Blow molding medical bag and preparing method thereof

A blow molding and medicinal technology, which is applied in the directions of medical containers, drug packaging, packaging items, etc., can solve the problems of large one-time investment, high manufacturing cost, drug pollution, etc., achieves low pollution probability, avoids secondary pollution, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

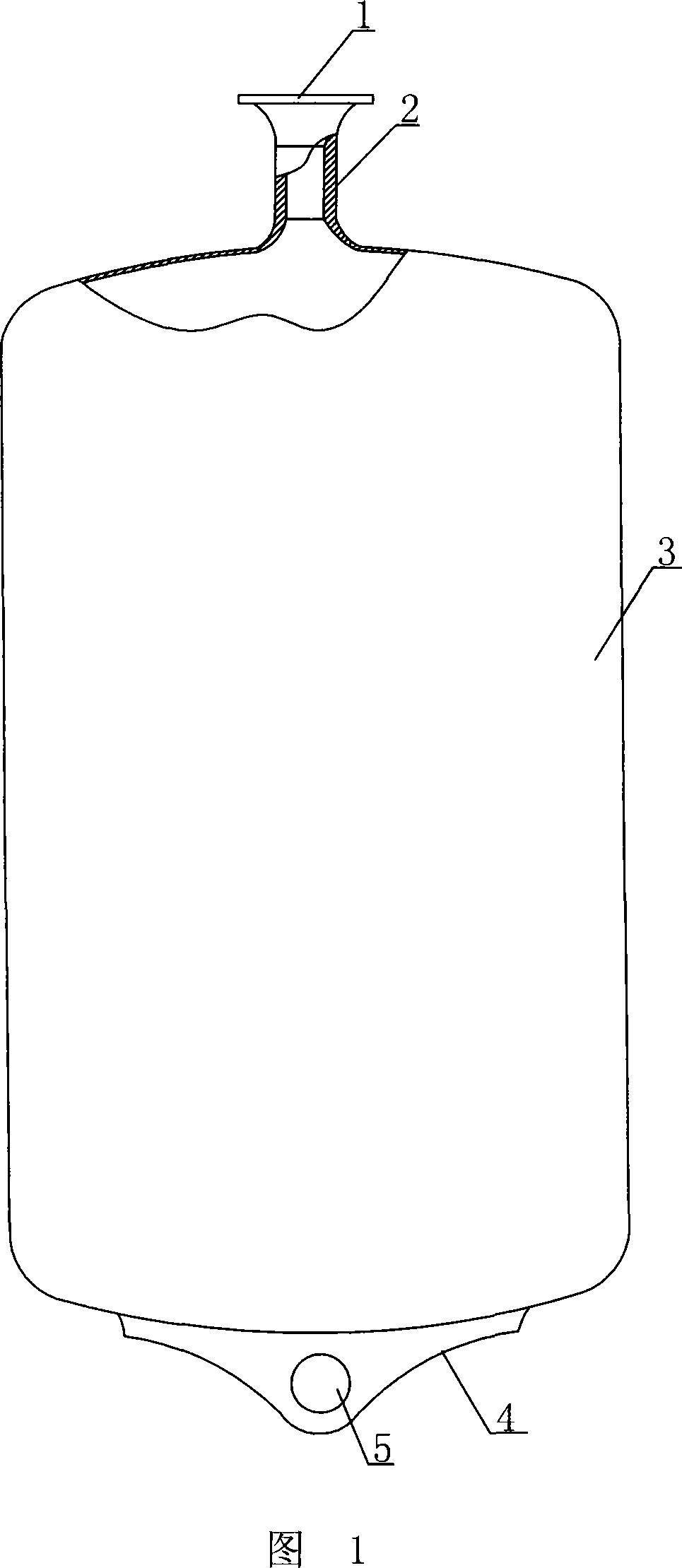

[0025] Embodiment 1 As shown in Figure 1, the bag body, filling port and suspension ring of the blow-molded pharmaceutical bag are integrally formed. The bag body 3 of the blow molding pharmaceutical bag is a flat soft structure, the edge of the bag body is curved, the thickness of the bag body wall is uniform, and one end of the bag body is provided with a protruding filling port 2, which is tubular body, the wall thickness of the tubular body is greater than the thickness of the bag body, and the end edge of the filling mouth is provided with an outwardly extending annular boss 1 . The suspension ring is a sheet body 4 integrally formed with the bag body, the sheet body is arranged at the end of the bag body opposite to the filling mouth, and a through hole 5 is offered on the sheet body.

[0026] The blow-molded pharmaceutical bag is made of medical-grade polyethylene, medical-grade polypropylene or medical-grade modified polypropylene, and the medical-grade polypropylene r...

