Array-type multi-channel fiber-process Fabry-Perot pressure sensor and pressure measurement method

A sensing device and Fab sensor technology, which is applied in fluid pressure measurement using optical methods, and measurement of the change force of optical properties of materials when they are stressed, can solve the problems of spectral working spectrum width, optical power jitter, Optical characteristics limitations and other issues, to achieve the effect of overcoming high-speed switching, switching speed improvement, and easy channel expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

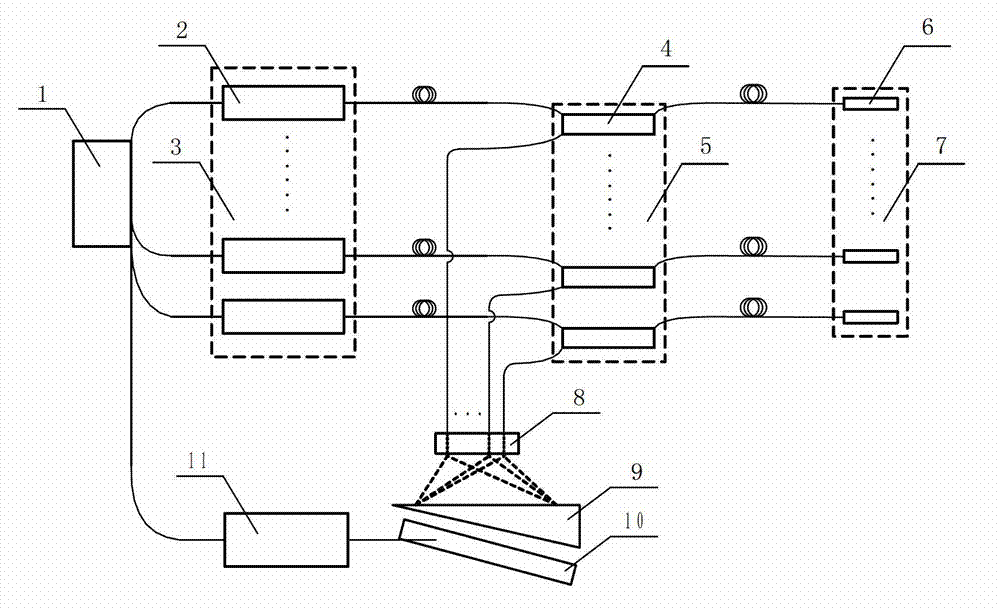

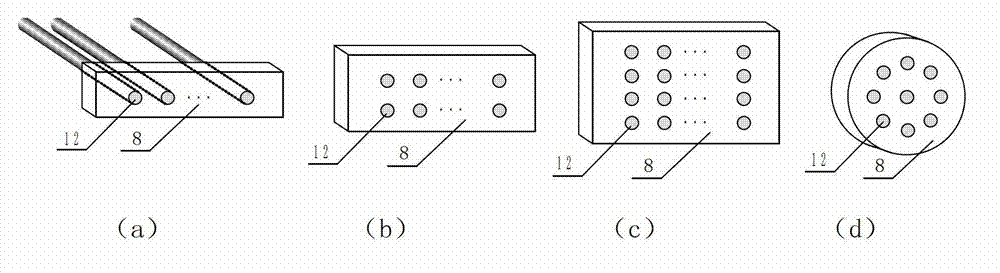

[0034] Such as figure 1 As shown, the array multi-channel fiber optic Fabry pressure sensing device includes: LED light source modulation module 1, LED light source array 3 composed of LED light source 2, fiber optic coupler array 5 composed of fiber coupler 4, and fiber optic Fabry sensor 6. The fiber optic sensor array 7, the fiber array 8, the optical wedge 9, the linear array CCD10 and the signal processing unit 11. Wherein, the optical fiber output ends 12 of the optical fiber array 8 are arranged in a certain lattice shape, including a single-row dot matrix structure, a double-row dot matrix structure, a multi-row dot matrix structure or a circular dot matrix structure, such as figure 2 shown.

[0035] An LED light source 2, an optical fiber Fab sensor 6 and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com