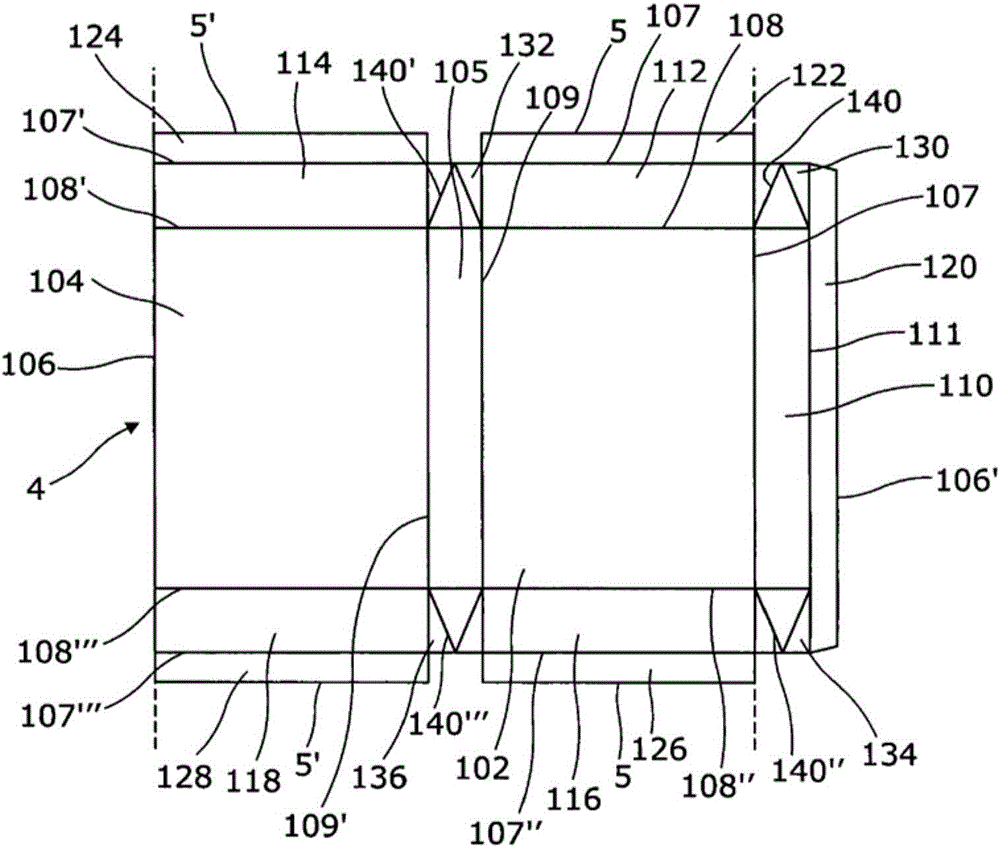

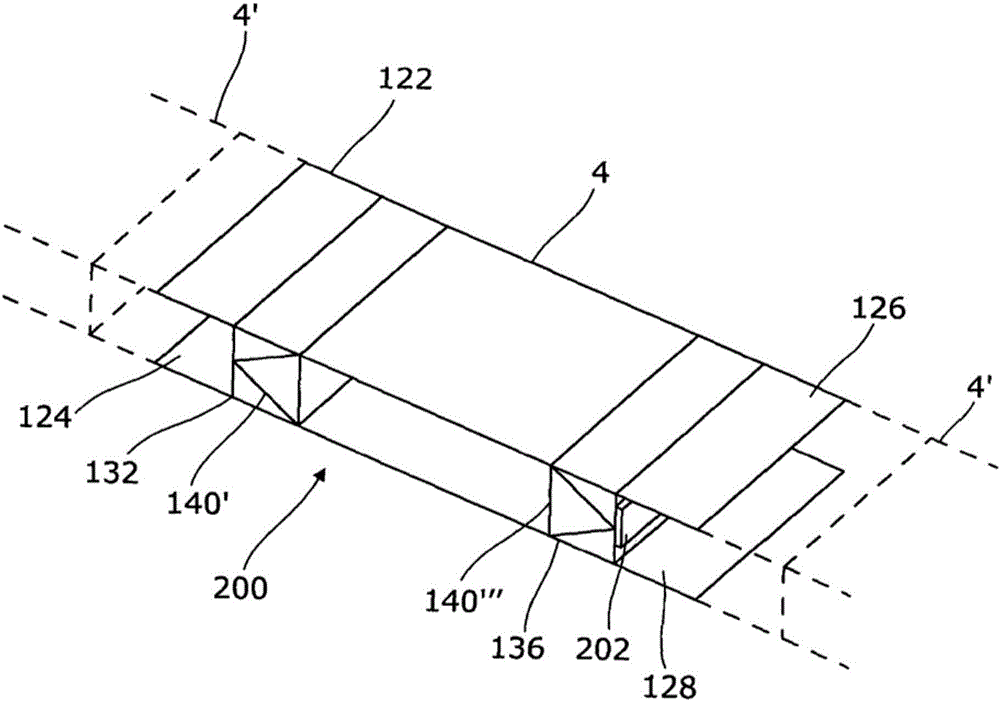

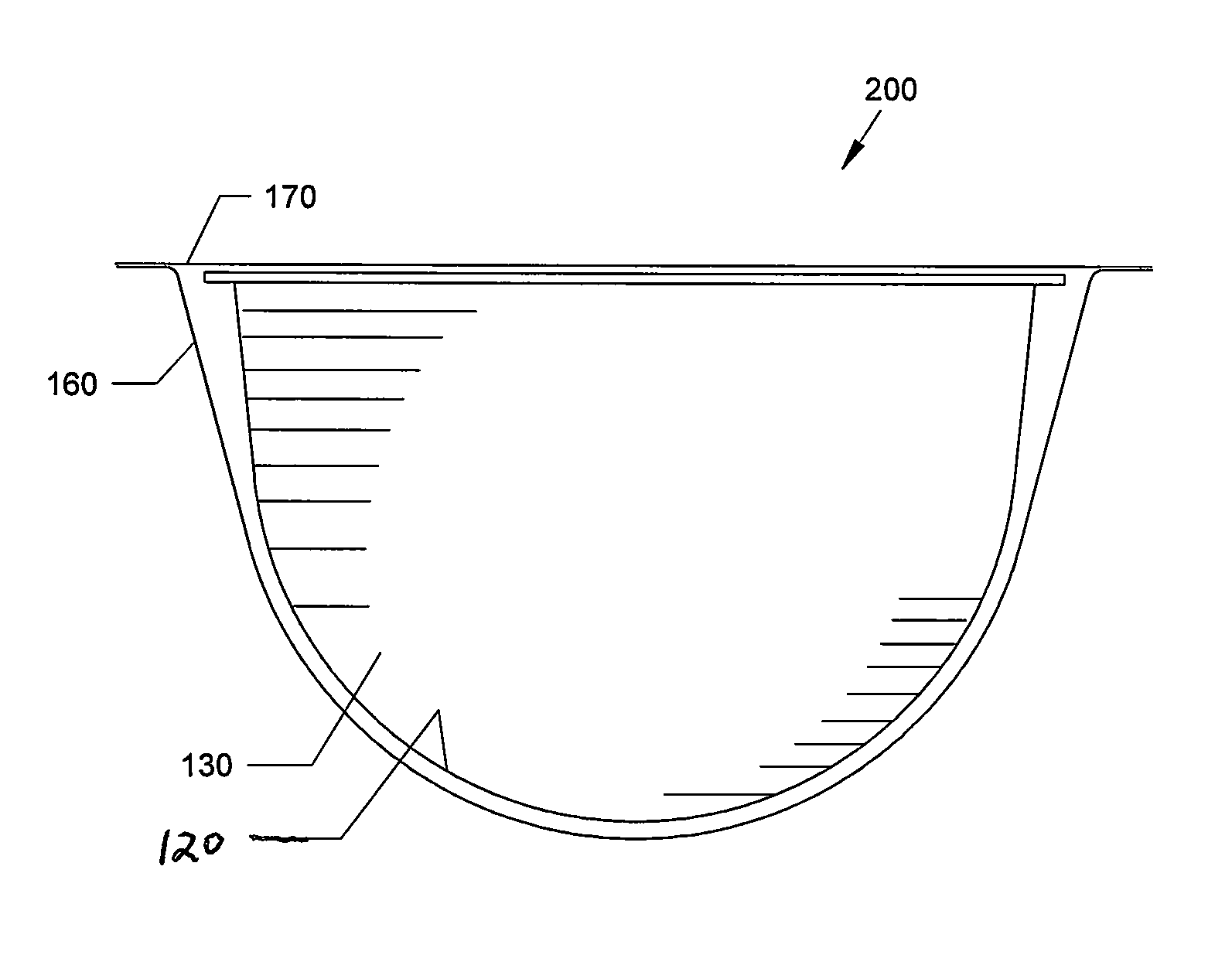

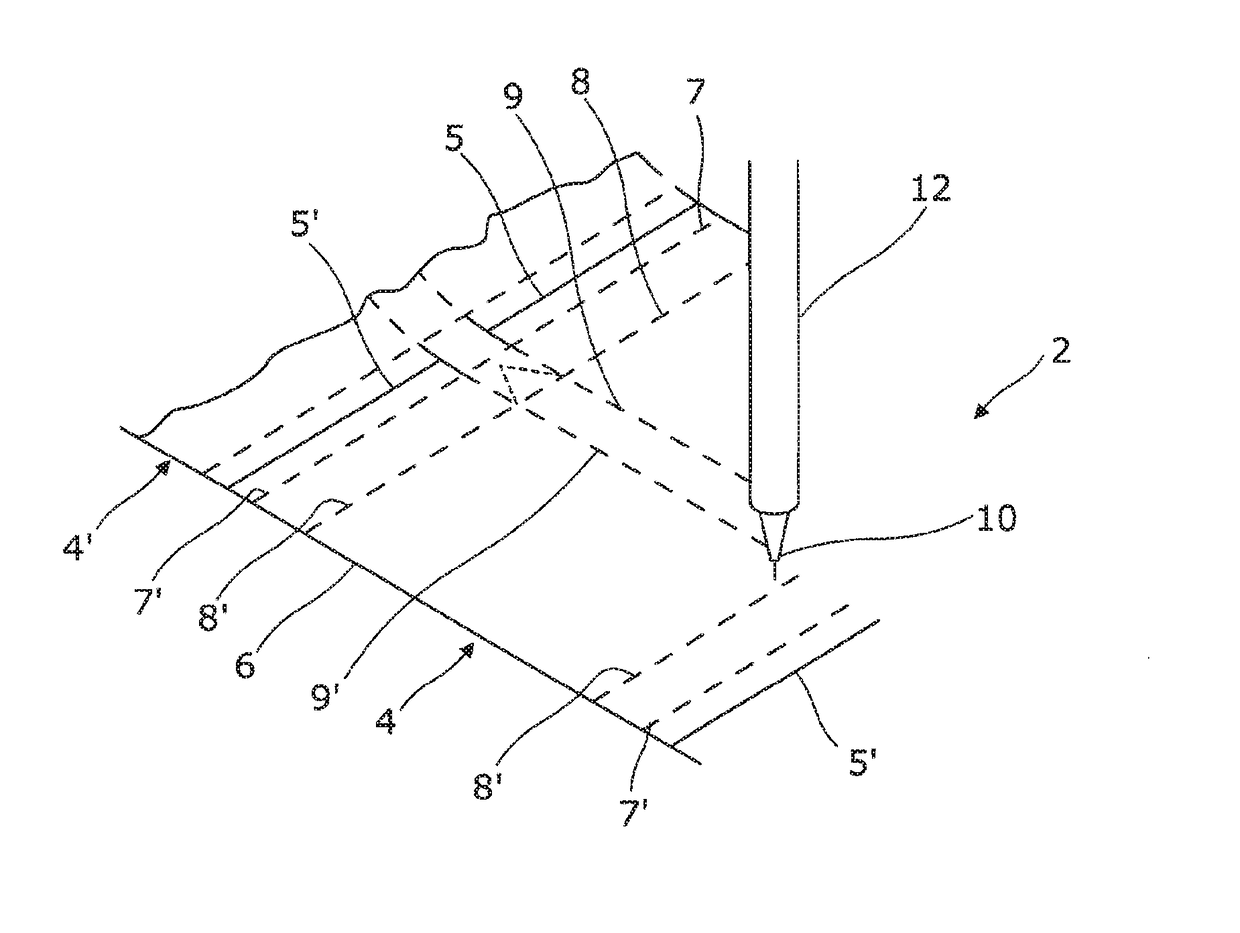

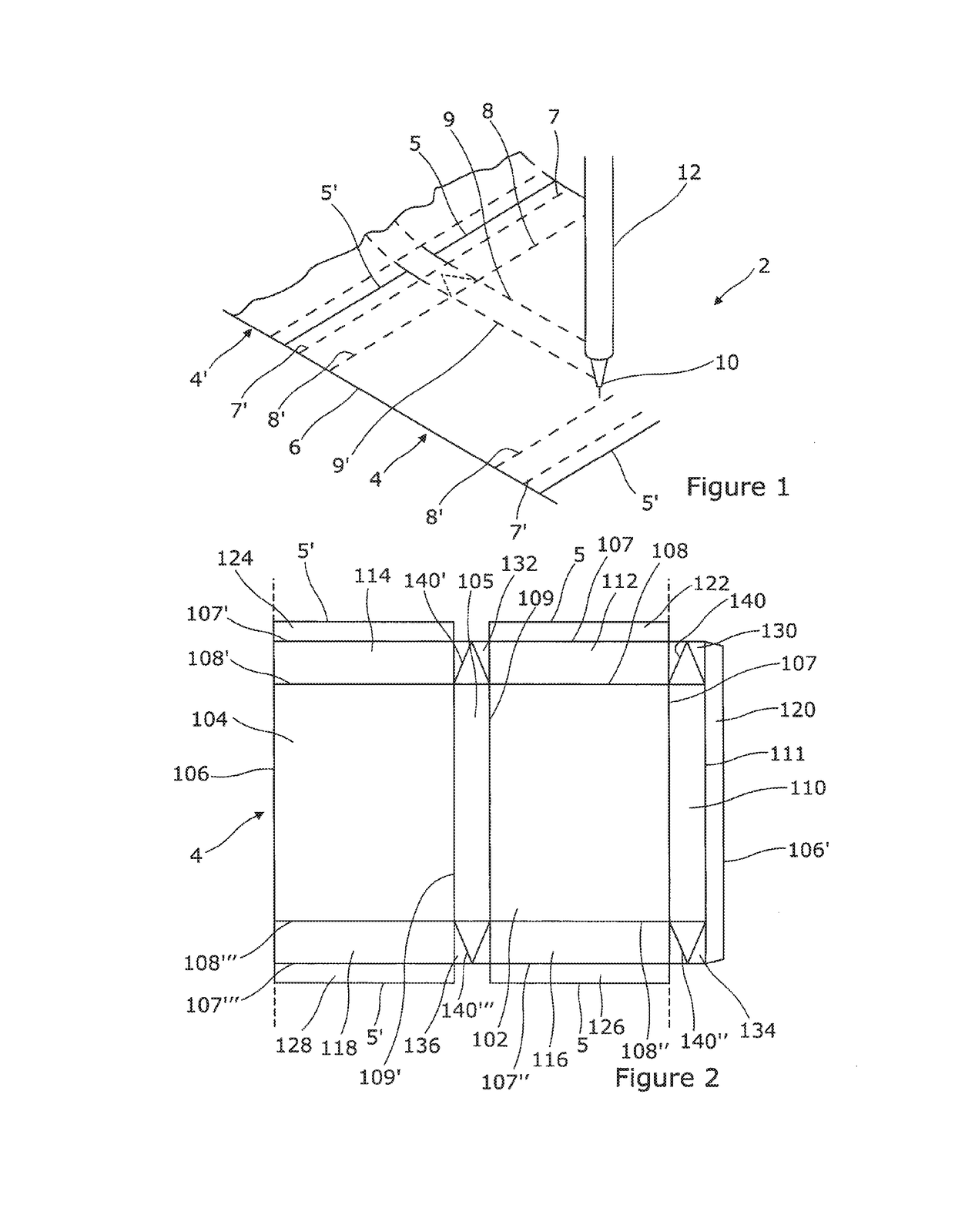

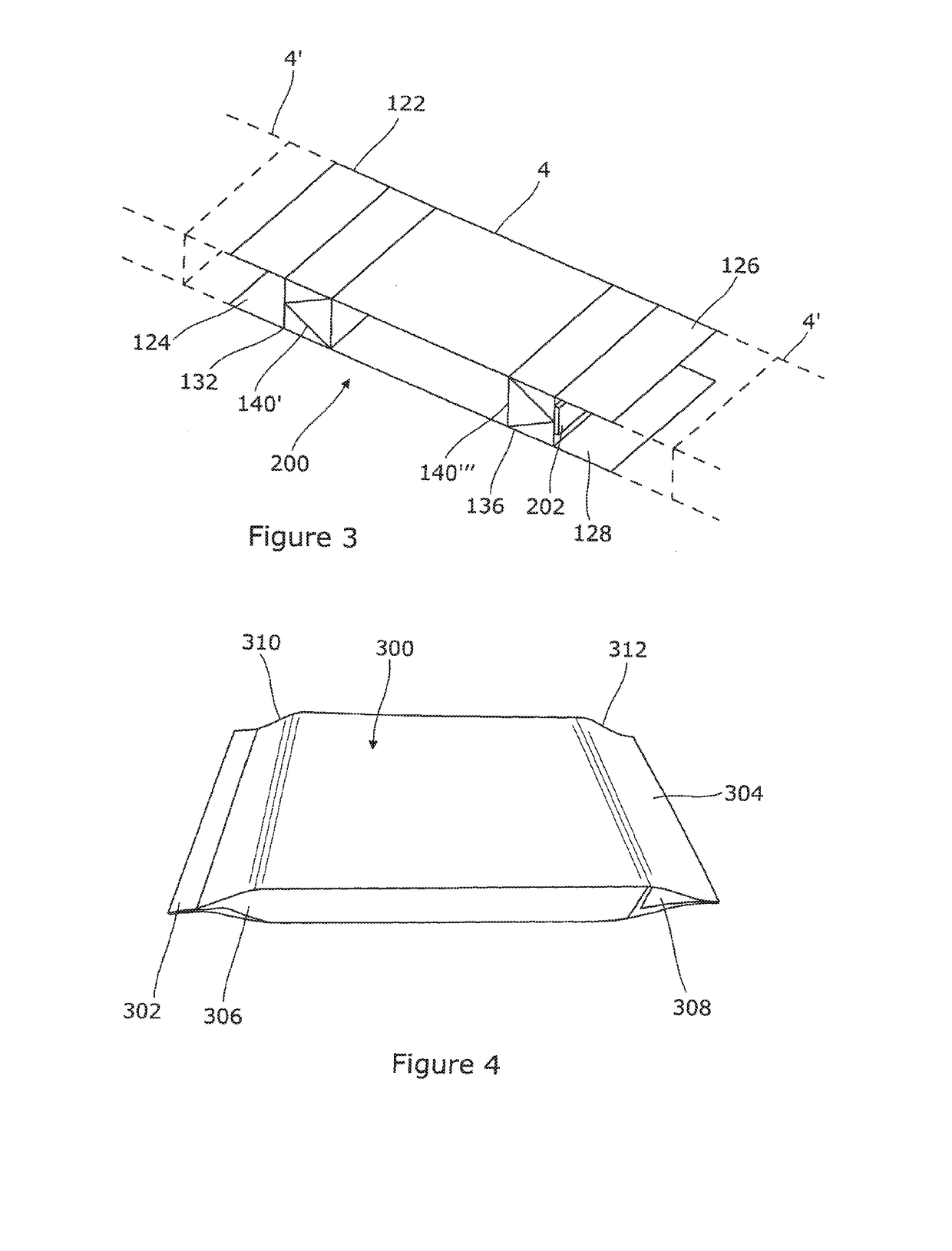

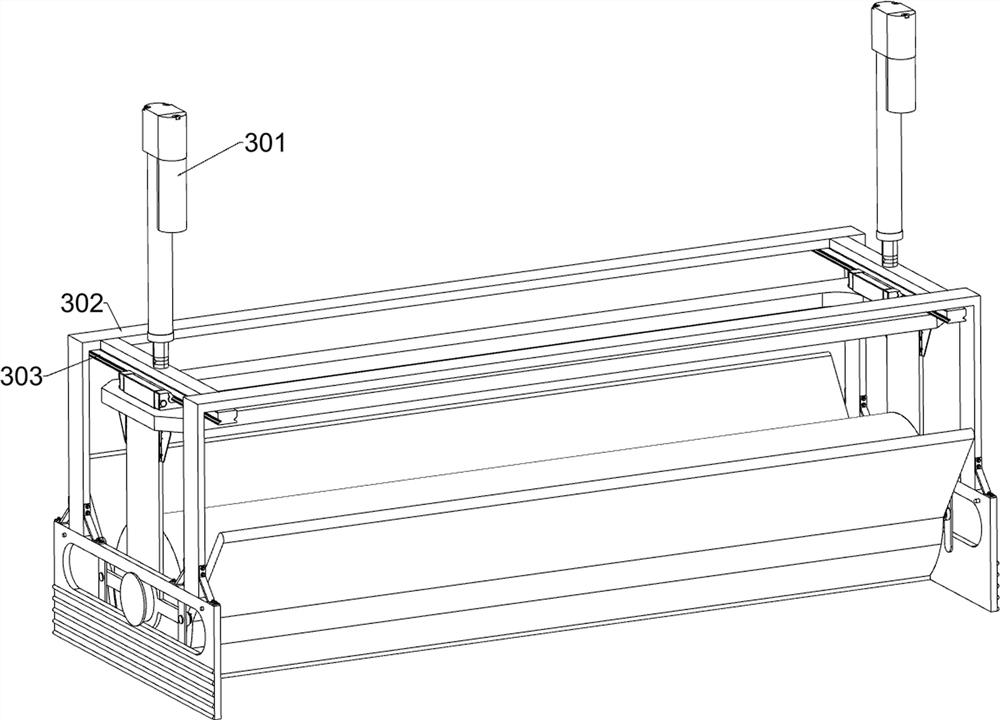

Packaging and a method of manufacture thereof

The invention provides a method of manufacturing packaging comprising the steps of: a) providing a packaging material (2) comprising cartonboard, semi-rigid plastics or other semi-rigid packaging material; b) forming fold lines (8) and / or cuts within the packaging material (2) by