Rapid die changing mould

A mold and fast technology, applied in the field of rapid mold change, can solve the problems of inability to replace the inner mold structure, affecting the injection production efficiency, and complicated replacement procedures, so as to improve the injection production efficiency and save the time for replacing the inner mold structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

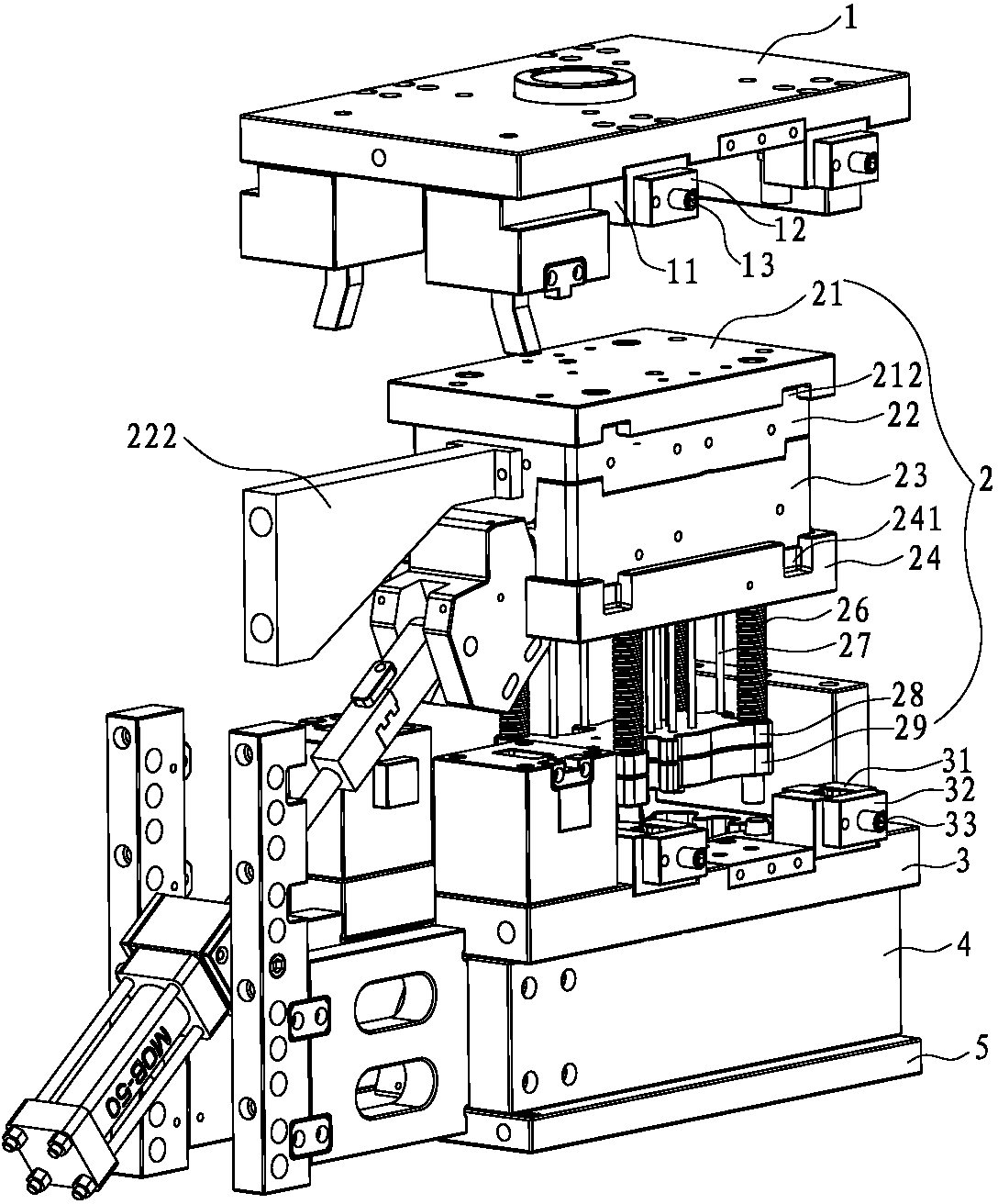

