Apparatus and method for separating stacks of food products slices

a technology of food products and stacking, applied in the field of food product packaging, can solve the problems of time-consuming and laborious process, difficulty for users, and difficulty in arranging cheese slices for end users of stacked cheese slices,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

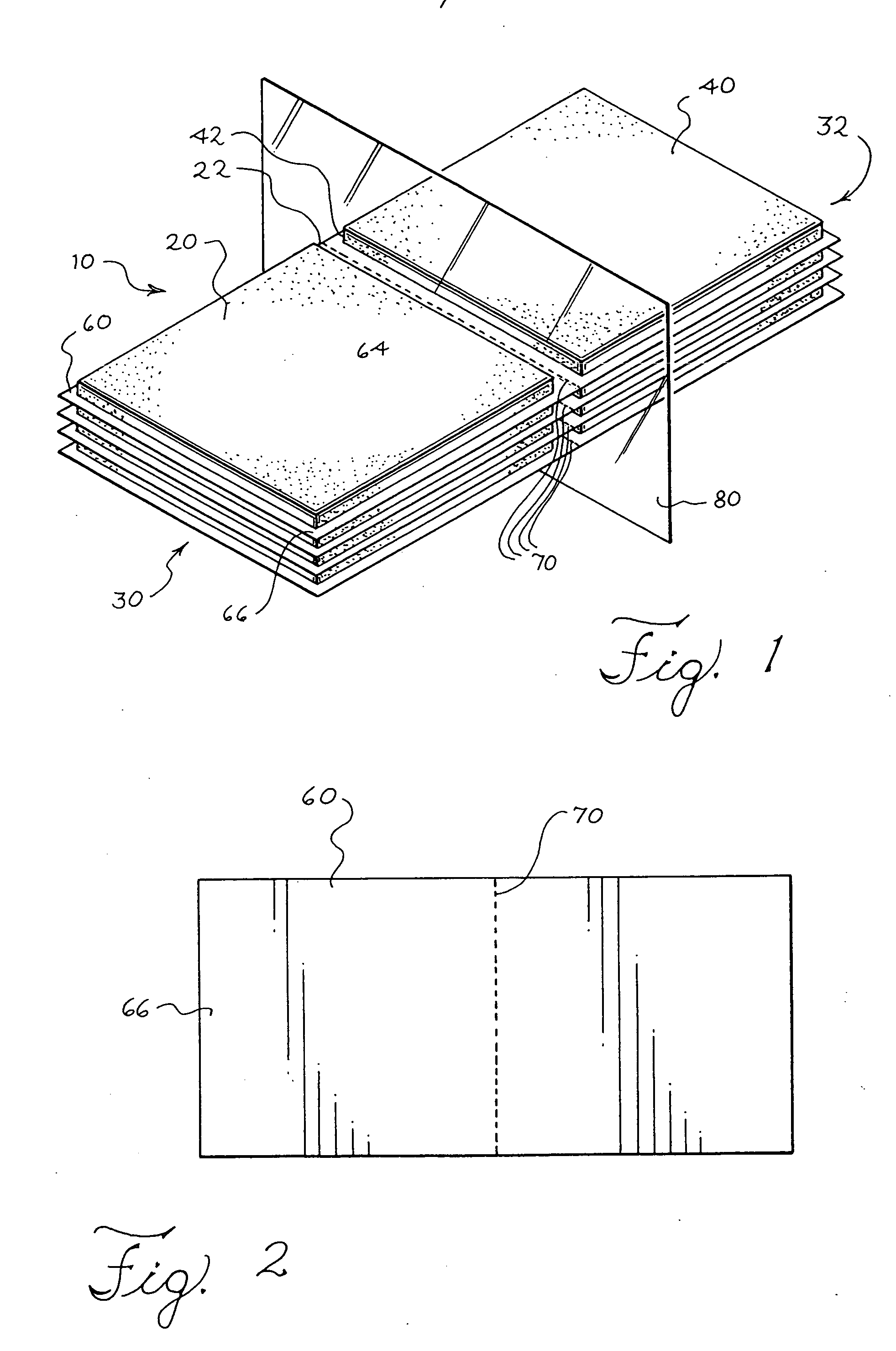

[0013] As shown in FIGS. 1-3, a plurality of food slices 20 and 40 can be arranged into adjacent columns 30 and 32. Specifically, as best shown in FIG. 1, columns 30 and 32 may be formed within close proximity to each other with an edge 22 of a first stack 30 arranged in parallel with an edge 42 of a second stack 32. In other embodiments, more than two columns of food slices can be formed in close proximity to the other stacks of food slices, with neighboring edges either parallel to each other or arranged in another manner to limit the space between the columns of food slices. Those skilled in the art will appreciate that the system and method described herein can apply to a variety of food products. For example, process cheese, meat, jelly, condiments, and the like can be arranged in accordance with this invention.

