Patents

Literature

58results about How to "Improve Injection Molding Production Efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

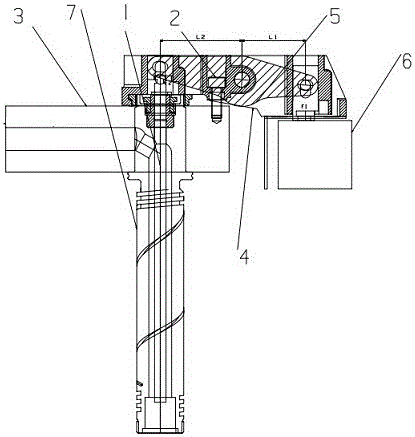

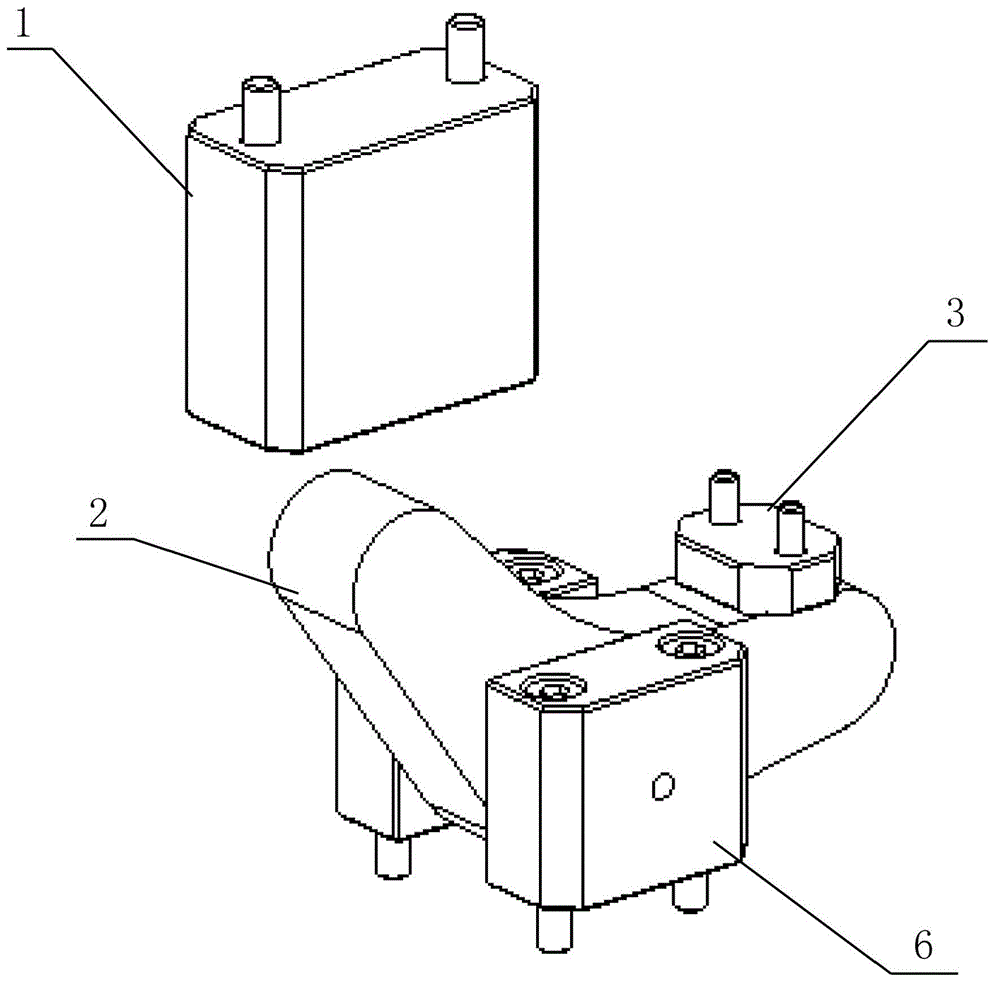

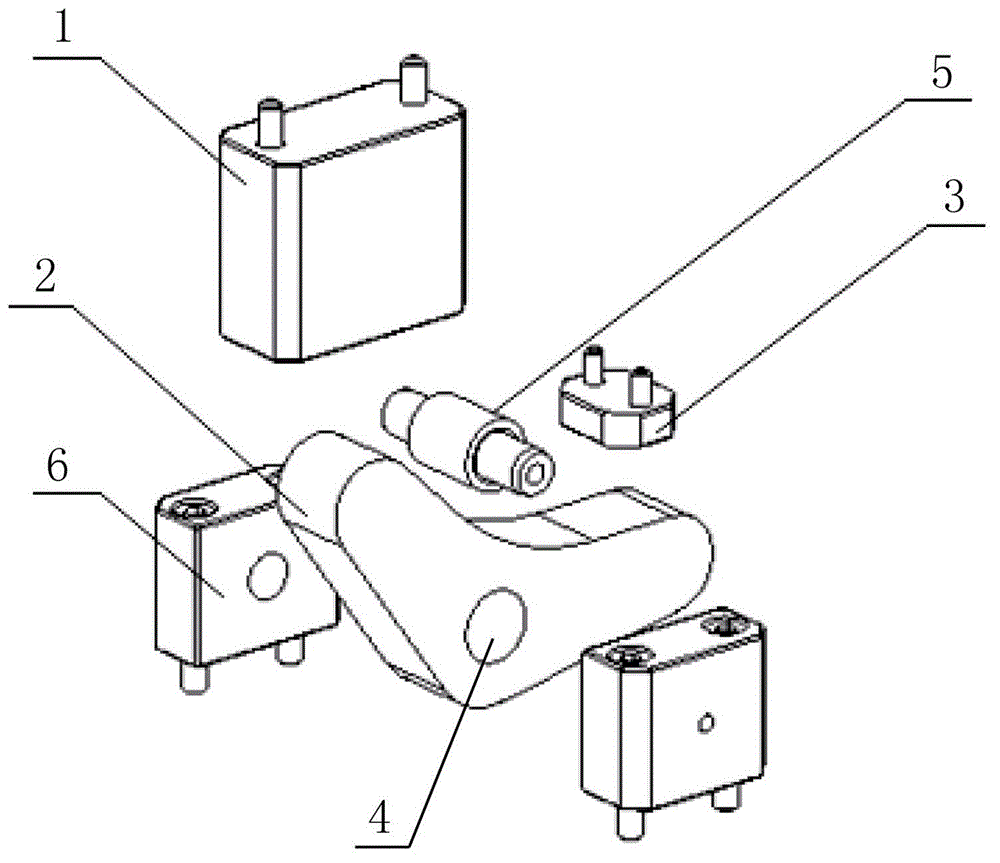

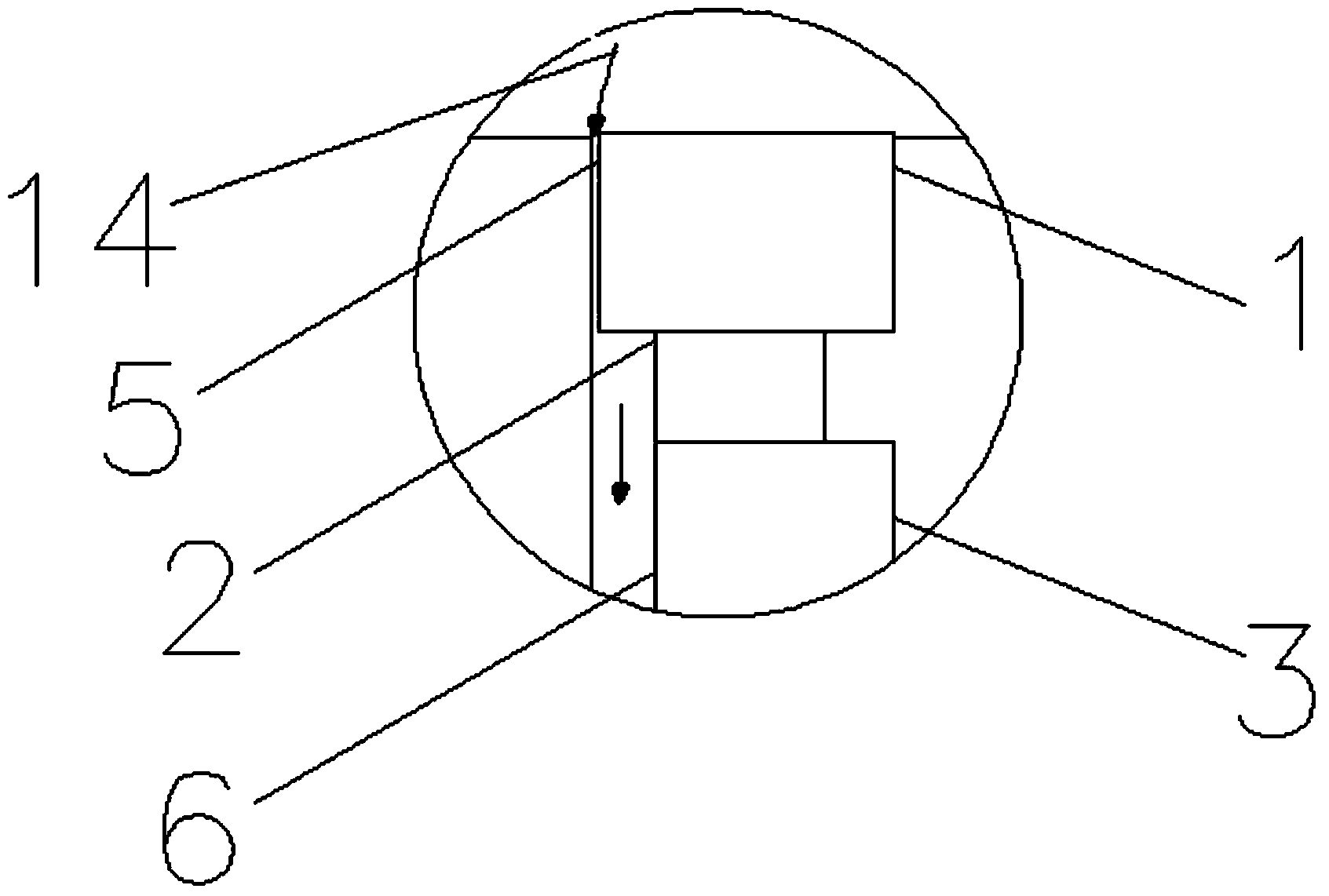

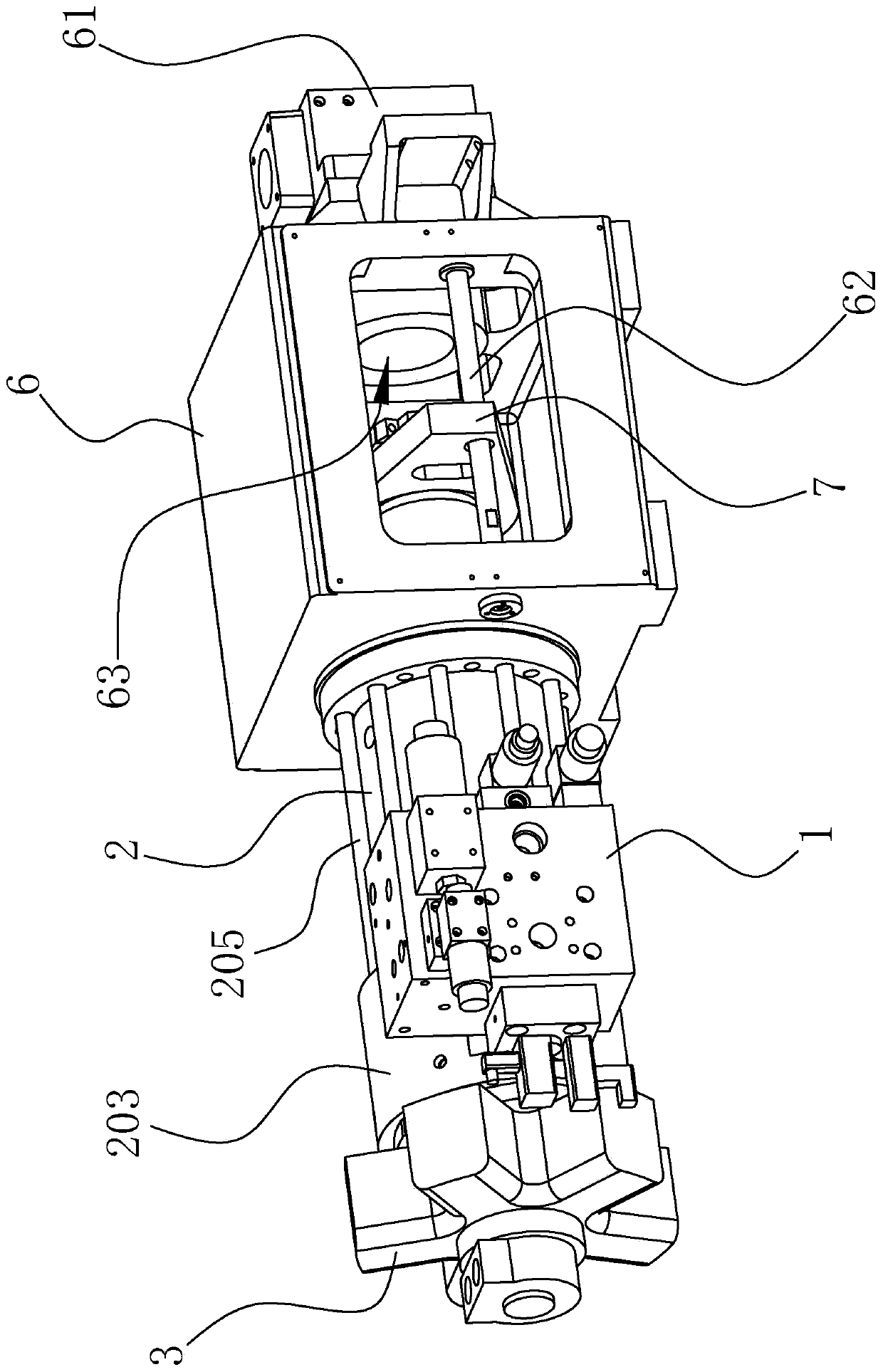

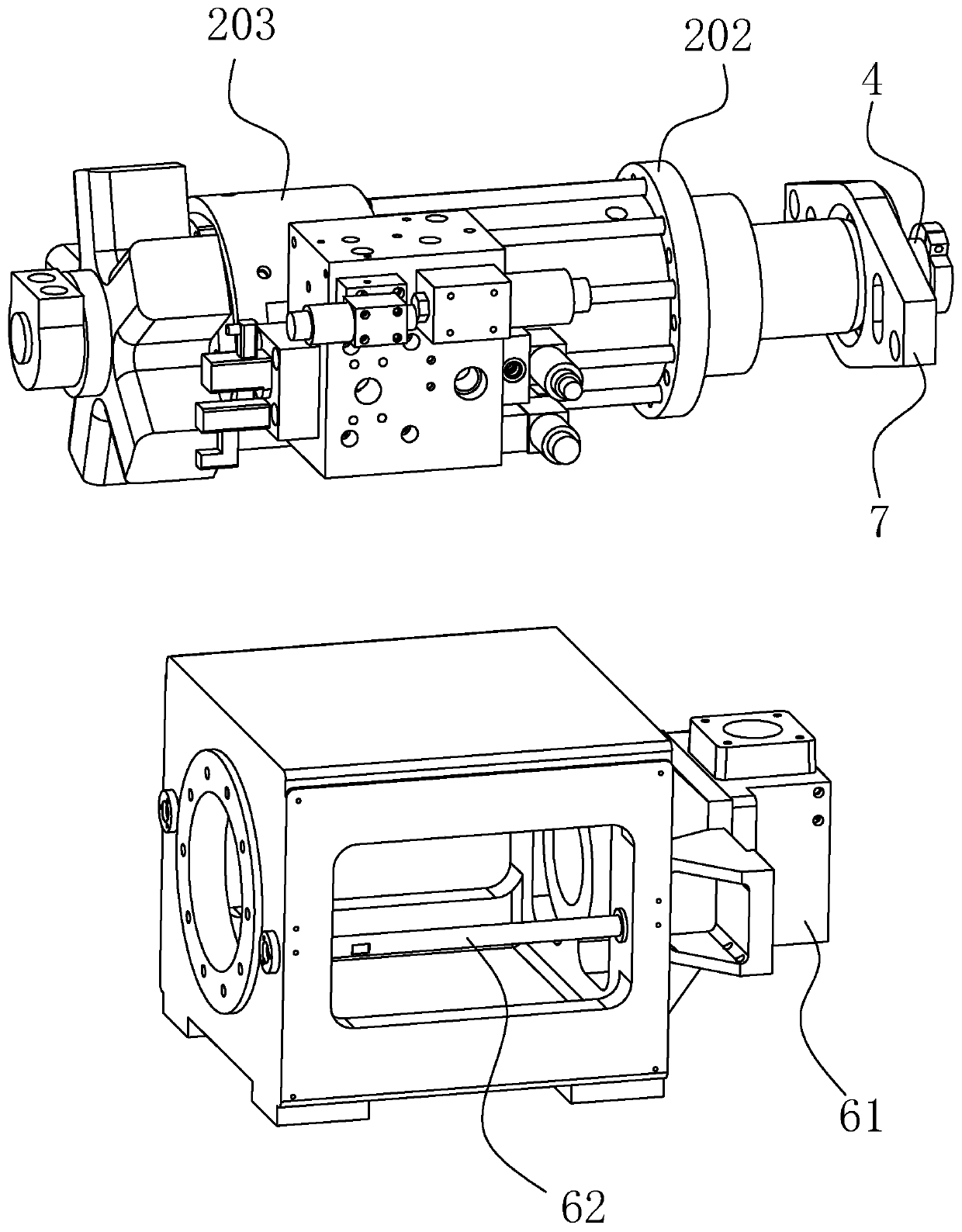

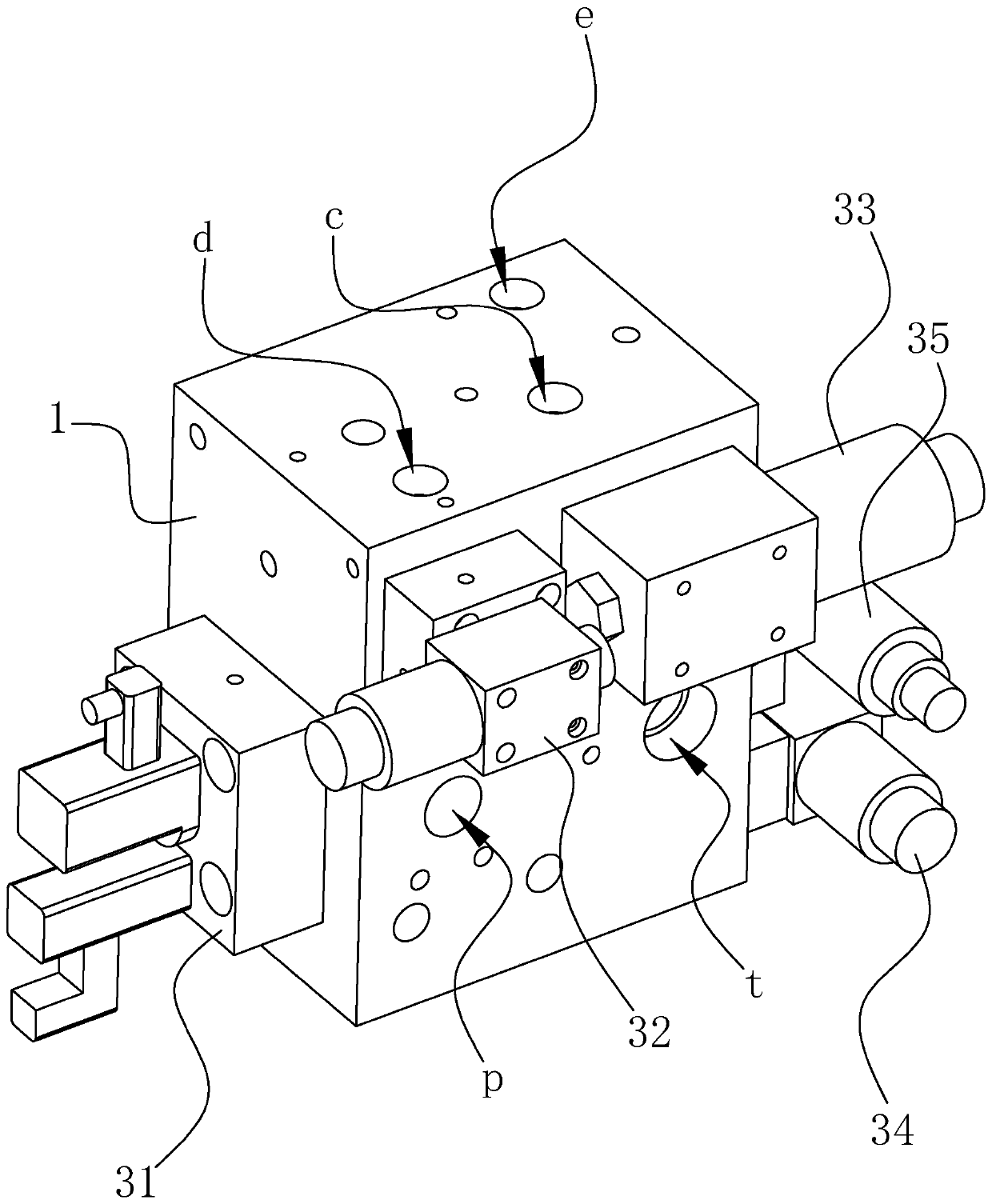

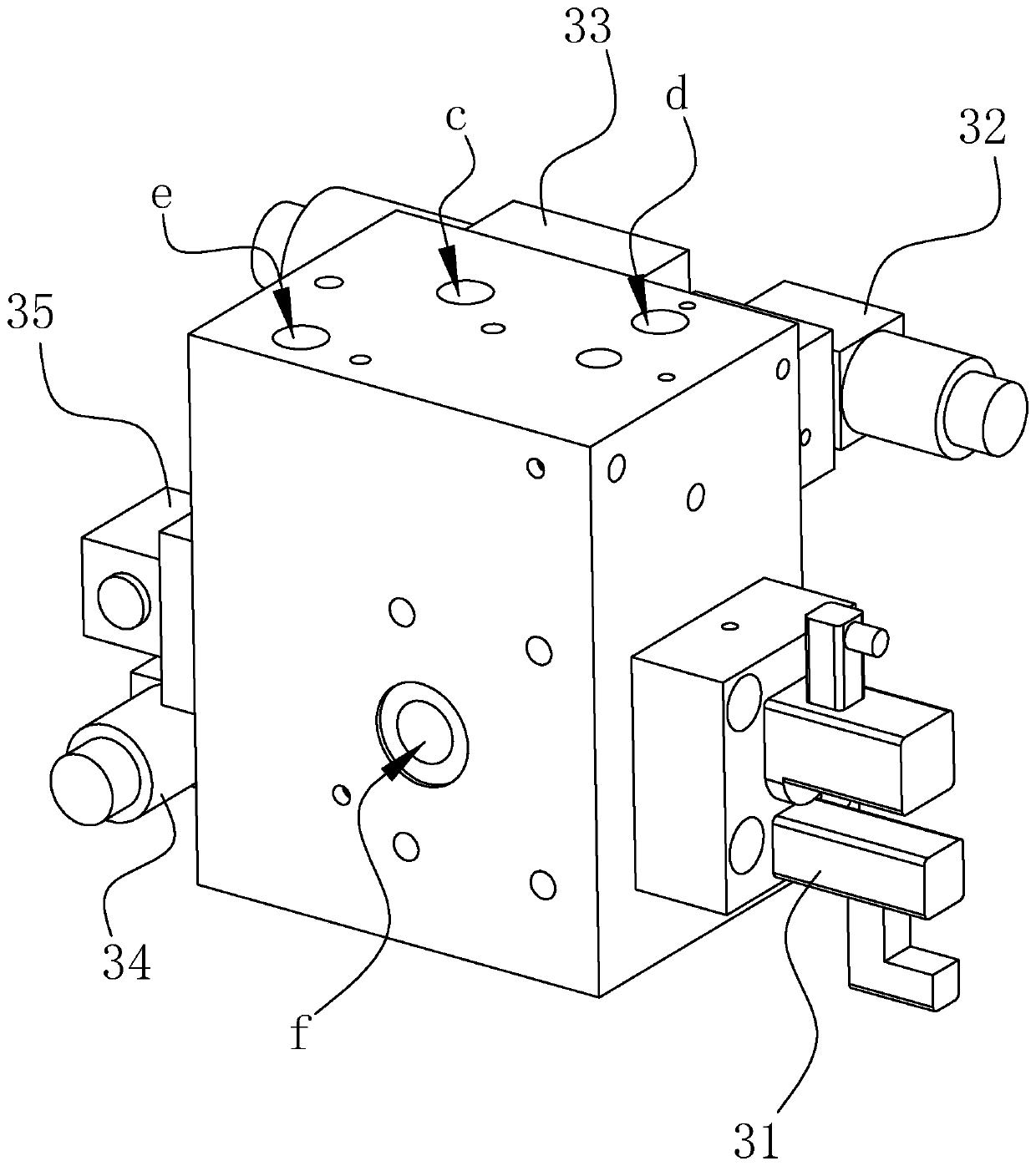

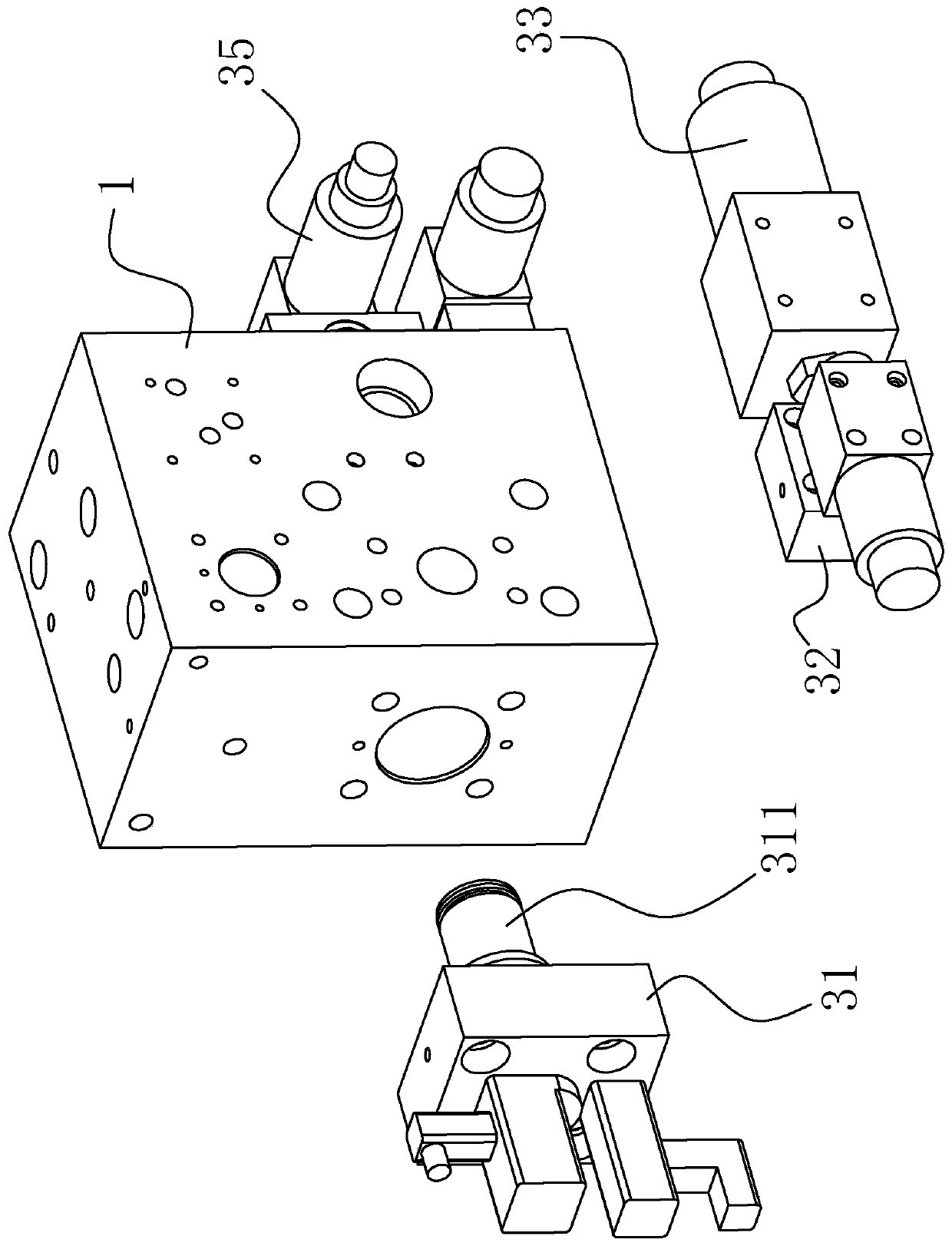

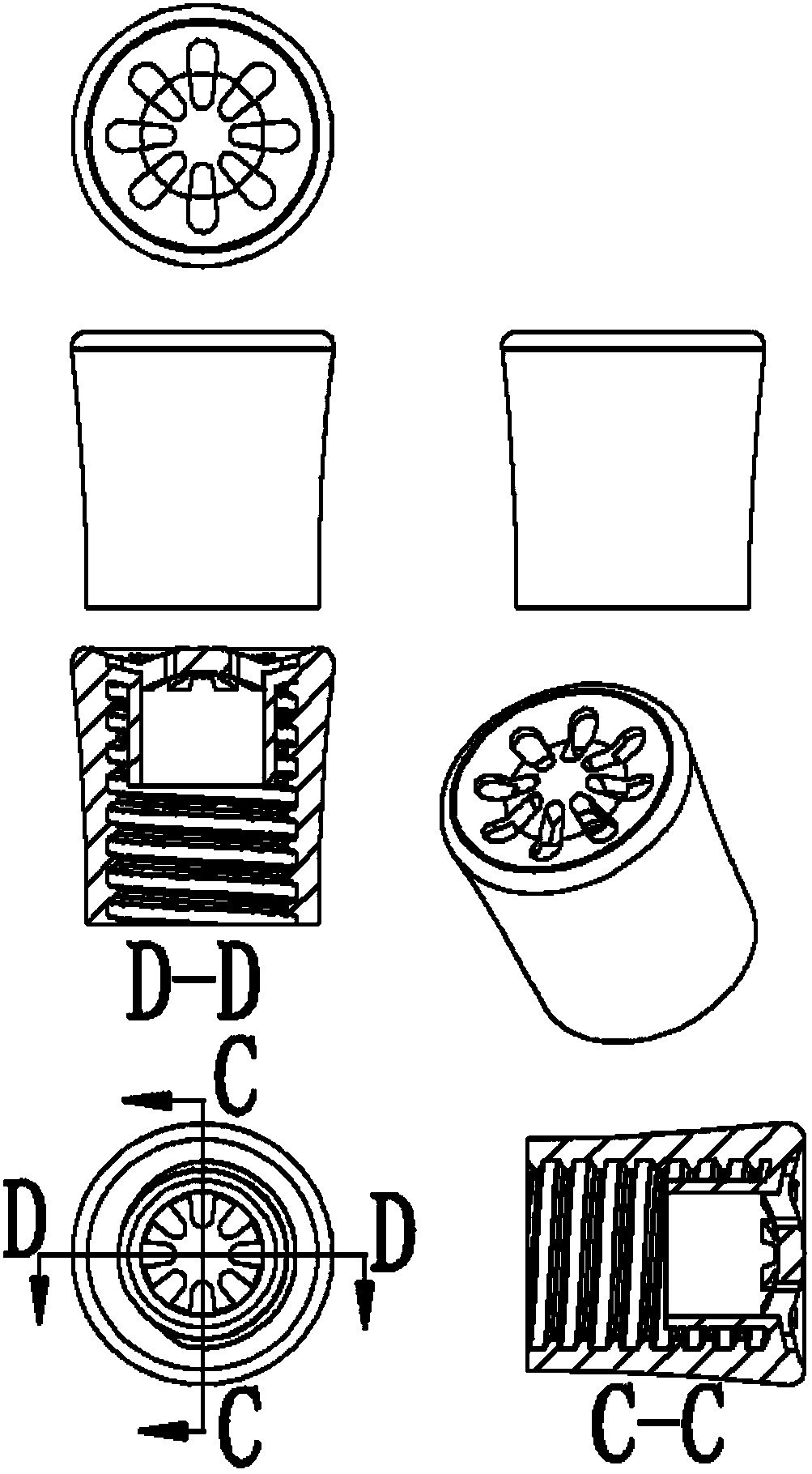

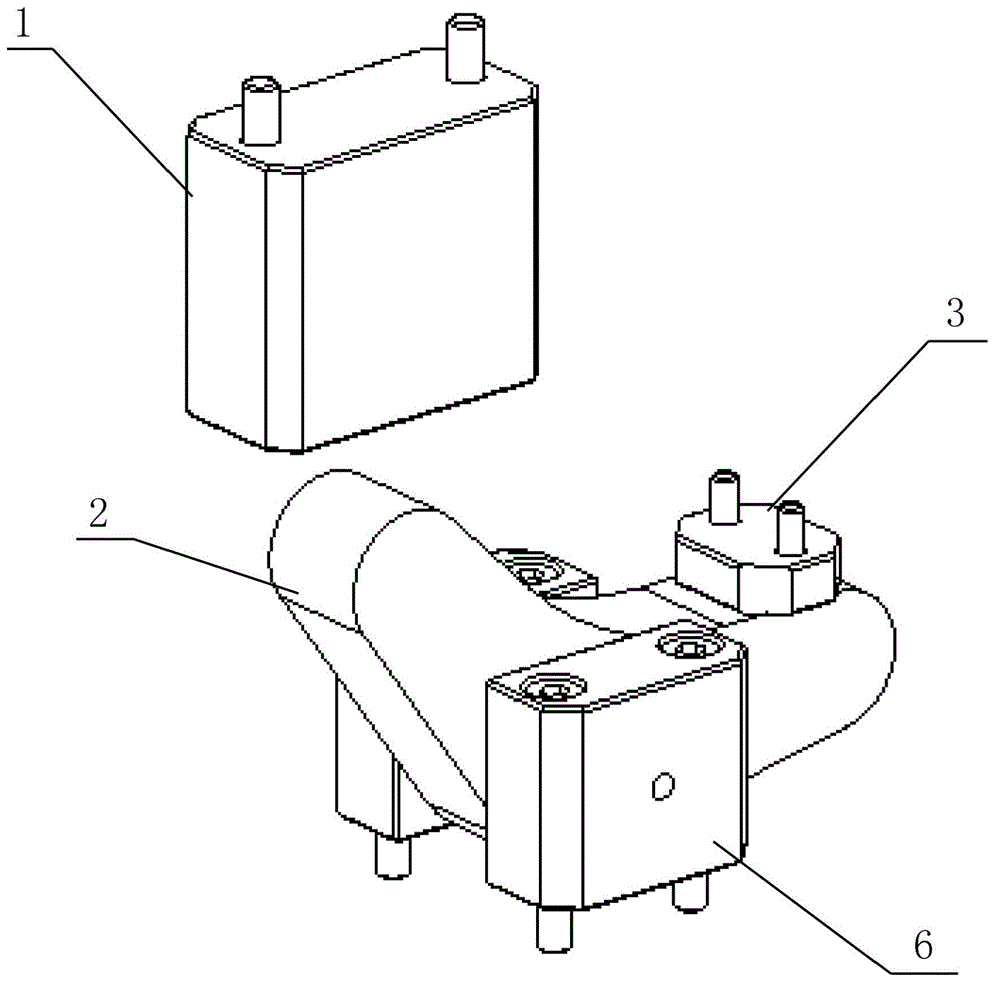

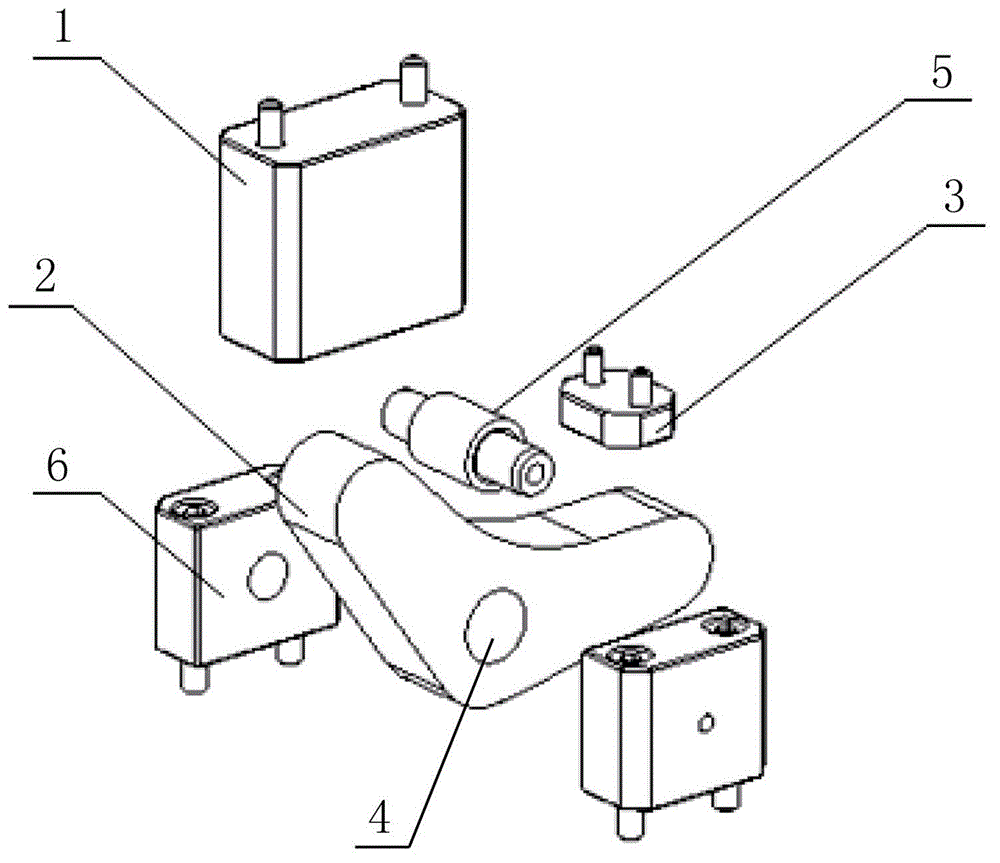

Integral type hot runner free of runner dead corner

InactiveCN105965790AImprove Injection Molding Production EfficiencyImprove appearanceHot runnerEngineering

An integral hot runner without runner dead angle, including: valve needle, fixing screw, diverter plate, lever body, sliding piece, hydraulic cylinder and hot nozzle, characterized in that: the front end of the hot nozzle is provided with opening and closing When the valve needle of the nozzle is opened, the plastic enters the mold cavity through the manifold and the hot nozzle in turn; the lever body and the manifold are connected and fixed with fixing screws. After the hot runner is assembled, the manifold and the hot nozzle runner are docked in place and connected without gaps to form a whole. The hot runner can be hoisted as a whole when the mold is assembled, and there is no seepage, leakage, and decomposition of the stock during the injection molding production process. It can effectively improve the production efficiency of injection molding, improve the appearance of injection molding products, and improve the quality of plastic parts.

Owner:曹淅

Controller and writing instrument containing same

ActiveCN101786395AEasy to shapeSimple structureDrawing boardsBall-point pensWater storageEngineering

The invention provides a controller which comprises a shell, a regulating valve, a sealing ring and at least one water storage core, wherein an opening is arranged at one end of the shell; an air returning groove is arranged at one side of the regulating valve and is fixed at one end of the opening of the shell through the sealing ring; the water storage core is accommodated in the shell and is positioned below the regulating valve; and center holes extending along the longitudinal direction of the shell are respectively arranged on the shell, the regulating valve and the water storage core. The invention also provides a writing instrument comprising the