Systems For Treating A Garment With Pre-Treatment Solution, And Related Methods

a technology for treating systems and garments, applied in textile treatment by spraying/projecting, dyeing process, cleaning using liquids, etc., can solve problems such as the failure of known dispensing systems, the overspray of treatment solutions directed at garments, and the bouncing of pre-treatment solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

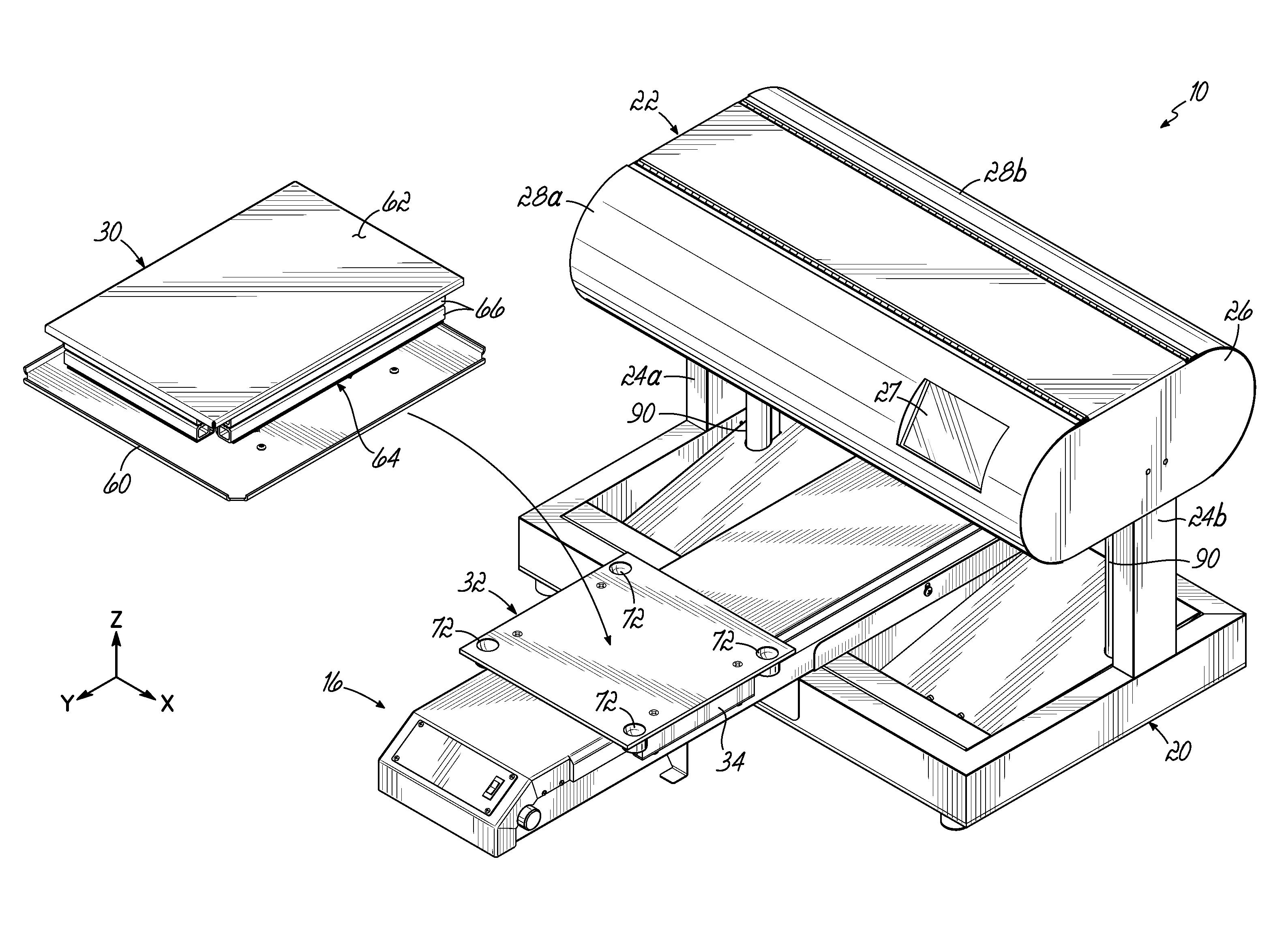

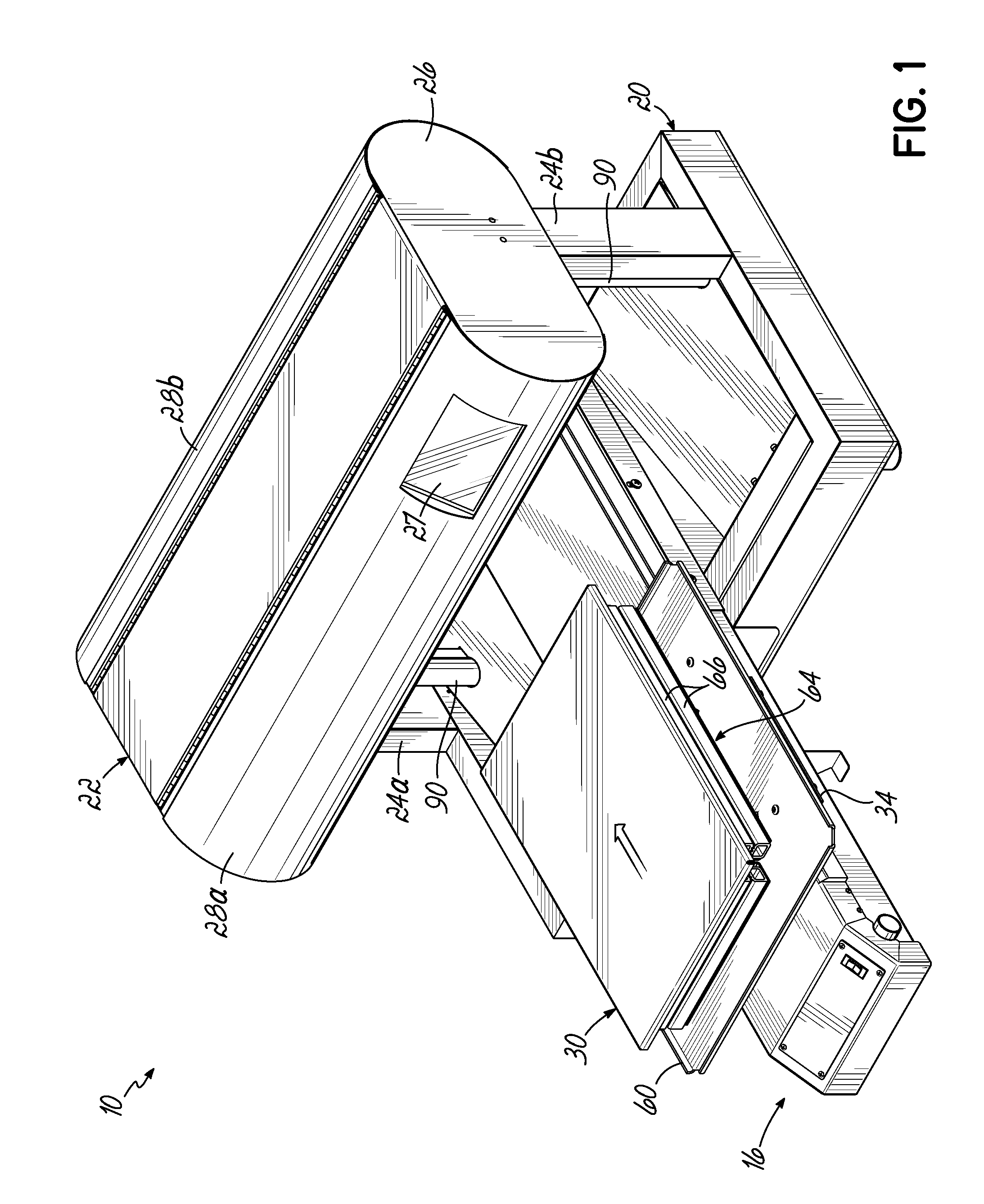

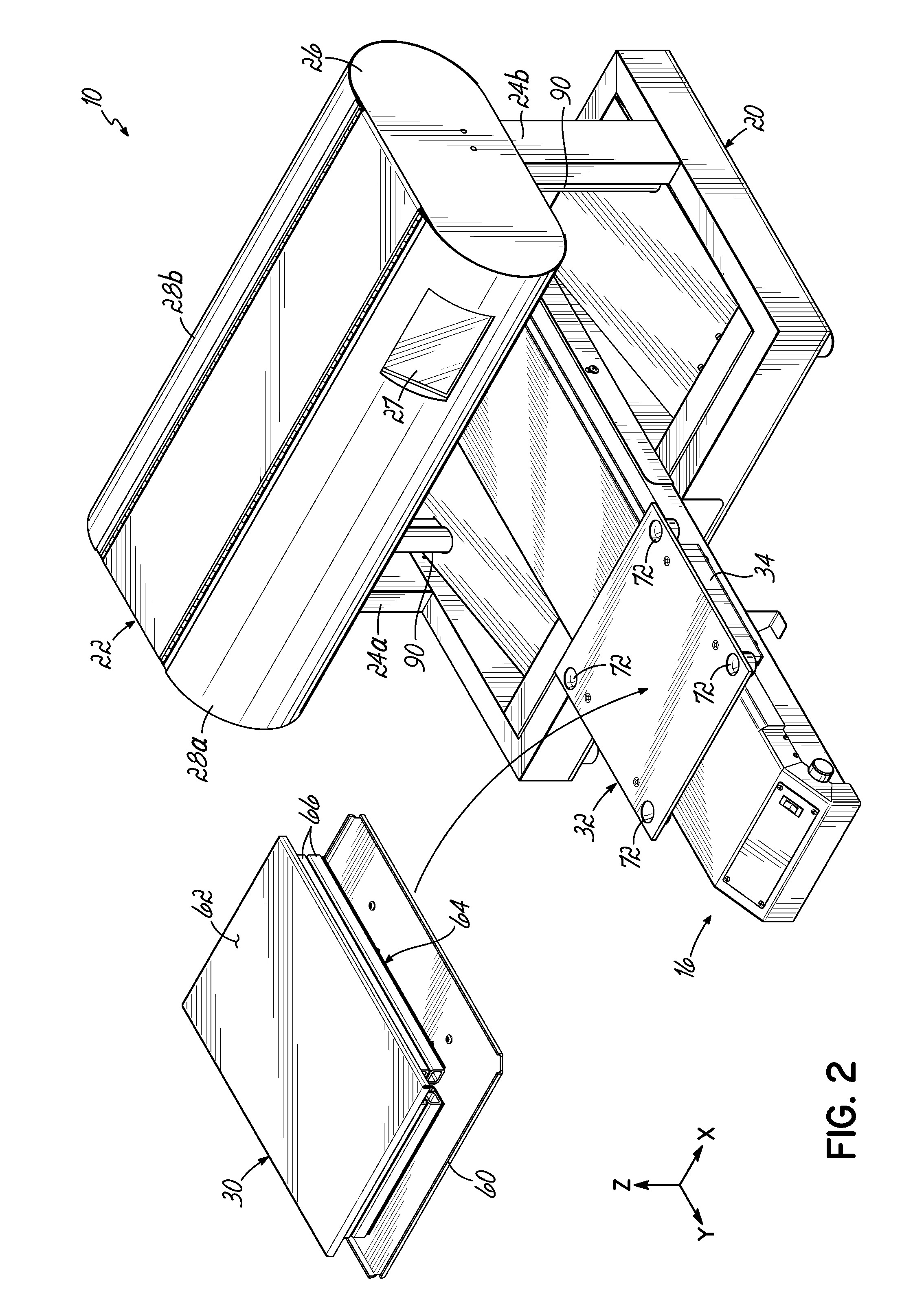

[0031]Referring to the figures, an exemplary system for treating a garment with a pre-treatment solution is shown and is generally indicated by the numeral 10. As will be apparent from the following discussion, the system 10 treats a garment with pre-treatment solution in a pre-treatment operation before the garment undergoes a printing operation.

[0032]As shown in FIGS. 1-5, the system 10 generally includes a fluid application assembly 12 that is configured to dispense pre-treatment solution onto a portion of a garment. In particular, the fluid application assembly 12 is configured to dispense pre-treatment solution onto pre-determined target areas of a garment, such as those areas of the garment that will be printed on during a printing operation.

[0033]The system 10 also generally includes a fluid supply and delivery assembly 14. The fluid supply and delivery assembly 14 is configured to provide a supply of pre-treatment solution to the fluid application assembly 12, to which it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressures | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| areas | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com