Water-based paint applied in aluminum-plastic plates and color steel coiled material

A water-based paint and pigment technology, applied in the paint field, can solve the problems of increasing respiratory diseases, reproductive system diseases, failing to meet the process requirements, poor paint effect, etc., achieving excellent solvent resistance (xylene) and not affecting production Efficiency, the effect of good marketing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

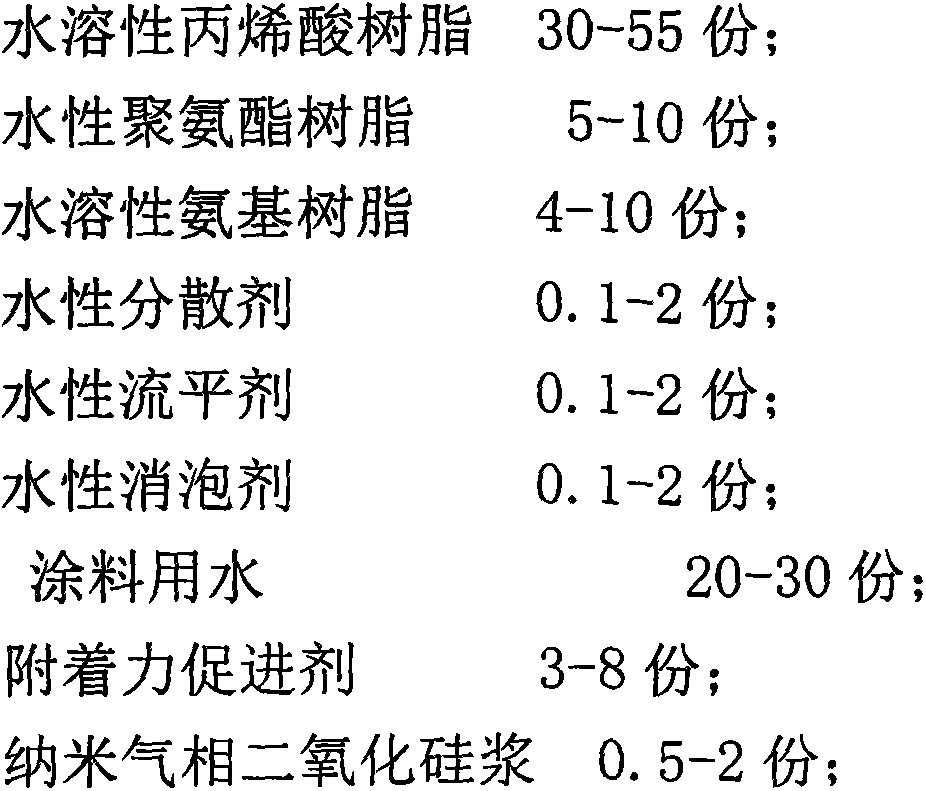

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of nano fumed silica slurry is to add 5 parts of water-based dispersant and 2 parts of water-based wetting agent to 100 parts of ethanol and stir until uniform, then add 20 parts of fumed silica and stir until uniform, soak for 24 hours and then grind Complete the preparation to a fineness of 2 μm

[0023] The character description for the used component of the present invention is as follows:

[0024] Water-soluble acrylic resin: an acrylic resin that contains enough polar groups or ions in the main chain or side chain to be soluble in water; mainly includes poly(meth)acrylic acid, poly(meth)acrylamide and some N-substituted poly(meth)acrylamide, poly(meth)acrylate, etc.; used in the examples of the present invention were purchased from Tianjin Ziming Chemical Co., Ltd., the product model is 503.

[0025] Water-soluble amino resin: it is an amino resin that can dissolve in water. The amino resin used in the embodiment of the present invention is...