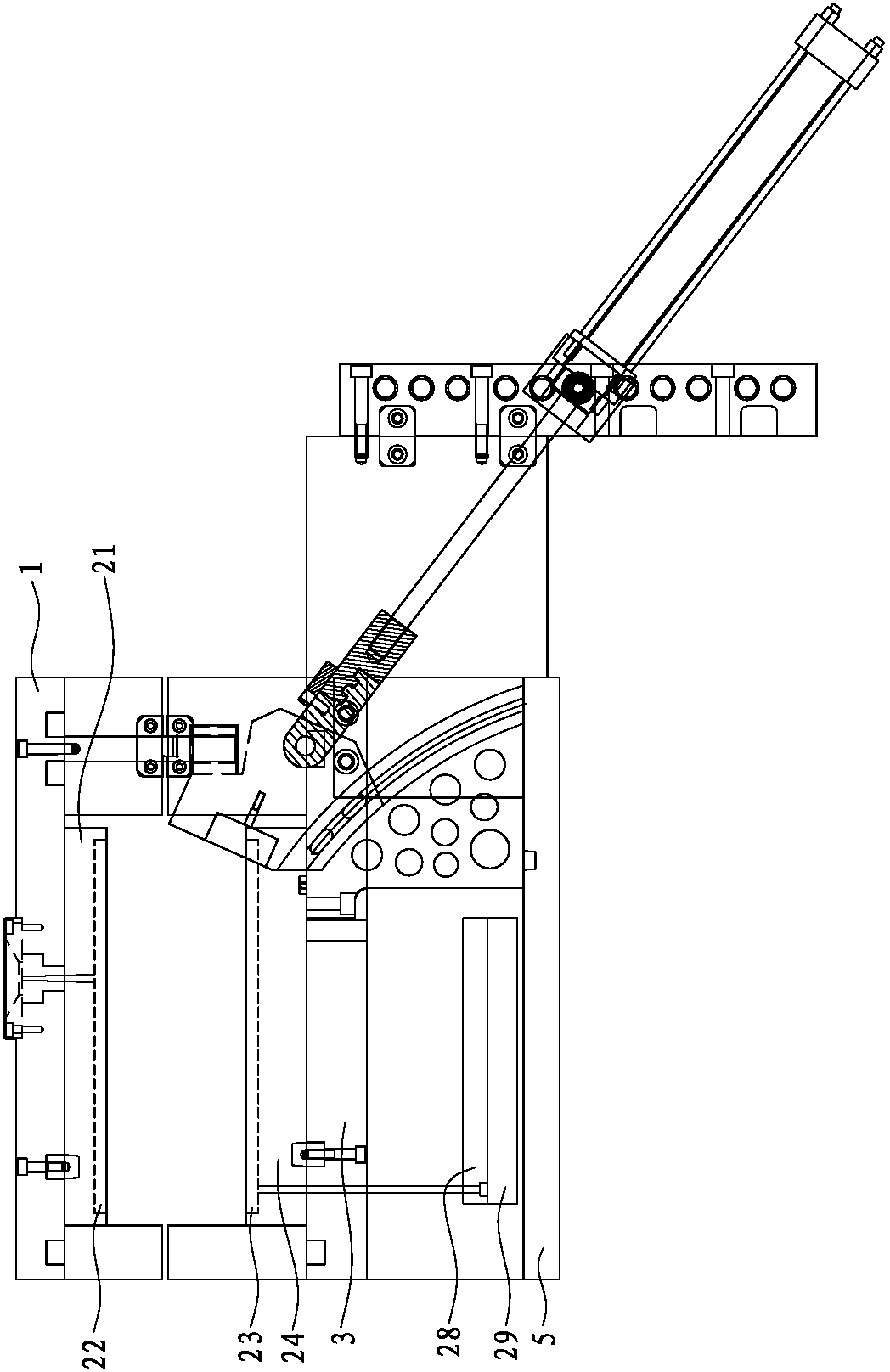

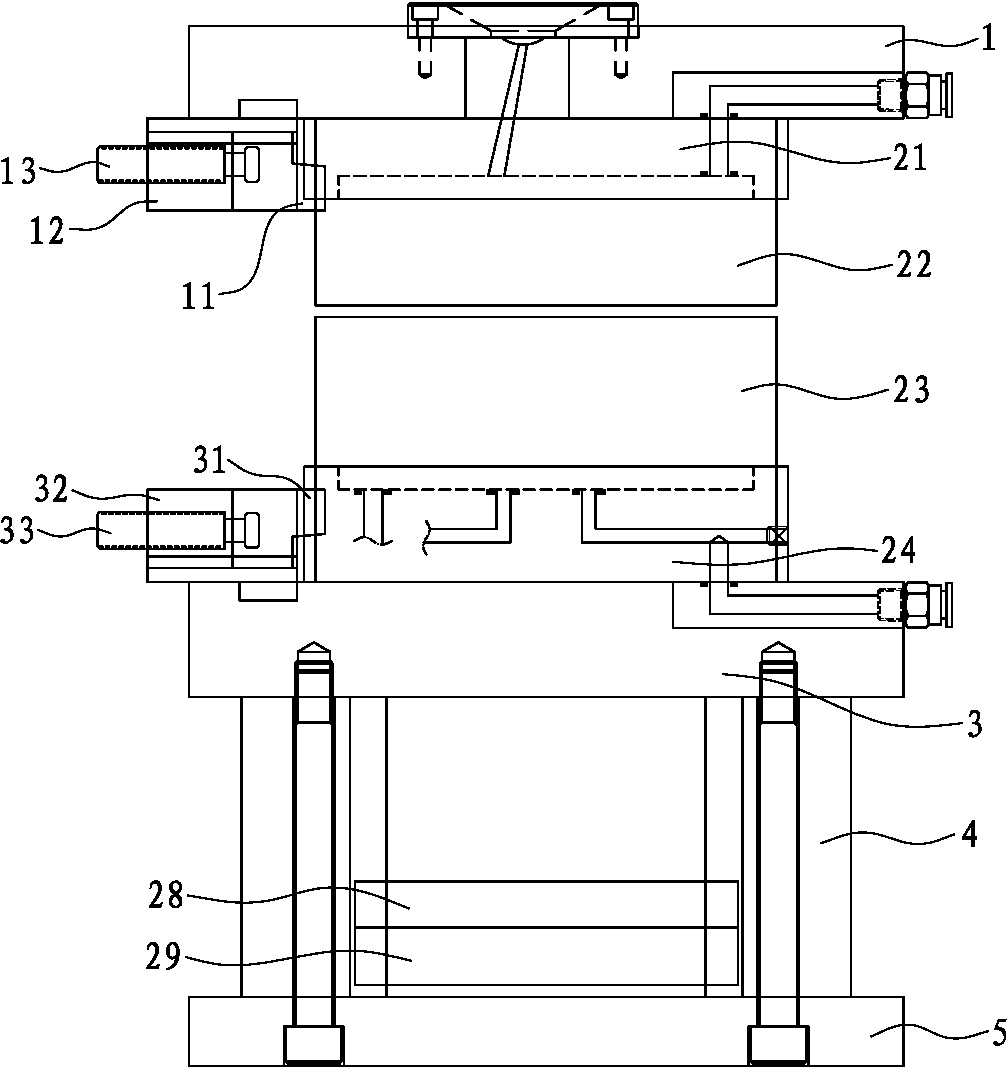

[0041] refer to Figure 1 to Figure 11 As shown, a quick mold change mold disclosed by the present invention includes a mold base A plate 1 , an inner mold structure 2 , a mold base B plate 3 , mold feet 4 and a bottom plate 5 .

[0042] Such as Figure 8 and Figure 9 As shown, the inner mold structure 2 includes a front mold core base plate 21, a front mold core 22, a rear mold core 23, a rear mold core base plate 24, a return lever 25, a return spring 26, a thimble 27, a face needle plate 28 and a bottom needle plate 29 .

[0043] The front mold core base plate 21 is installed on the front mold core 22, and the front mold core 22 is movably installed on the rear mold core 23. The specific installation method is: the rear mold core 23 is provided with a guide post 231. In this embodiment, the guide post 231 There are four sets, which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com