Ozone process for denim

a denim fabric and ozone technology, applied in the dyeing process, other washing machines, liquid cleaning, etc., can solve the problems of high cost, unfriendly to the environment, and high cost of the process, and achieve the effects of high cost, unfriendly to the environment, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

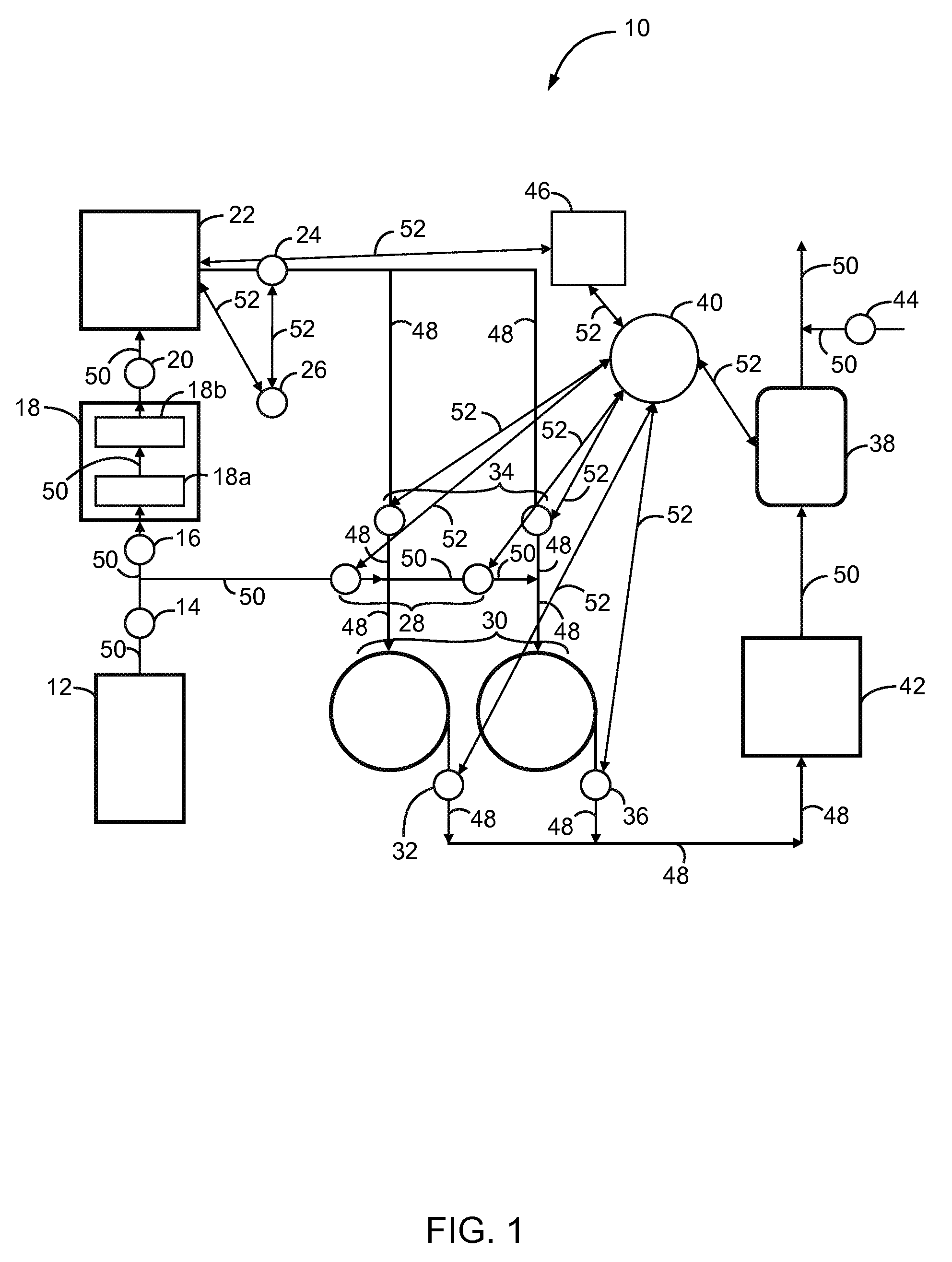

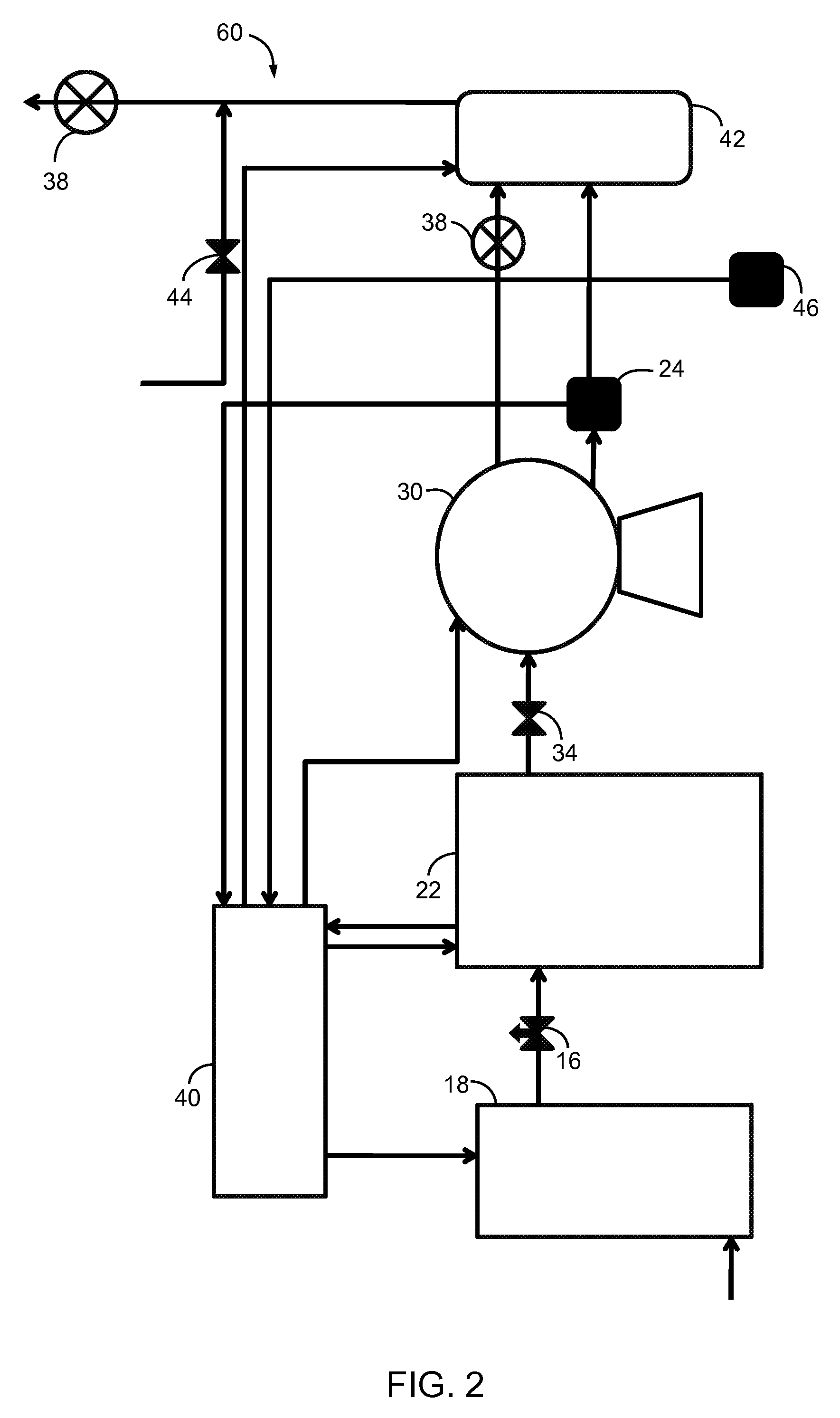

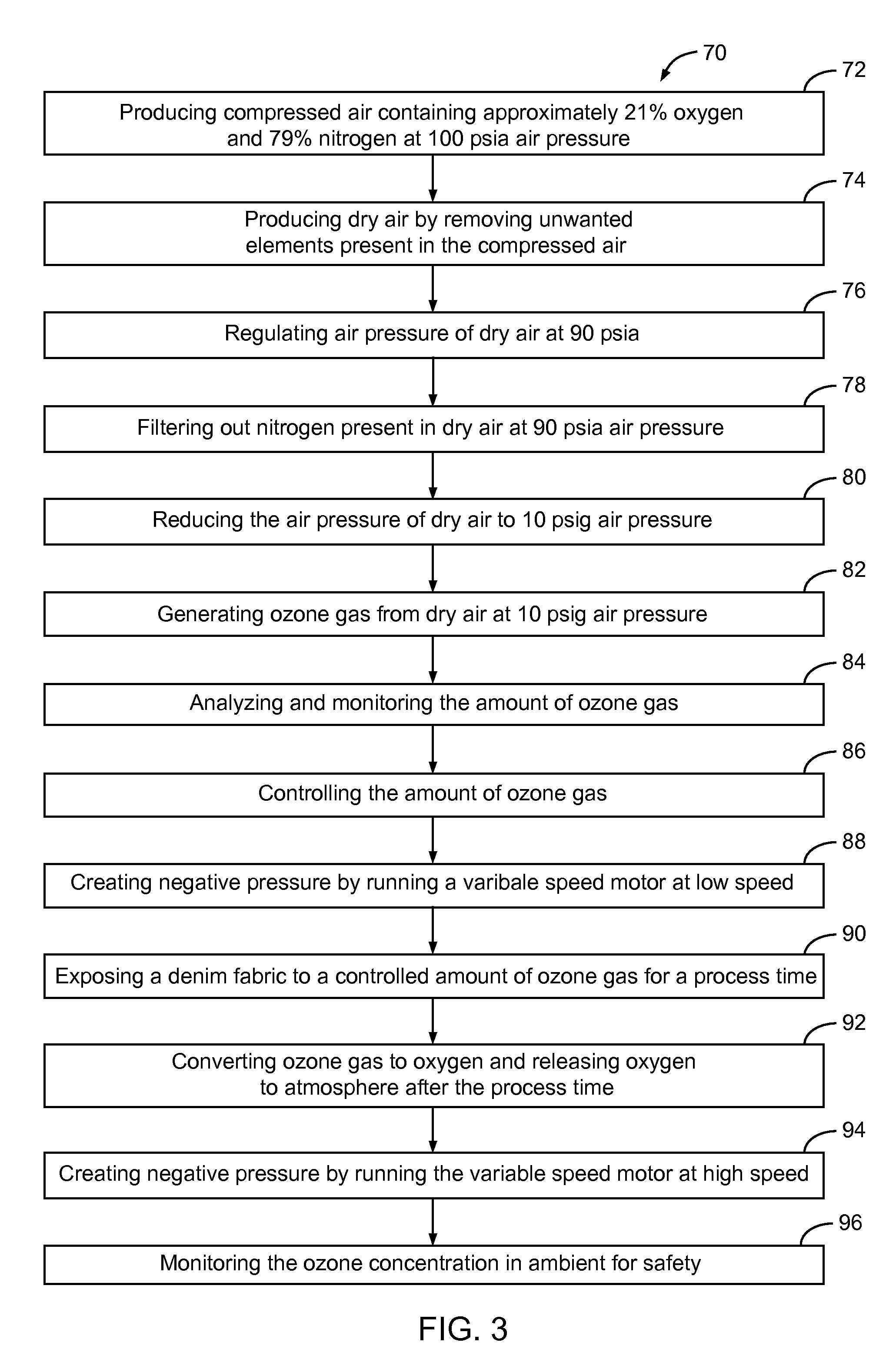

[0019]FIG. 1 illustrates an apparatus for decolorizing at least one denim fabric 10 with an oxidizing gas comprising at least one air compressor 12 for producing compressed air, at least one air separator 14 for producing dry air, and at least one pressure regulator 16 for regulating the air pressure of dry air at an air pressure of about 90 psia. The at least one air compressor 12 produces compressed air containing approximately of about 21% oxygen and approximately of about 79% nitrogen at an air pressure of about 100 psia (pounds per square inch absolute). The at least one air separator 14 removes the unwanted elements from the compressed air. The unwanted particles in the compressed air may include oil, moisture or the like.

[0020]The apparatus 10 further includes at least one oxygen generator 18 that filters out nitrogen present in the dry air at the air pressure of about 90 psia for producing dry air containing approximately of about 95% pure oxygen. The at least one oxygen gen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com