Embodiment 2

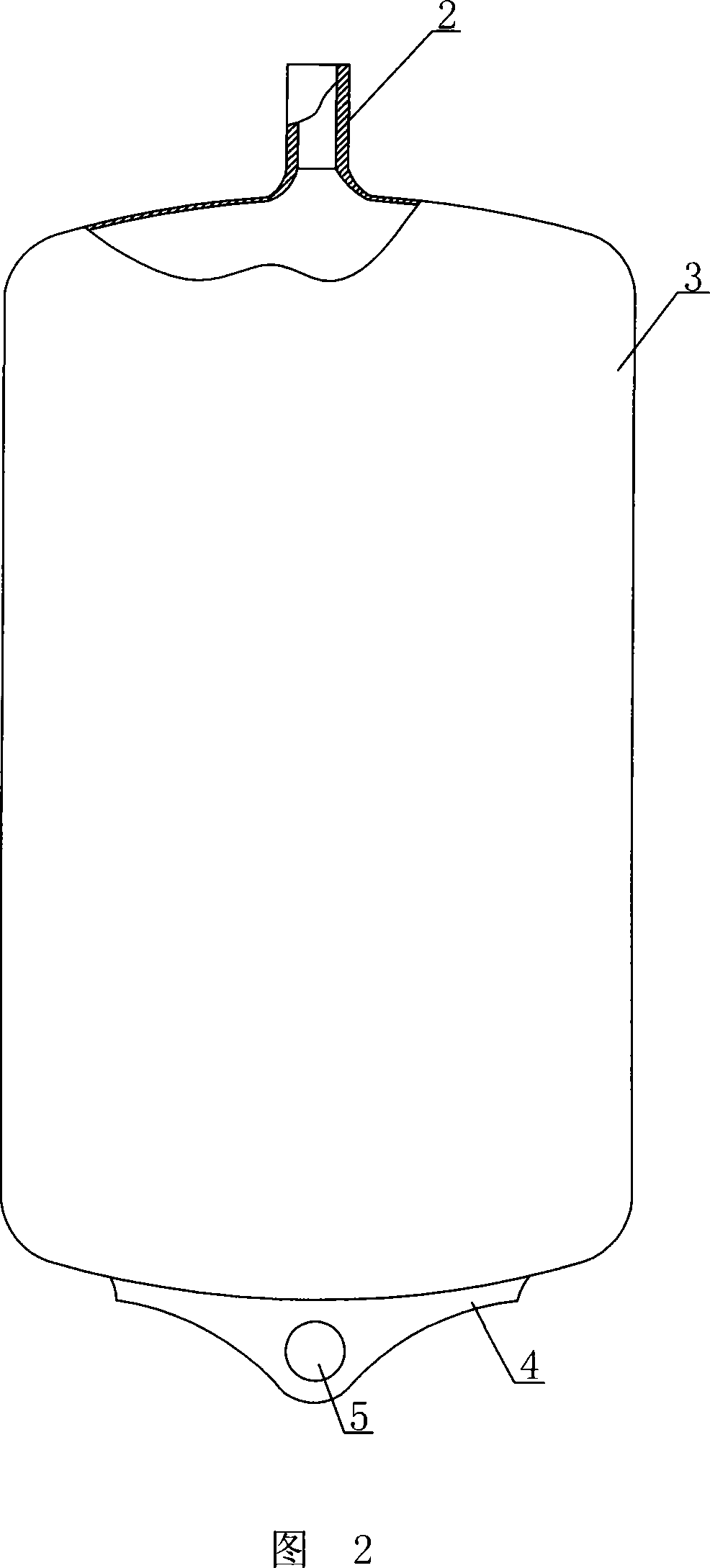

[0027] Embodiment 2 As shown in Figure 2, the bag body, filling port and suspension ring of the blow-molded pharmaceutical bag are integrally formed. The bag body 3 of the blow molding pharmaceutical bag is a flat soft structure, the edge of the bag body is curved, the thickness of the bag body wall is uniform, and one end of the bag body is provided with a protruding filling port 2, which is tubular Body, the wall thickness of the tubular body is greater than the thickness of the bag body, the suspension ring is a sheet body 4 integrally formed with the bag body, the sheet body is arranged at the end of the bag body opposite to the filling mouth, and a through hole is opened on the sheet body 5.

[0028] The blow molding pharmaceutical bag medical grade polyethylene, medical grade polypropylene or medical grade modified polypropylene adopts hollow blow molding method and hollow blow molding equipment to make medical grade polyethylene, medical grade polypropylene or medical g...

