Circuit board welding quality detection method and device

A welding quality and detection method technology, which is applied in the field of circuit board welding quality detection, can solve problems such as fatigue, low efficiency, and difficulty in ensuring reliability, and achieve the effects of overcoming low reliability, low false detection rate, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

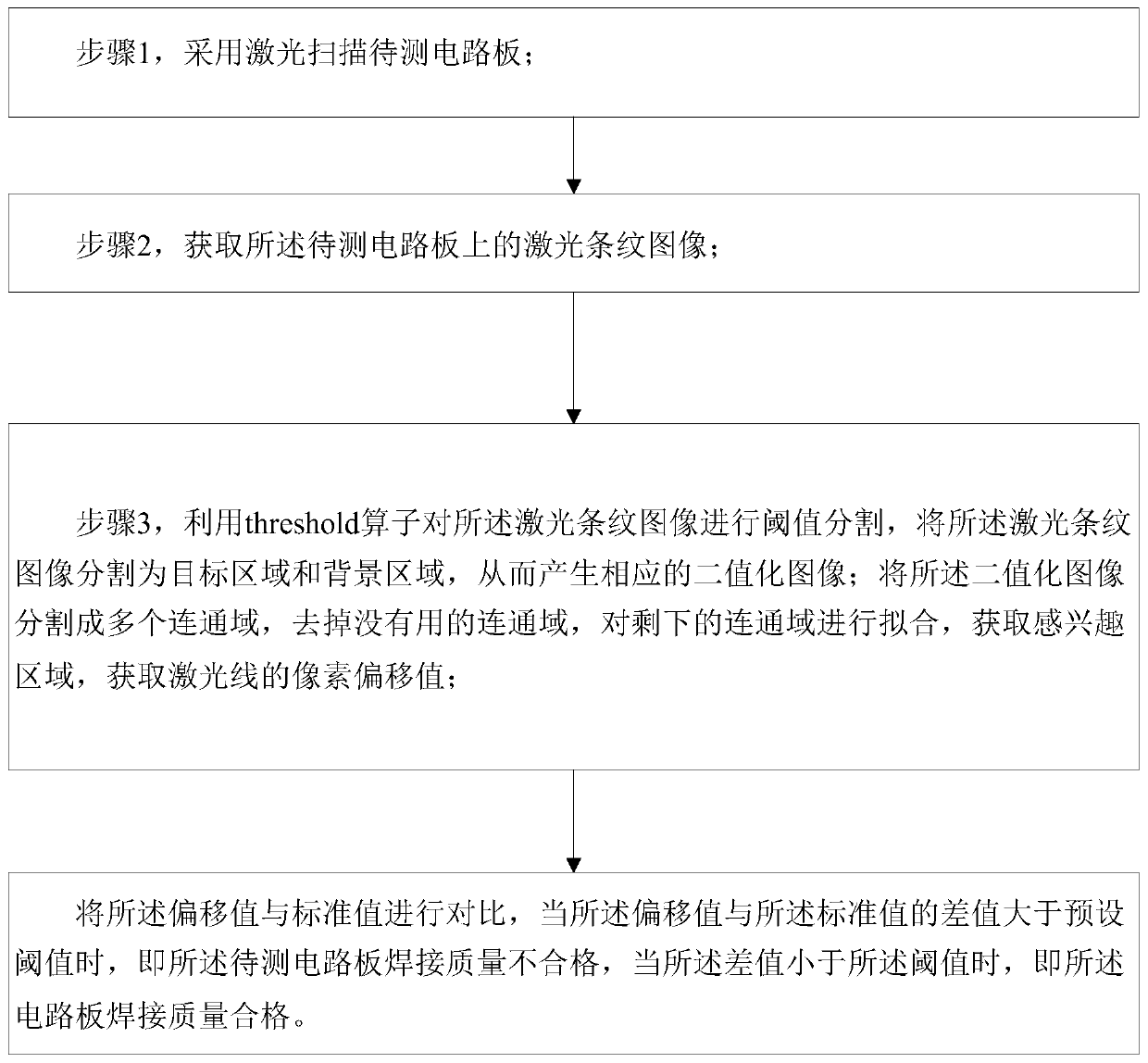

[0043] Use laser to scan the circuit board to be tested. After obtaining the laser image, process its binarized image (the grayscale image with 256 brightness levels is selected through appropriate threshold value and can still reflect the overall and local characteristics of the image).

[0044] Taking advantage of the difference in grayscale characteristics between the target area (laser stripe) to be extracted and its black background in the image, the image is regarded as a combination of two types of areas (target area and background area) with different gray levels, and it is more reasonable to choose one The threshold to determine whether each pixel in the image should belong to the target area or the background area, so as to generate a corresponding binary image.

[0045] The threshold selection method is to use the threshold(Image1,Regions1,48,253) operator to segment the acquired image in halcon, because the contrast between the target area and the background area is...