controller, and the writing instrument can be a ball-point pen, a highlighter, a marking pen or a fountain pen and can be also used as a pen core. The controller has simple shape structure, and by adopting the sealing ring made of soft materials, the requirement for matching the controller and the inner wall of a pen holder can be met easily, thereby the accuracy requirement and the manufacturing difficulty of parts are greatly reduced. The controller can also regulate the air returning passage area, thereby adapting to the requirements of ink of different types and properties and pen points of different types and specifications.

Owner:SHANGHAI M&G STATIONERY INC

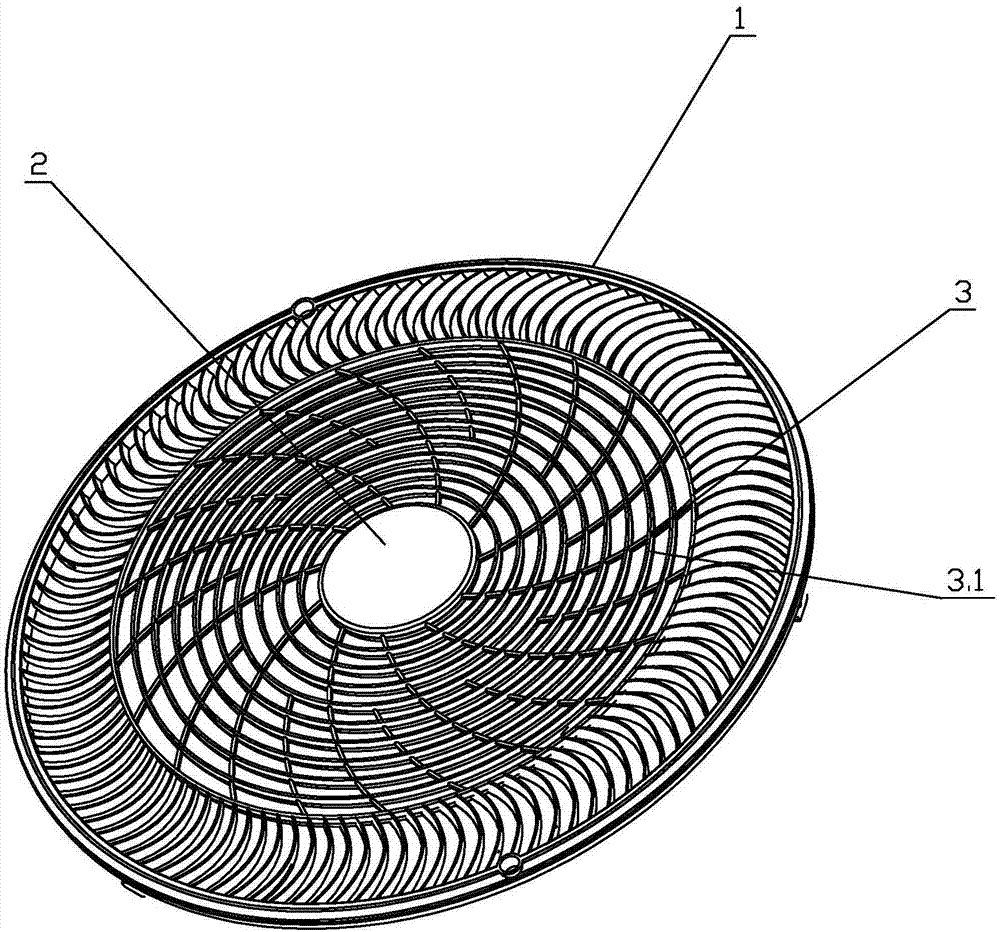

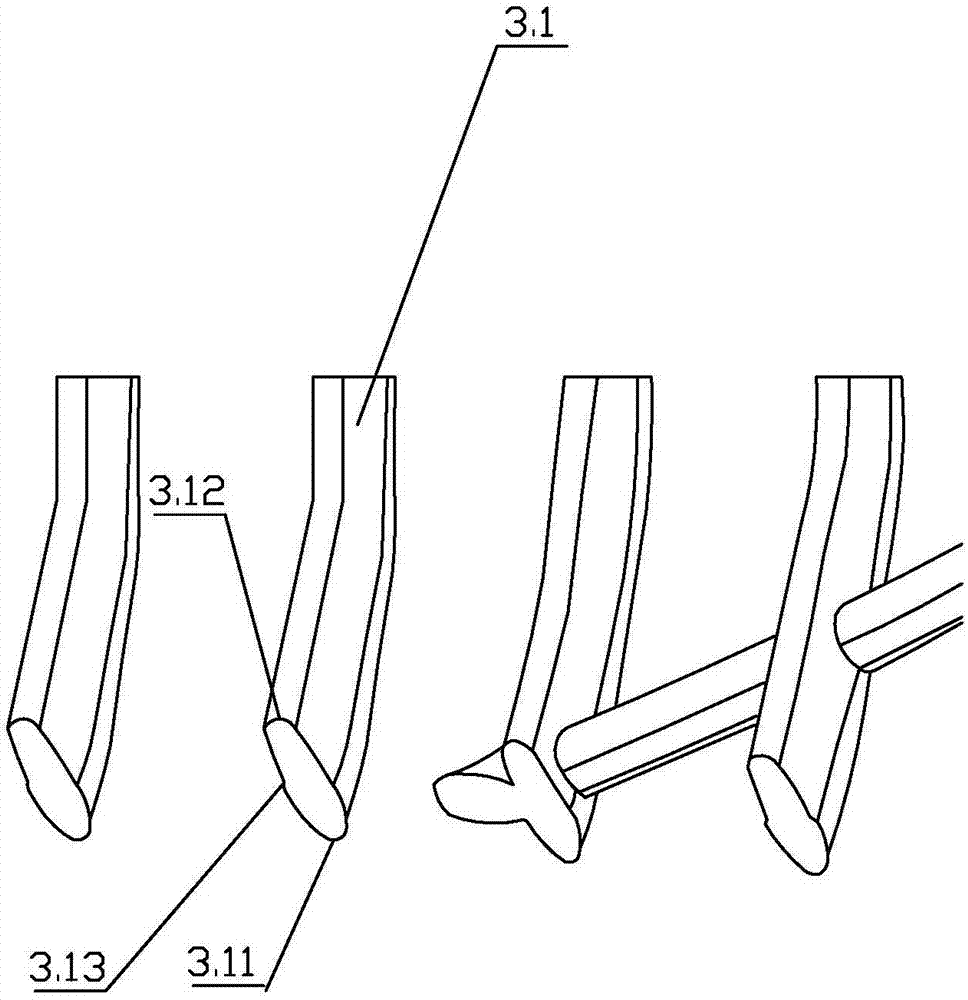

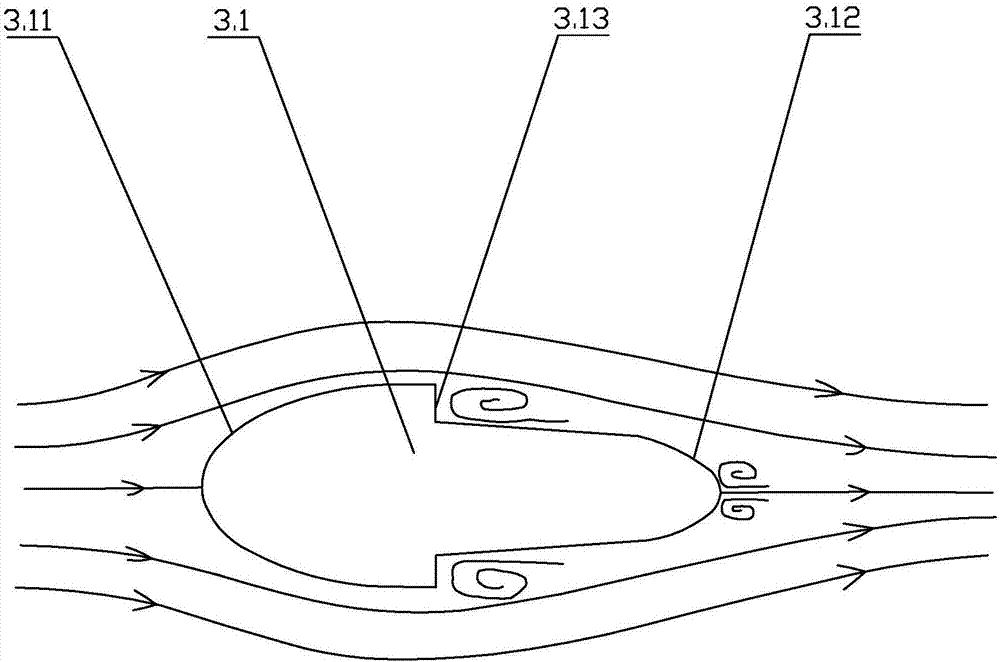

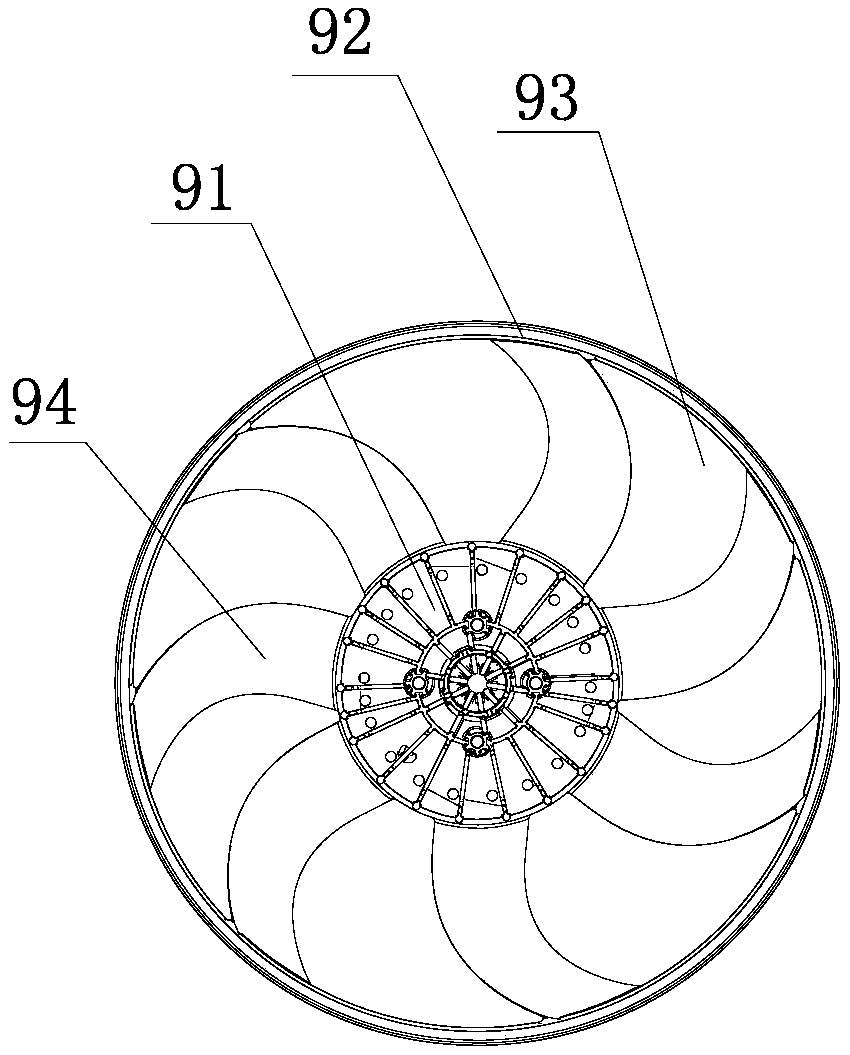

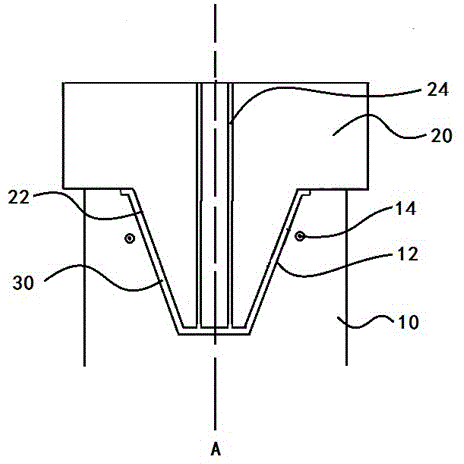

Air outlet grating of air conditioner outdoor unit

PendingCN107461835ASmooth demouldingIncrease productivityPump componentsLighting and heating apparatusImpellerEngineering

The invention discloses an air outlet grating of an air conditioner outdoor unit. The air outlet grating comprises a grating body arranged between an outer frame body and a central plate; the grating body is provided with a circular ring rib and is characterized in that a head part air inlet end of the circular ring rib is larger than a tail part air outlet end; and a sunk step is arranged between the head part and the tail part of the circular ring rib. The air outlet grating enables airflows to be more naturally gathered at the tail part, so that wake loss is reduced, the circulation performance and the flow state of the impeller outlet of a draught fan are improved, the efficiency and the noise reduction performance of the draught fan are improved, and the overall power consumption of is reduced. On the other hand, the air outlet grating can also play the role in improving the production efficiency during actual production. The grating is an injection molding part; a conventional grating rib strip is a straight body face; and an improved grating is of special-shaped structure. A die joint face can be placed at the plane of a rib strip step. As the two ends of the rib strip with the structure are not straight bodies and are provided with demoulding slope, demoulding of the injection molding part is ensured to be smooth, and the rib strip produced through injection molding can be effectively prevented from drag damage and technological problems including burr during production also can be effectively prevented.