subjecting the packaging material (2) to laser (12) or mechanical scoring; c) folding the packaging material (2) along the fold lines (8) and / or cuts and securing in position to form a substantially tubular container (200); and d) forming at least one seal (302, 304) by sealing together at least two opposing regions (122, 124, 126, 128) of a blank (4) to form an at least partially sealed package (300); e) performing at least one of steps b), c) and d) on a horizontal or vertical fill, form and seal apparatus (400).

Owner:KRAFT FOODS SCHWEIZ HLDG AG

Apparatus and method for vacuumizing and sealing a package

ActiveUS10941879B2Reduced footprintEasy loading and unloadingWrappers shrinkagePackaging cheeseRotational axisEngineering

An apparatus (10) for vacuumizing and sealing a package (322) includes a plurality of platens (12) and vacuum chambers (14), each chamber (14) adapted to mate with a dedicated one of the platens (12); a conveying system (16) for conveying the platens (12) and chambers (14) along a generally angular path having a single axis of rotation (18); an automated loading assembly (20) having a linear component (22c) and configured to load a package (322) onto each of the platens (12); an automated unloading assembly (26) having a linear portion and configured to unload a vacuumized, sealed package (322) from each loaded platen (12) onto an outfeed conveyor (30); and a vacuumizing / sealing system configured to cause relative movement of each chamber (14) / platen (12) pair, along a portion of the angular path, to form therebetween an air-tight enclosure accommodating the package (322) and effect vacuumization and sealing of the package (322).

Owner:FURUKAWA MFG +1

Gripper

ActiveUS20210268665A1Machine and line performanceImprove performancePackaging cheeseProgramme-controlled manipulatorPinch gripStructural engineering

