Automated feeding and loading mechanism of plastic car frame inserts

A technology of loading mechanism and inserts, applied in coating and other directions, to eliminate errors, improve injection molding production efficiency, and liberate manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

[0022] In view of the poor efficiency of manual loading of metal inserts by injection molding equipment in the prior art, errors such as missing loading are prone to occur, resulting in defective molded parts, the purpose of the present invention is to propose an automatic loading and loading mechanism for plastic frame inserts, To improve the efficiency and accuracy of insert loading and liberate human labor. .

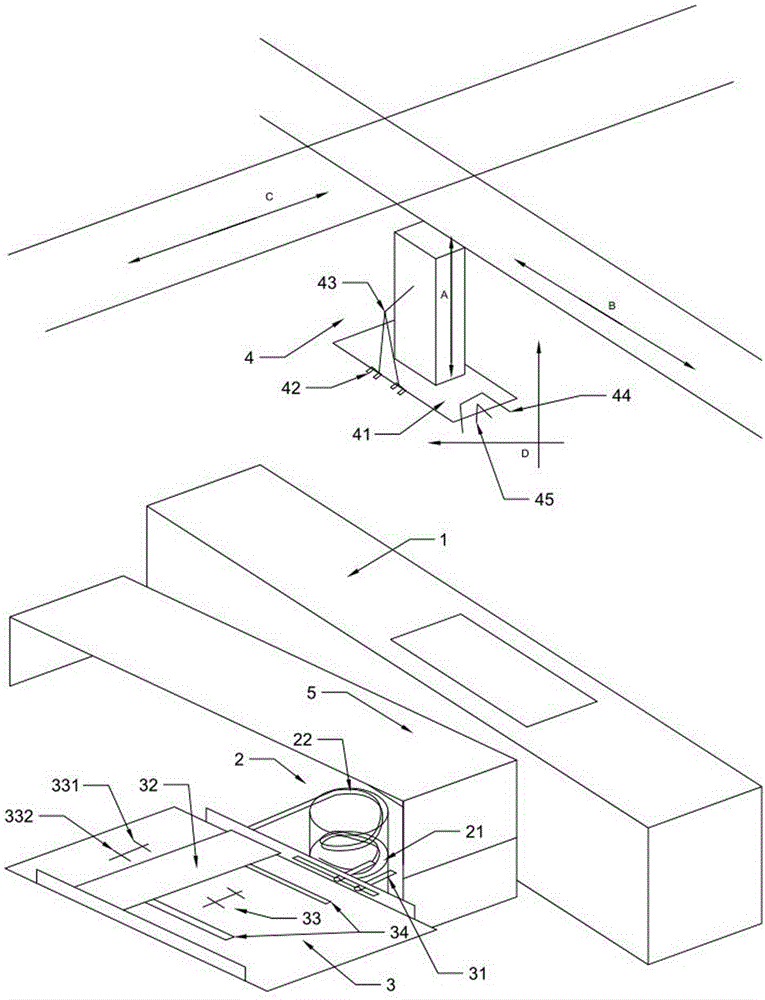

[0023] The innovative structure of this automatic feeding loader of the present invention, as figure 1 As shown, it is mainly composed of three parts: vibrating table feeder 2 , transition loading table 3 and mechanical arm 4 . As a reasonable additional mechanism of the injection moldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com