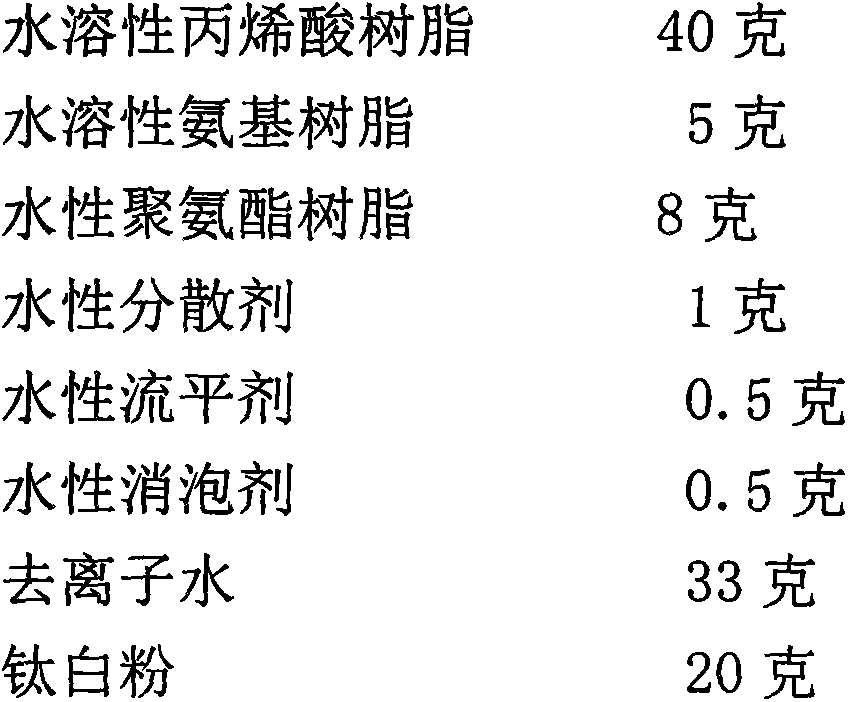

Embodiment 1

[0041] Embodiment 1 is used for the white paint of aluminum-plastic panel surface coating

[0042] First prepare adhesion promoter, its preparation method is as follows:

[0043] 1) Mix and stir 100 g of branched-chain polyester resin and 5 g of N, N-dimethylethanolamine; the stirring time is 20 min;

[0044] 2) Then mix and stir 50 g of N-methylpyrrolidone and 5 g of 3-(2,3-epoxypropoxy)propyltrimethoxysilane; stir for 20 minutes in the same way;

[0045] 3) Warm up the mixed solution prepared in step 1) to 95°C, then add dropwise the solution prepared in step 2) (completely added within 10-15 minutes), stir and react for 30 minutes, and then cool down to 40°C after the reaction is completed. After ℃, add 1 g of N,N-dimethylacetamide, and stir for 20 minutes to complete the preparation.

[0046] Prepare nano fumed silica slurry, add water-based dispersant 5g, water-based wetting agent 2g in 100ml ethanol (in the specification sheet of the present invention, ethanol, water 1...

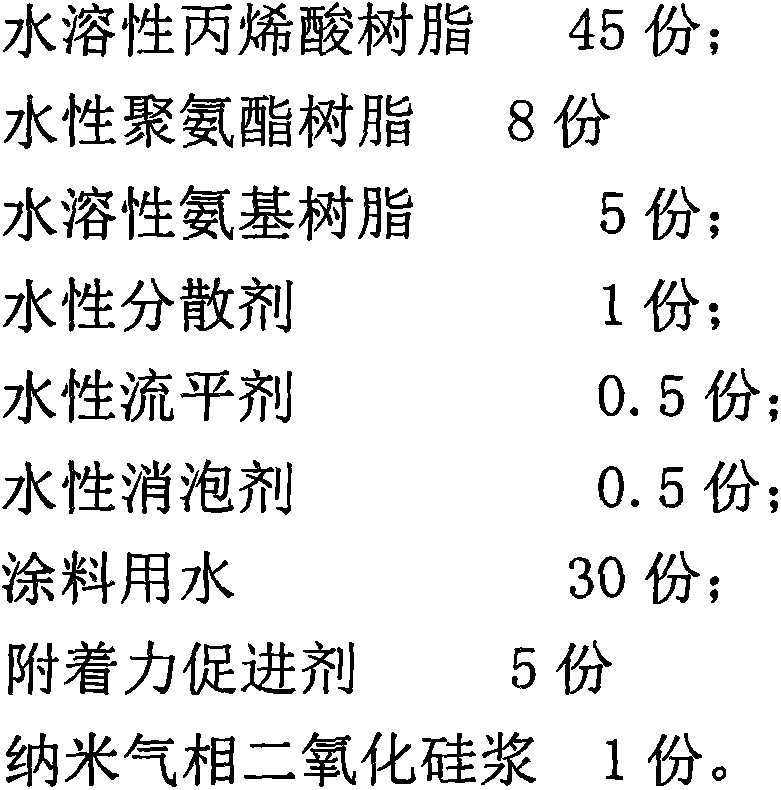

Embodiment 2

[0051] Embodiment 2 is used for the silver paint of aluminum-plastic panel surface coating

[0052] The silver paint used for the surface coating of aluminum-plastic panels, the distribution ratio of each component (by weight):

[0053]

[0054] Wherein the adhesion promoter and the nano fumed silica slurry are prepared by the method described in Example 1, but the amounts of the components can be adjusted within the scope of the description of the invention.

[0055] When preparing coatings, add water-soluble acrylic resin, water-soluble amino resin, water-based polyurethane resin, water-based leveling agent, water-based dispersant, adhesion promoter, and water-based defoamer to a clean container in sequence, stir evenly, and filter (800-mesh filter screen) for subsequent use; then mix and stir with nano fumed silica slurry for 30 minutes, then add aluminum slurry and water and stir evenly to obtain the finished water-based paint. In order to have a better effect during u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com