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

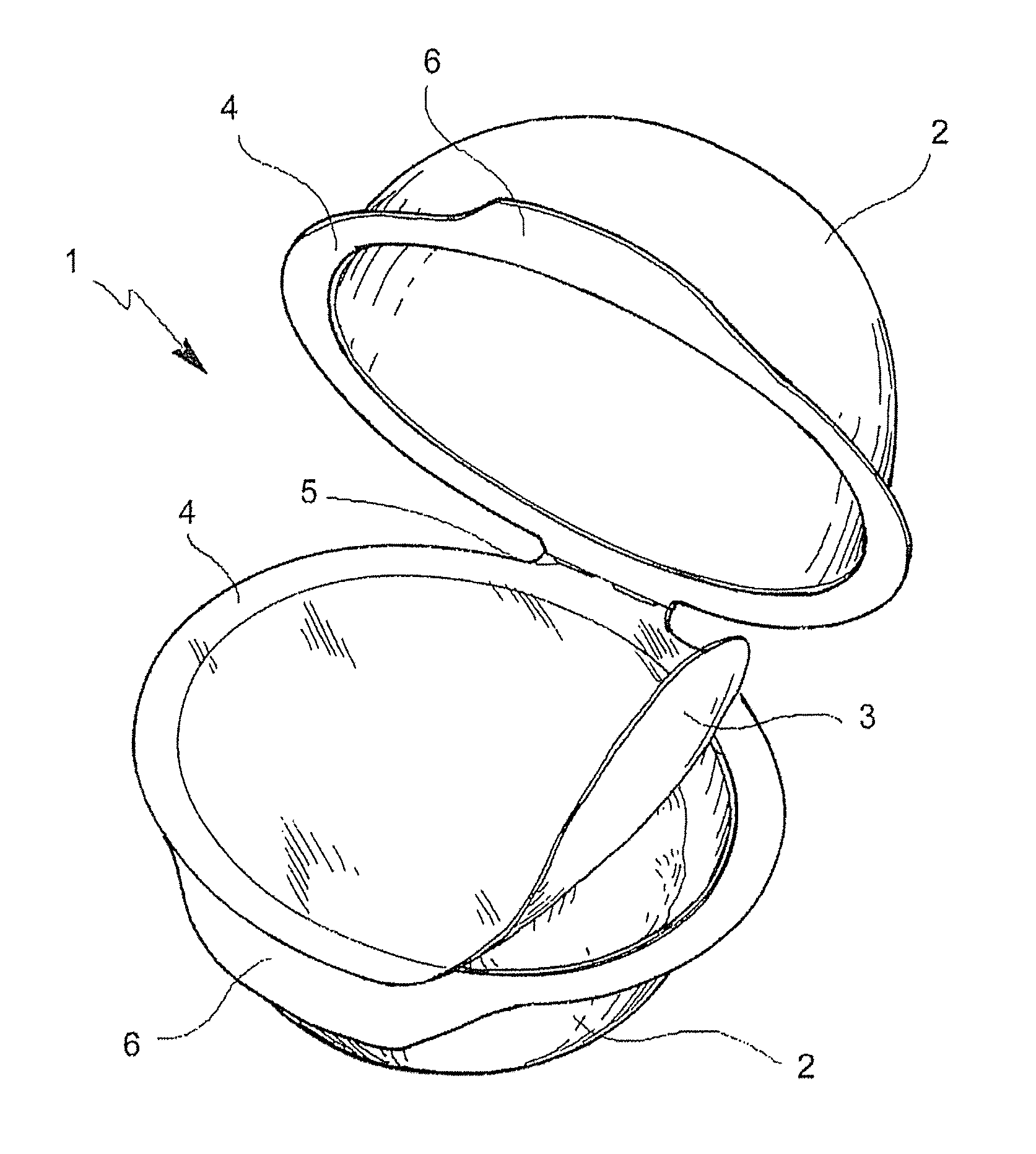

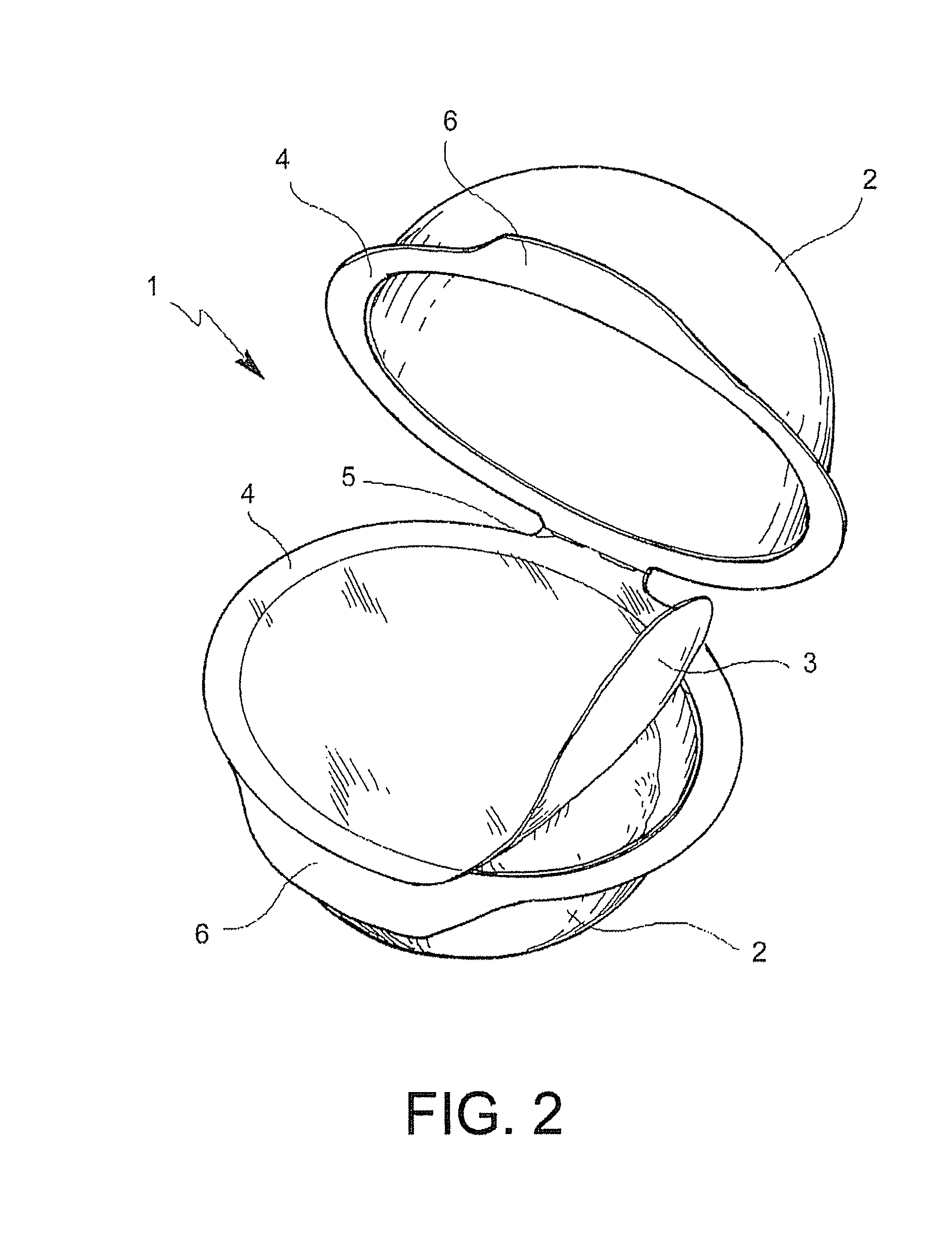

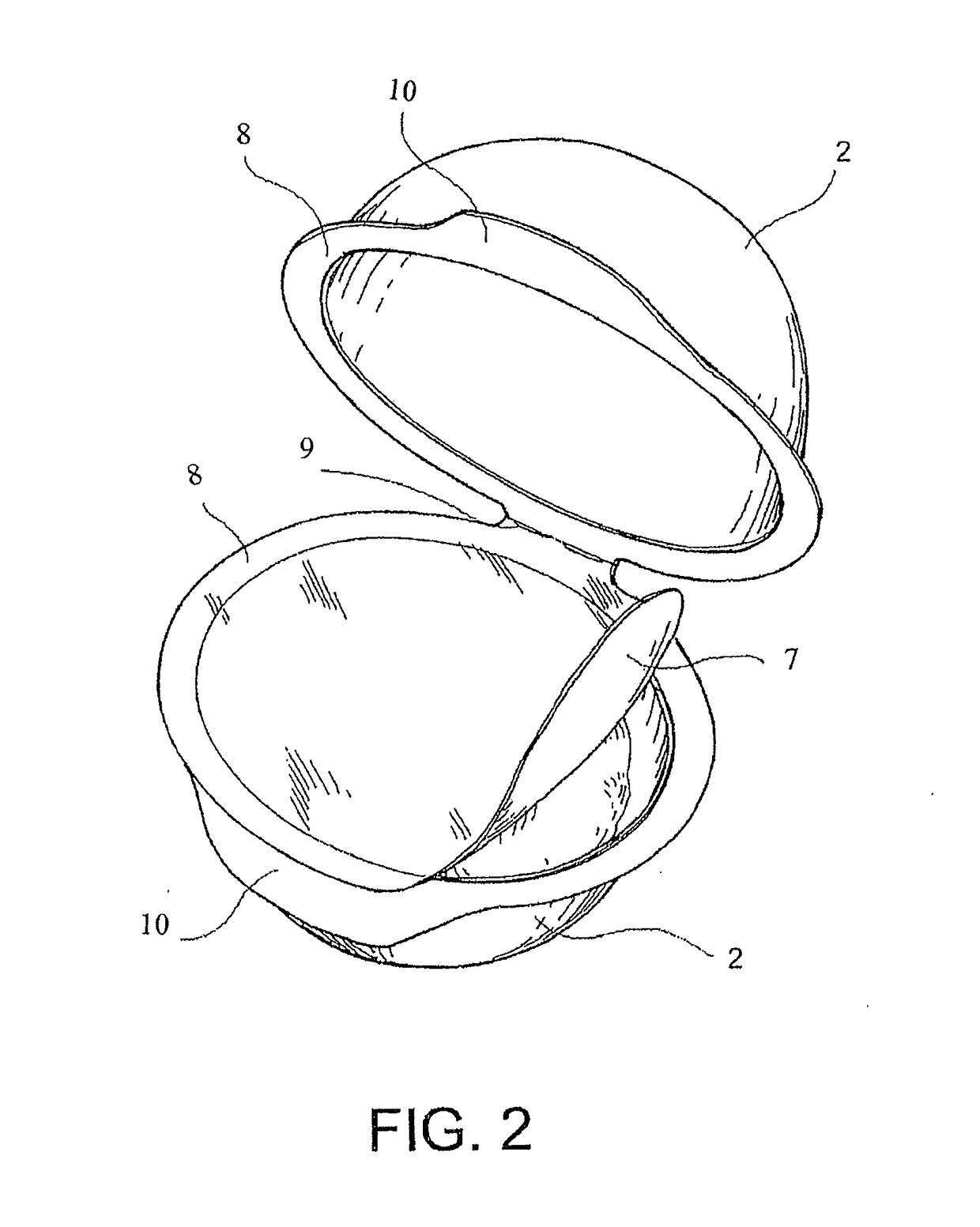

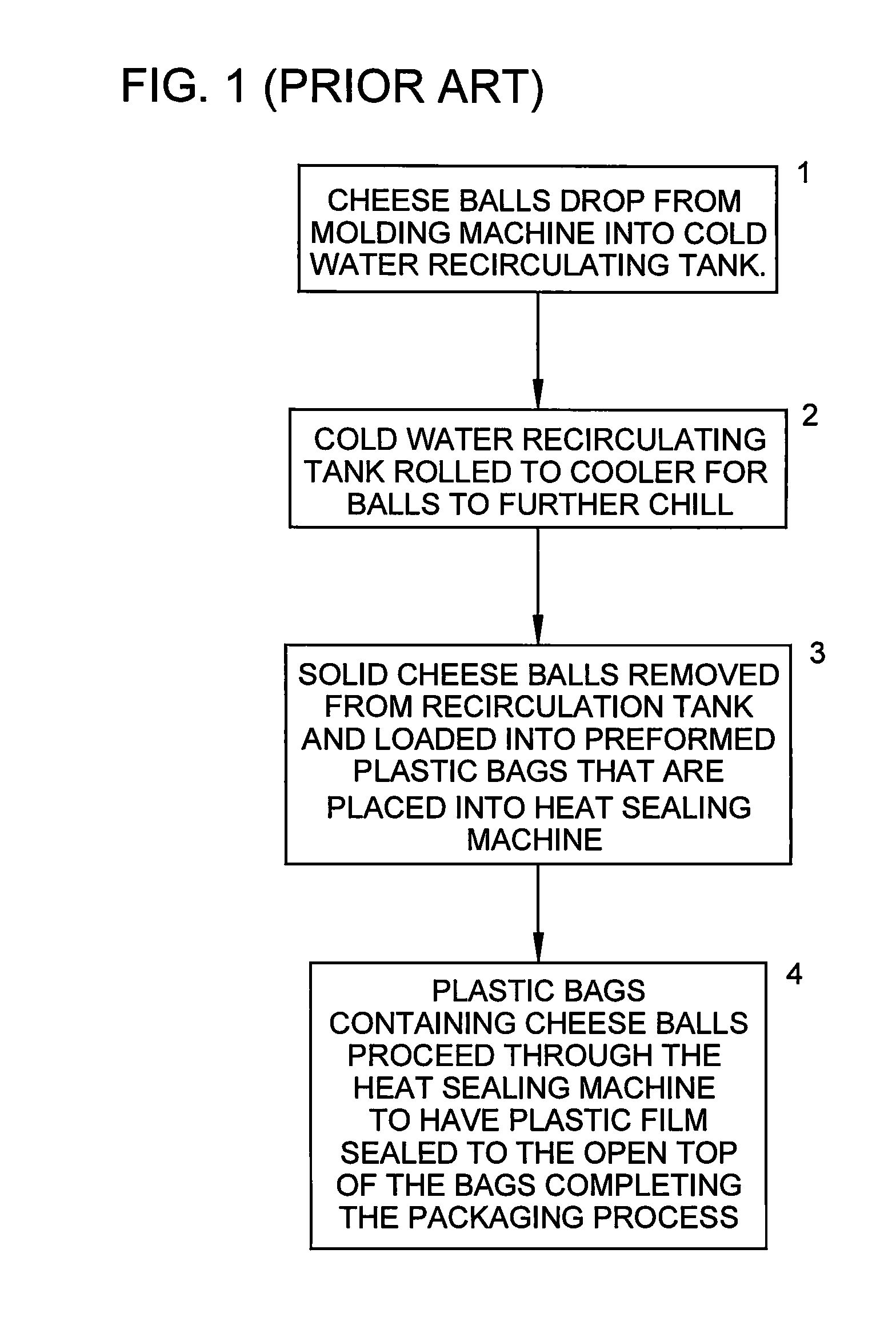

Method of making and processing cheese in dome containers

Processes, methods, systems, containers, and apparatus for making and processing pasta filata cheese in dome containers that are packaged in plastic. The novel invention uses a rigid see through plastic dome to safely store the cheese within and can be heat sealed in a bag with a plastic film across the top of the bag and open end of the dome. Another embodiment uses only a plastic film to seal off the open end of the dome without using a bag. The process eliminates the need for a water tank to hold the cheese balls before packaging, where water has allowed for cross contamination of all the balls if one ball is contaminated with bacteria and germs. The plastic dome allows for an aesthetically appearing cheese package that maintains a semi-spherical ball shape with the dents and deformations that occur with the prior art plastic bag packaged cheeses.

Owner:CALLIGARO LEO

Film, package and method for cheese ripening and preservation

The present invention relates to a method, to a biodegradable film and to a package for cheese ripening or preservation, in particular for ripening hard or semi-hard cheese, preferably rind cheese. This method, thanks to the peculiar transmission properties of the film, provides cheese more similar to naturally ripened cheese, with a minor loss of water, due to evaporation, with reduced mold and yeast growth, and without significant flavor, consistency and color deviations.

Owner:CRYOVAC LLC

Packaging and a method of manufacture thereof

The invention provides a method of manufacturing packaging comprising the steps of: a) providing a packaging material (2) comprising cartonboard, semi-rigid plastics or other semi-rigid packaging material; b) forming fold lines (8) and / or cuts within the packaging material (2) by subjecting the packaging material (2) to laser (12) or mechanical scoring; c) folding the packaging material (2) along the fold lines (8) and / or cuts and securing in position to form a substantially tubular container (200); and d) forming at least one seal (302, 304) by sealing together at least two opposing regions (122, 124, 126, 128) of a blank (4) to form an at least partially sealed package (300); e) performing at least one of steps b), c) and d) on a horizontal or vertical fill, form and seal apparatus (400).