Owner:GUANGDONG SUNWILL PRECISING PLASITC CO LTD

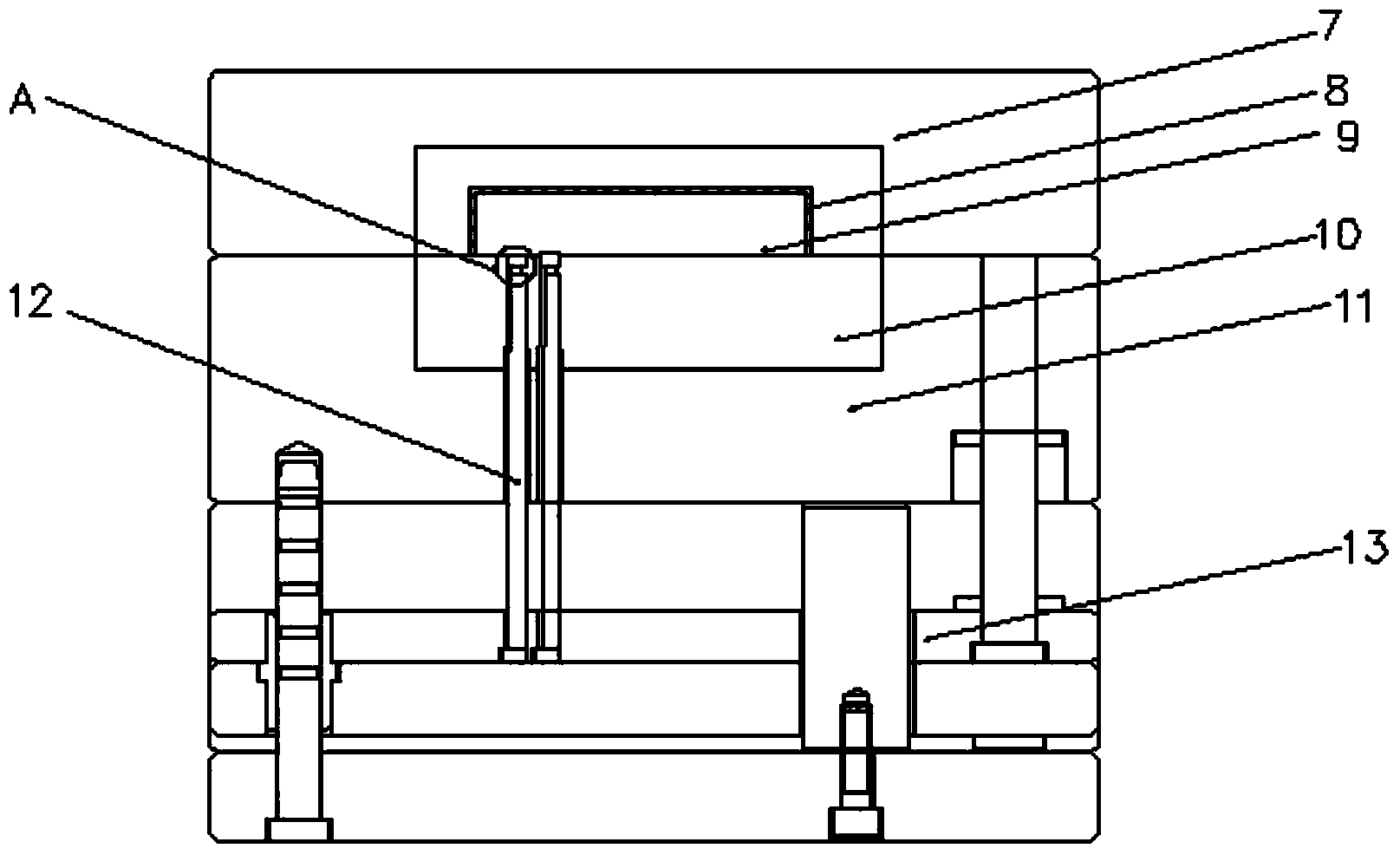

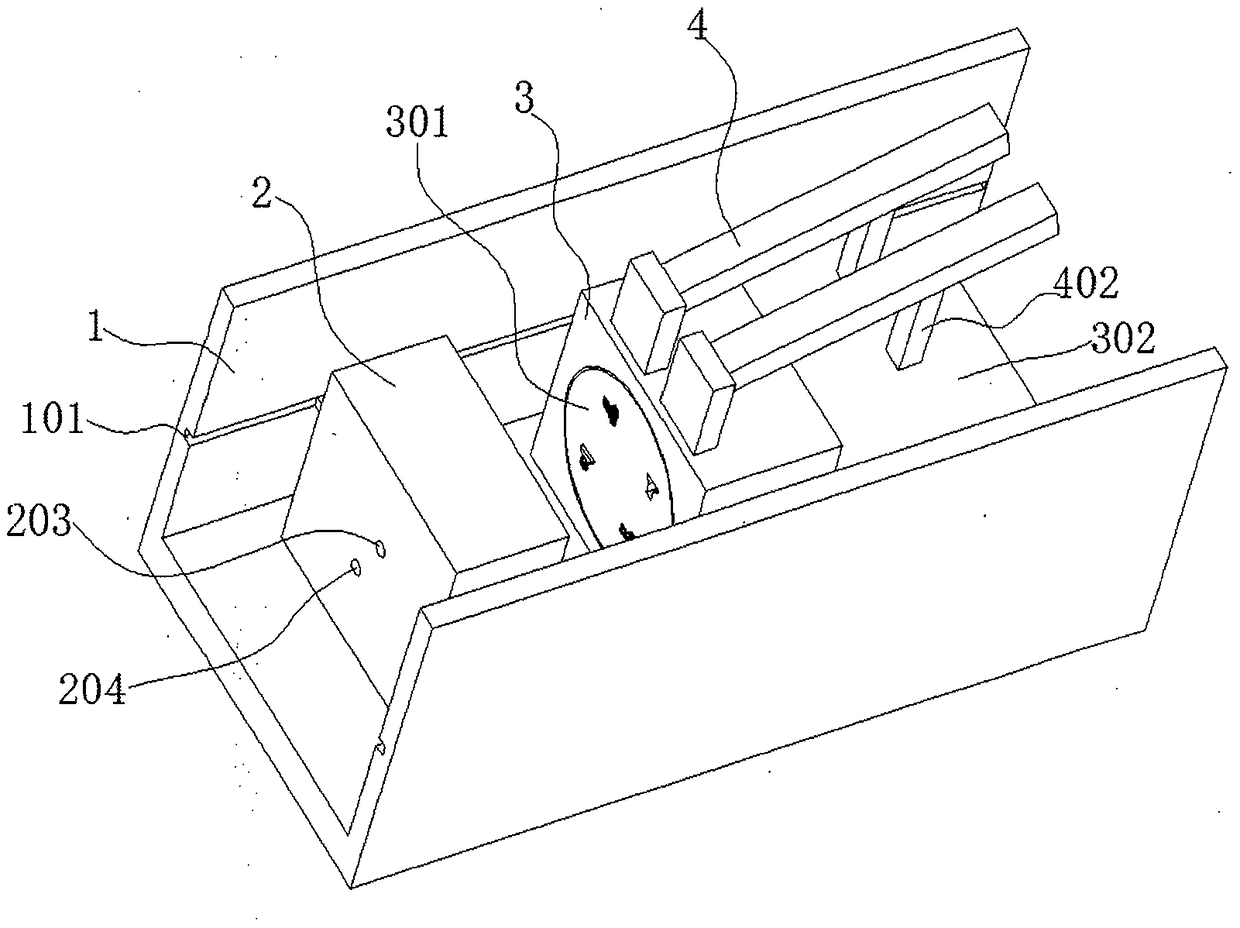

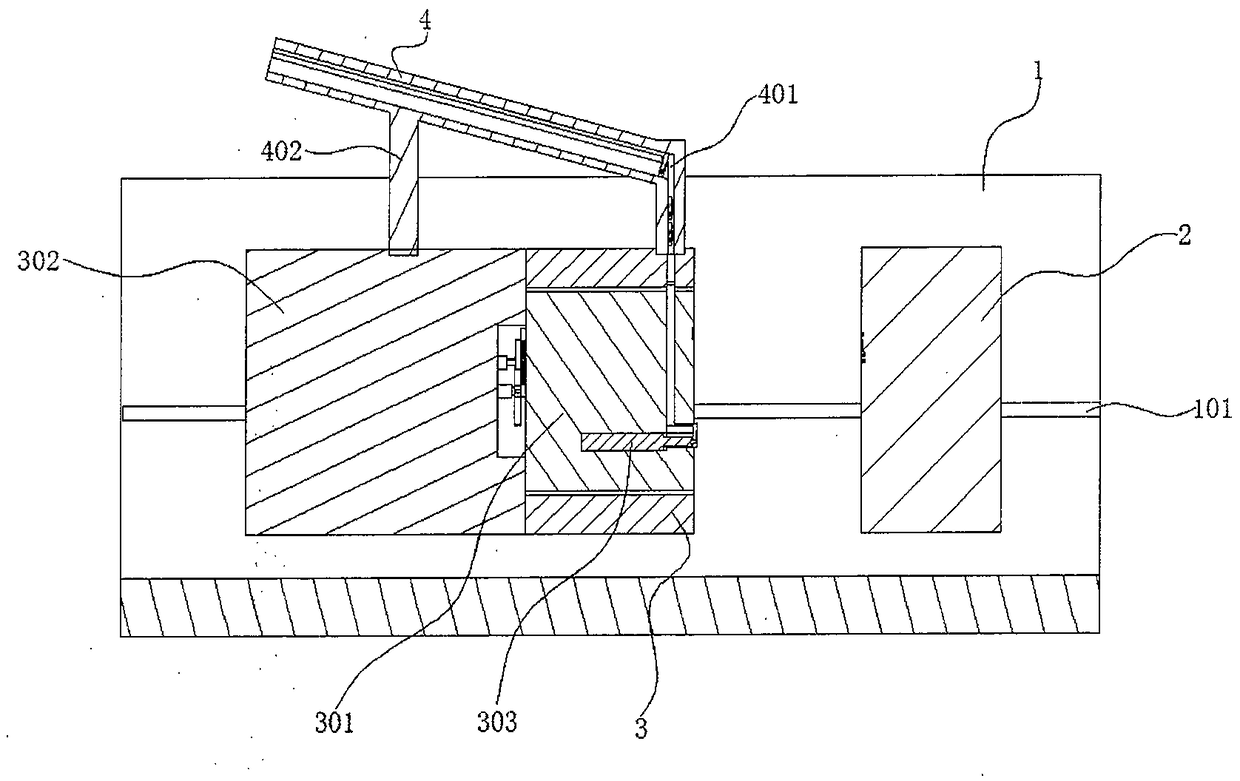

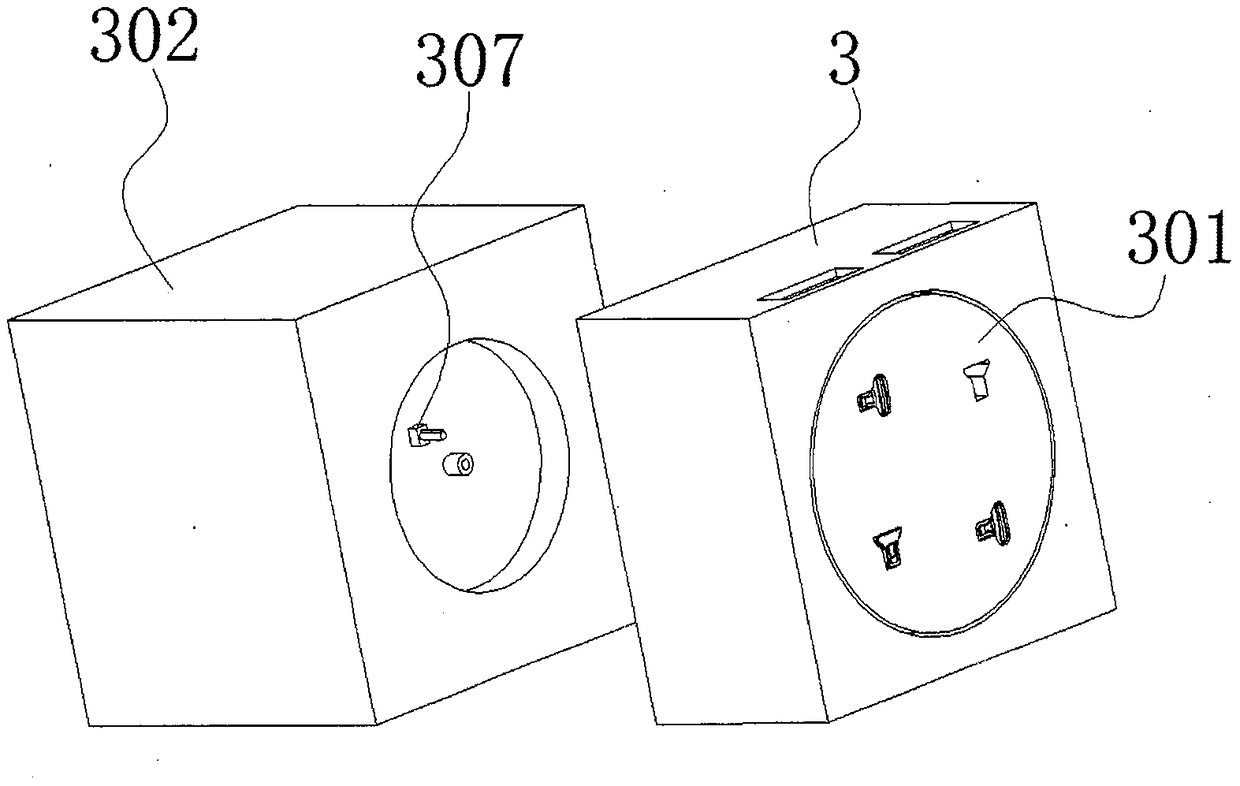

Injection molding mold of container plastic part and injection molding method thereof

ActiveCN102825746AImprove injection mold release performanceShorten the timeHollow articlesEngineeringInjection molding machine

The invention provides an injection molding mold of a container plastic part. A moving mold is provided with at least two pushing rods at the peripheral position along the outer diameter of a mold core of the moving mold; the pushing rods can move along pushing-rod sliding way holes of the moving mold and are internally provided with flow channel holes for leading in compressed air; the flowing channel holes bend from the final ends to the direction of the axis, and outlets are formed at the corresponding side walls of the pushing rods; when the pushing rods move to the set distance along the pushing-rod sliding way holes, and the outlets of the flow channel holes are communicated with a demolding space formed between the mold core and the container plastic part by movement of the pushing rods. An injection method comprises the following steps: the pushing rods move to the direction of a fixed mold along the pushing-rod sliding way holes, and simultaneously the compressed air is led into the flow channel holes; along with the movement of the pushing rods to the direction of the fixed mold, the plastic part separates from the mold core of the moving mold, simultaneously the compressed air enters the demolding space, and the compressed air in the demolding space further pushes the plastic part to separate from the mold core of the moving mold, so that the demolding action is quickly and fully finished.

Owner:珠海市富林科技有限公司

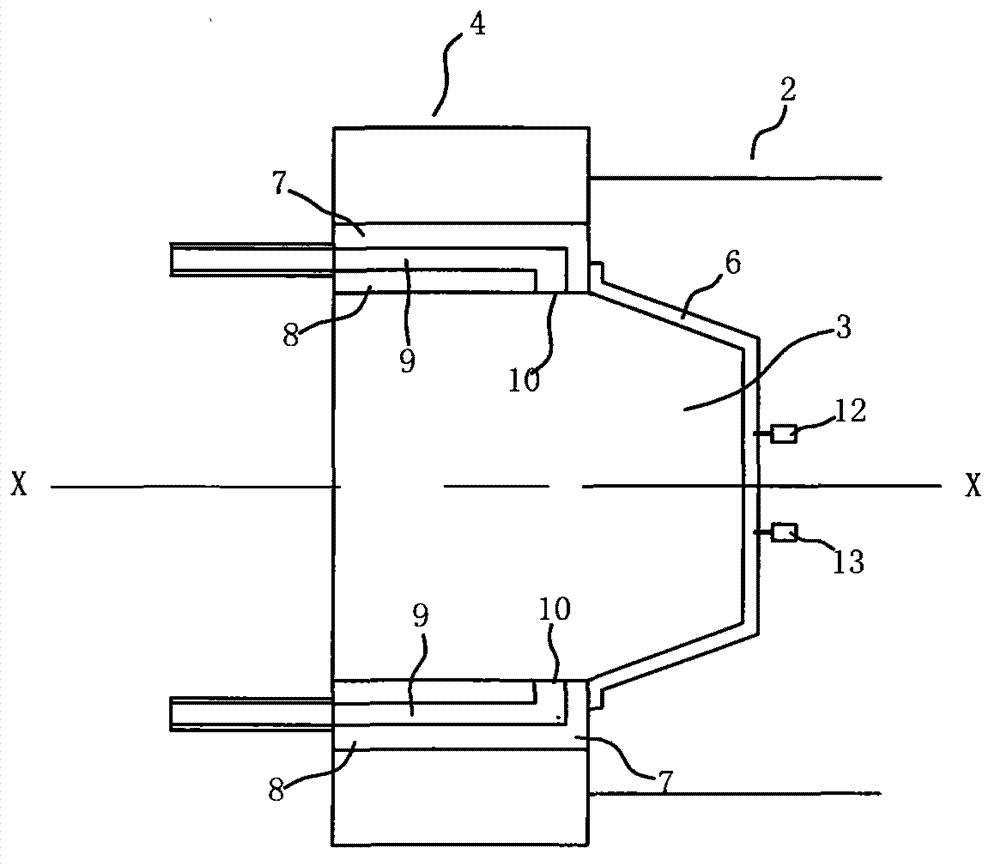

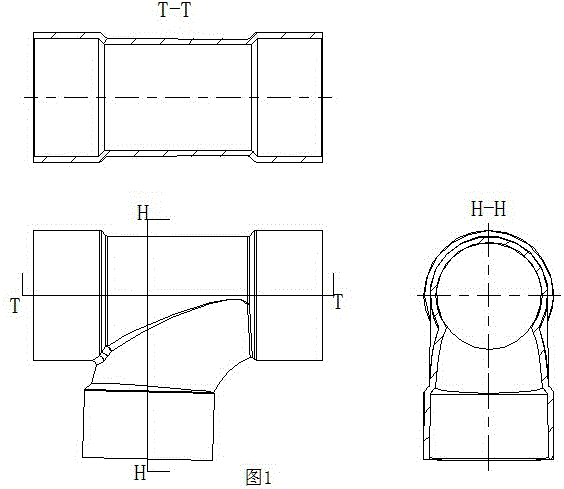

Tee pipe injection mold and using method thereof

InactiveCN107116756AImprove Injection Molding Production EfficiencyReduce manufacturing costMaterials science

Owner:贵阳合众精密机械制造有限公司

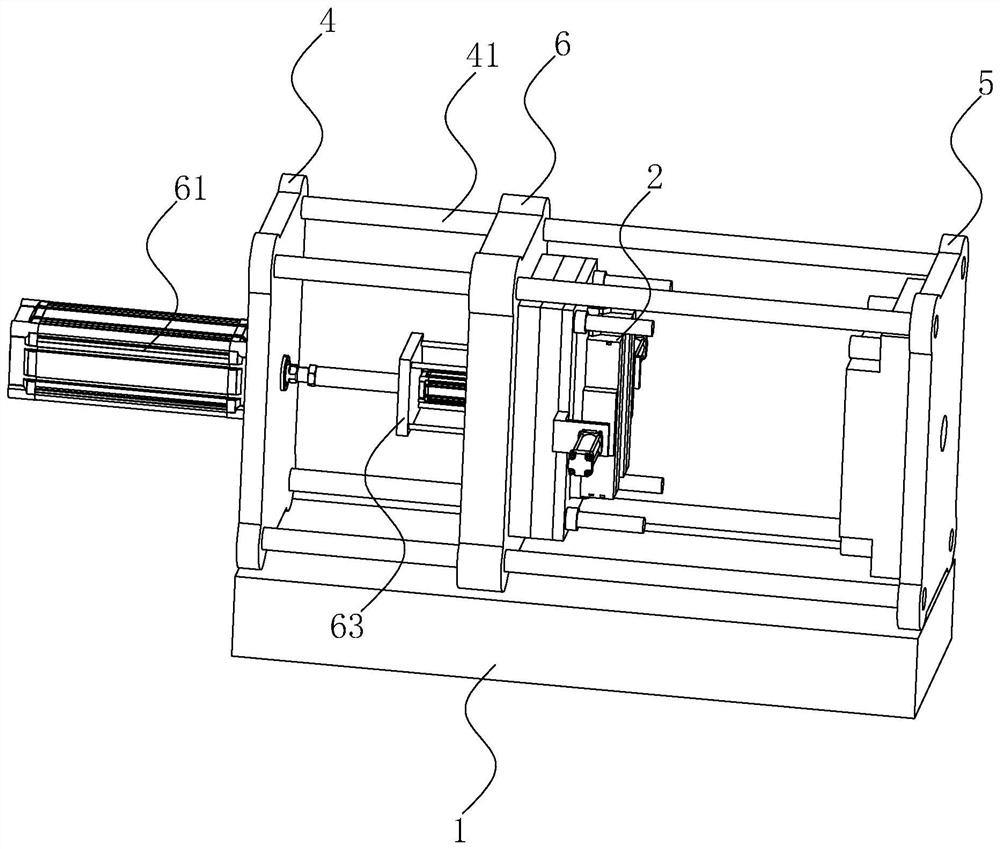

Rapid die changing mould

InactiveCN103128925AShorten the timeImprove Injection Molding Production EfficiencyMechanical engineering

Owner:KAIJIE XIAMEN PRECISE MOLDING

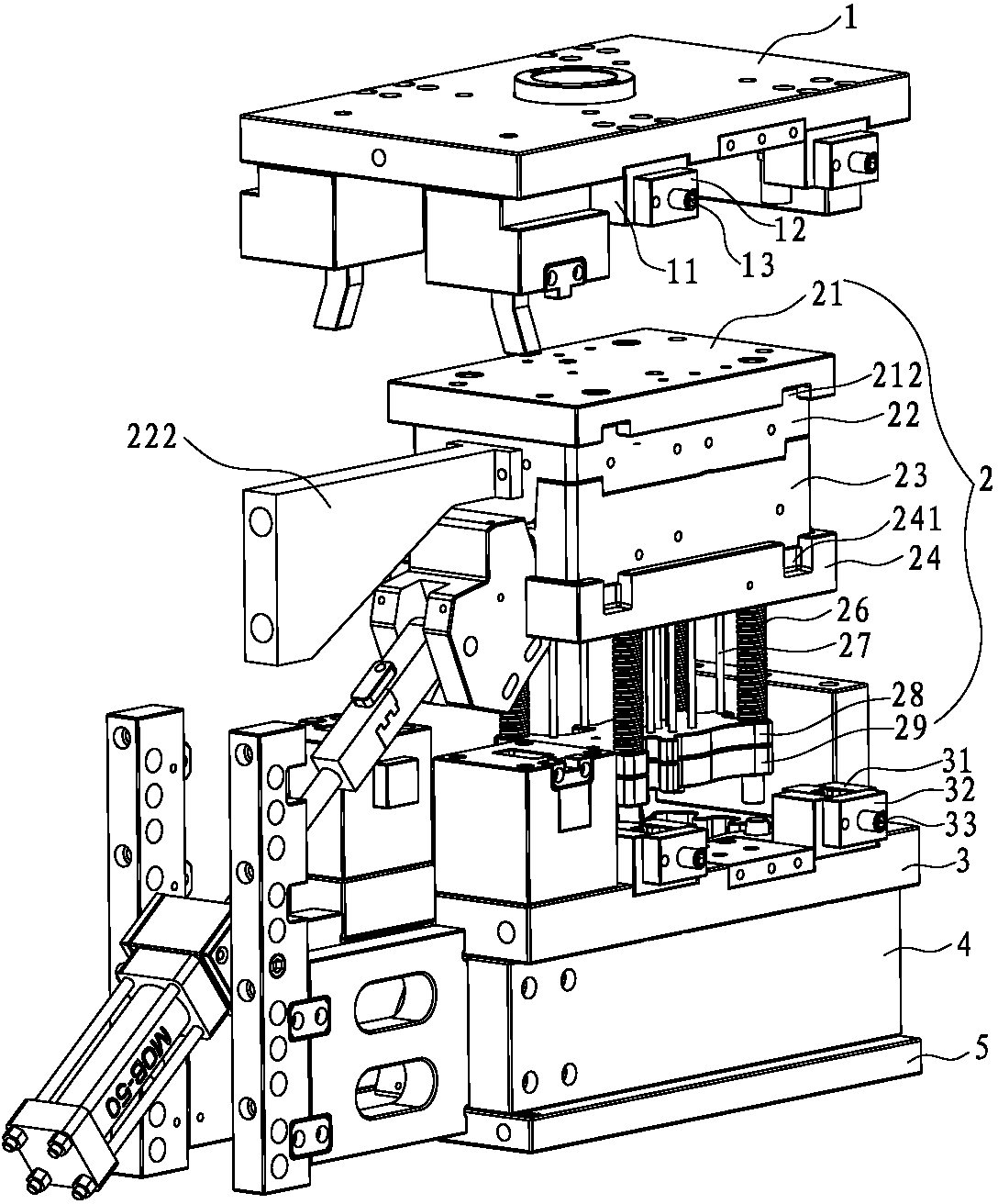

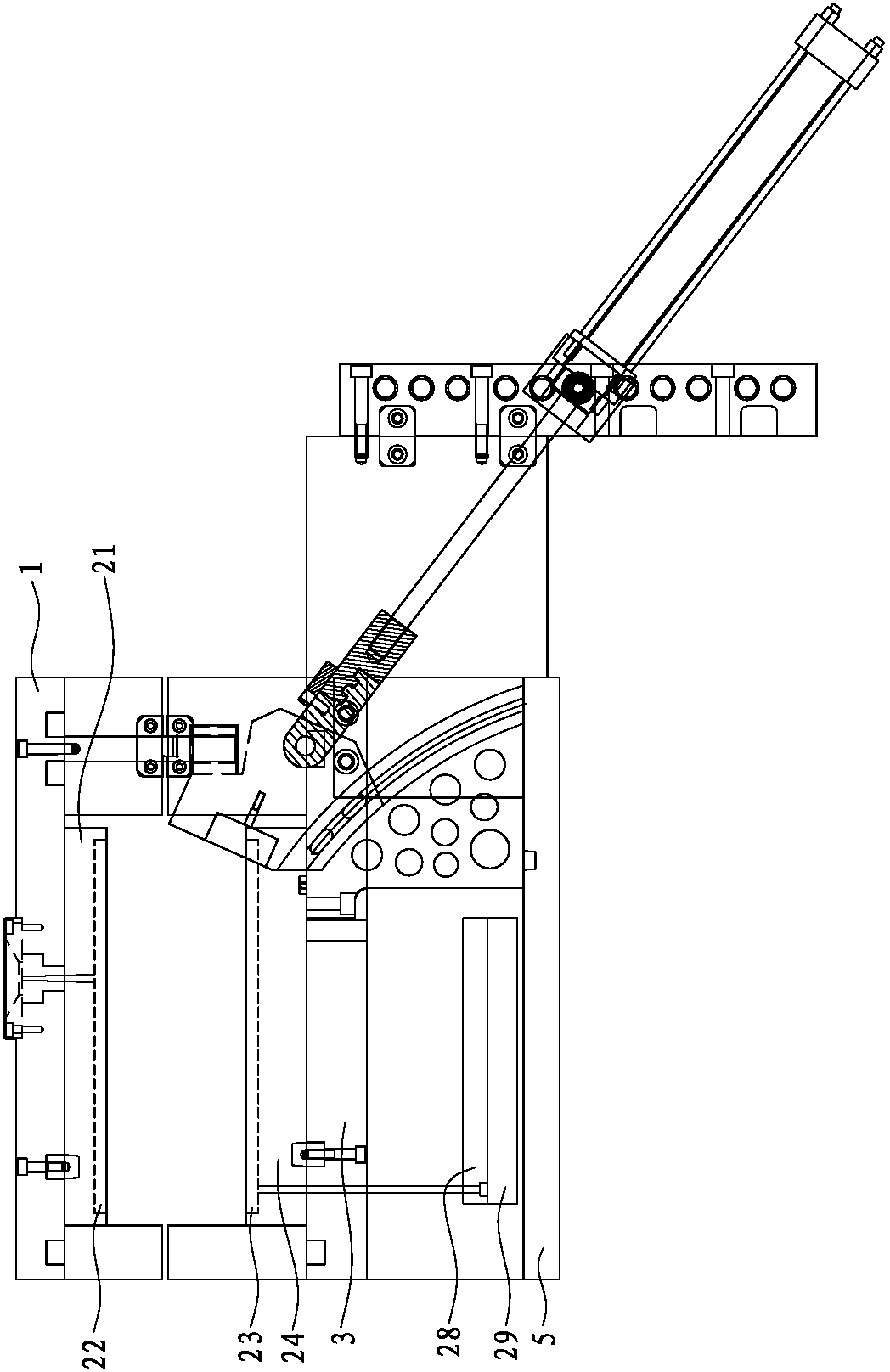

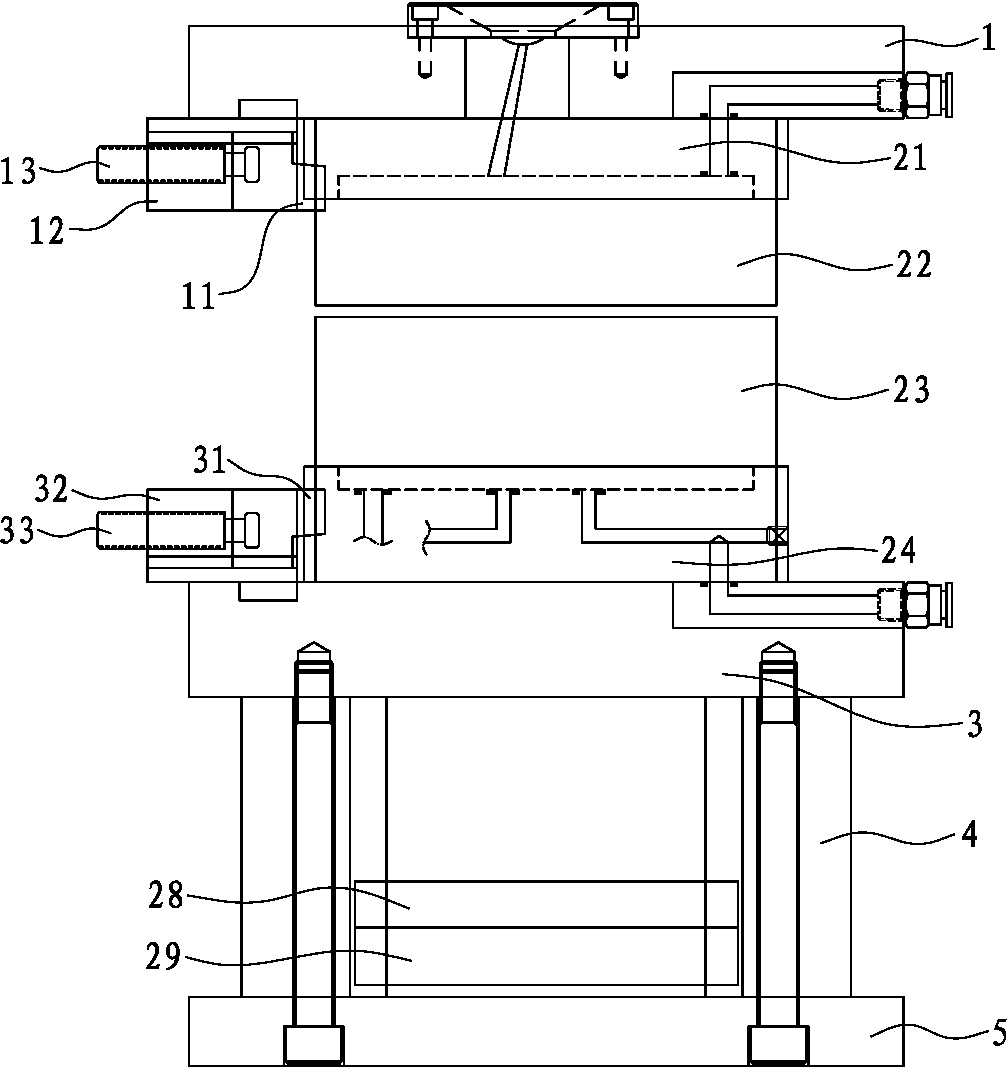

Secondary ejecting mechanism and laminated injection die adopting same

ActiveCN102909835AAchieve secondary ejection effectImprove Injection Molding Production EfficiencyMechanical engineering

