Thermal-insulation photovoltaic tile and producing method thereof

A technology of thermal insulation and photovoltaic tiles, applied in photovoltaic power generation, roofs using tiles/slate tiles, sustainable buildings, etc., can solve problems such as heavy weight and complicated installation, and achieve low density, convenient construction, environmental protection, and space The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

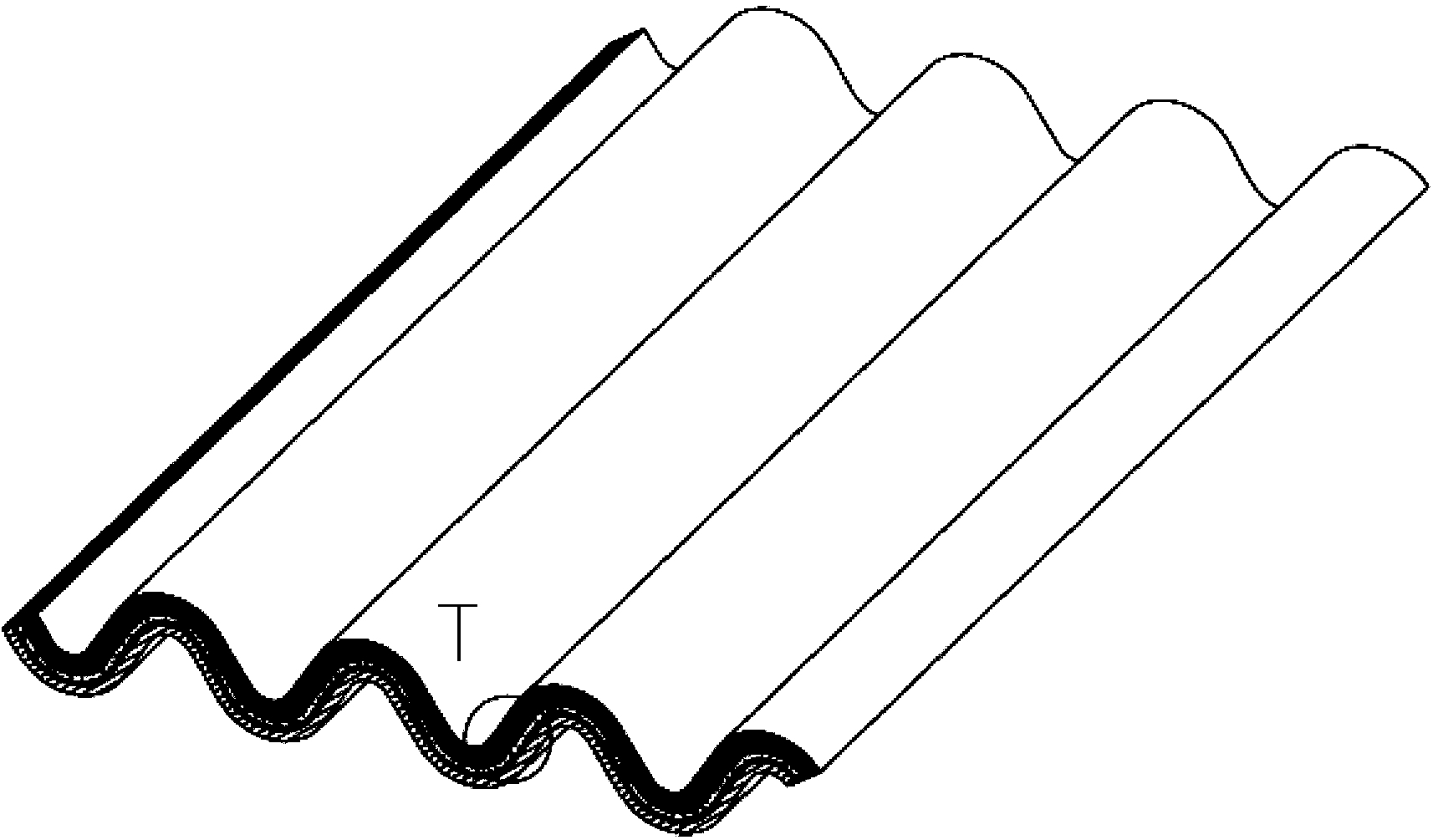

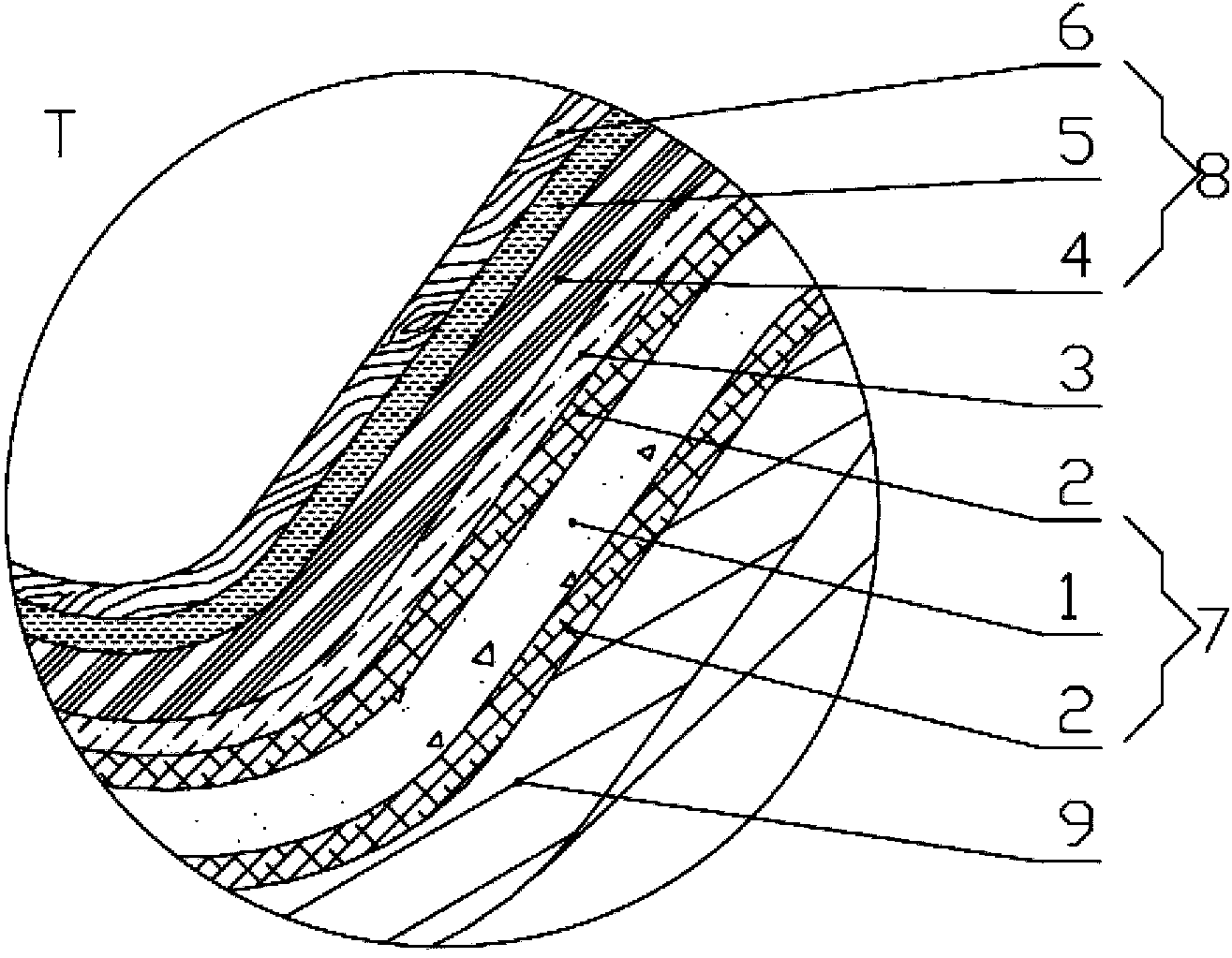

[0042] Such as figure 1 and figure 2 As shown, a thermal insulation photovoltaic tile is composed of a flexible thermal insulation substrate 7 and a flexible photovoltaic cell assembly 8 bonded thereon by a flame-retardant polymer binder 3, and the flexible thermal insulation substrate 7 is The nano-silica airgel felt core material 1 covered with flexible waterproof sheets 2 on both sides; the flexible photovoltaic cell assembly 8 sequentially includes a flexible thin-film battery assembly 4, a film layer 5 and a coating layer 6 from the inside to the outside; The above-mentioned flexible waterproof sheet 2 has a layered structure, and from bottom to top are: a lower flame-retardant polymer cement mortar layer, a high-tough glass fiber reinforced flame-retardant non-woven fabric base and an upper flame-retardant polymer cement mortar layer, three layers The structure is consolidated into one; the nano-silica airgel felt 1 is a flexible nano-silica airgel as the main material...

Embodiment 2

