Environmental-protection energy-saving drum biomass coal making process and device

A biomass and energy-saving technology, applied in the direction of biofuel, waste fuel, petroleum industry, etc., can solve the problems of incomplete oxidative combustion, inaccurate temperature control, poor quality, etc., and achieve the convenience of long-distance transportation and storage, and the degree of automation High, high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

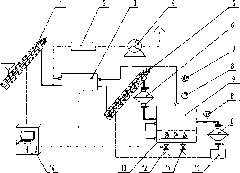

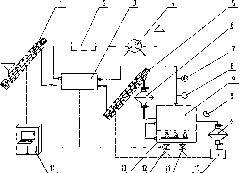

[0015] An environment-friendly and energy-saving rotary drum biomass coal production process includes biomass transportation, drying, dry distillation, and high-temperature pressing to produce coal. Drying and carbonization of biomass are carried out in an environmentally friendly and energy-saving rotary drum biomass coal production device, which includes the following steps: (A) co-combustion of air and liquefied gas in the combustion chamber, high-temperature flue gas to the rotary drum carbonization device Heating, the associated gas generated during the heating process of the biomass in the drum carbonization device, burns and releases heat to form high-temperature flue gas, and the high-temperature flue gas performs carbonization on the biomass, and the associated gas generated during the carbonization process enters the combustion chamber for oxidation and heat release , to provide energy for the drying and retorting of the entire system. After the system is in normal op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com