Owner:QINGDAO HAIER MOLDS

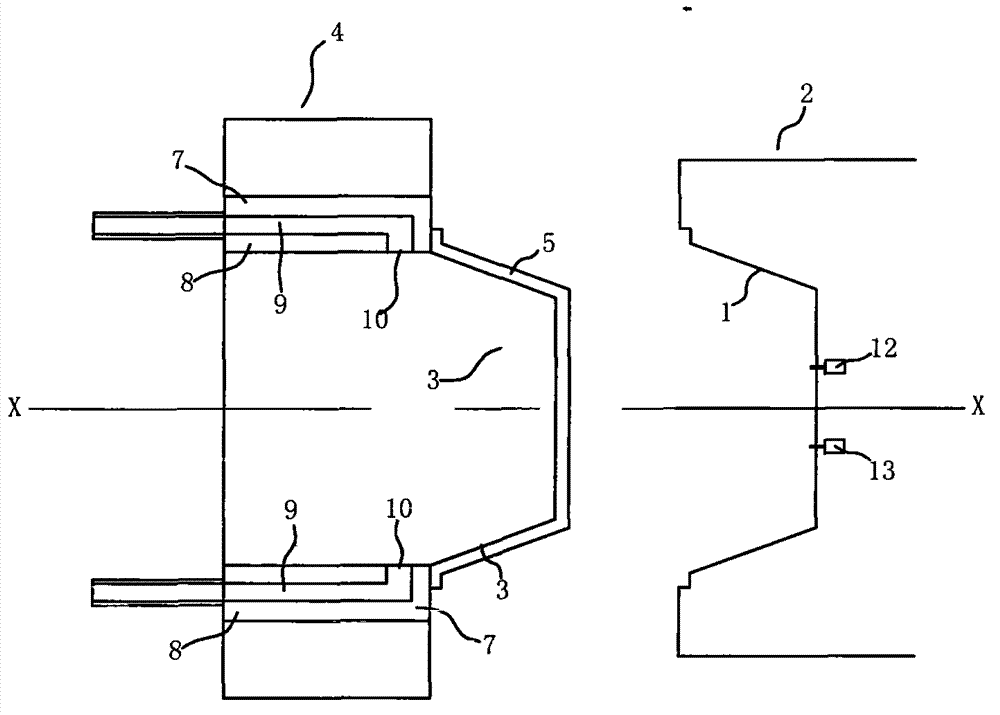

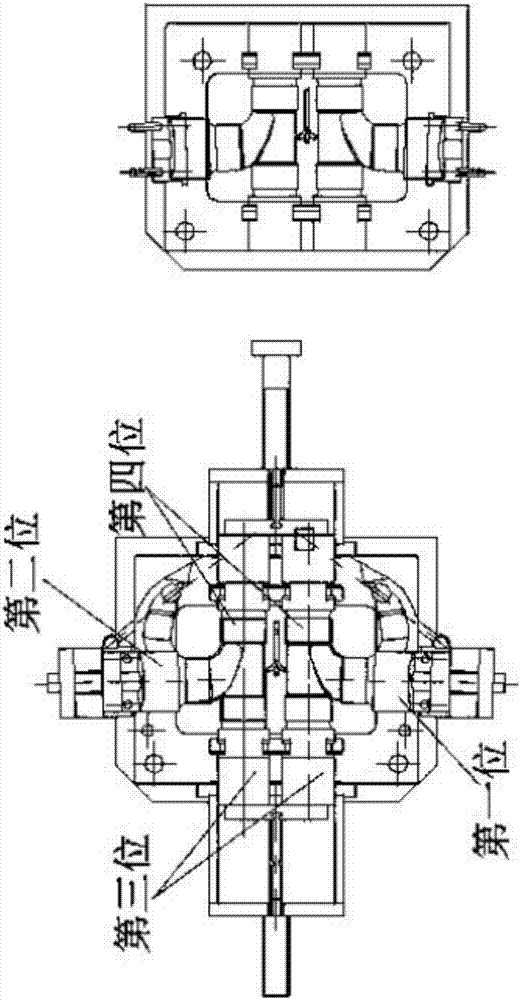

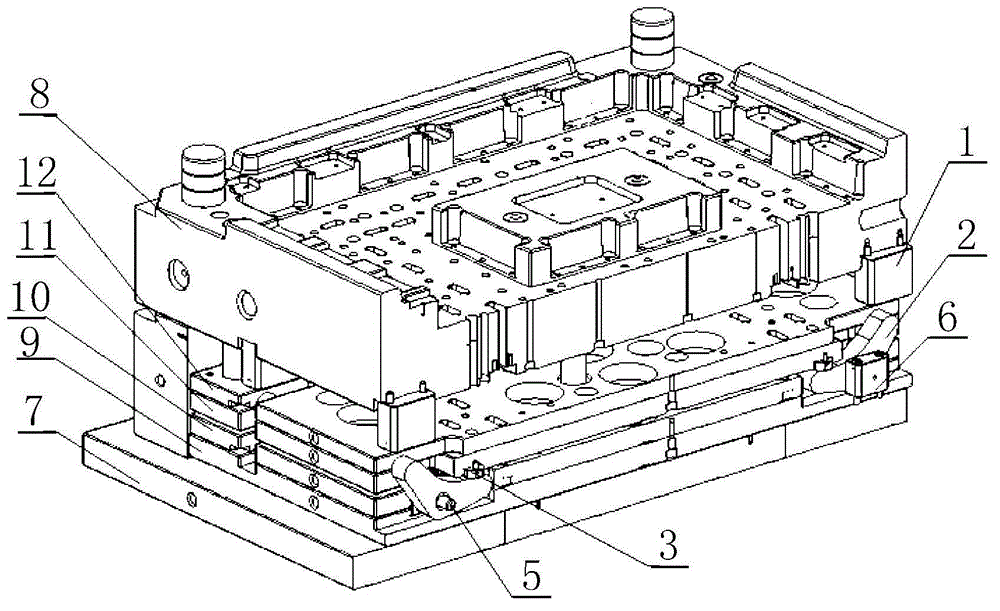

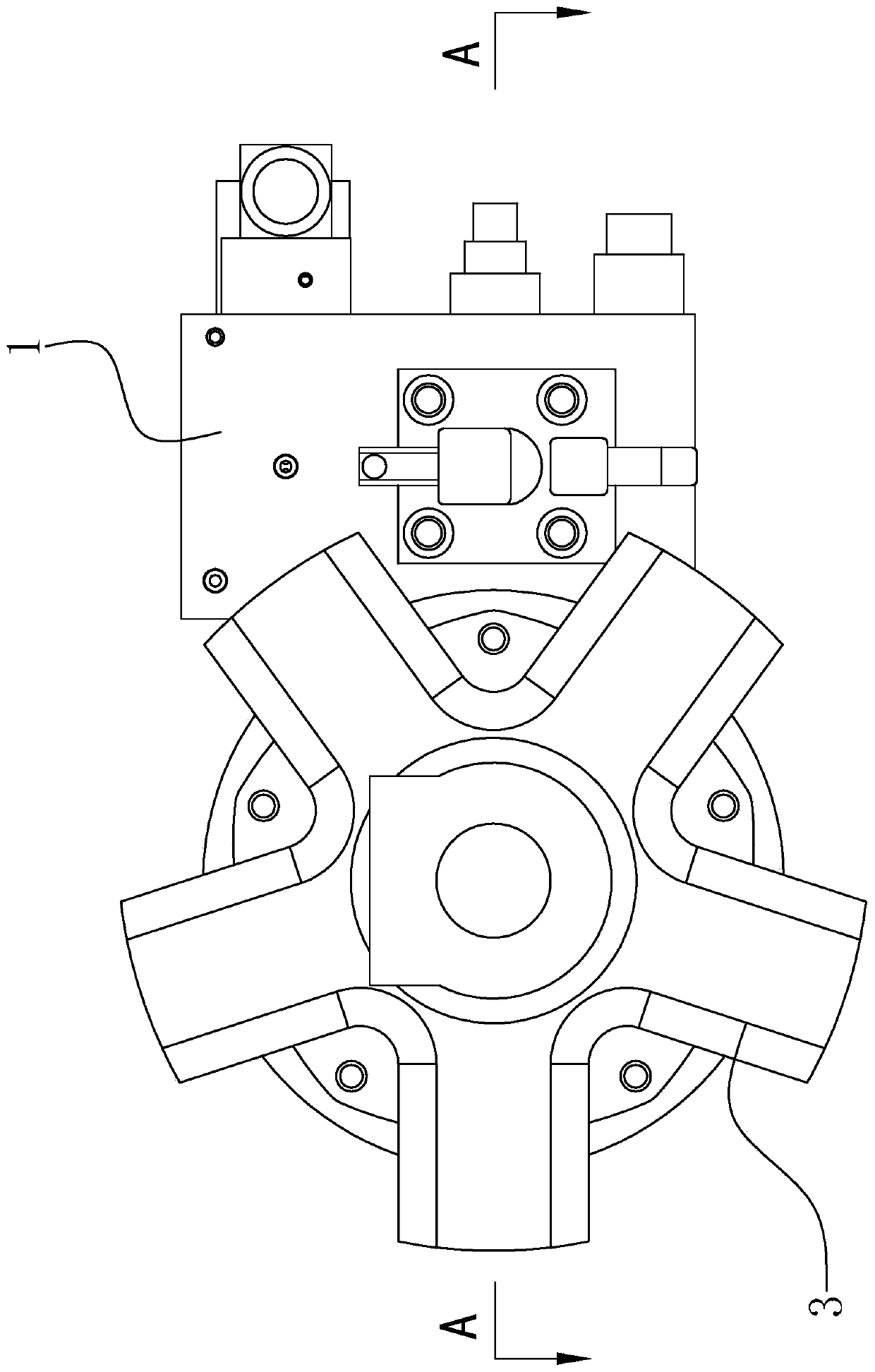

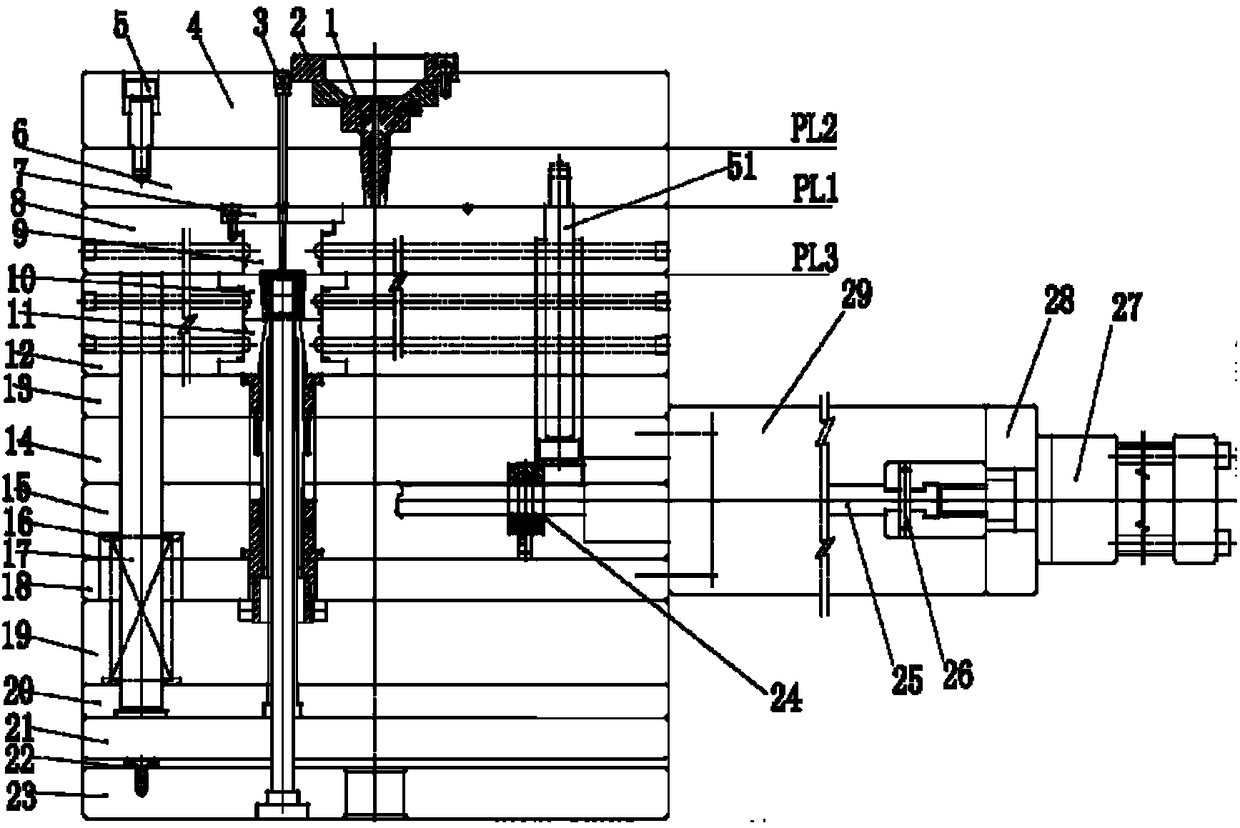

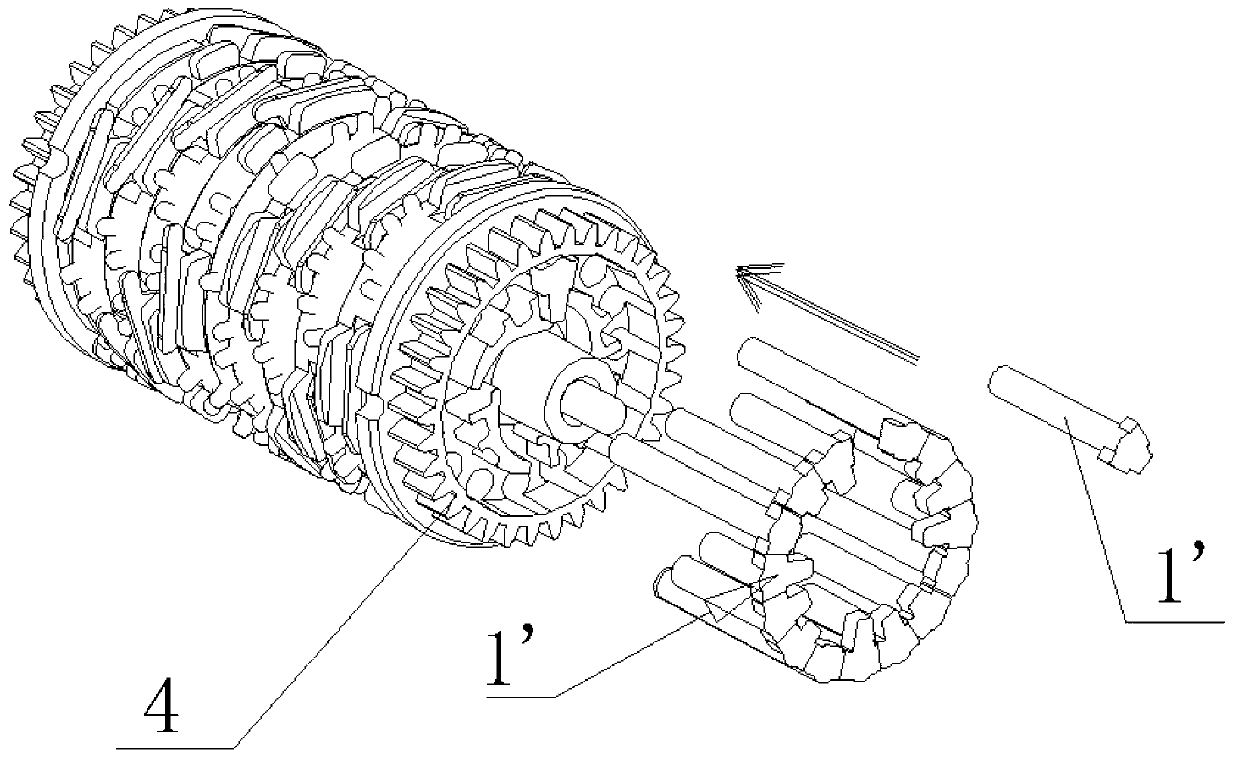

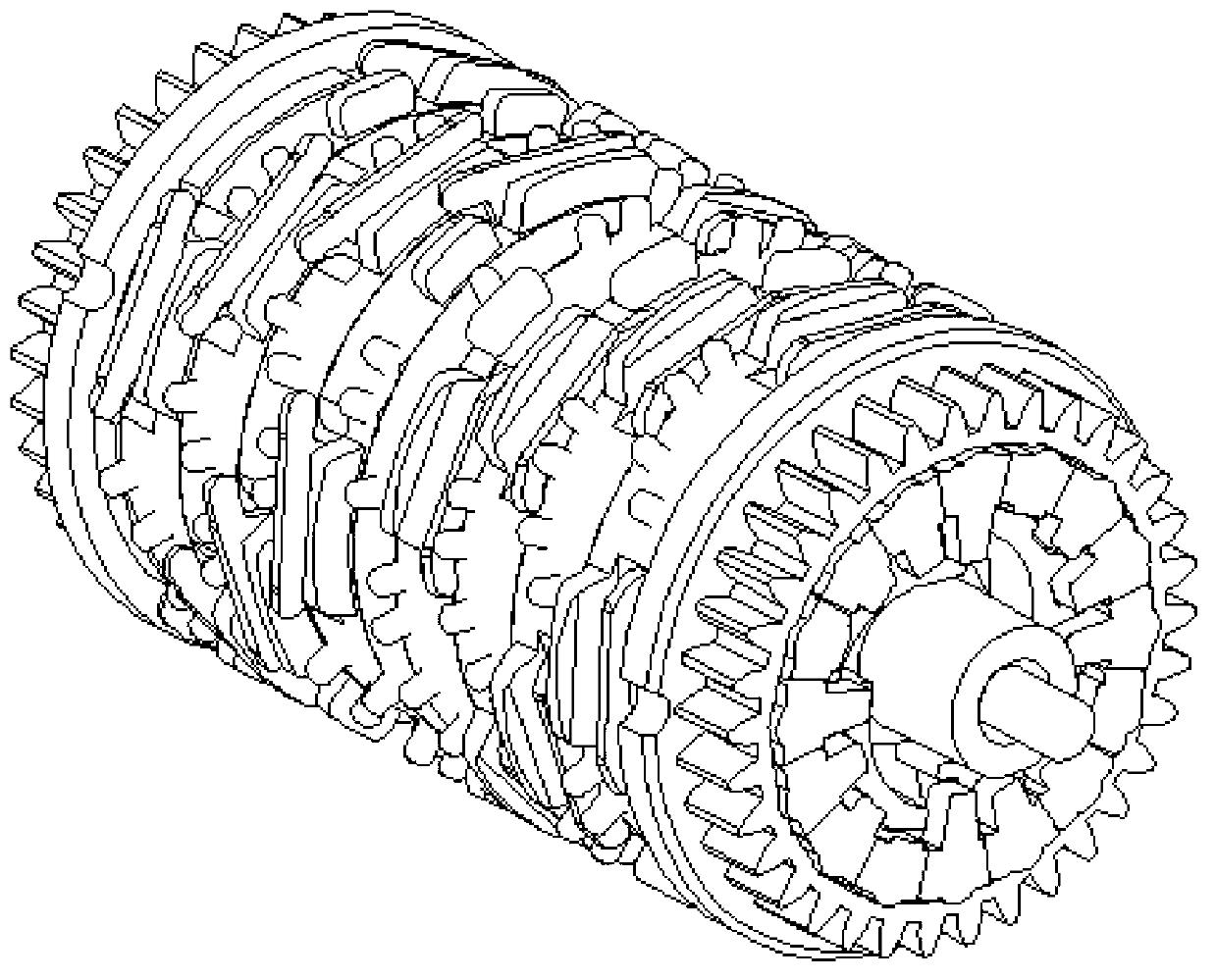

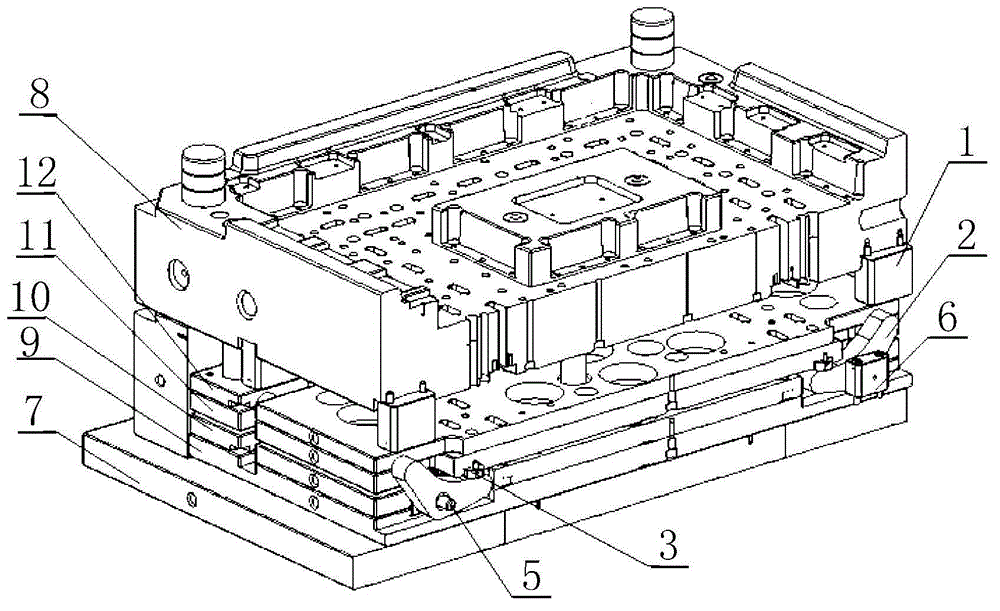

Gear-driven bent pipe multi-directional demolding mechanism

InactiveCN106608028AImprove Injection Molding Production EfficiencyReduce manufacturing costGear driveEngineering

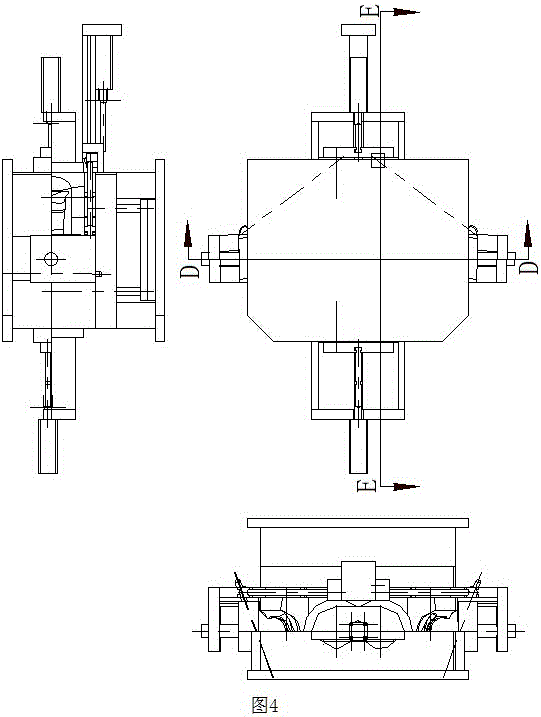

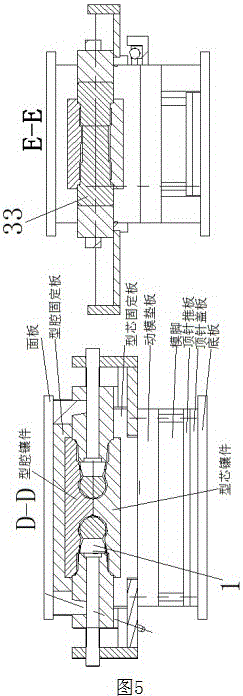

The invention provides a gear-driven bent pipe multi-directional demolding mechanism which comprises a mold frame structure as well as first-position, second-position, third-position and fourth-position core-pulling demolding mechanisms of a core-pulling demolding part, wherein similar oil cylinder driving double-linkage mechanisms serve as the first-position and second-position core-pulling demolding mechanisms; and circular pipe-circular sliding block core-pulling demolding mechanisms serve as the third-position and fourth-position core-pulling demolding mechanisms. The gear-driven bent pipe multi-directional demolding mechanism provided by the invention adopts the above technical scheme and can be applied to a three-way pipe injection mold; accordingly, the complexity and the mold structure of a side core-pulling mechanism at a middle bent pipe part can be simplified when a conventional three-way pipe product adopts the multi-cavity mold design, the reliability of a circular-arc core-pulling mechanism and the mold injection production efficiency can be improved; and the mold production cost can be reduced; and besides, the structural design is reasonable, the structure is compact, the work is stable, and the safety and the reliability are achieved.