Embodiment 2

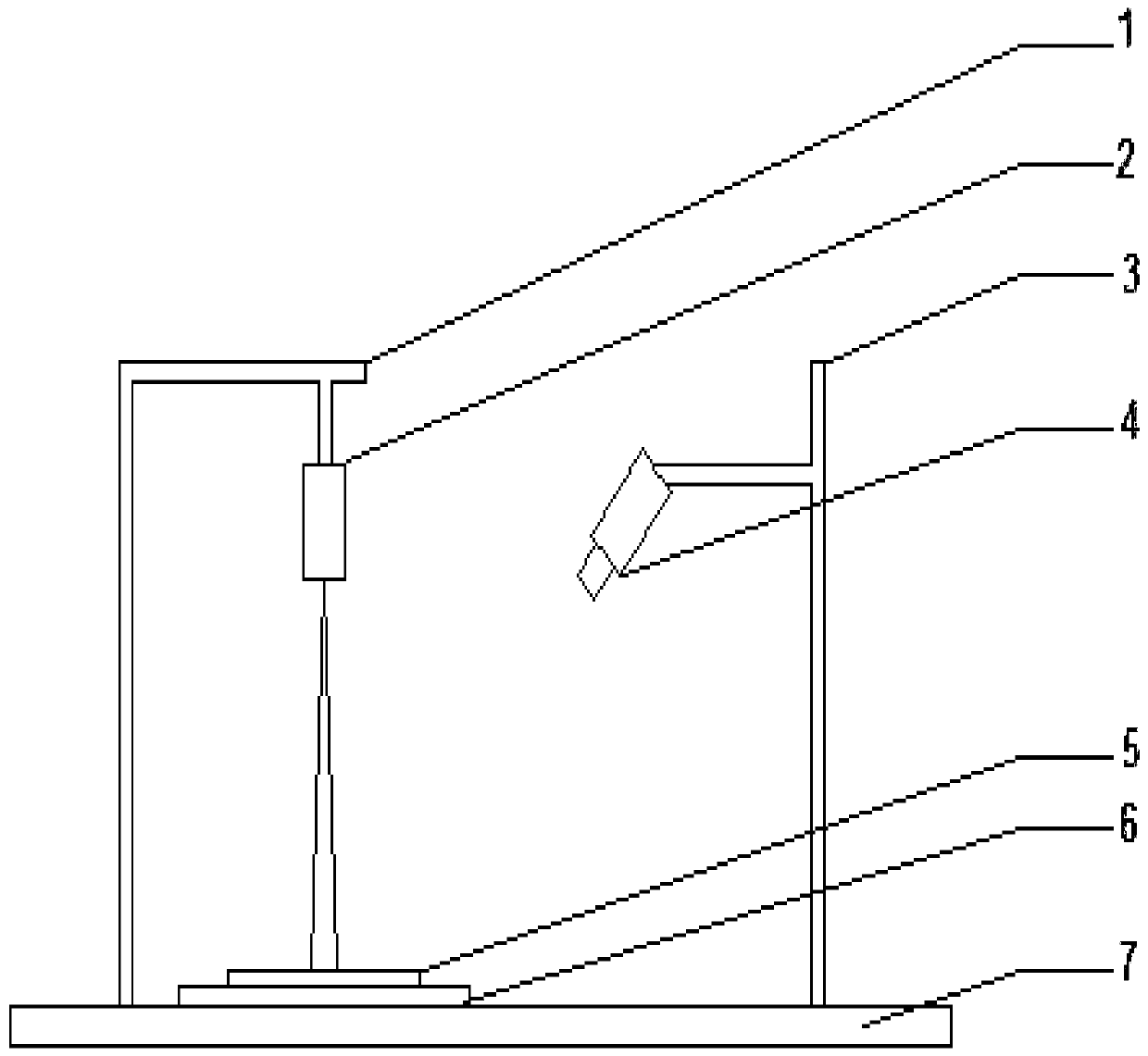

[0062] In this embodiment, the laser module is a red laser with a line width of <100m and an output angle of 60 degrees, and the image acquisition module is an Advantech 5-megapixel network port camera.

[0063] like figure 2 As shown, it shows a circuit board welding quality inspection device, including two support structures 1 and 3, which are respectively the support of the laser 2 and the support of the camera 4, and the laser 2 and the camera 4 are respectively fixed at the top position In terms of angle and angle, the camera 4 and the laser 2 are placed on the same horizontal line. Preferably, the optical axis of the camera 4 forms an angle of 45 degrees with the working platform 7 . And ensure that the entire circuit board 5 is within the field of view of the camera. The circuit board 5 of the product under test is directly below the laser 2. The circuit board 5 is placed on the mobile support plate 6. The guide rails on the mobile support plate 6 and the working platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com