Owner:KRAFT FOODS SCHWEIZ HLDG AG

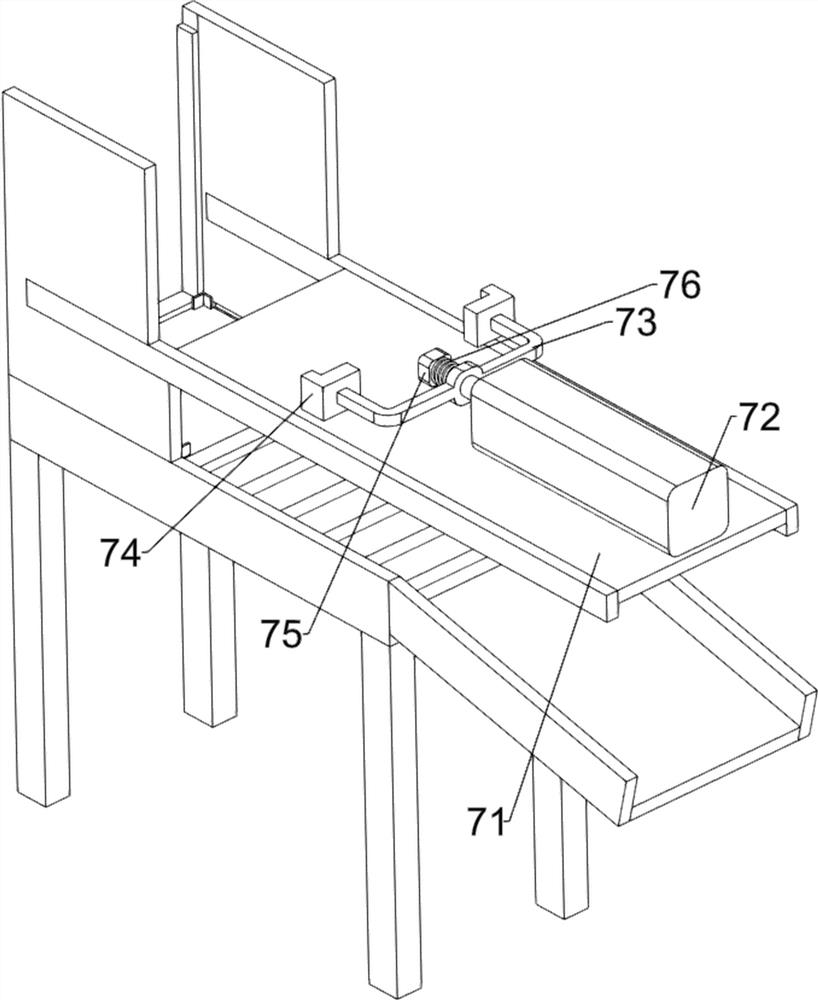

Pretreatment deslagging equipment for dairy product packaging and deslagging method thereof

ActiveCN114476193AQuick putAvoid damagePackaging cheeseClimate change adaptationProcess engineeringBiology

The invention relates to the field of dairy products, in particular to pretreatment deslagging equipment for dairy product packaging and a deslagging method of the pretreatment deslagging equipment. The cheese packaging box solves the technical problems that after cheese is pressed and formed, some protruding cheese disintegrating slag can be reserved on the surface of the cheese, the packaging effect is affected, and the cheese is inconvenient to put into the packaging box due to the fact that the packaging box is prone to being concaved inwards. According to the technical scheme, the pretreatment deslagging equipment for dairy product packaging comprises a supporting frame, a disintegrating slag collecting box and the like; and a disintegrating slag collecting box is arranged on the left side in the supporting frame. According to the cheese residue collecting device, residues on the surface of cheese are removed, the cheese residues stored in the collecting frame are transferred in a linkage mode, manual taking-out is not needed, continuous cheese residue collecting is rapidly carried out, the working efficiency is improved, meanwhile, the inner wall of a packaging box is leveled, the corners of the packaging box are pressed through semi-cylindrical protrusions of two pressing plates, and the packaging box is convenient to use. And corner blind areas during pressing are avoided, subsequent cheese can be quickly put in conveniently, and the situation that the cheese is damaged is avoided.