Owner:ZHEJIANG BUSINESS TECH INST

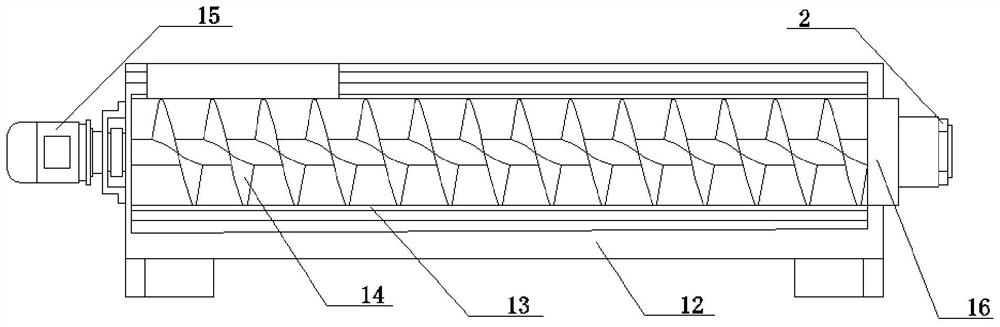

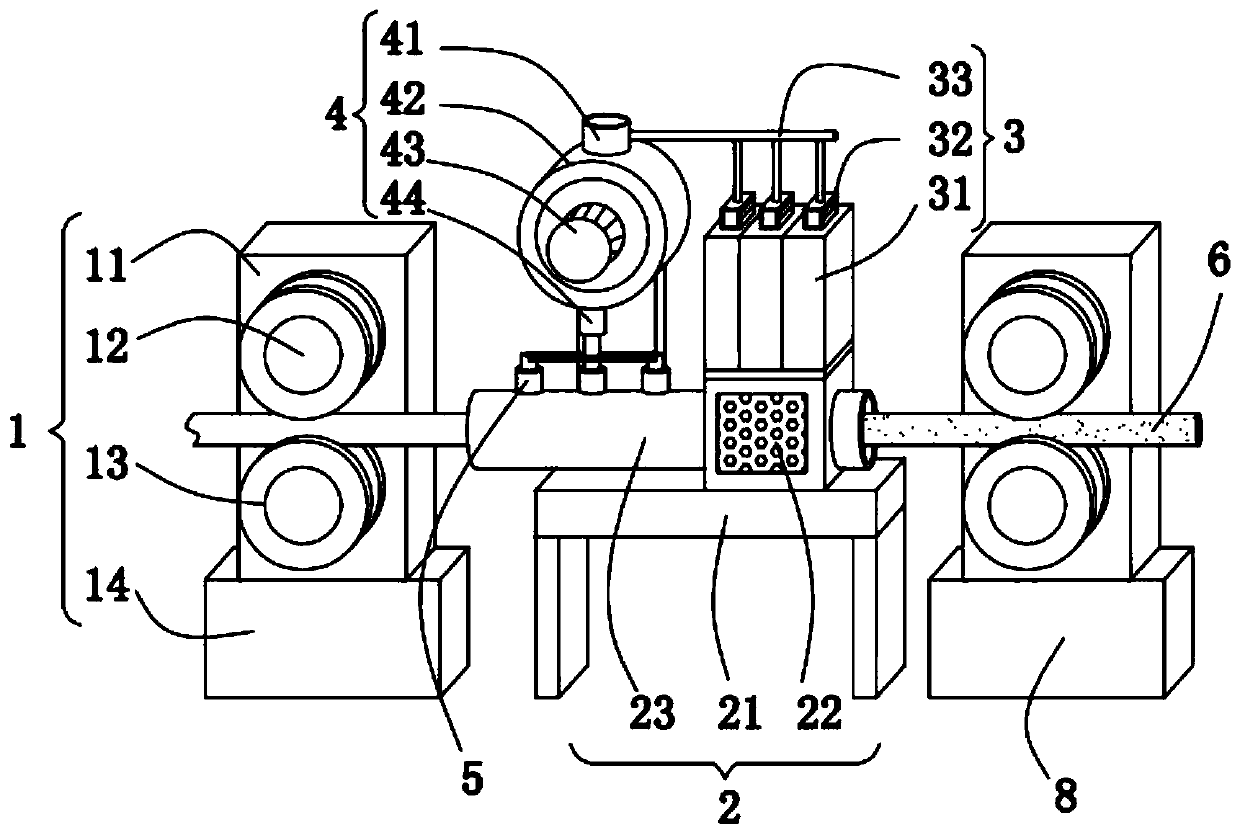

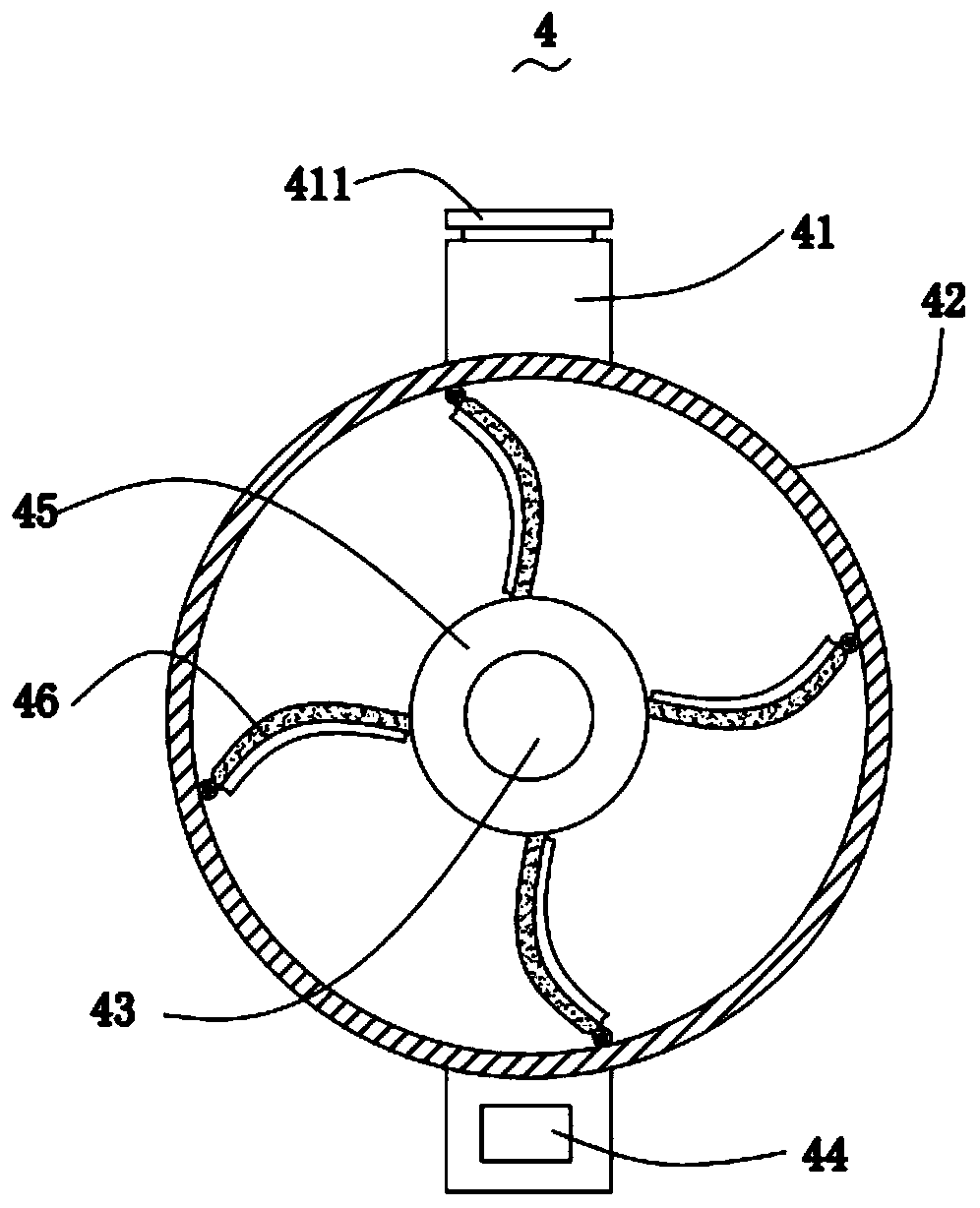

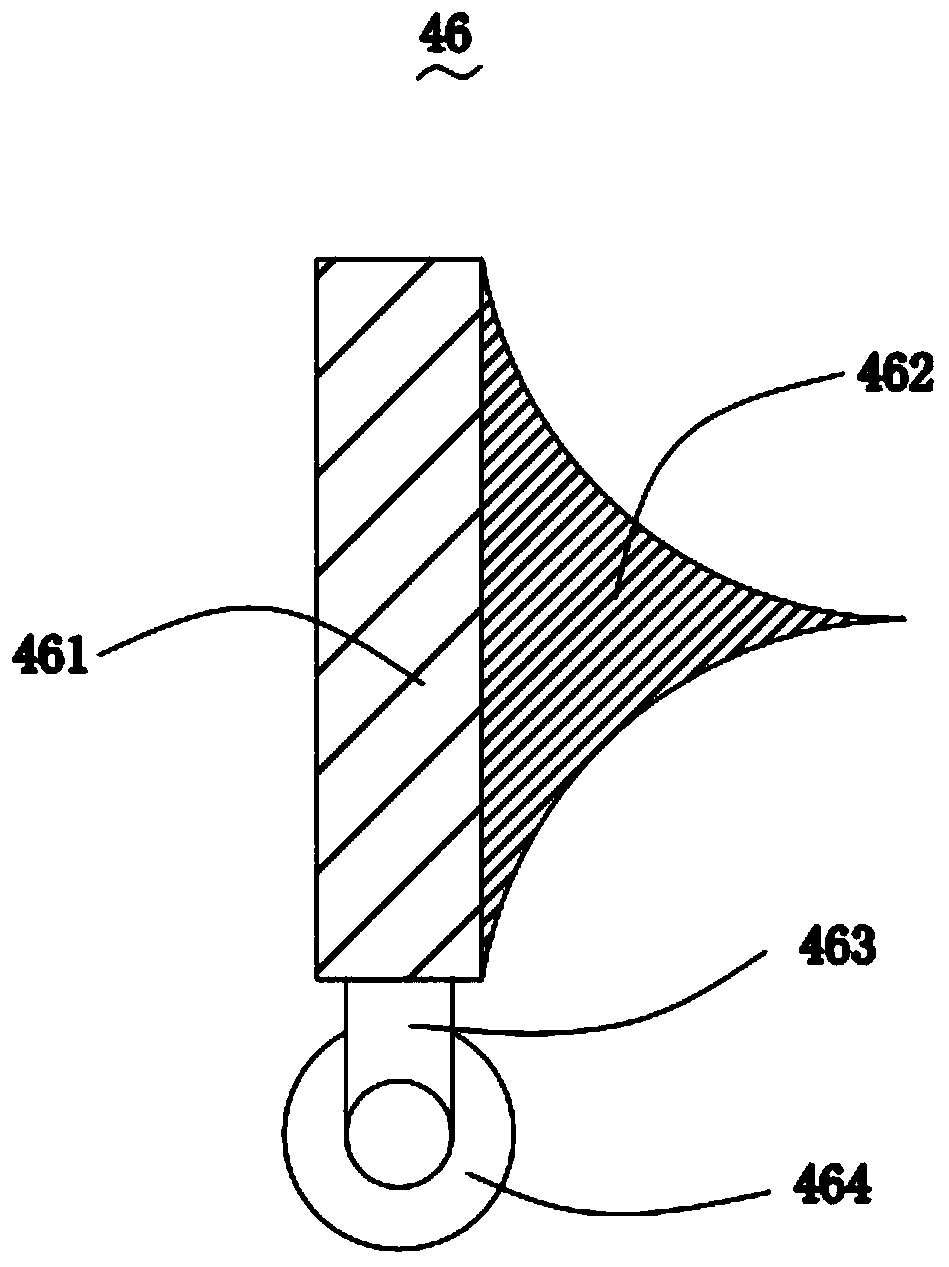

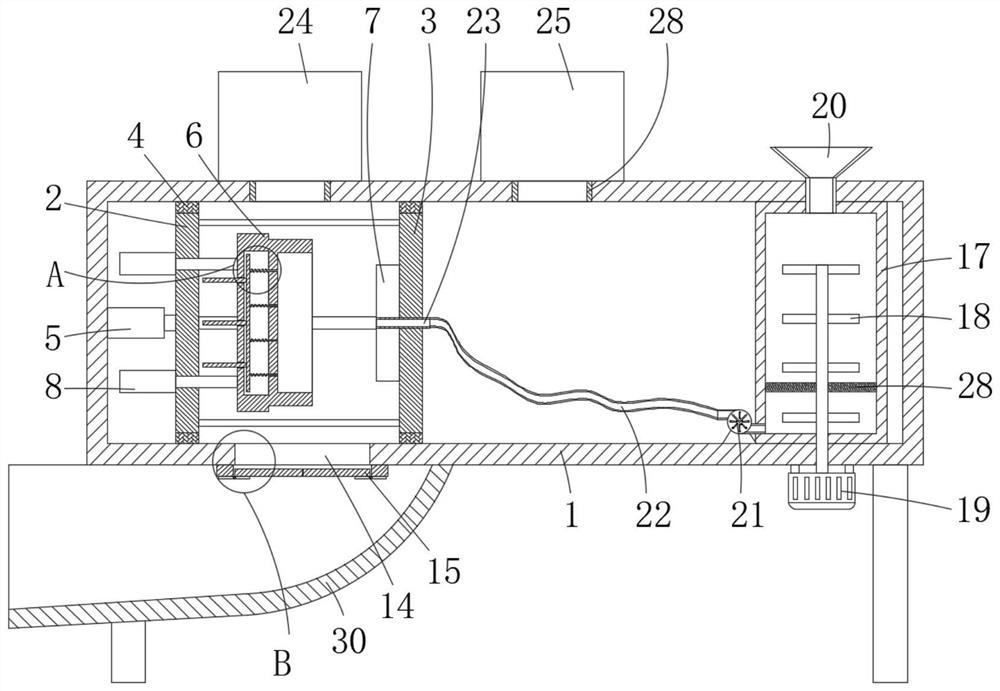

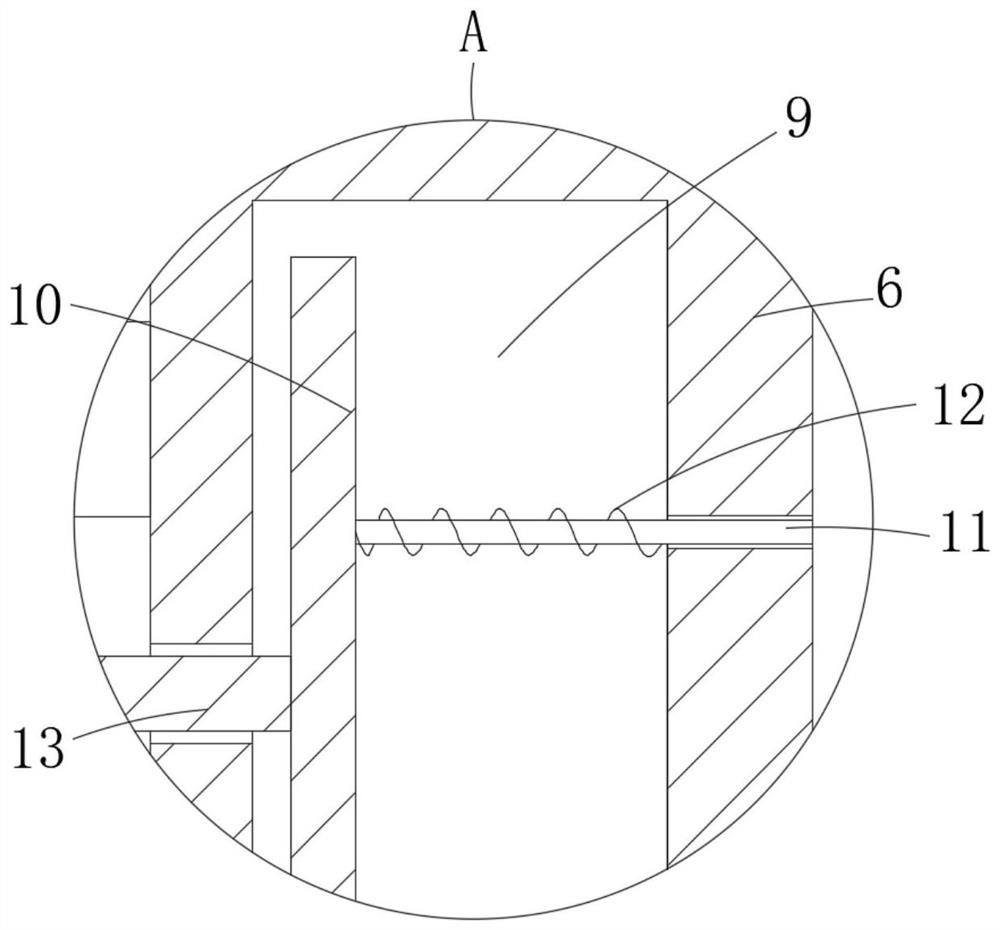

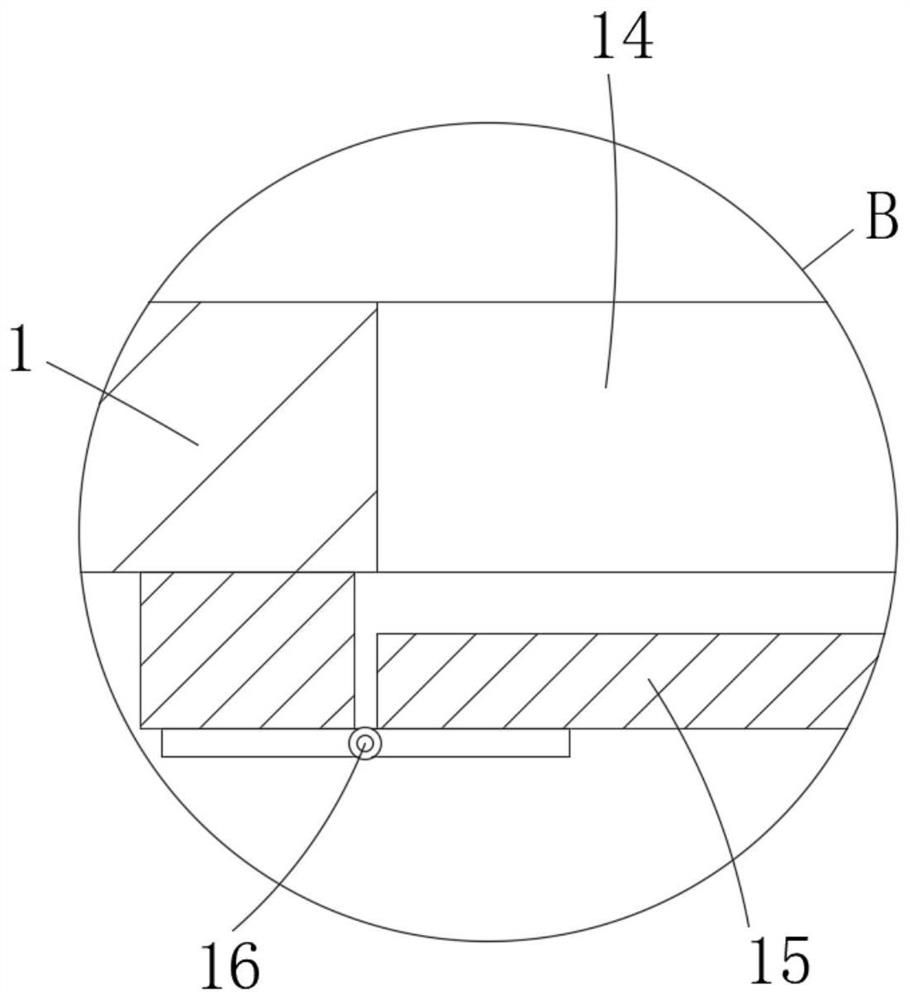

Equipment for reducing internal stress of injection-molded part and injection-molding production method

InactiveCN112606313AAvoid the phenomenon of poor plasticizationMeet the qualityPlasticultureMixed materials

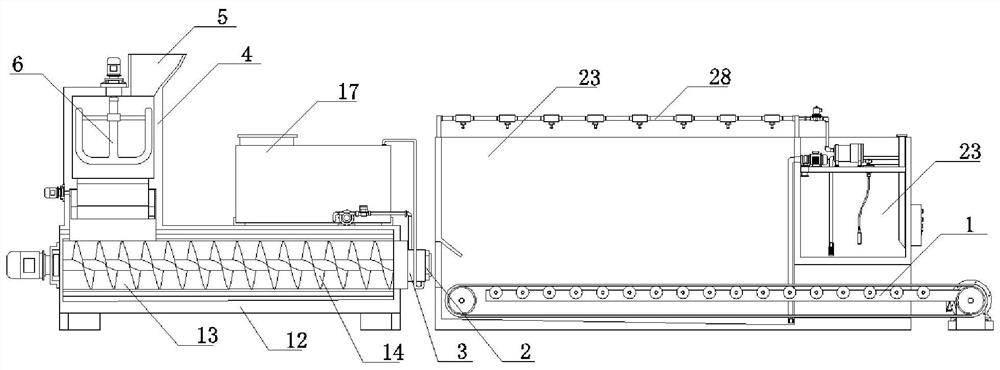

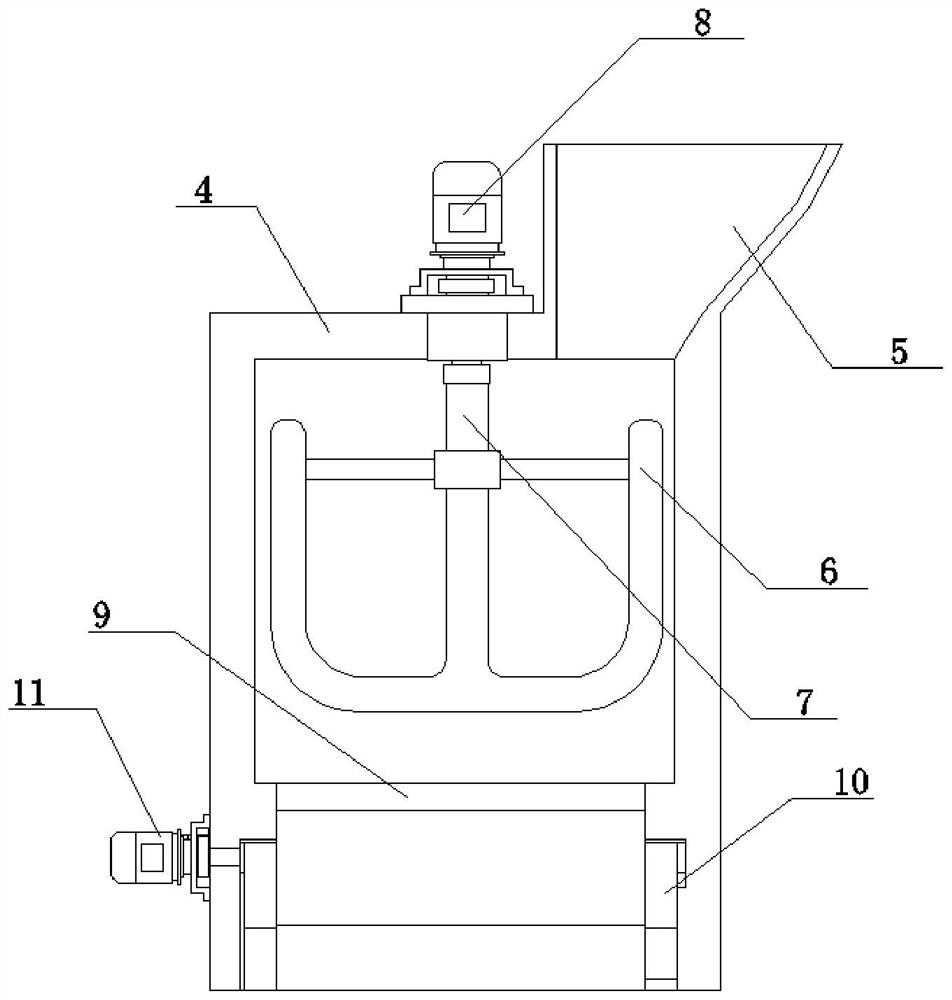

The invention discloses equipment for reducing internal stress of an injection-molded part and an injection molding production method. The equipment comprises a raw material mixing assembly, an injection molding assembly, an injection molding cooling assembly, a finished product cooling assembly and a conveying belt; the raw material mixing assembly is connected with the injection molding assembly; and an injection molding mold is connected to a discharging outlet of the injection molding assembly, a cooling cavity is formed outside the injection molding mold, the cooling cavity is connected with the injection molding cooling assembly, the finished product cooling assembly is located on the side of the injection molding mold, and the conveying belt is arranged in the finished product cooling assembly. By arranging the raw material mixing assembly, material particles for injection molding can be mixed, the material mixing uniformity can be effectively improved, and the mixed material plasticizing capacity is guaranteed; by arranging the injection molding cooling assembly, the injection molding mold can be cooled, and the internal stress existing in an injection molding product can be eliminated advantageously; and by arranging the finished product cooling assembly, the injection-molded part can be continuously cooled through spraying of cooling liquid after being demolded, and the situations that the thick part of the injection-molded part is sunken and the surface bonding line is enlarged due to the fact that internal heat is difficult to release can be prevented.

Owner:NANJING TAOTESI SOFTWARE TECH CO LTD

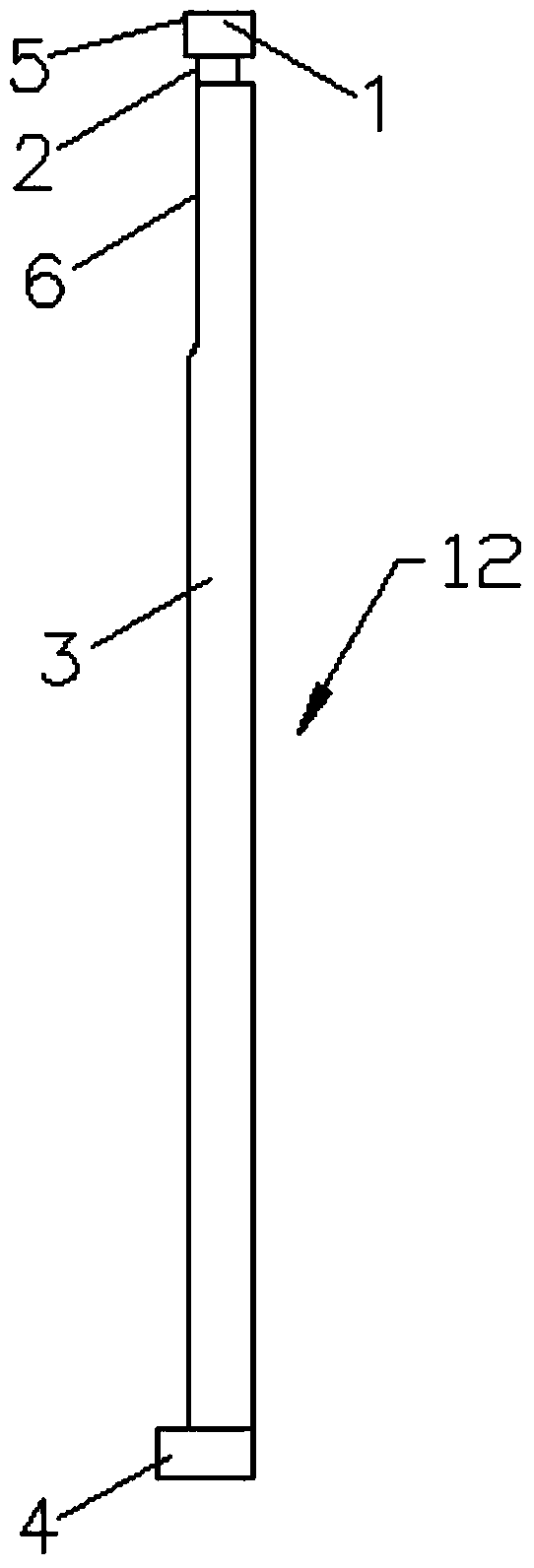

Push rod capable of exhausting

The invention discloses a push rod capable of exhausting. The push rod comprises a push rod head, a tool withdrawal groove, a rod body and a suspension table, wherein the tool withdrawal groove is formed in the lower end of the push rod head; the rod body is arranged below the tool withdrawal groove; the suspension table is arranged at the bottom end of the rod body; an upper exhausting groove is formed in one side of the push rod head; a lateral exhausting groove is formed in the rod body; the lateral exhausting groove and the upper exhausting groove are formed in the same side; the lateral surface of the lateral exhausting groove is levelly connected with the tool withdrawal groove in parallel; a convex shoulder is arranged on the suspension table on the same side of the lateral exhausting groove in the rod body; the other side of the suspension table is level and parallel to the rod body without any convex shoulder. The push rod provided by the invention has the advantages of simple structure and convenience in repairing and assembling, so that the quality of a modeling product can be ensured; meanwhile, the modeling period can be shortened; energy consumed by an injector can be reduced; the production efficiency of injection molding is greatly improved.

Owner:SUZHOU VOCATIONAL UNIV

Injection mold for safety belt buckles

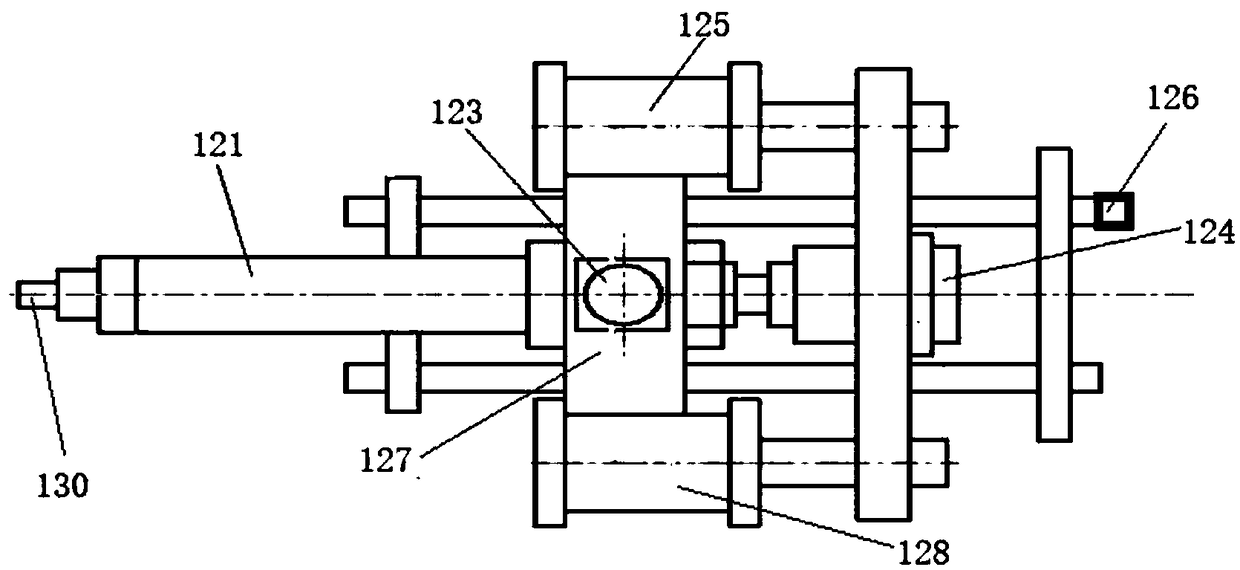

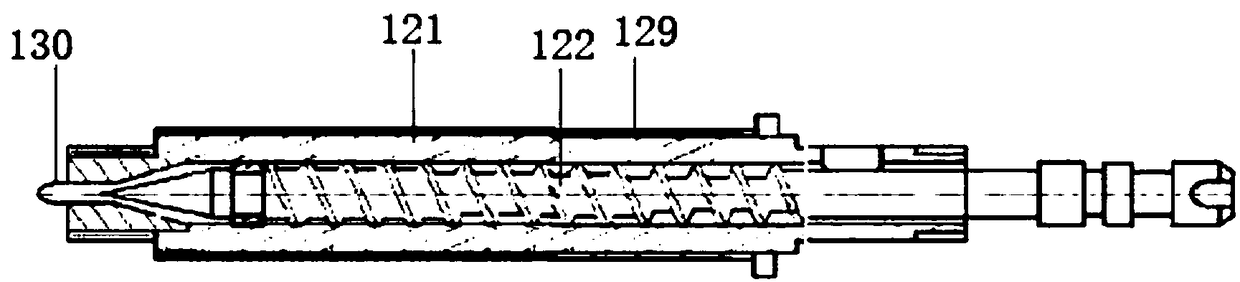

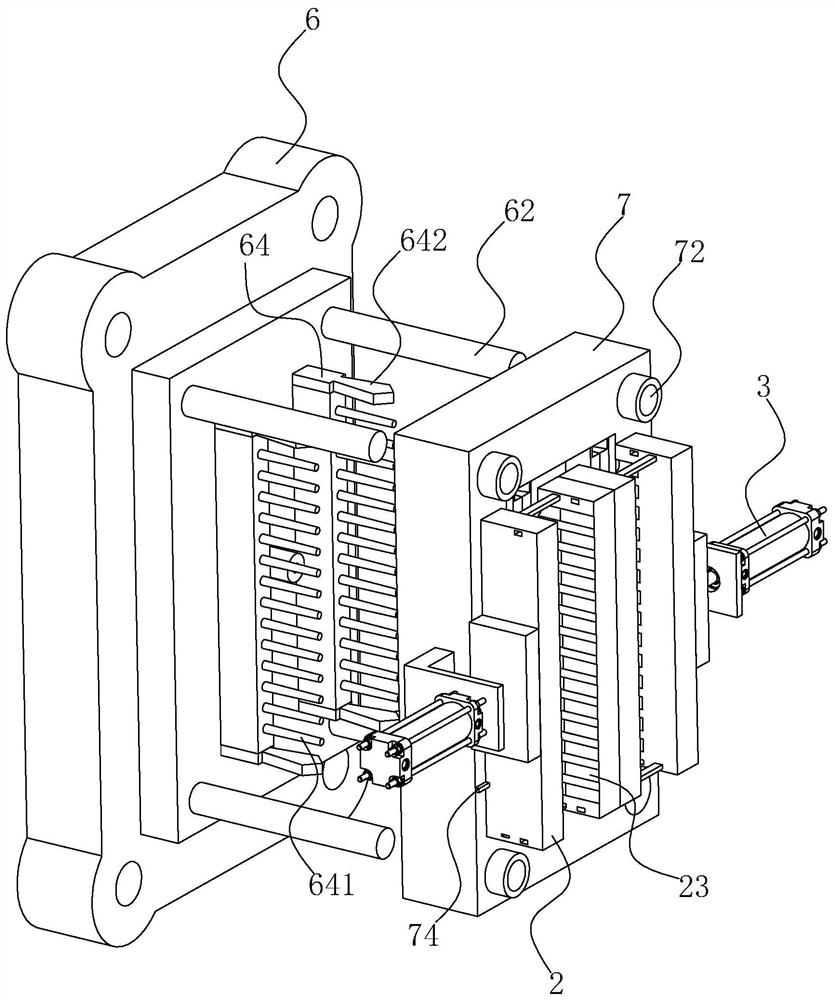

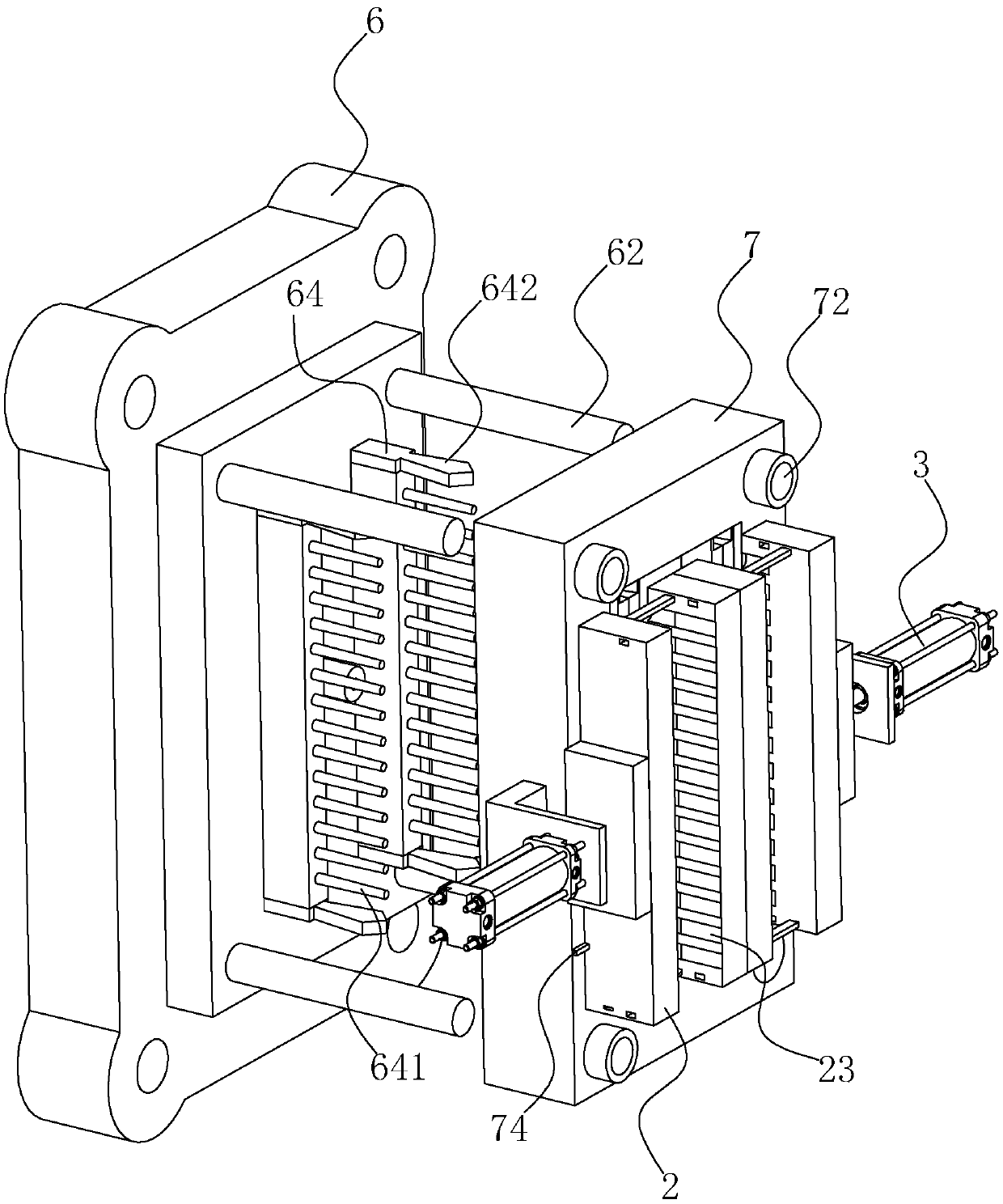

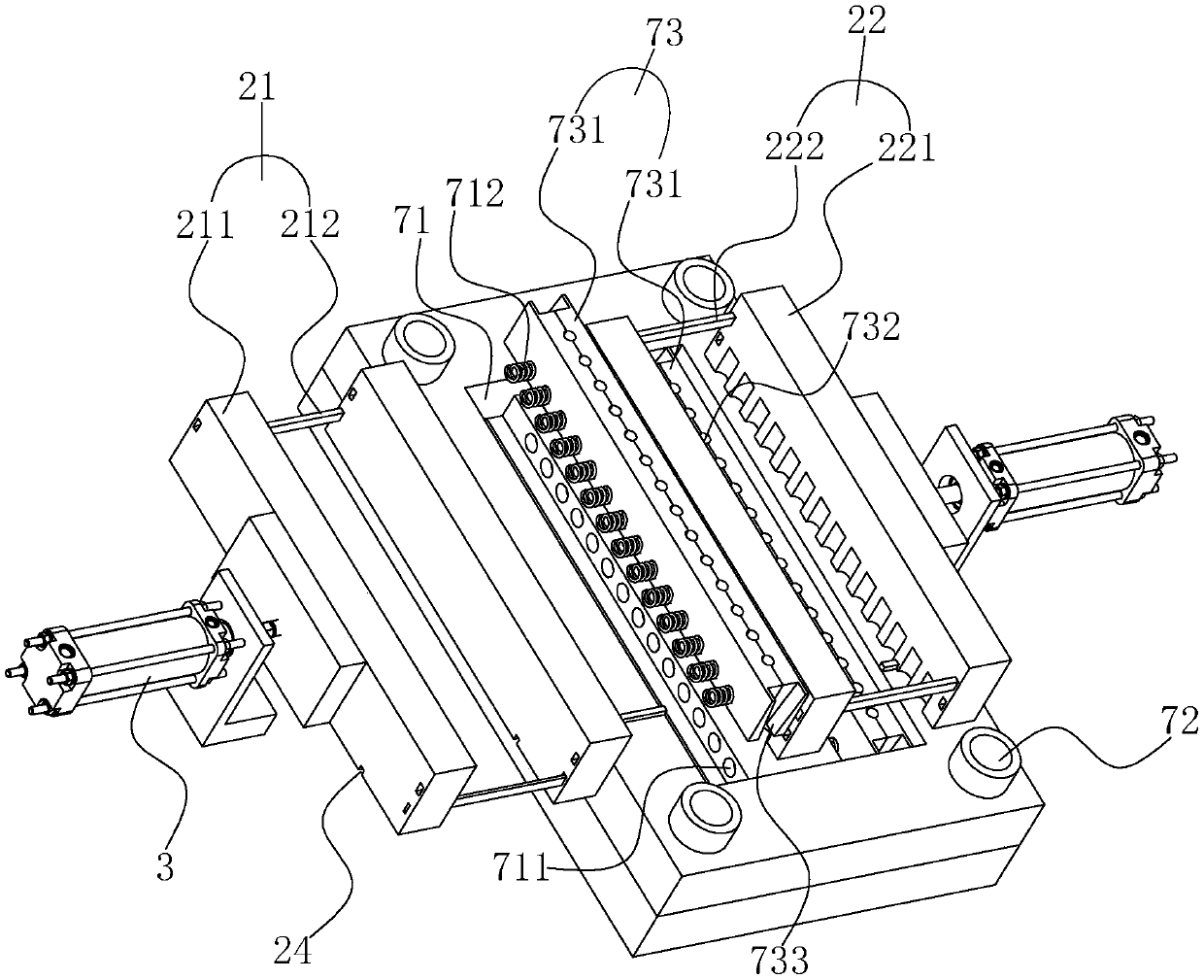

ActiveCN108247952AWill not changeImprove Injection Molding Production EfficiencyCoatingsHydraulic cylinderBelt safety

The invention discloses an injection mold for safety belt buckles. The injection mold comprises an injection molding frame, and is characterized by comprising a mold arranged on the injection moldingframe; the mold comprises a first mold and a second mold; the first mold and the second mold are both arranged on a movable rail of the injection molding frame; the first mold is provided with a firstmolding cavity and a second molding cavity; a mold core capable of rotating relative to the second mold is arranged in the second mold; a back cover is fixedly connected behind the second mold; a metal clamp material way module is fixedly connected above the second mold; a metal clamp material way of the metal clamp material way module is used for placing metal clamps with a certain number; a switch is arranged in an inlet of the second mold, and comprises a first switch and a second switch; the second switch is positioned on the lower side of the first switch; a hydraulic cylinder for pushing the metal clamps is arranged in the mold core; and the mold core comprises a cross groove disc, a rotating shaft and a half-moon disc. The injection mold can improve the injection molding productionefficiency of the safety belt buckles.

