Method for testing fatigue damage of inorganic binding material stabilizing material

An inorganic binder, fatigue damage technology, applied in the direction of testing the strength of materials by applying a stable bending force, can solve the problems of uneven surface of the test piece, damage problems, and inability to obtain test results, etc., to achieve easy implementation and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

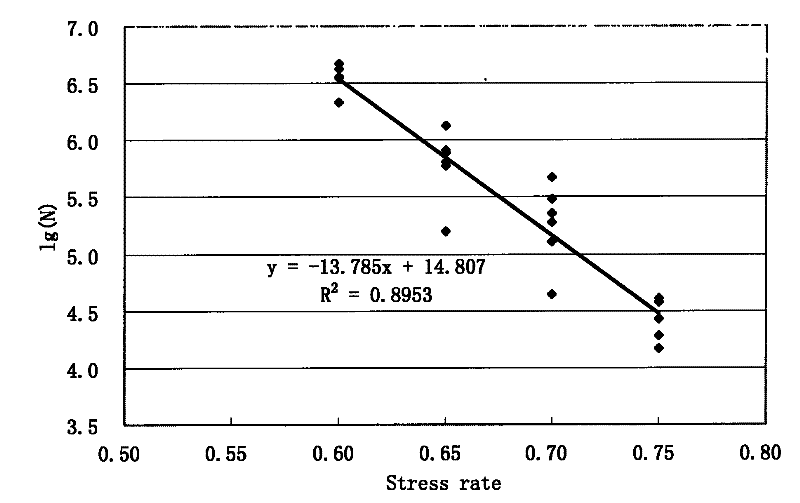

[0037] Inorganic binder stabilized material fatigue damage test method of the present invention comprises the following steps (taking lime fly ash stabilized gravel material fatigue damage test as example):

[0038] a) Vibration formed girder specimen

[0039] In this embodiment, 4 stress ratios are used, and each stress ratio requires at least 5 fatigue test samples, that is, 3 girder specimens are required for one stress ratio, so a total of 12 girder specimens are required.

[0040] Lime-fly ash-stabilized macadam material girder specimens were formed using a vibrating table. The length × width × height of the girder specimen is 550mm × 150mm × 150mm.

[0041] In the height direction, the material is loaded in two layers. The bottom layer is 75mm high, and the material is evenly loaded. On one side, use a wooden stick with a diameter of about 2cm to insert and tamp. After installation, level the surface and compact it slightly, and then place it on a vibrating table for m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com