Owner:黑龙江省康平生物工程有限责任公司

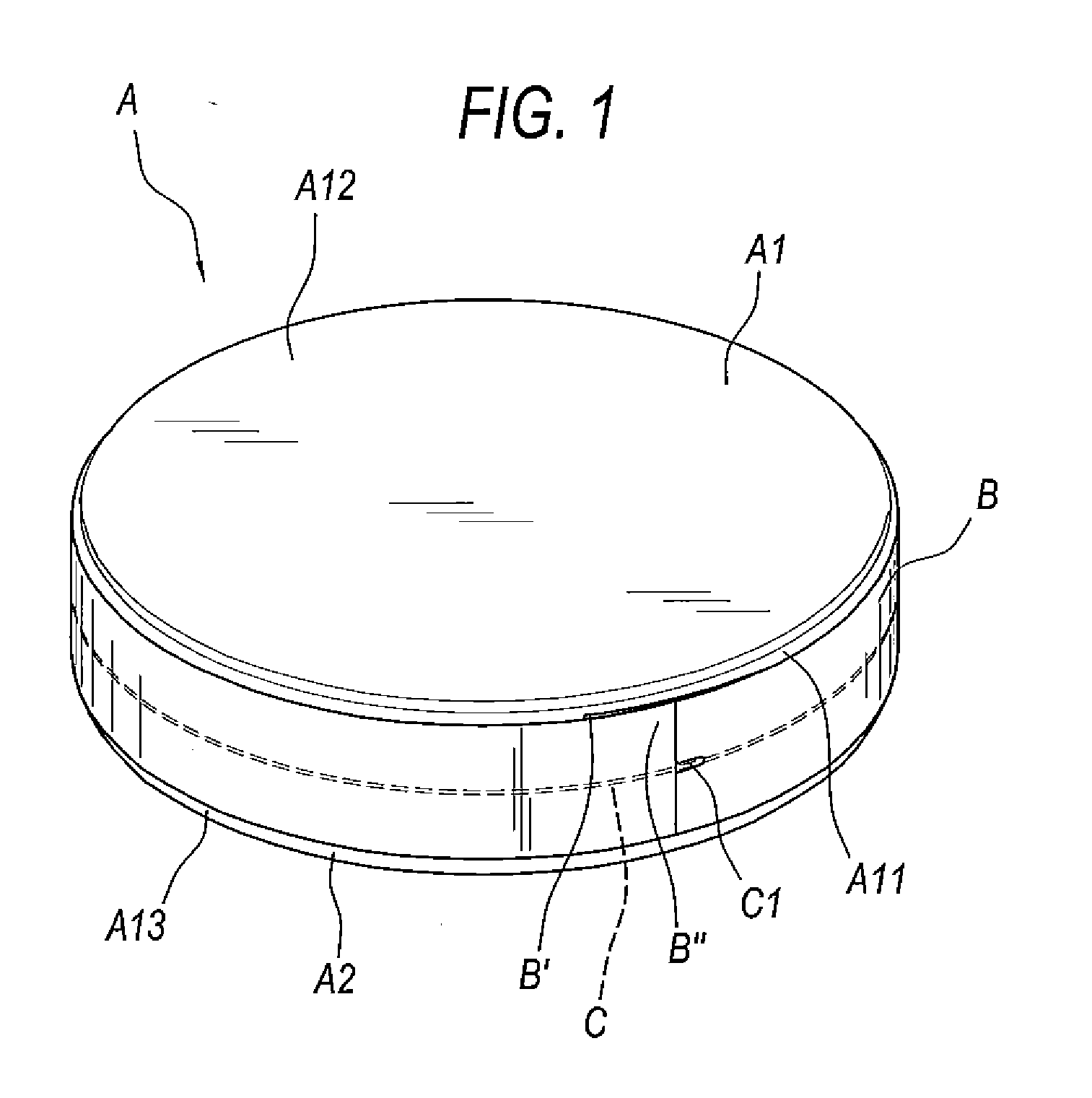

Seal banding machine

A seal banding machine (1) designed to apply a sealing band (B) to the lateral surface (A11) of a circular container body (A) includes: elements (11) which apply the sealing band (B) to the lateral surface (A11) of container body (A), which are rotatable about a respective axis and which have a surface (111) for retaining and supporting the sealing band (B); and elements (12) for rotating the container body (A) with the respective lateral surface (A11) engaging the peripheral surface (111) of the elements (11) which apply the sealing band (B). Elements (21) are provided for spreading an adhesive on the sealing band (B), which are located at the elements (11) for applying the sealing band (B).

Owner:CORAZZA

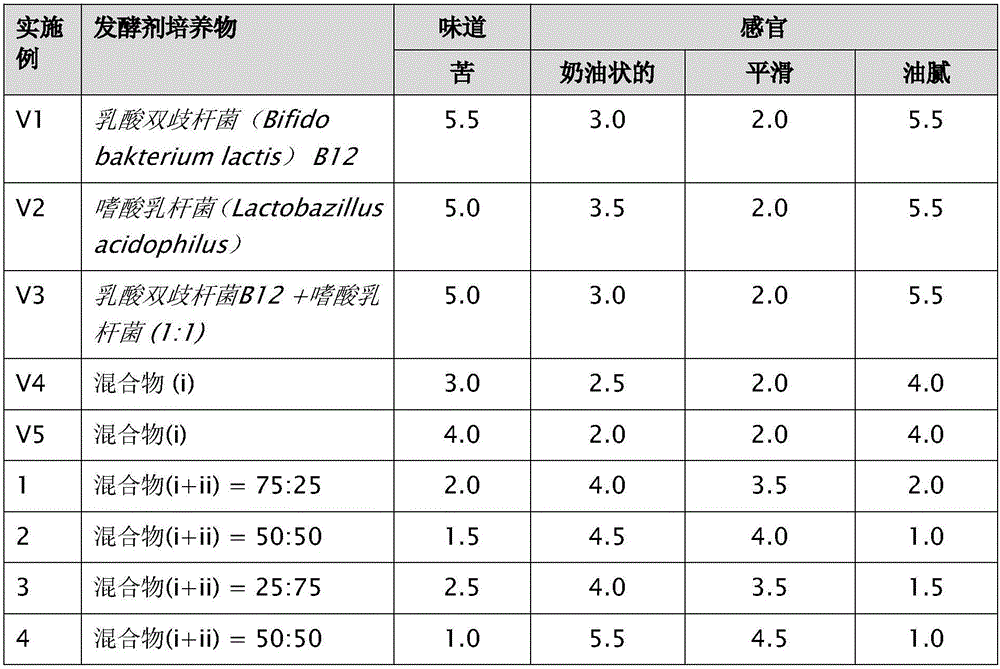

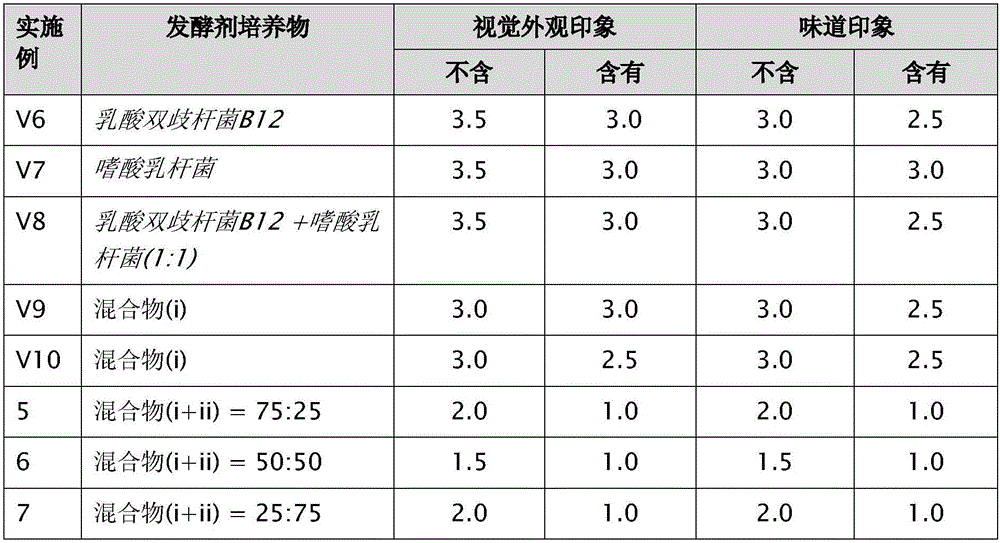

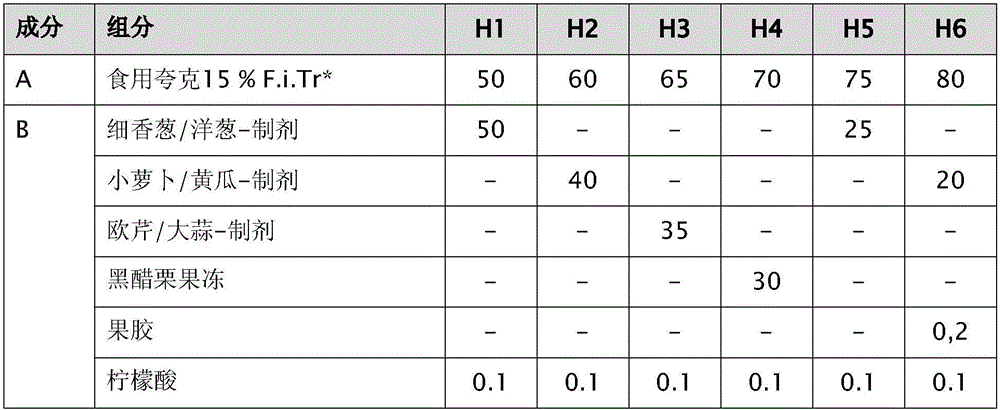

Foodstuffs

A spreadable foodstuffs preparation is proposed comprising (a) a fresh cheese component and (b) a vegetable or herb preparation, wherein the components (a) and (b) are present side by side in a container such that they occupy three-dimensionally continuous volumes that do not mix.

Owner:DMK DEUT MILCHKONTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com