Integral type hot runner free of runner dead corner

An integral, no runner technology, applied in the field of hot runner devices, can solve problems such as inadequate sealing, dead corners of runners, inaccurate positioning, etc., and achieve the effects of improving appearance, product quality, and injection molding production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

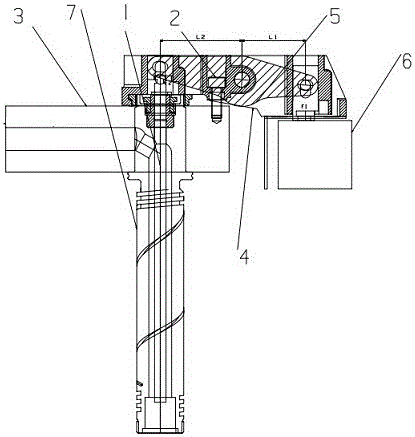

[0023] combine figure 1 and Examples illustrate the present invention in detail.

[0024] Integral hot runner without runner dead angle includes: valve needle (1), fixing screw (2), diverter plate (3), lever body (4), sliding piece (5), hydraulic cylinder (6) and hot nozzle (7 ).

[0025] The front end of the hot nozzle (7) is provided with a valve needle (1) for opening and closing the nozzle.

[0026] The lever body (4) and the diverter plate (3) are connected and fixed with fixing screws (2).

[0027] The lever body (4) and sliding piece (5) are assembled together after being connected with the vertical shaft, the horizontal shaft and the middle shaft.

[0028] The lever body (4) is the main supporting object for the action of the sliding piece (5), and one end of the lever is connected to the hydraulic cylinder (6) through screws.

[0029] One end of the lever is connected to the hydraulic cylinder (6) by screws, and the other end is fixed on the splitter plate (3). T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com