[0048] Nano silica airgel felt core material 1 of the present invention has a thickness of 10mm, a width of 1500mm, and a density of 220kg / m 2 , the upper flame-retardant polymer cement mortar and the lower flame-retardant polymer cement mortar are both composed of the following raw materials in parts by weight: 42.5 parts of ordinary silicon cement, 40 parts of quartz sand, and silicon with a glass transition temperature at least below -5°C. 23 parts of acrylic emulsion, 17 parts of water, 8 parts of composite flame retardant; the thickness of the flame retardant polymer cement mortar layer is 4mm.

[0049] The composite flame retardant in the flame-retardant polymer cement mortar is formed by mixing aluminum hydroxide, magnesium hydroxide, decabromodiphenylethane and antimony trioxide, and the mass ratio is aluminum hydroxide: magnesium hydroxide: decabromo Diphenylethane: antimony trioxide=4:2:3:3. The high-tough glass fiber reinforced flame-retardant non-woven fabric base...

Embodiment 3

[0052] Nano silica airgel felt core material 1 of the present invention thickness: 5mm, width: 1100mm, density: 200kg / m 2 , the upper flame retardant polymer cement mortar and the lower flame retardant polymer cement mortar are both composed of the following raw materials in parts by weight: 15 parts of ordinary silicon 42.5 cement, 42 parts of quartz sand, silicon with a glass transition temperature at least below -5°C 20 parts of acrylic emulsion, 20 parts of water, 6 parts of composite flame retardant; the thickness of the flame retardant polymer cement mortar layer is 2.5mm.

[0053] The base material of the high-tough glass fiber reinforced flame-retardant non-woven fabric is made of denim reinforced non-woven fabric with a thickness of 0.5-1mm and a weight of 160g / m 2 . The flame retardant polymer binder 3 is composed of the following mass percentages: 60% silicone acrylic emulsion, 8.5% organophosphorus nitrogen flame retardant, 16.5% crosslinking agent, 15% solvent, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com