Mobile terminal shell and machining method thereof

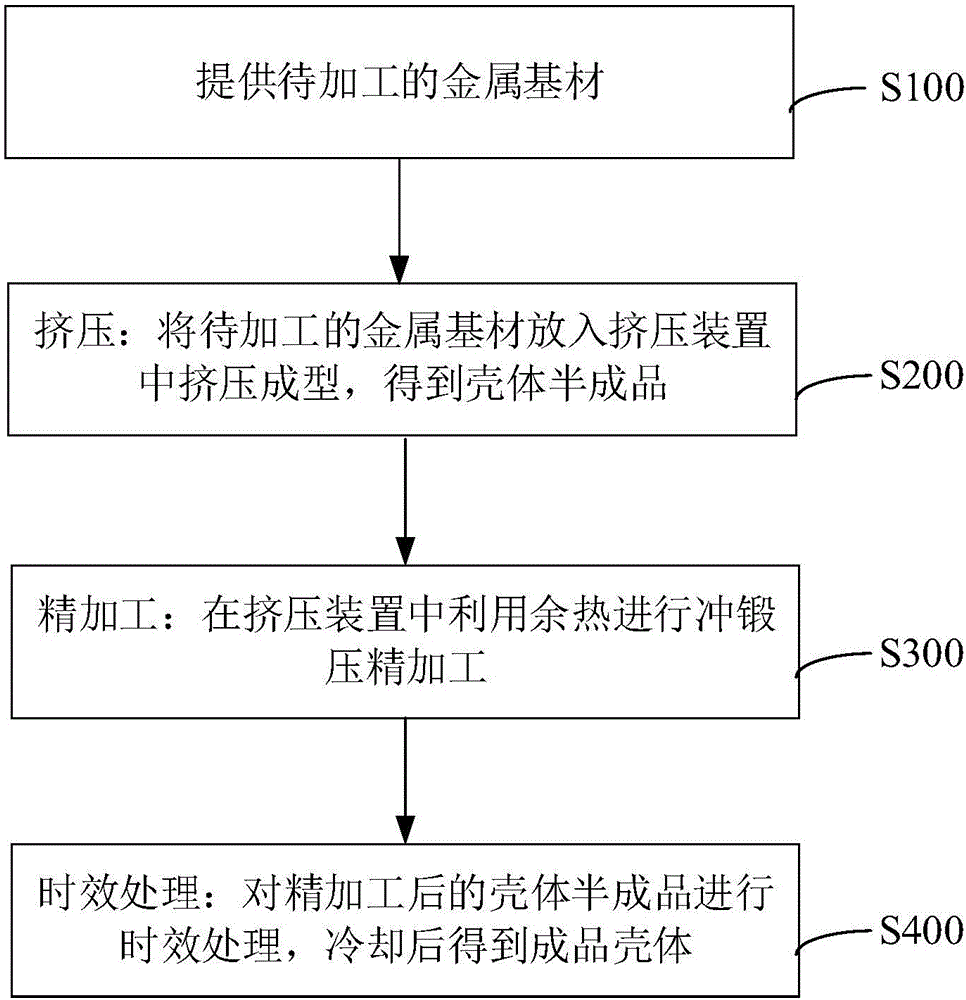

A technology of a mobile terminal and a processing method, which is applied in the processing field of mobile terminal equipment, can solve the problems of high CNC processing cost, low material utilization rate, and many wastes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: 6063 aluminum alloy is used as the raw material. After the rough machining of the 6063 aluminum alloy and the finish machining of stamping and forging, aging treatment is performed on the finished shell semi-finished product.

[0032] Among them, during the aluminum extrusion molding process, the regulating valve is controlled so that the nitrogen gas enters the extrusion device at a speed of 1m 3 / h.

[0033] The aging treatment temperature is 200° C., and the aging treatment time is 2 hours.

Embodiment 2

[0034] Embodiment 2: 6063 aluminum alloy is used as the raw material. After the rough machining of the 6063 aluminum alloy aluminum extrusion and the finish machining of stamping and forging, aging treatment is performed on the semi-finished shell finished after finishing.

[0035] Among them, during the aluminum extrusion molding process, control the regulating valve so that the speed of nitrogen entering the extrusion device is 0.6m 3 / h.

[0036] The aging treatment temperature is 195° C., and the aging treatment time is 3 hours.

Embodiment 3

[0037] Embodiment 3: 6063 aluminum alloy is used as the raw material. After the rough machining of the 6063 aluminum alloy and the finish machining of stamping and forging, aging treatment is performed on the finished shell semi-finished product.

[0038] Among them, during the aluminum extrusion molding process, the regulating valve is controlled so that the nitrogen gas enters the extrusion device at a speed of 0.3m 3 / h.

[0039] The aging treatment temperature is 180°C, and the aging treatment time is 6h.

[0040] The present invention also provides mobile terminal casings, such as middle frames of mobile phones, middle frames of tablet computers, etc., made by using the above-mentioned processing method for mobile terminal casings.

[0041] The above mobile terminal shell processing method adopts the extrusion molding method, no residual material is generated during extrusion, and a large amount of CNC processing is saved, and both rough machining and finishing are carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com