Novel pipeline polishing device

A pipeline and a new type of technology, applied in the direction of grinding drive devices, grinding machines, grinding frames, etc., can solve the problems of affecting the health of workers, high labor intensity, and dust prone to grinding, so as to achieve less manpower consumption and high grinding efficiency , Increase the effect of grinding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

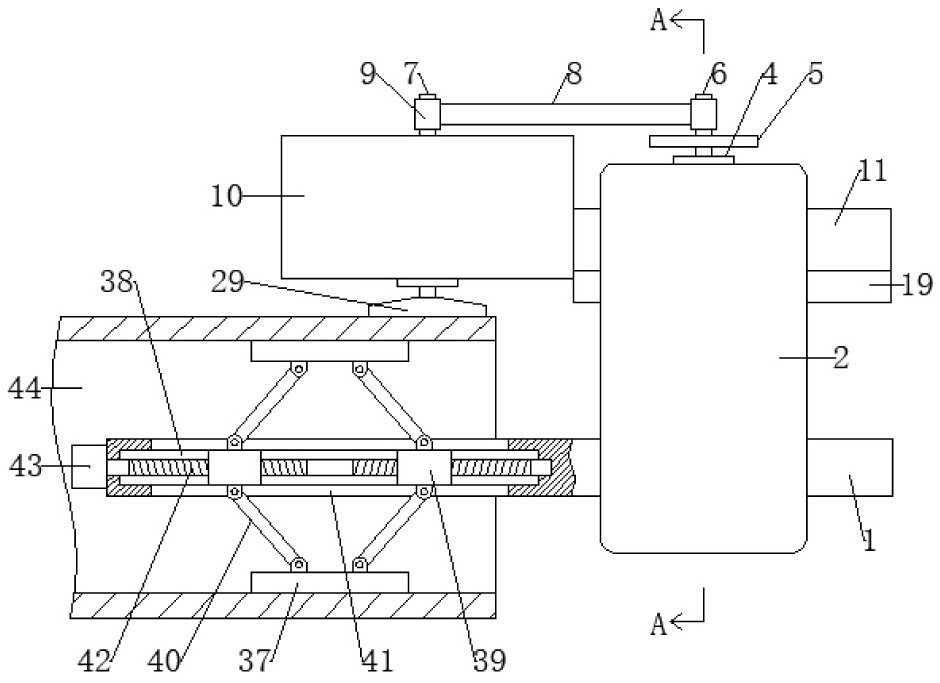

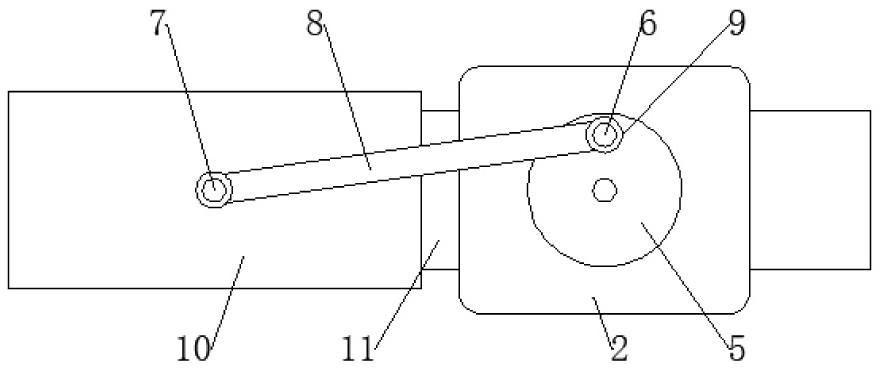

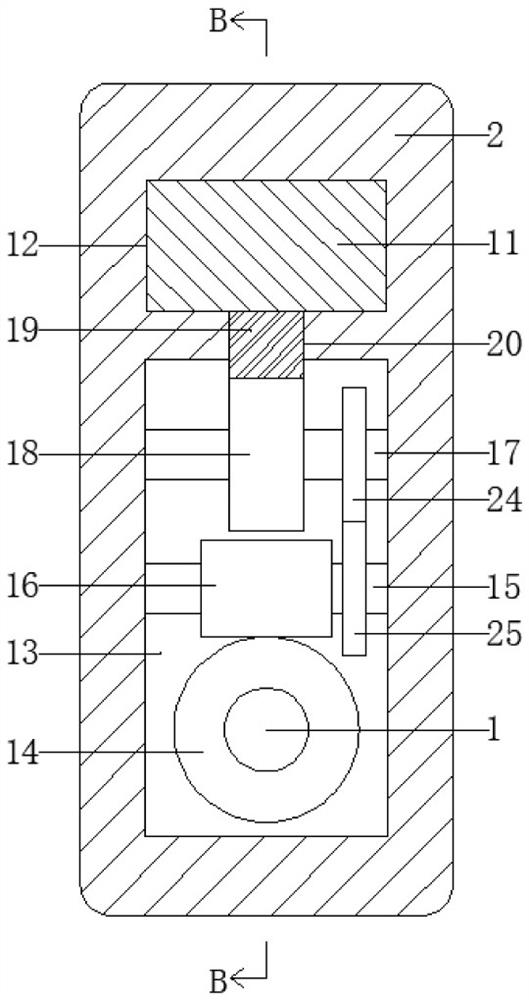

[0019] like Figure 1 to Figure 6 As shown, a new type of pipe grinding device includes a central shaft 1, one end of the central shaft 1 is provided with a pipe support mechanism, and the other end of the central shaft 1 is rotatably mounted with a rotating seat 2, on which the rotating seat 2 A support frame 3 is slidably installed along the length direction of the central axis 1, and a grinding mechanism is arranged on the support frame 3; a driving motor 4 is fixedly installed on the rotating base 2, and the rotation axis of the driving motor 4 is perpendicular to The central shaft 1 and the rotating shaft of the driving motor 4 are coaxially fixed with a drive disc 5, and the first small shaft 6 is fixedly mounted eccentrically on the drive disc 5, and the support frame 3 is fixedly mounted with a The first small shaft 6 is parallel to the second small shaft 7, a connecting rod 8 is arranged between the first small shaft 6 and the second small shaft 7, and the two ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com