Seal banding machine

a banding machine and sealing technology, applied in the field of sealing bands, can solve the problems of economic loss, more prone to tear,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

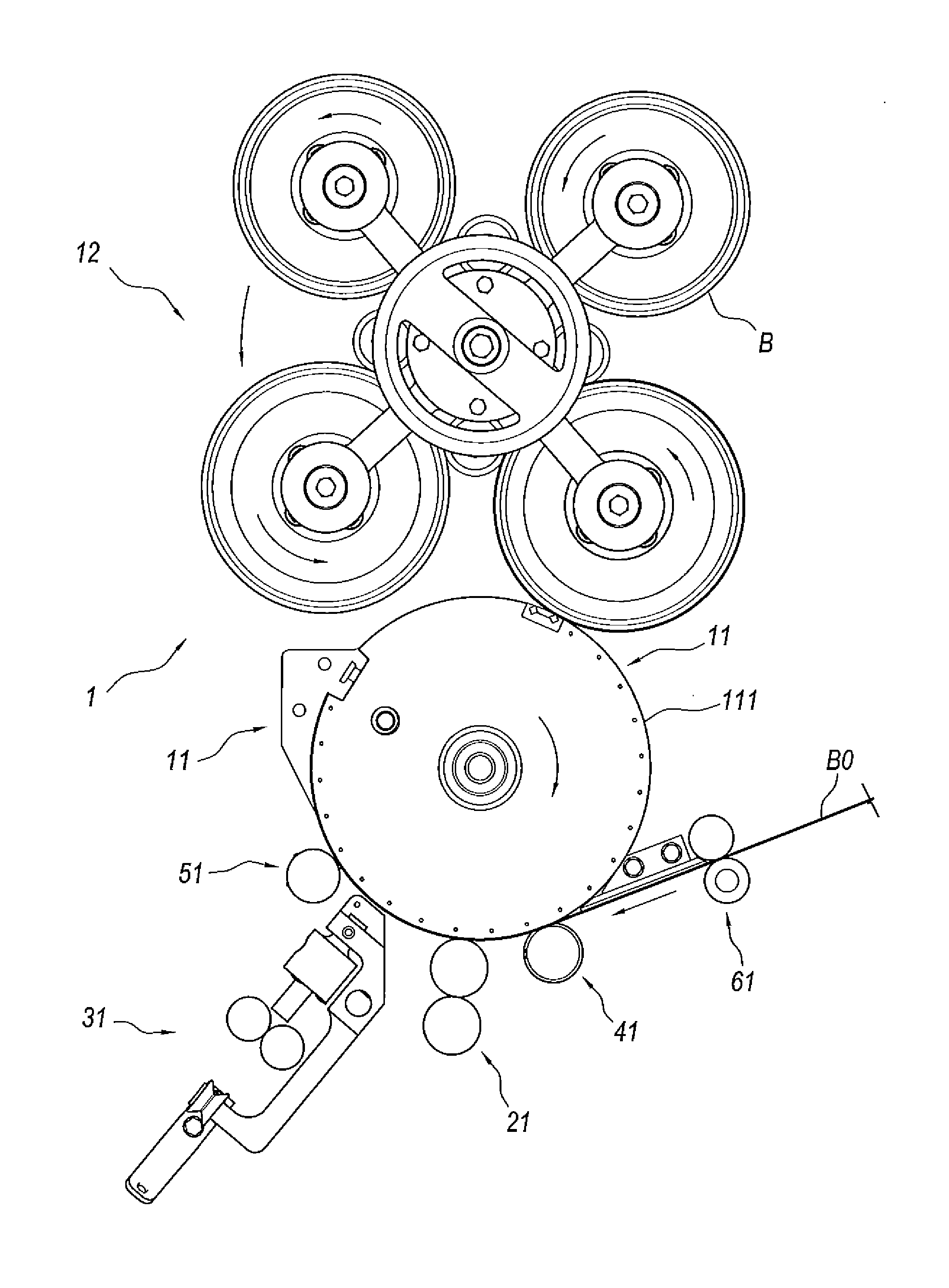

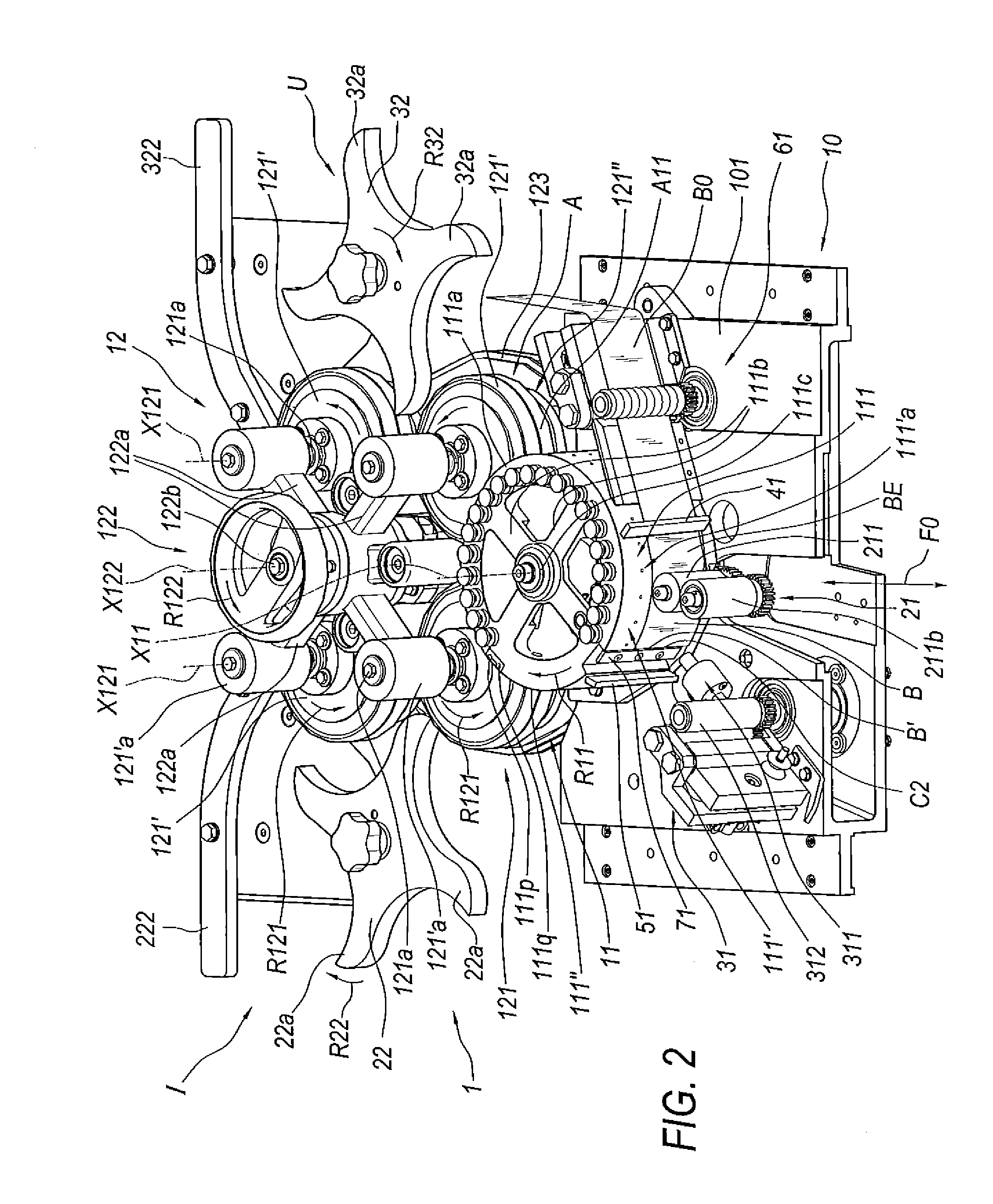

[0022]A preferred embodiment 1 of the seal banding machine is illustrated in FIG. 2. The seal banding machine 1 is designed to apply a sealing band B to the lateral surface A11 of a container body A, illustrated in FIG. 1, with a circular profile, in particular constituting a carton for containing portions of a pasty food product, especially processed cheese.