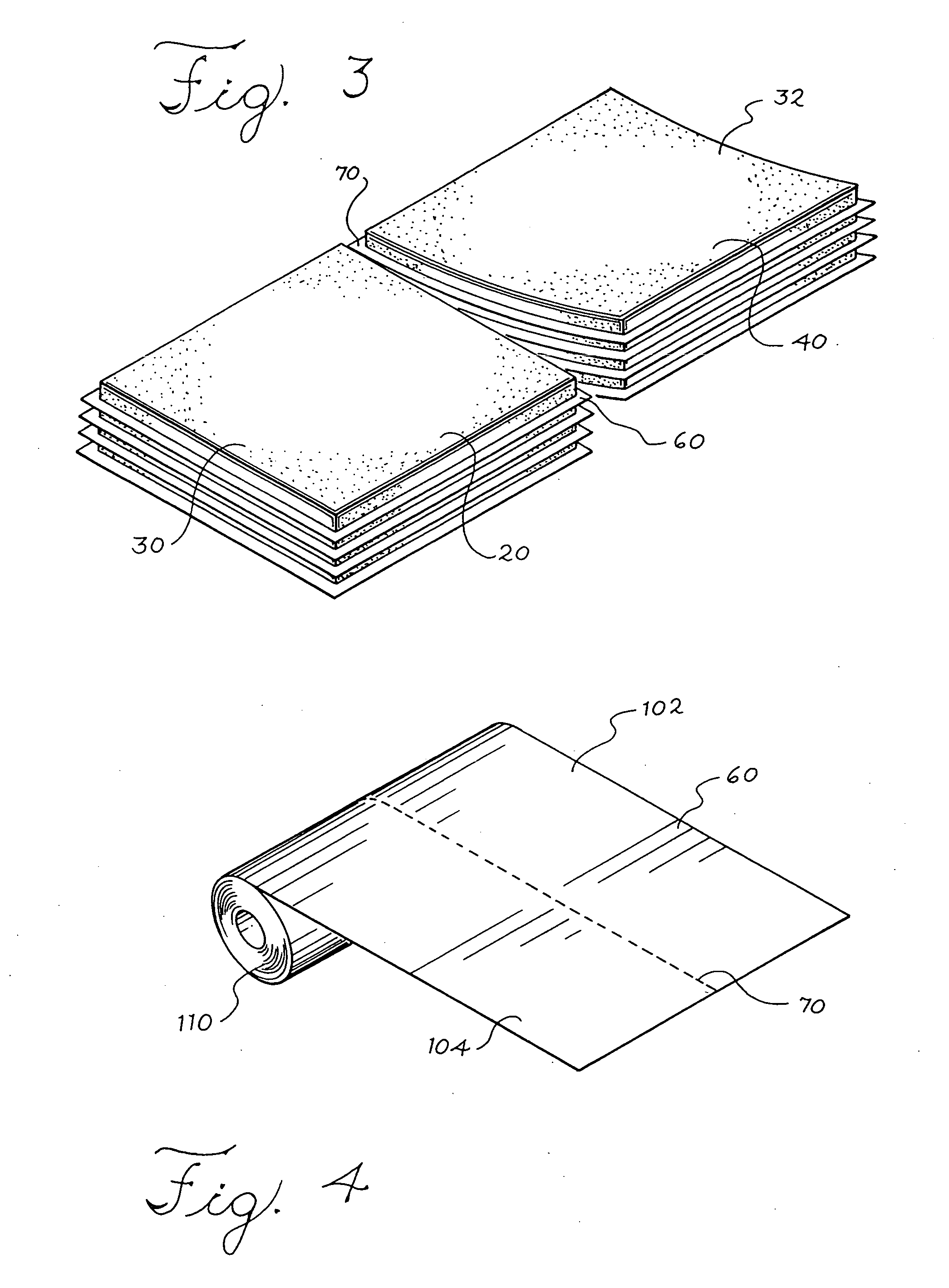

[0014] Each of the multiple food slices 20 and 40 in each column are separated by a divider, such as an interleaf 60. Preferably, interleaf 60 is formed as a sheet of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com