Owner:宁波诚泰汽车部件有限公司

Multicolor injection molding machine and use method thereof

The invention relates to the technical field of injection molding and discloses a multicolor injection molding machine and a use method of the multicolor injection molding machine. The multicolor injection molding machine comprises an injection molding body, a secondary injection device, a controller, a mold and a mechanical arm. The secondary injection device is connected to the injection moldingmachine body. The mechanical arm is connected to the top of the injection molding machine body. The injection molding machine body further comprises a shell, a first screw type injection device. Thefirst screw type injection device and the mold are both installed on the shell. The first screw type injection device is directed at a first cavity of the mold. The controller is connected with the first screw type injection device and the mechanical arm. The secondary injection device further comprises a machine frame, a connector and a second screw type injection device, wherein the machine frame is connected with the shell through the connector, and the second screw type injection device is installed on the machine frame and connected with the controller. According to the multicolor injection molding machine, the auxiliary secondary injection device and the mechanical arm are additionally arranged, and then the bicolor injection molding purpose is achieved; and meanwhile, the structureof a bicolor injection molding machine with a rotating disk is not needed, the mold structure is simple, cost is low, continuous operation can be conducted, and the injection molding production efficiency is high.

Owner:宏利科技(苏州)有限公司

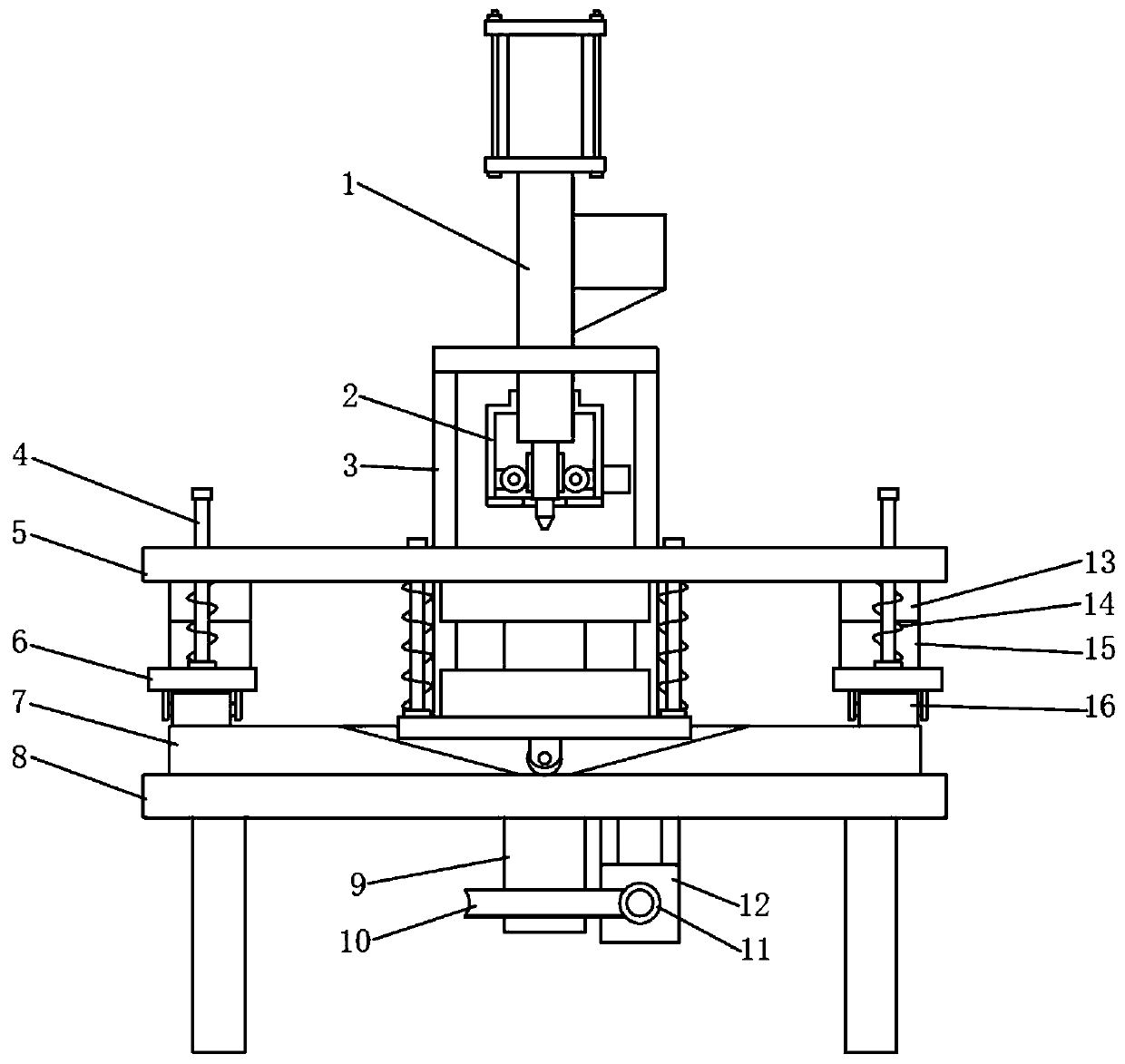

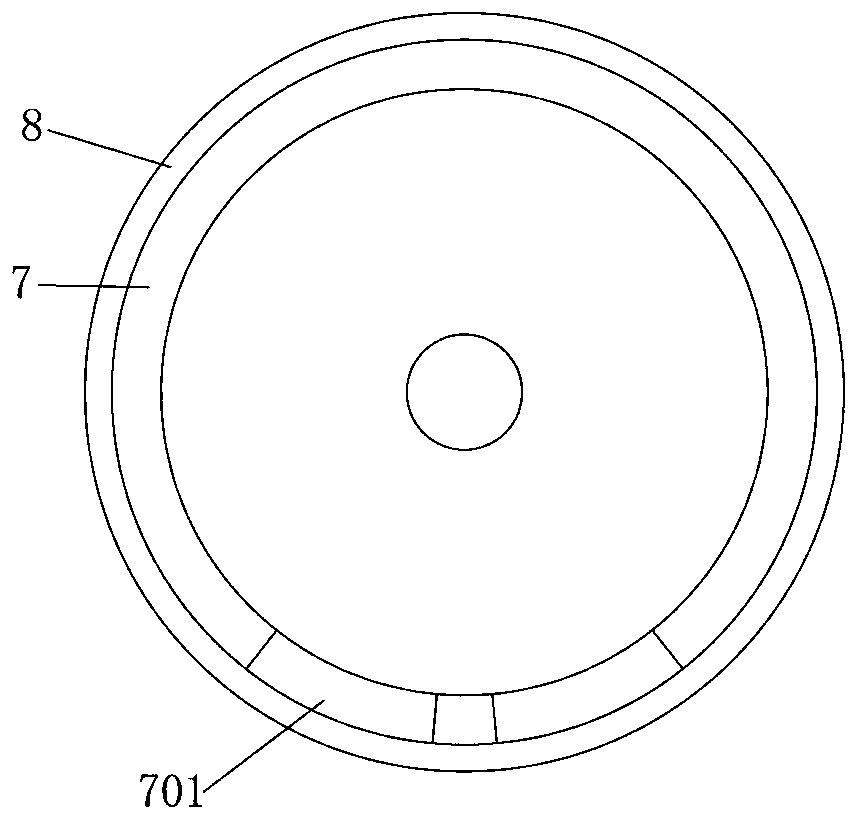

Injection molding machine for toy processing

InactiveCN110625882AEasy to take outImprove Injection Molding Production EfficiencyDomestic articlesEngineeringInjection molding machine

The invention discloses an injection molding machine for toy processing. The injection molding machine for toy processing comprise a rotating disc, wherein the middle of the rotating disc is fixed atthe end of a rotating shaft, the rotating shaft is arranged on a rack through a bearing seat, the bottom of the rack is provided with a first motor through a support, and the output end of the first motor is provided with a worm which meshes with a gear fixed at the bottom end of the rotating shaft; a plurality of groups of mold assemblies are arranged on the rotating disc at equal intervals; anda lifting guide rail is fixed on the surface of the rack, a screw injection molding machine is further arranged on the rack through a supporting arm, an injection molding nozzle is movably arranged atthe end of the bottom end of the screw injection molding machine, and a transmission box for driving the injection molding nozzle is further arranged at the bottom of the screw injection molding machine. According to the injection molding machine for toy processing, the rotating disc rotates to drive the mold assemblies to rotate synchronously, in the rotating process of the mold assemblies, automatic opening and closing of the mold assemblies is achieved through the lifting guide rail, molded pieces are conveniently taken out, continuous production can be carried out, the cooling waiting time is shortened, and the injection molding production efficiency of toys is improved.

Owner:义乌市拓一斯玩具有限公司

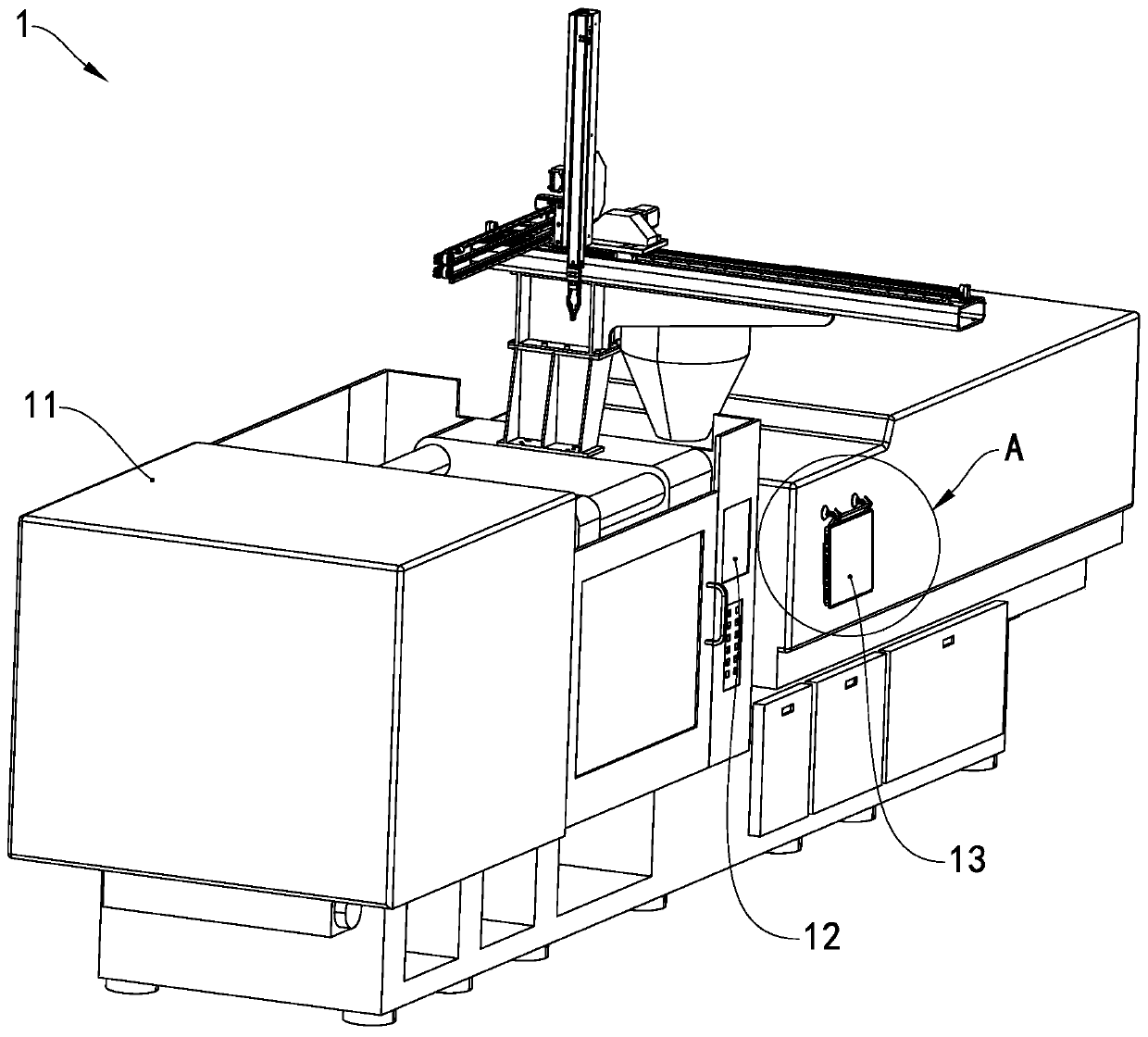

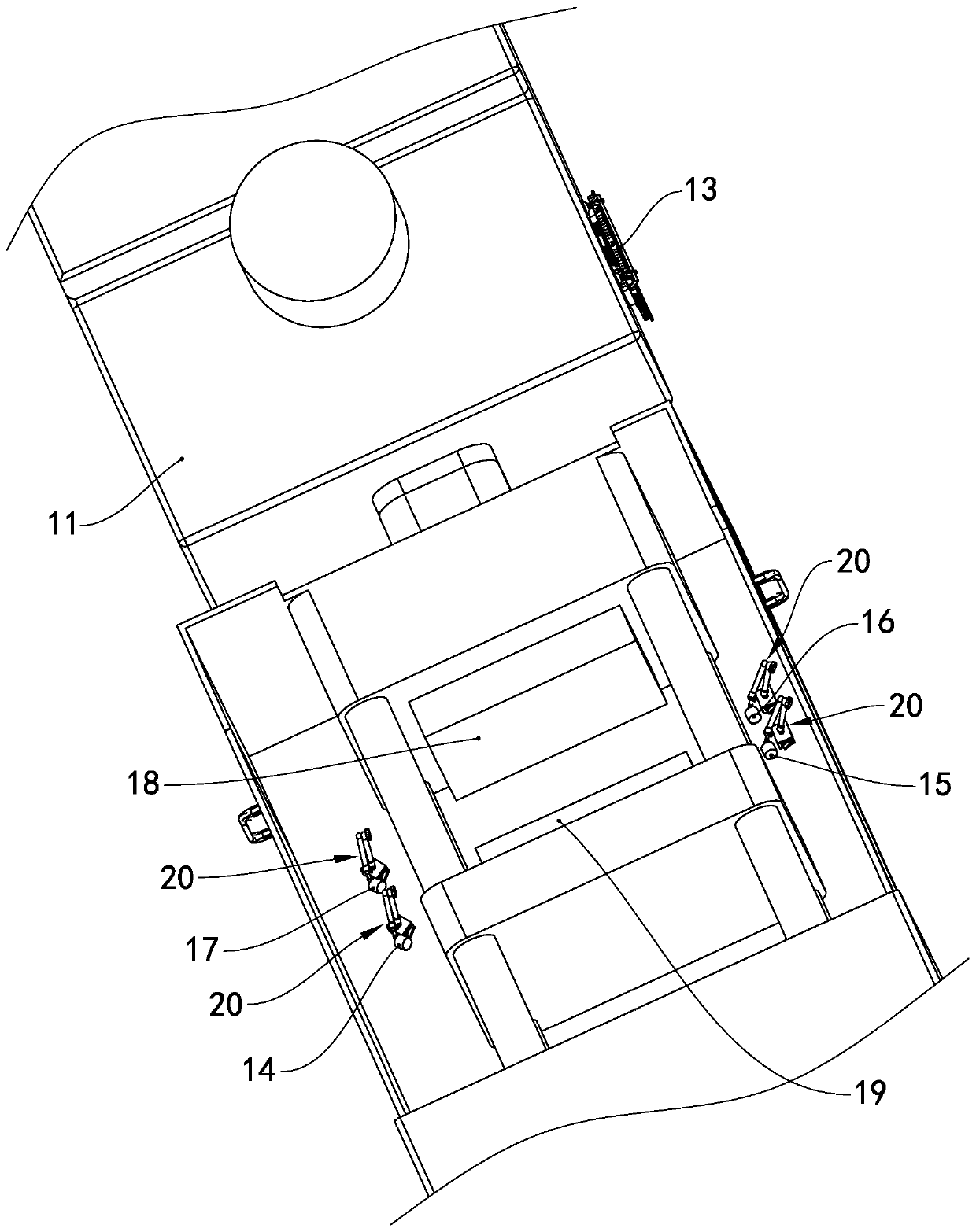

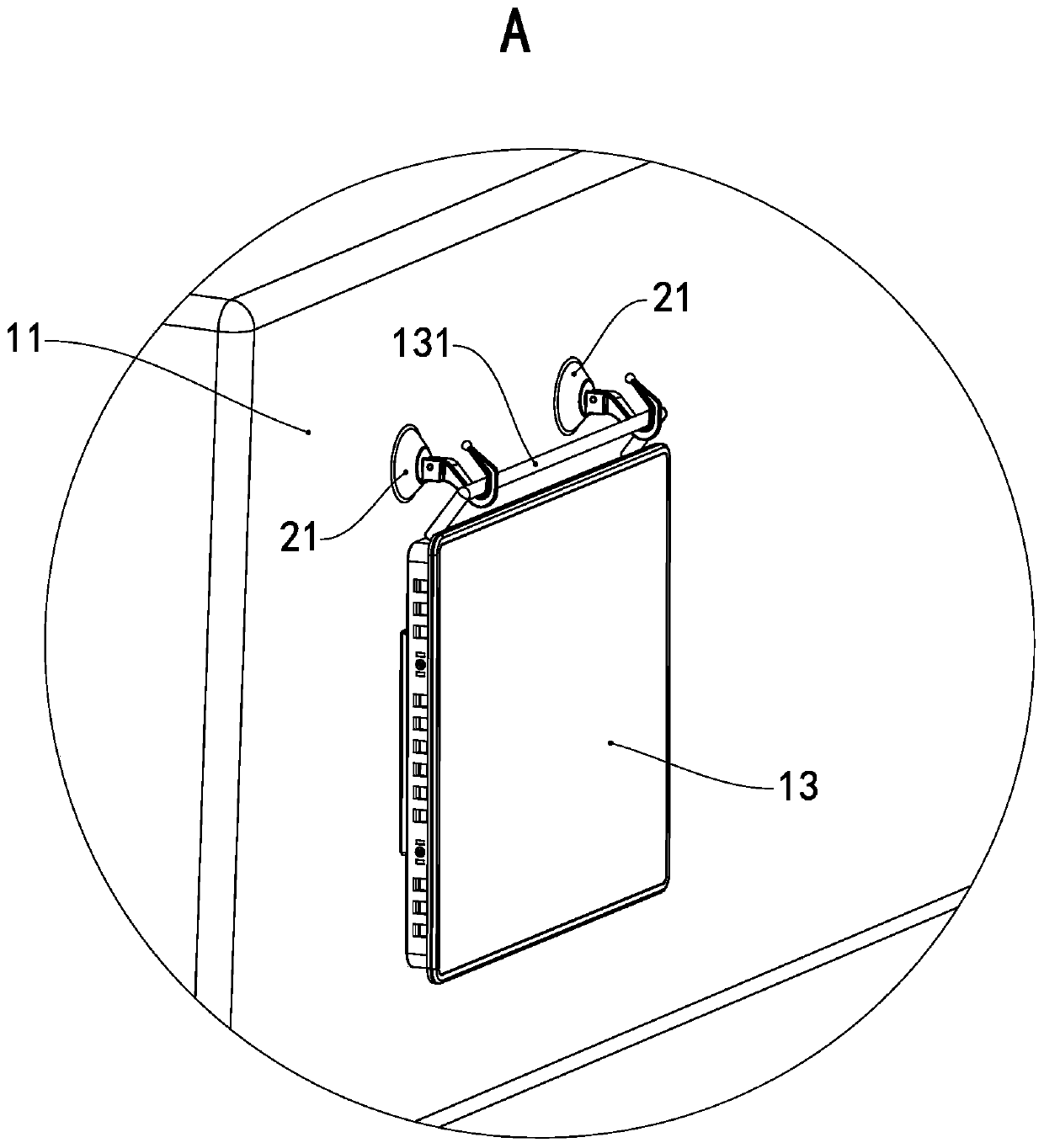

Injection molding system with visual monitoring function and monitoring method of injection molding system with visual monitoring function

The invention provides an injection molding system with a visual monitoring function and a monitoring method of the injection molding system with the visual monitoring function. The monitoring methodincludes the steps that a monitoring display obtains injection molding machine mold-open in place signals of a main controller; the monitoring display outputs an image capture signal to a first cameraand / or a second camera; the first camera and / or the second camera take pictures and capture images; the images acquired by the first camera and / or the second camera are displayed on the monitoring display; the monitoring display performs the image recognition processing; and the result of the image recognition processing is output to the main controller. Through the monitoring method, a working state of the injection molding system is monitored, while the service life of a mold is prolonged, the injection molding production efficiency is improved, and therefore, the production cost is reduced, and the product quality is improved.

Owner:珠海正川塑胶制品有限公司

Single-oil-cylinder drive device

A single-oil-cylinder drive device comprises an oil cylinder and an oil cylinder drive module. A transmission seat is arranged at the end of a piston rod of the oil cylinder, and a propulsion cavity and a retreating cavity communicate with the oil cylinder drive module through pipelines. A rotation mechanism is arranged in the propulsion cavity in a sealed manner, one end of the rotation mechanismis in transmission connection with a piston rod, and the piston rod can slide back and forth relative to the rotation mechanism. The other end of the rotation mechanism extends out of the oil cylinder and is in transmission connection with a hydraulic motor. The hydraulic motor is used for driving the rotation mechanism to drive the piston rod to rotate relative to an oil cylinder block, and thehydraulic motor communicates with the oil cylinder drive module through the pipeline. The oil cylinder drive module is connected with the control module through a line. The oil cylinder drive module can be controlled by the control module to switch to drive the piston rod to move forward and backward and drive an output shaft of the hydraulic motor to rotate. The single-oil-cylinder drive device has the advantages that the control module controls oil channels to be automatically switched, the injection molding efficiency is high, the drive module can both push and pull a lead screw to conductinjection molding and drive the lead screw to rotate for rubber melting, and the use effect is good.

Owner:浙江台意德塑机制造有限公司

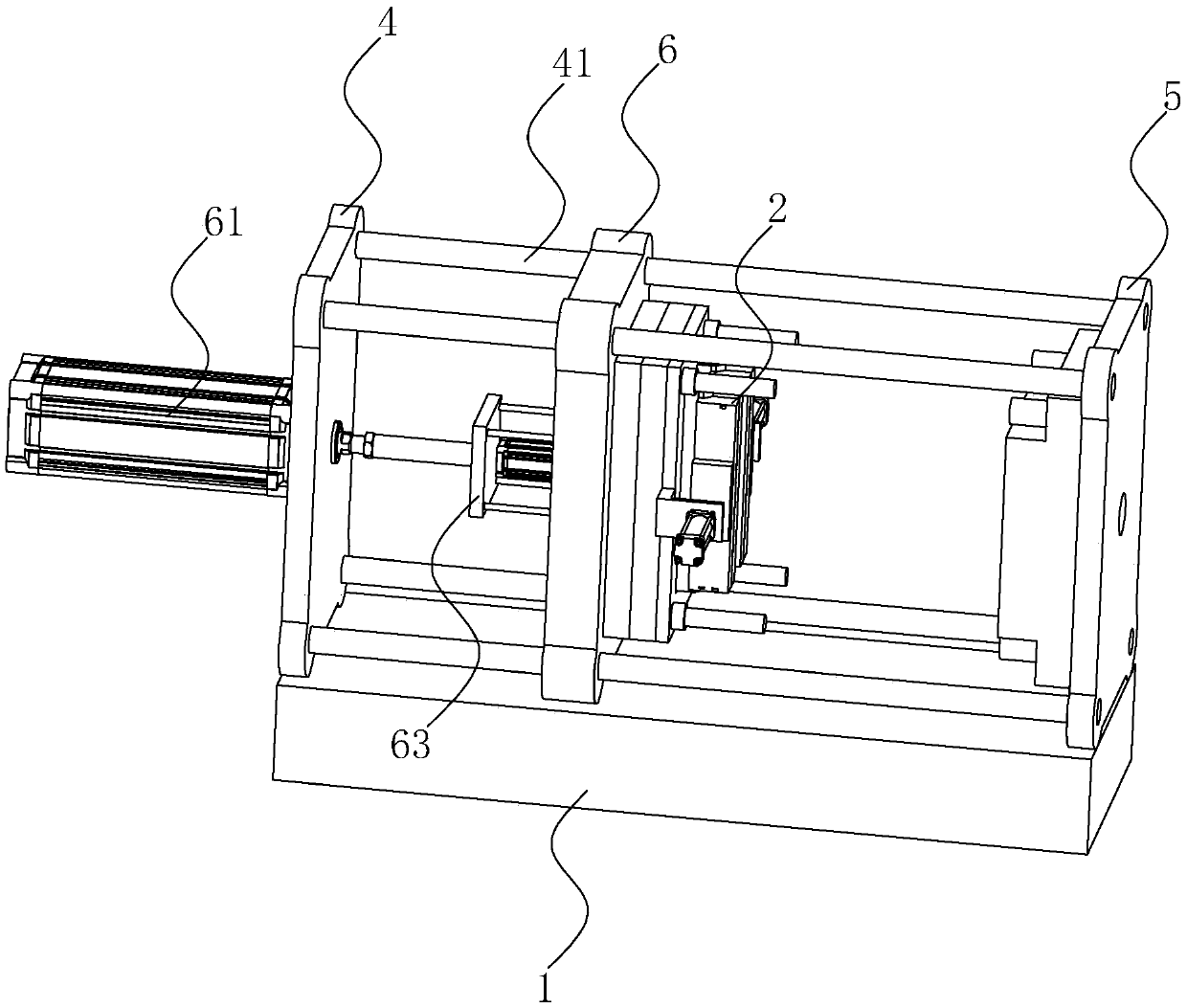

A plastic bottle injection molding machine

ActiveCN109624246BShorten the lengthReduce excess spaceDomestic articlesVertical planeInjection molding machine

The invention discloses a plastic bottle injection molding machine, and relates to the technical field of application of injection molding equipment. The technical problems that a fixed mold plate anda movable mold plate slide in the pull rod direction, consequently, the length of the injection molding machine is increased, and the space utilization efficiency is reduced are solved. According tothe technical key points, the plastic bottle injection molding machine comprises a machine table, a forming mold fixed to the machine table, and a driving air cylinder for driving the forming mold tobe opened and closed, the forming mold comprises a left movable mold and a right movable mold, the left movable mold comprises a pair of left mold plates vertically arranged in a spaced mode, and a left connecting rod is fixed between the left mold plates; and the right movable mold comprises a pair of right mold plates arranged in a spaced mode, wherein the right mold plates and the left mold plates are located on the same vertical plane, a right connecting rod is fixed between the right mold plates, mold cavities are formed in the opposite faces of the left mold plates and the right mold plates correspondingly, and mold columns matched with the mold cavities for injection molding are arranged at the positions, between each left mold plate and the corresponding adjacent right mold plate,of a bottom plate. The plastic bottle injection molding machine has the advantages that the space utilization efficiency of the injection molding machine is improved while the forming efficiency of the injection molding machine is ensured.

