Continuous production device for agricultural water-retaining agent

A technology for agricultural water-retaining agent and production equipment, which is applied in the direction of extrusion and granulation of raw materials, chemical/physical/physical-chemical stationary reactors, etc. Small floor area, simple structure, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

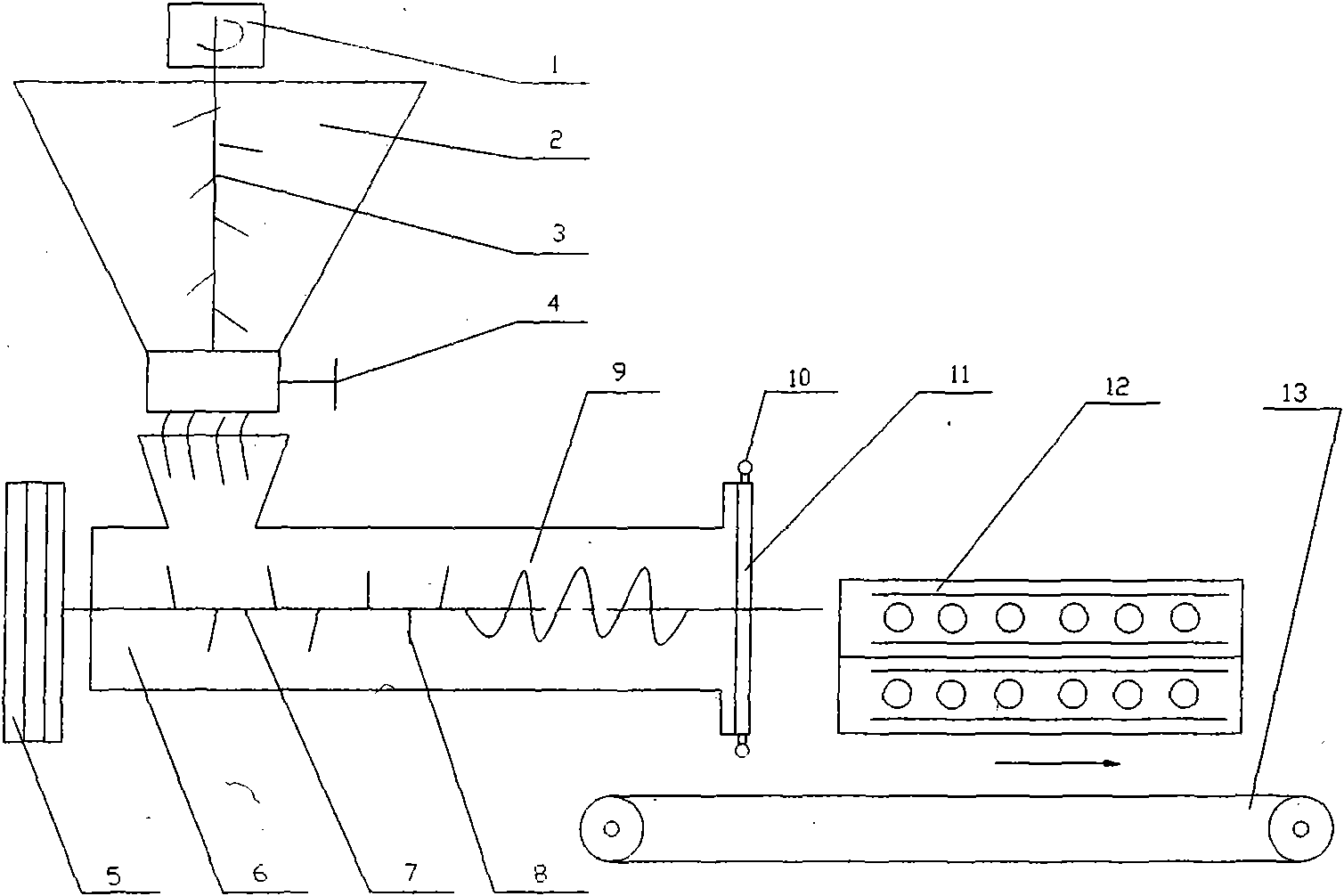

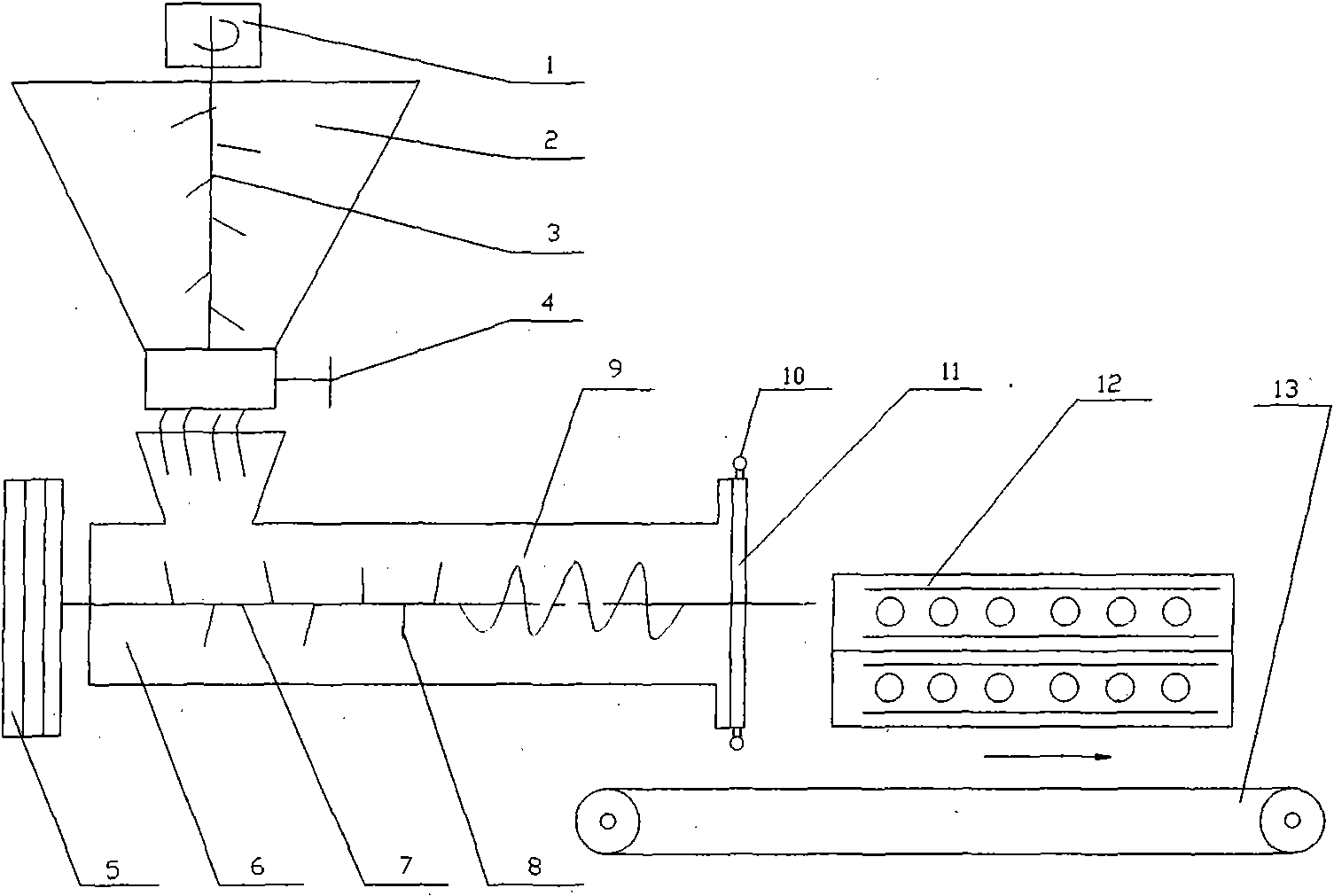

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the reactor body 2 is provided with a stirring shaft 3 of the reactor body, the reactor body is conical, and the stirring shaft of the reactor body is connected to the variable speed motor 1, and the stirring speed can be adjusted; the outlet at the bottom of the reactor body is provided with a valve 4, the cylinder The feed port of the body 6 is located below the discharge port at the bottom of the reactor body, and the cylinder stirring shaft 7 is arranged in the cylinder, and the cylinder stirring shaft is connected to the power pulley 5, and the cylinder stirring shaft is successively provided with a conveying device and a belt stirring extrusion shaft 9 The granulation device, the conveying device is composed of the cylinder stirring shaft 7 and the conveying stirring blade 8; the cylinder granulation outlet 11 is equipped with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com