Automatic stacking device for flake cream

A technology for flaky cream and cream slices, applied in the directions of packaging cheese, stacking of objects, de-stacking of objects, etc., can solve the problems of easy deformation and deterioration, contamination of cream slices, etc., to achieve convenient production and operation, improve production efficiency, design scientifically sound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

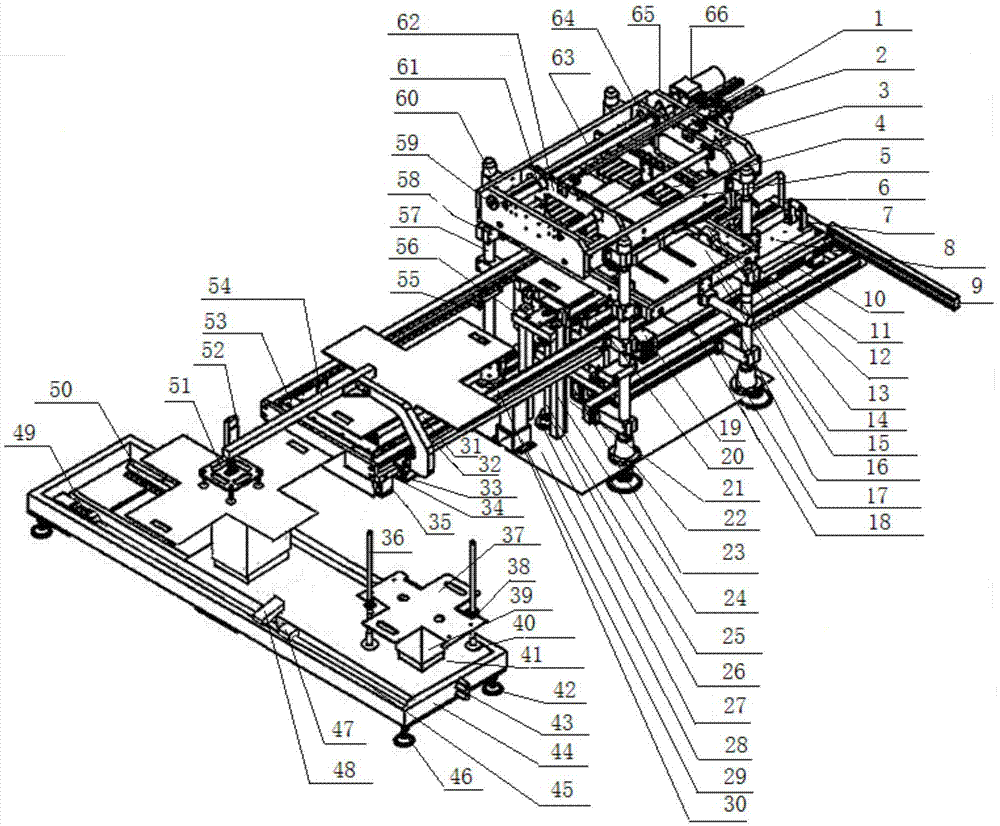

[0013] Referring to the accompanying drawings, an automatic lamination equipment for sheet cream includes four parts: a cross pallet part; a cross cardboard moving part; an automatic lamination part for cream flakes;

[0014] Cross pallet part:

[0015] Including cross pallet 37 (2 pieces), cross pallet lifting platform 39 (2 pieces), cross pallet moving platform 41, lead screw 45, servo motor 49, linear bearing 47, cross pallet moving platform guide shaft 50, base 46, buffer cylinder 43, bottom plate 44; said cross pallet 37 (2 pieces) and cross pallet lifting platform 39 (2 pieces) are made into one, and there are driving motor and lead screw inside the one, driven by the motor, through the wire Driven by the bar, the lifting work is automatically completed; the cross pallet 37 (2), the cross pallet lifting platform 39 (2) and the cross pallet mobile platform 41 are made into one, and the screw 45 is driven by the servo motor 49 to rotate , driven by the linear bearing 47 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com