Owner:杭州永星塑料包装有限公司

Plastic bottle injection molding machine

The invention discloses a plastic bottle injection molding machine, and relates to the technical field of application of injection molding equipment. The technical problems that a fixed mold plate anda movable mold plate slide in the pull rod direction, consequently, the length of the injection molding machine is increased, and the space utilization efficiency is reduced are solved. According tothe technical key points, the plastic bottle injection molding machine comprises a machine table, a forming mold fixed to the machine table, and a driving air cylinder for driving the forming mold tobe opened and closed, the forming mold comprises a left movable mold and a right movable mold, the left movable mold comprises a pair of left mold plates vertically arranged in a spaced mode, and a left connecting rod is fixed between the left mold plates; and the right movable mold comprises a pair of right mold plates arranged in a spaced mode, wherein the right mold plates and the left mold plates are located on the same vertical plane, a right connecting rod is fixed between the right mold plates, mold cavities are formed in the opposite faces of the left mold plates and the right mold plates correspondingly, and mold columns matched with the mold cavities for injection molding are arranged at the positions, between each left mold plate and the corresponding adjacent right mold plate,of a bottom plate. The plastic bottle injection molding machine has the advantages that the space utilization efficiency of the injection molding machine is improved while the forming efficiency of the injection molding machine is ensured.

Owner:杭州永星塑料包装有限公司

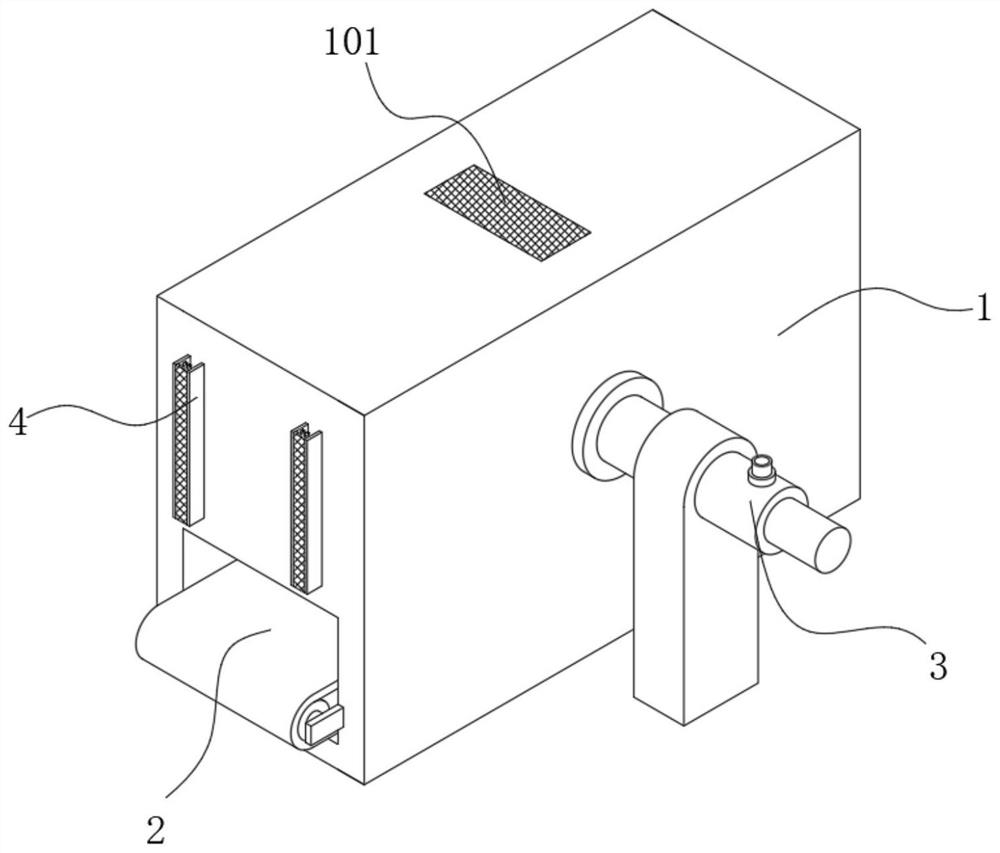

Notebook computer battery case production mold and cooling method

InactiveCN114589879AEasy to unloadImprove Injection Molding Production EfficiencyDomestic articlesElectric machineryBattery cell

The invention discloses a notebook computer battery shell production mold and a cooling method, and relates to the field of battery shell molding.The notebook computer battery shell production mold comprises a shell, a conveying belt is installed at the bottom end of the interior of the shell, a feeding machine and a motor are installed on the two sides of the shell respectively, and a fixed mold is installed in the shell; air cylinders are installed at the two ends of the inner wall of the shell, the output end of each set of air cylinders is connected with a movable mold, and a mold core is installed in each movable mold. Through the cooler, the movable mold, the heat conduction pipe and the guide pipe, in the moving process of the movable mold, the movable mold can be inserted into the movable mold through the guide pipe, so that the push plate in the cavity is pushed to move, the push plate extrudes air in the cavity and sends the air into the other set of movable mold through the heat conduction pipe, and when the push plate moves, external air is sucked in through the guide pipe; and outside air can pass through the cooler, so that the temperature of the entering air can be reduced.

Owner:友鑫达塑胶电子(深圳)有限公司

Single-oil-cylinder drive module

InactiveCN110206777ASmall footprintReduce shockServomotor componentsFluid-pressure actuator componentsEngineeringMechanical engineering

A single-oil-cylinder drive module comprises a module body. An oil inlet, an oil outlet, an oil conveying opening and an oil backflow opening are arranged on the module body, and a second oil outlet and a second oil inlet are further arranged on the module body. The oil inlet communicates with the oil conveying opening, the oil backflow opening and the second oil outlet through a pipeline. The oiloutlet communicates with the oil conveying opening, the second oil inlet and the oil backflow opening through a pipeline. A propelling control valve, a sol control valve and a return control valve are arranged on the module body and are connected with a control module through a circuit. The single-oil-cylinder drive module has the advantages that structural design is ingenious, communicating of different oil ways is achieved through adjustment of a valve body on a through cavity in the module body, and therefore the drive module can serve as a power source of piston pushing and pulling and can serve as a power source of piston rotating at the same time, one machine achieves multiple purposes, and the use effect is good.

Owner:浙江台意德塑机制造有限公司

Sewage treatment device and manufacturing method thereof

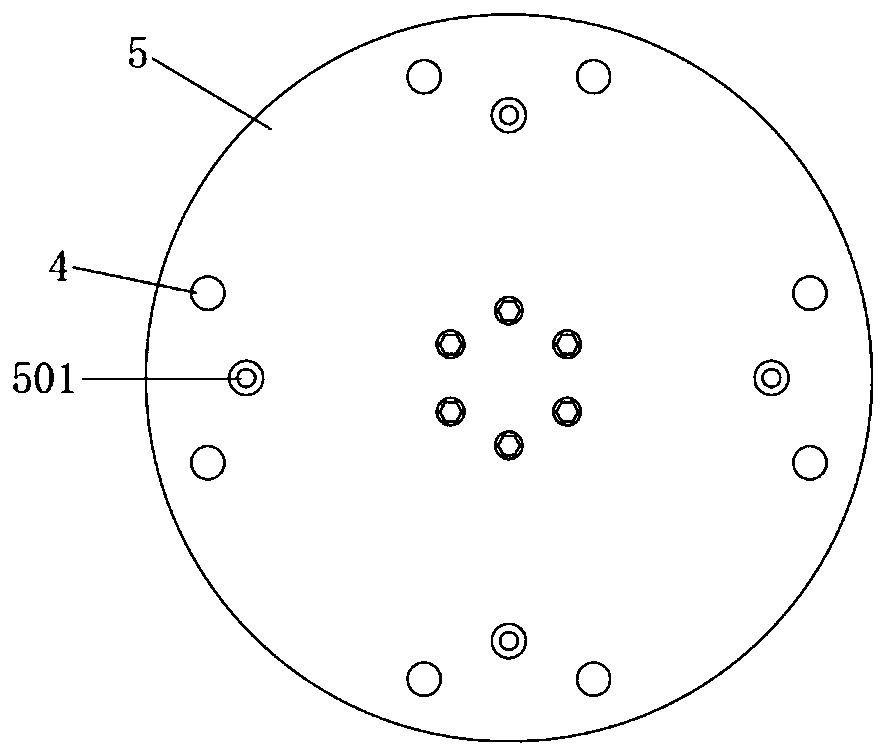

InactiveCN108327187ASolve injection deformationSolve the difficulty of unthreadingCoatingsSewageSewage treatment

The invention provides a sewage treatment device and a manufacturing method thereof. The sewage treatment device comprises a sprue bush, a positioning ring, a front mold drawing rod, a panel, a runnerplate front drawing rod, a runner plate, a runner plate embedding part, a front mold plate, a front mold embedding part and the like. A flange cover manufactured by the mold has the advantages that the forming precision, structure strength, deformation control, sealing property and anti-aging property are greatly improved; furthermore, the quality and production efficiency of the sewage treatmentdevice are ensured.

Owner:仇成杰

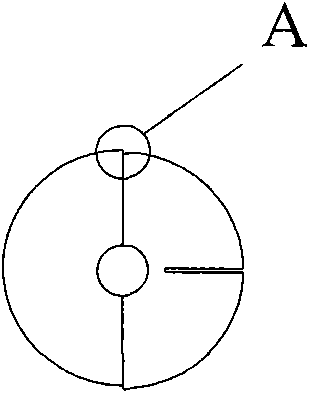

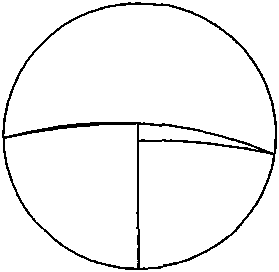

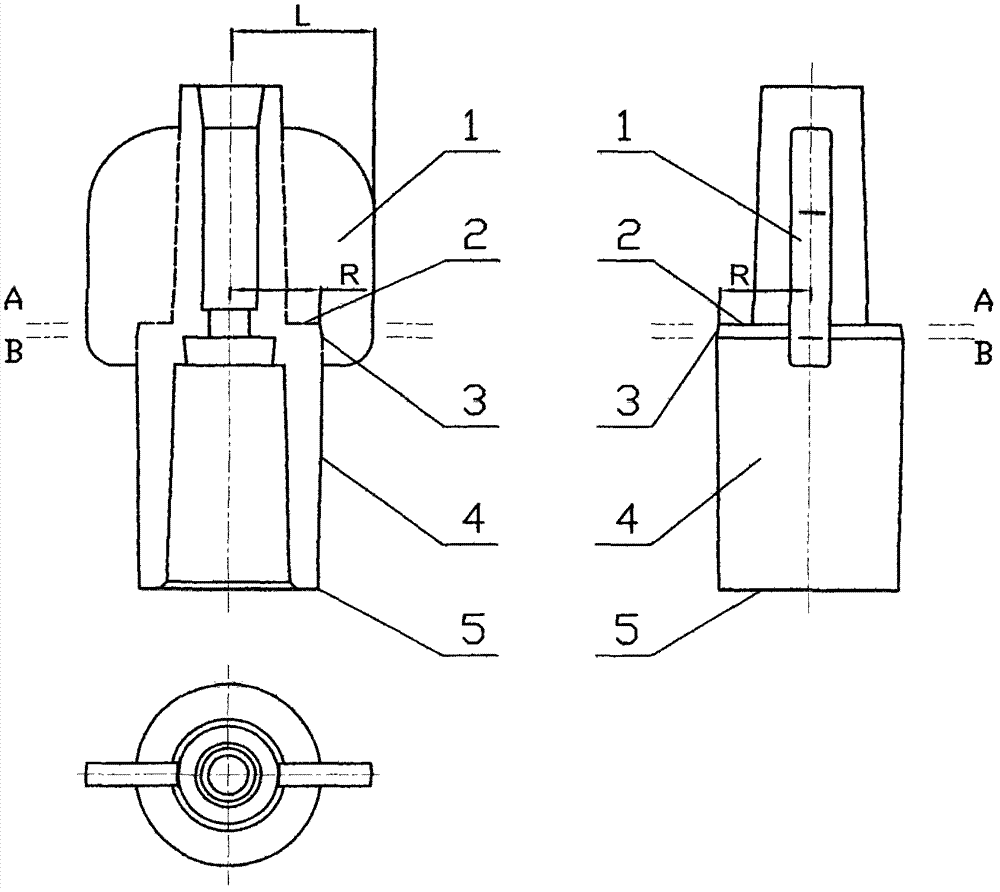

Wing-shaped infusion needle connection seat

The invention relates to a connection seat with wings, which is matched with an intravenous infusion needle for an infusion set, and belongs to the technical field of medical devices. A wing-shaped infusion needle connection seat is characterized in that when the extension widths L of the wings are not less than the radius R of the bottom of a connection seat body, the external circumferential diameter of the rear end of the seat body is not less than the external circumferential diameter of the end opening of the seat body, and the parting surfaces of the connection seat are respectively positioned between the widest extension parts of the wings and the bottom of the seat, so the plastic is enabled to be moulded in a die in an injection manner and then be axially demoulded. Consequently, when the die is used for manufacturing, a double-line or multi-line accessory arrangement mode can be adopted, relatively more injection moulding accessories are produced at a single time, so the seat injection molding production efficiency is greatly improved.

Owner:稳健平安医疗科技(湖南)有限公司

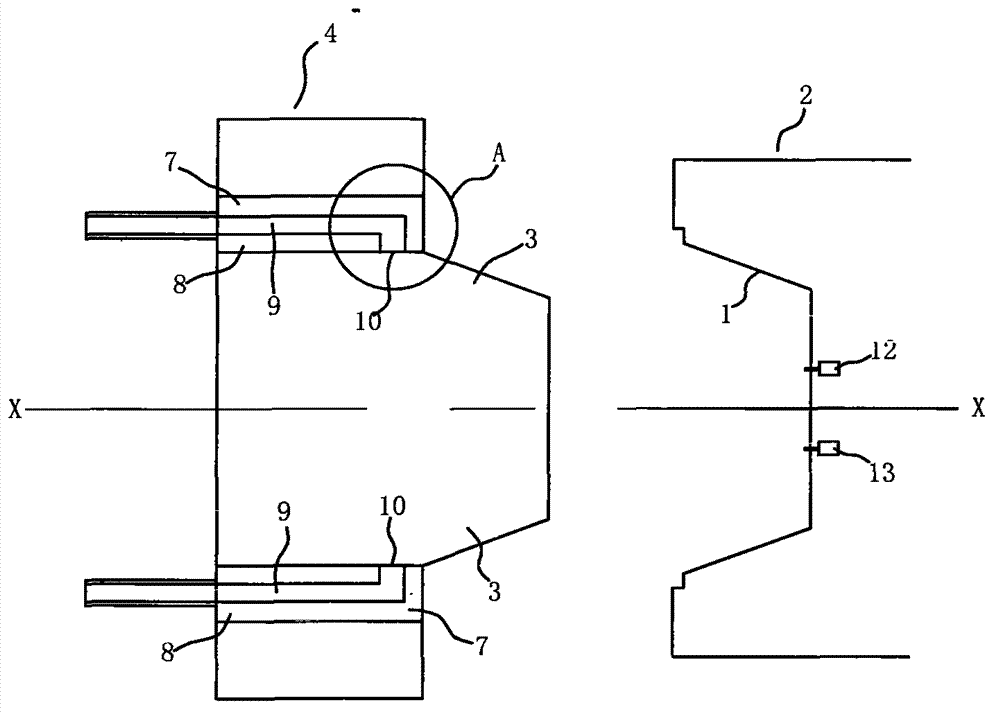

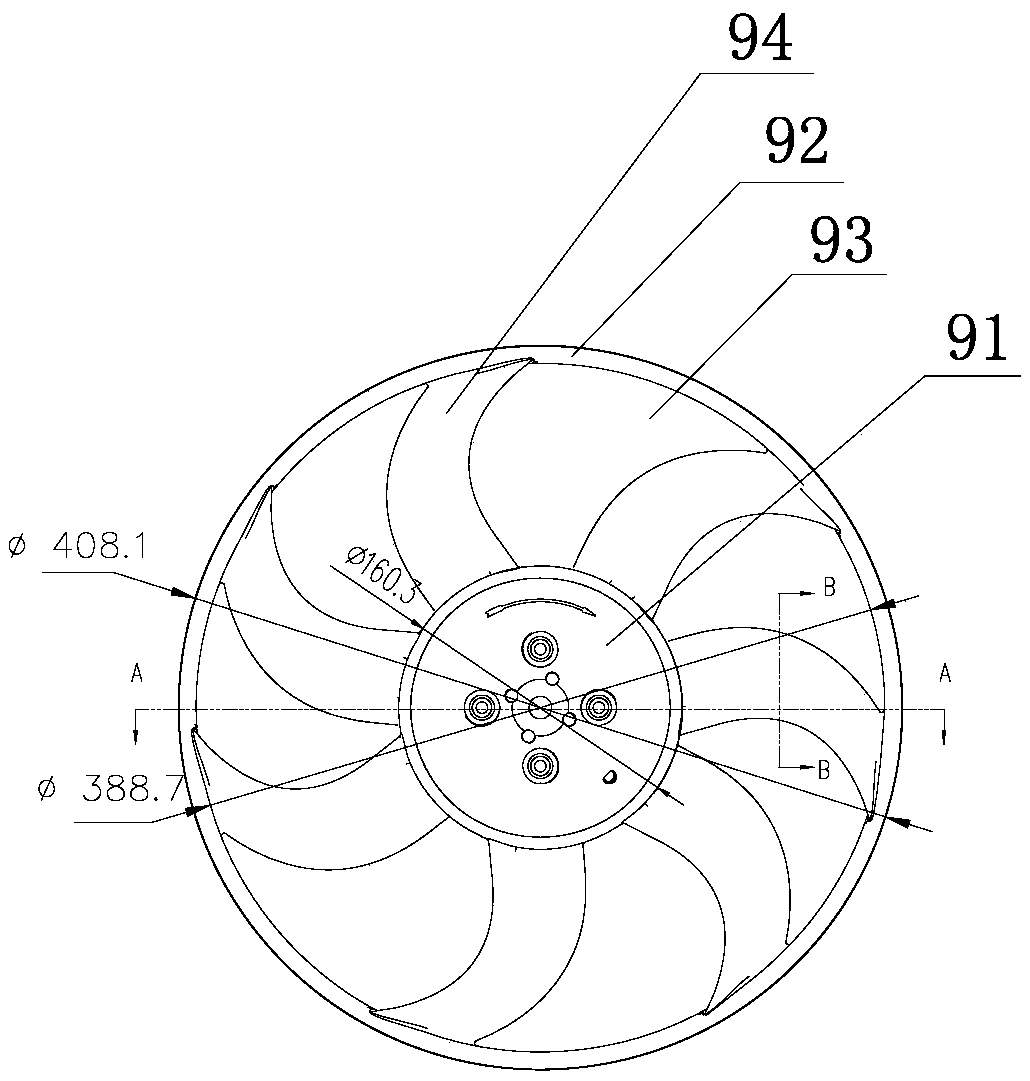

Cooling water channel structure of automobile engine cooling fan mold

The invention discloses a cooling water channel structure of an automobile engine cooling fan mold. The cooling water channel structure is composed of a fixed mold side water channel arranged on the back side of a fixed mold side fan mold cavity and a movable mold side water channel arranged on the back side of a movable mold side fan mold cavity. The fixed mold side water channel comprises a plurality of independent fixed mold side well type water channels. Each fixed mold side well type water channel is arranged on the back side of a blade cavity in the fixed mold side fan mold cavity. Eachfixed mold side well type water channel is provided with an inlet and an outlet. The movable mold side water channel comprises a plurality of independent movable mold side well type water channels. Each movable mold side well type water channel is arranged on the back side of a blade cavity in the movable mold side fan mold cavity. Each movable mold side well type water channel is provided with aninlet and an outlet. The cooling water channel structure has the advantages that the cooling effect is good; the shape of the curved surface of each injection molded fan blade can reach the expectedideal shape; the injection molding period can be shortened; and the injection molding production efficiency is greatly improved.

Owner:NINGBO TIANLONG ELECTRONICS

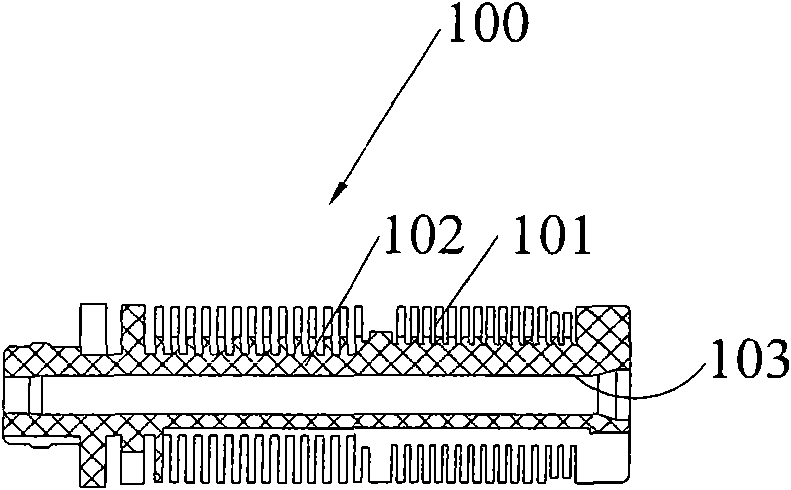

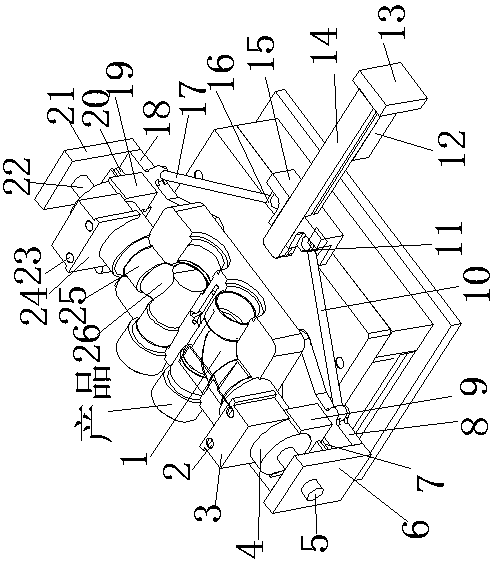

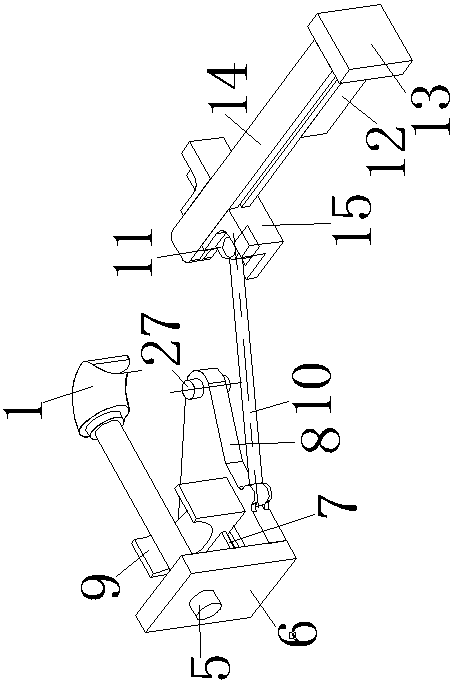

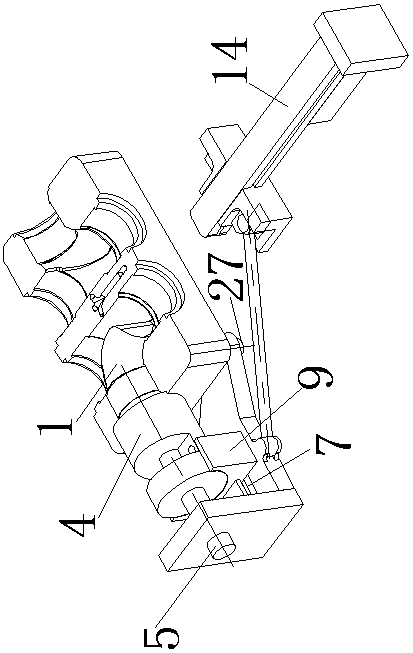

Hair removing device and hair removing head ejector rod thereof

InactiveCN103271536AImprove Injection Molding Production EfficiencyReduce overall production costHair-singeingBiomedical engineeringEngineering

The invention relates to a hair removing device, in particular to the hair removing device and a hair removing head ejector rod of the hair removing device. The hair removing head ejector rod of the hair removing device is characterized in that the hair removing head ejector rod (1) comprises a longer ejector rod (1a) and a shorter ejector rod (1b); the longer ejector rod (1a) is connected with the shorter ejector rod (1b) into a whole through a spiral arm; connecting flexible points (a) are arranged in the middle of the spiral arm; the hair removing head ejector rod is bent along the connecting flexible points (a); flexible connection is achieved in each bending portion. The injection molding production efficiency of an ejector rod assembly can be improved and comprehensive production cost can be reduced; assembling efficiency is obviously improved and the probability of fault assembly is reduced; an operation environment of the ejector rod is improved and the hair removing head ejector rod of the hair removing device is helpful to reduction of noise generated by mutual collision.

Owner:SHANGHAI POVOS ELECTRIC WORKS

A cable skin insulation coating injection molding equipment

ActiveCN108295685BAvoid gatheringIncrease contact areaRotary stirring mixersMixing methodsAgricultural engineeringElectric cables

The invention relates to the technical field of insulating paint processing, in particular to a cable skin insulating paint injection molding equipment, including a first traction mechanism, a cable body, a second traction mechanism, a support mechanism, a liquid adding mechanism, a mixing mechanism, a spraying mechanism and an air-drying mechanism. Mechanism; the present invention adopts a vertically rotating stirring mechanism, which can continuously stir the solid raw materials at the bottom of the mixing box, so that it can be fully mixed with the liquid raw materials, avoiding the accumulation of solid raw materials at the bottom, and the stirring blade adopts an arc surface structure , can increase the contact area between the blade and the liquid, increase the number of times of mixing each time, and shorten the mixing time; the resistance of the blade during the rotation process can be greatly reduced by dividing the fluid, thereby reducing the energy consumption of the motor and further improving the blade rotation. Speed, it can grind the solid raw materials in the mixing box, so that the solid raw materials can be quickly dissolved and mixed with the liquid raw materials; it can air-dry the outside of the sprayed cable.

