Concrete mixing plant control system construction method

A control system and construction method technology, applied in the direction of mixing operation control, mixing plant, clay preparation equipment, etc., can solve problems such as poor reliability and unstable communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

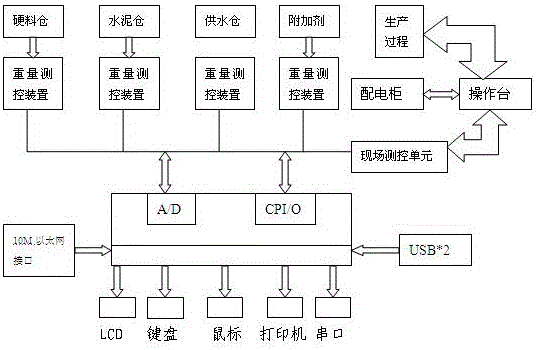

[0007] As described in Book 1, a concrete mixing plant control system described in the embodiment of the present invention is constructed, and its system is realized by the system hardware structure and system software design. It is characterized in that the LPC2210 microcontroller is based on a 32 / 16-bit ARM7TDM1-SCPU supporting real-time simulation and embedded tracking, and the software design adopts UC / OS-II, which is more suitable for embedded systems with tight resources. It is specifically implemented according to the following embodiments.

[0008] LPC2210 and interface circuit. The LPC2210 microcontroller is based on a 32 / 16-bit ARM7TDM1-SCPU that supports real-time simulation and embedded tracking. Due to the 144-pin package of the LPC2210, extremely low power consumption, multiple 32-bit timers, 8-way 10-bit ADC, and internal viewing Gates and up to 70 CPI / Os make it especially suitable for automatic control of mixing plants. Among them, 8 channels of 10-bit A / D co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com