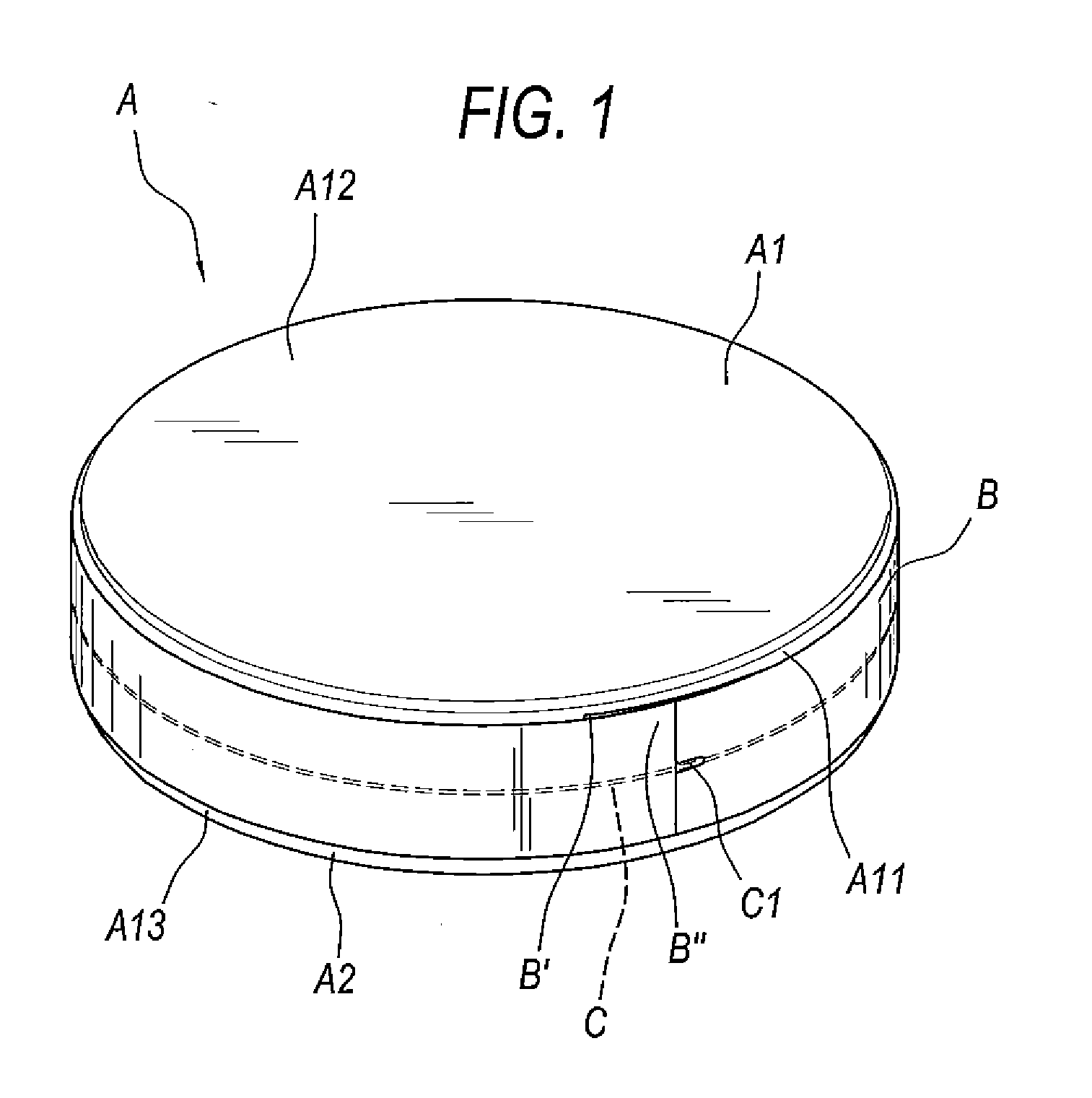

[0023]The carton A provided with the sealing band B is, as illustrated in FIG. 1, composed of a first and a second opposed half-shells A1, A2, which face each other in such a way as to form a chamber for housing the product or processed cheese portions.

[0024]As may be well inferred from FIG. 1, the half-shells A1, A2 have respective flat faces A12, A13, from which corresponding perpendicular portions extend to engage with each other and together form the circular perimeter wall A11 of the carton which, along its centre line has a perimeter slot to be covered with a sealing band B, or strip, of paper or other material wound round...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com