Owner:ANHUI SURXIN WIRE & CABLE CO LTD

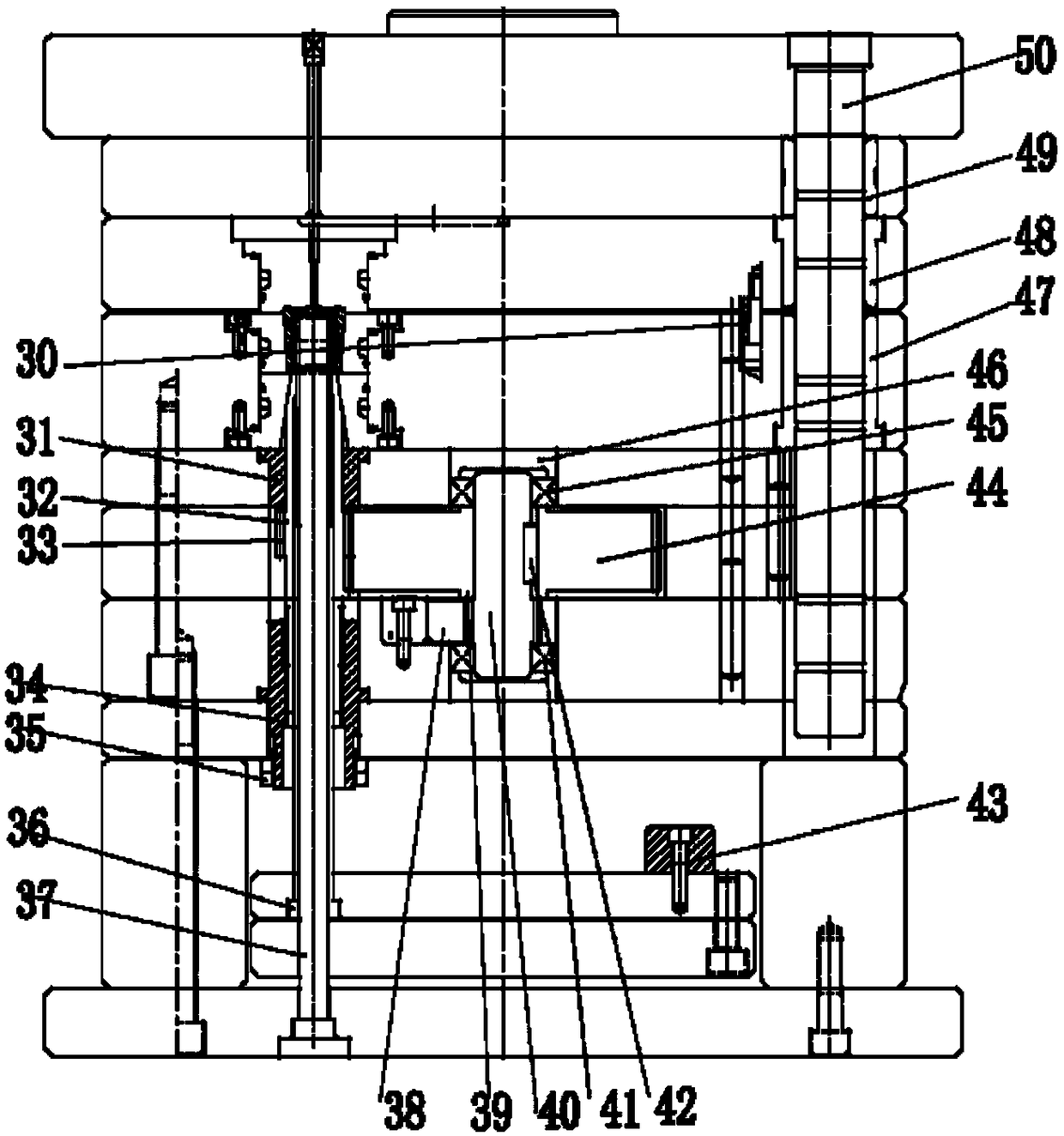

A secondary ejection mechanism and laminated injection mold adopting the mechanism

ActiveCN102909835BImprove Injection Molding Production EfficiencyReduce manufacturing costMechanical engineeringPhysics

Owner:QINGDAO HAIER MOLDS

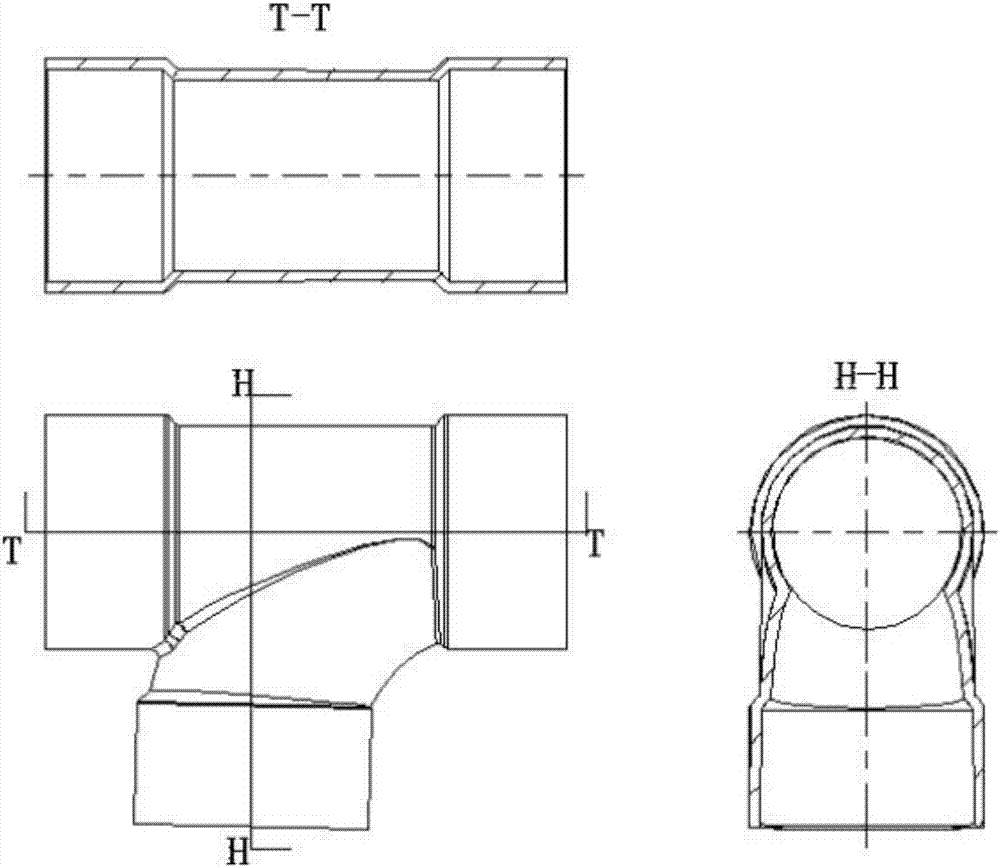

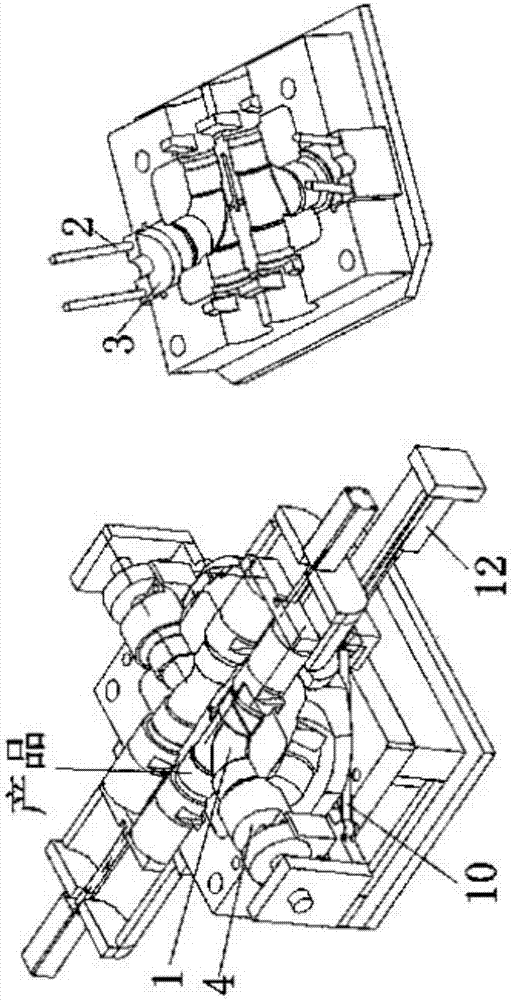

A double-linkage type three-way pipe bending core-pulling mechanism

InactiveCN104943084BImprove Injection Molding Production EfficiencyReduce manufacturing costEngineeringMechanical engineering

Owner:河北龙润管道集团有限公司

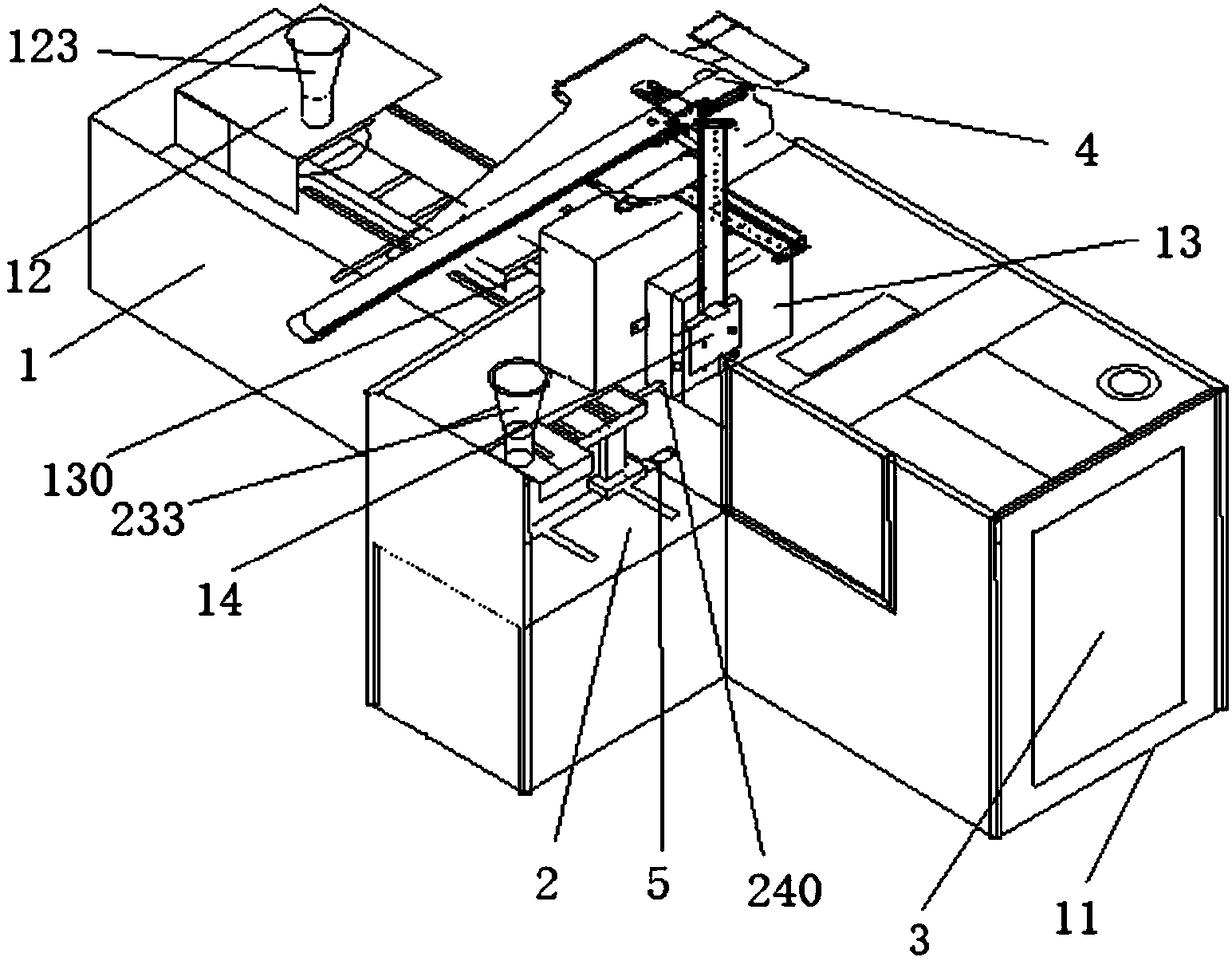

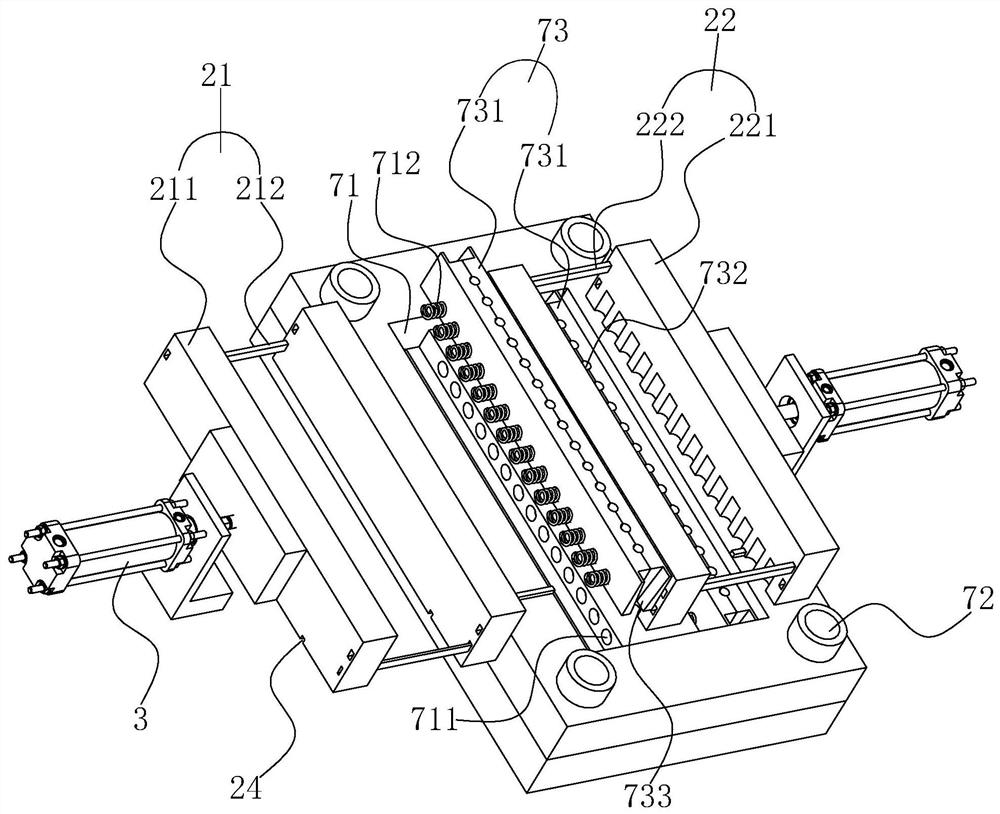

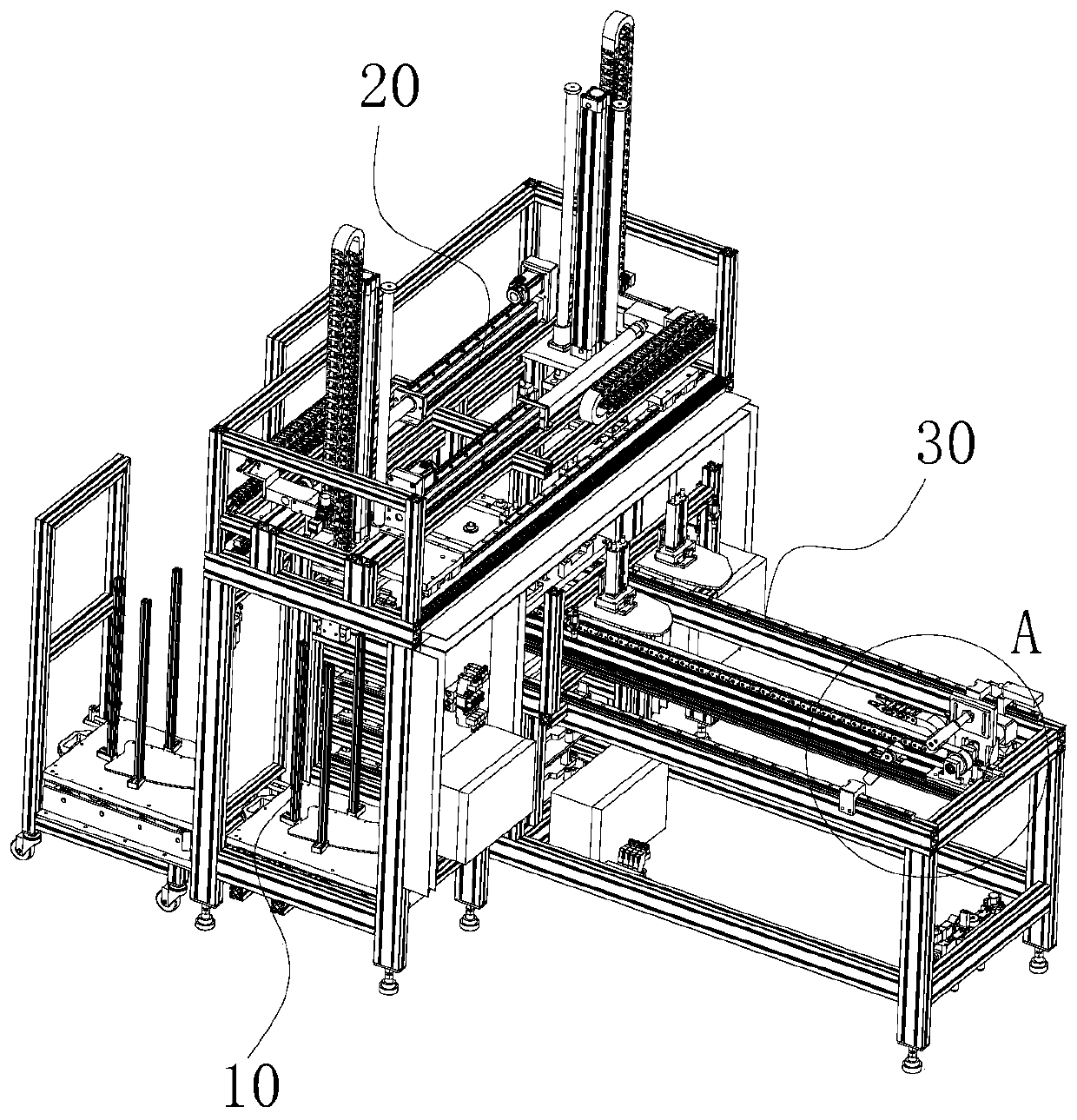

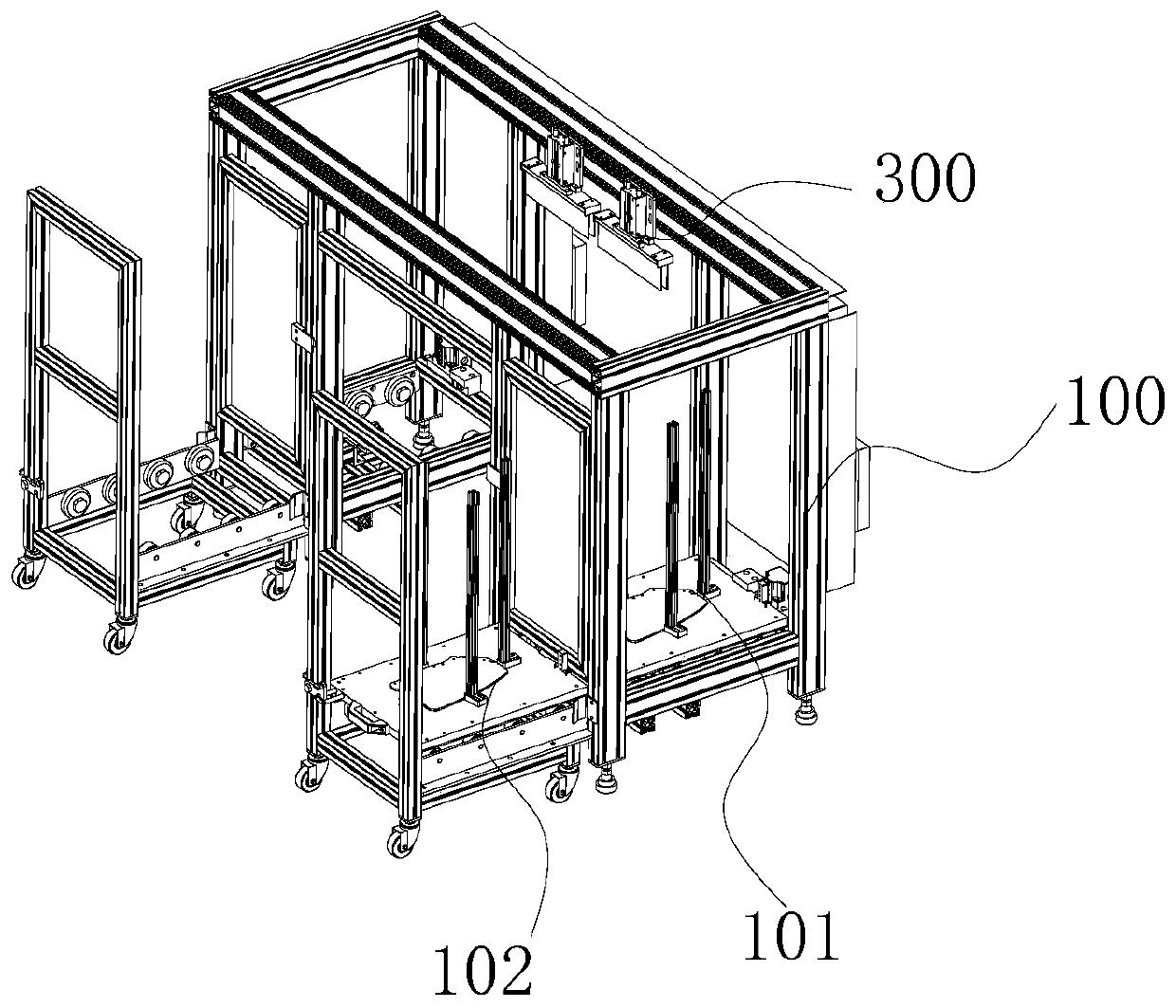

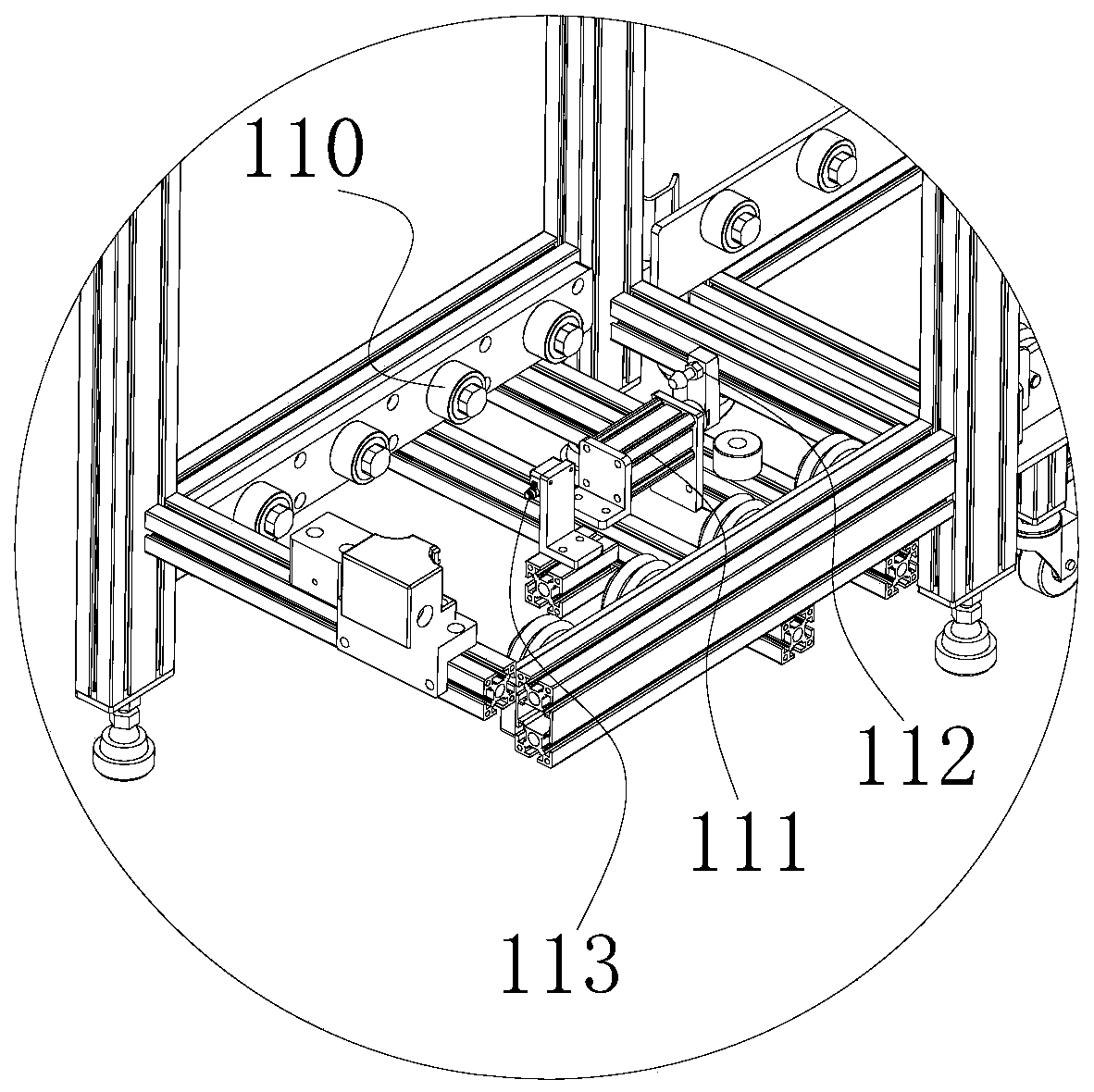

Fabric positioning conveying equipment used for inlaying injection molding and fabric positioning method

The invention discloses fabric positioning conveying equipment used for inlaying injection molding and a fabric positioning method. A fabric storage unit, a fabric grabbing unit and a fabric positioning unit are included. The fabric storage unit comprises a fabric transportation trolley and a frame which are symmetric left and right. The fabric grabbing unit comprises two parallel first sliding rails. A first moving plate and a second moving plate which are parallel and are matched through first sliding blocks pass through the first sliding rails. A clamping air cylinder and a guiding column fixed through a shaft sleeve are fixed to the middle portion of the first moving plate. The fabric positioning unit comprises a conveying module, a fabric base, a brush positioning mechanism and a pressing mechanism, and the brush positioning mechanism is arranged between the pressing mechanism and a clamping claw. Since leather fabric has certain ductility, the leather fabric is in a hook face shape after being grabbed. The brush positioning mechanism is adopted for conducting stepping type beating on the fabric, accordingly, accurate fabric positioning is achieved, and the high-precision leather fabric inlaying injection molding production technology requirement is met.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

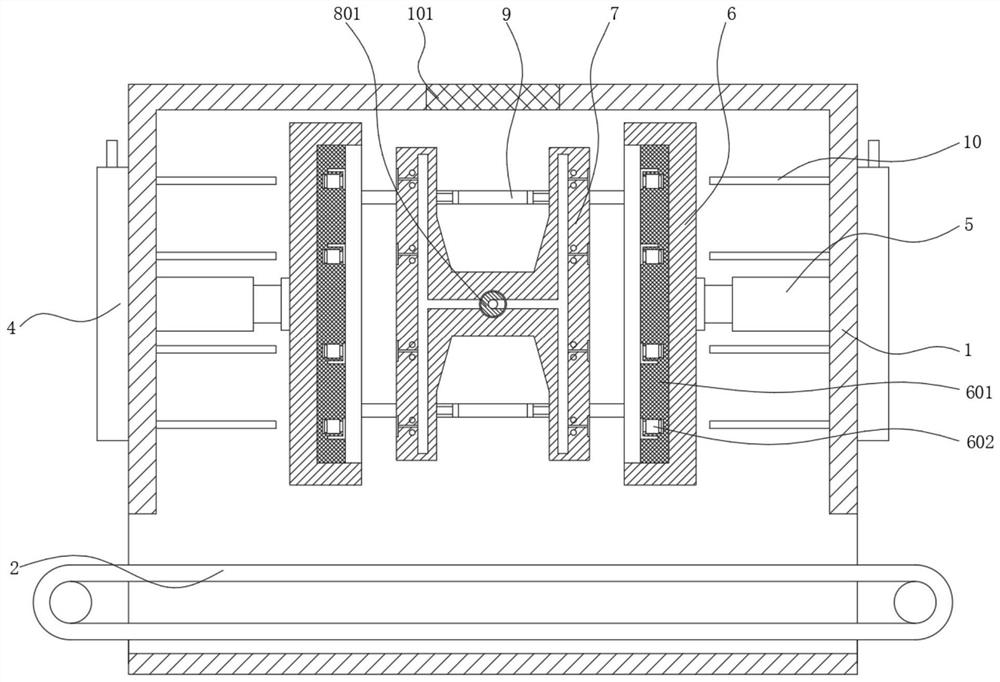

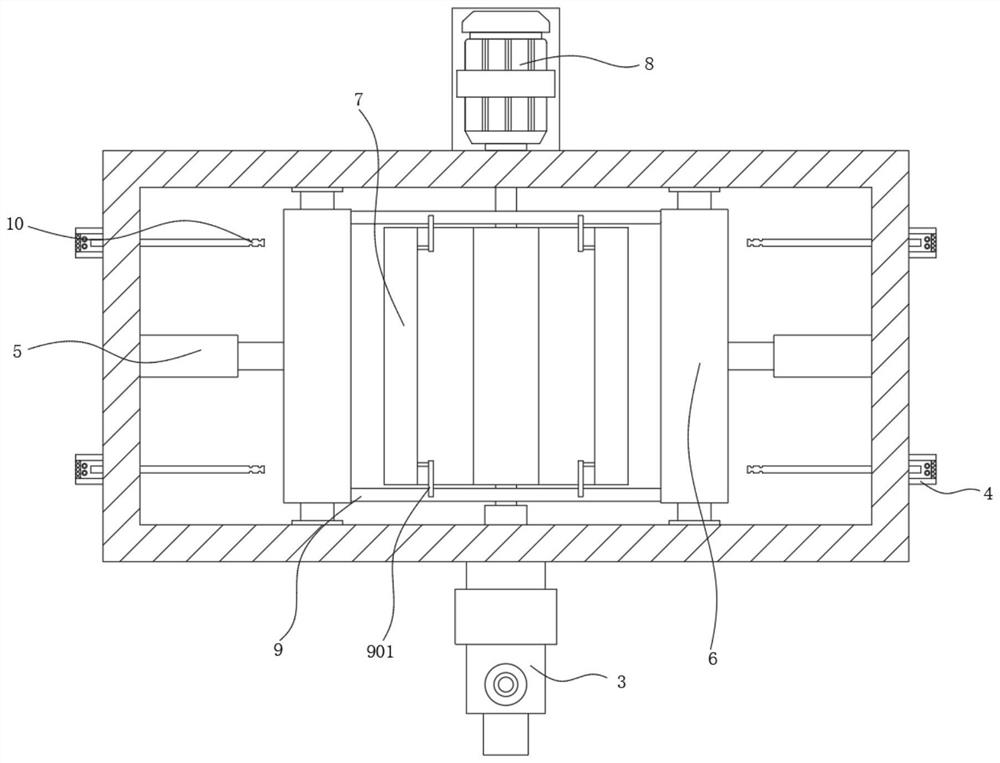

Injection molding process and injection molding device for automobile instrument panel

ActiveCN113733504ATemperature controlImprove temperature control effectDomestic articlesTemperature controlInjection molding process

The invention relates to the technical field of automobile production, in particular to an injection molding process and injection molding device for an automobile instrument panel, and aims to solve the problems of poor temperature control and low injection molding production efficiency of an injection mold in the prior art, the following scheme is provided. The injection molding device comprises a shell, a first electric telescopic rod is fixedly connected to the inner wall of one side of the shell; the extending end of the first electric telescopic rod is fixedly connected with a first baffle, the outer portion of the side, away from the first electric telescopic rod, of the first baffle is fixedly connected with a plurality of sets of connecting rods, the other ends of the multiple sets of connecting rods are fixedly connected with a second baffle, and a female die and a male die are installed between the first baffle and the second baffle. According to the injection molding process and injection molding device for the automobile instrument panel, the structure is reasonable and stable, operation is easy, the temperature of the injection mold is effectively controlled, the injection molding quality is improved, the injection molding production efficiency is effectively improved, and the injection molding process and injection molding device for the automobile instrument panel is easy to popularize and use.

Owner:常熟常春汽车零部件有限公司

Light-odor high-heat-resistance polystyrene resin and preparation method thereof

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

Mould for plastic container

ActiveCN103240846BImprove injection molding release performanceImprove surface qualityEngineeringMechanical engineering

The invention relates to a mould of a plastic container. The ratio value of the depth of the plastic container to the diameter of the bottom of the container is more than 1.5. The mould comprises a movable mould with a mould cavity and a fixed mould with a mould core, wherein the mould core is in a convex shape corresponding to the inner surface of the plastic container; the mould cavity is in a concave shape corresponding to the outer surface of the plastic container; a molding cavity of the plastic container is formed by combining the mould cavity and the mould core; the fixed mould is provided with a vertical injection molding pipeline which extends to the lower surface from the upper surface of the fixed mould; and the movable mould is provided with a magnetic induction heating coil along the periphery of the mould cavity. According to the mould of the plastic container disclosed by the invention, the direct injection molding of the plastic container with a high length-diameter ratio can be realized; and the performance of injection molding and de-molding of the plastic container can be effectively improved, the time required for de-molding is shortened and the injection molding production efficiency is improved; and the surface quality of the plastic container is improved.

Owner:LONGYUAN IND SHANTOU CITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com