Embodiment 3

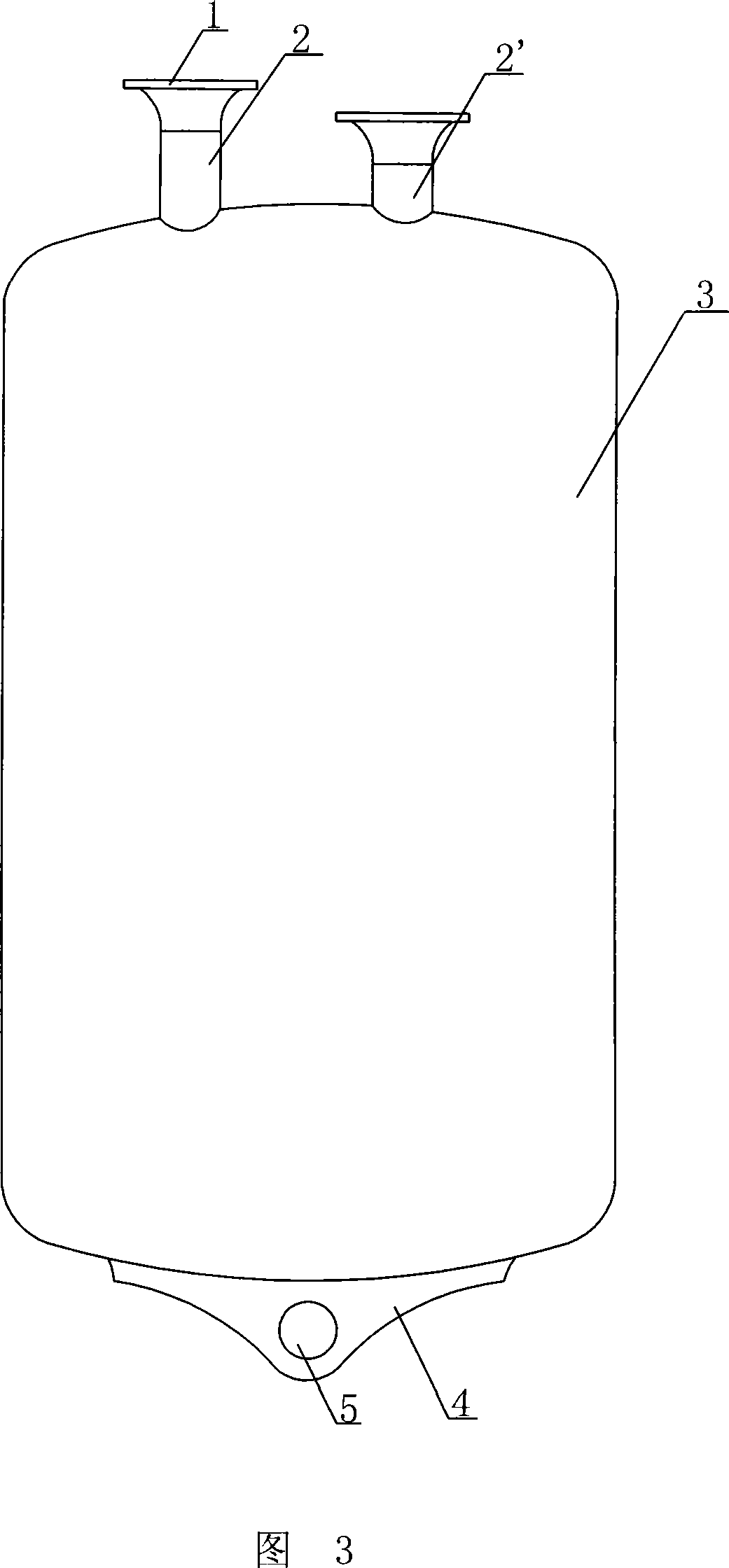

[0029] Embodiment 3 As shown in Figure 3, the bag body, filling port and suspension ring of the blow-molded pharmaceutical bag are integrally formed. The bag body 3 of the blow-molded pharmaceutical bag is a flat soft body structure, the edge of the bag body is arc-shaped, the thickness of the bag body wall is uniform, and one end of the bag body is provided with protruding filling ports 2 and 2'. The mouth is two tubular bodies arranged at the same end of the bag body. The two tubular bodies are adjacently arranged at one end of the bag body opposite to the suspension ring. The thickness of the pipe wall of the tubular body is greater than the thickness of the bag body. There is an annular boss 1 extending outward. The suspension ring is a sheet-shaped body 4 integrally formed with the bag body, the sheet-shaped body is arranged at the end of the bag body opposite to the filling mouth, and a through hole 5 is opened on the sheet-shaped body.

[0030] The preparation method o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com