Injection molding system with visual monitoring function and monitoring method of injection molding system with visual monitoring function

An injection molding system and visual monitoring technology, applied in the field of injection molding production, can solve the problems of large mold loss, unavoidable mold loss and personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

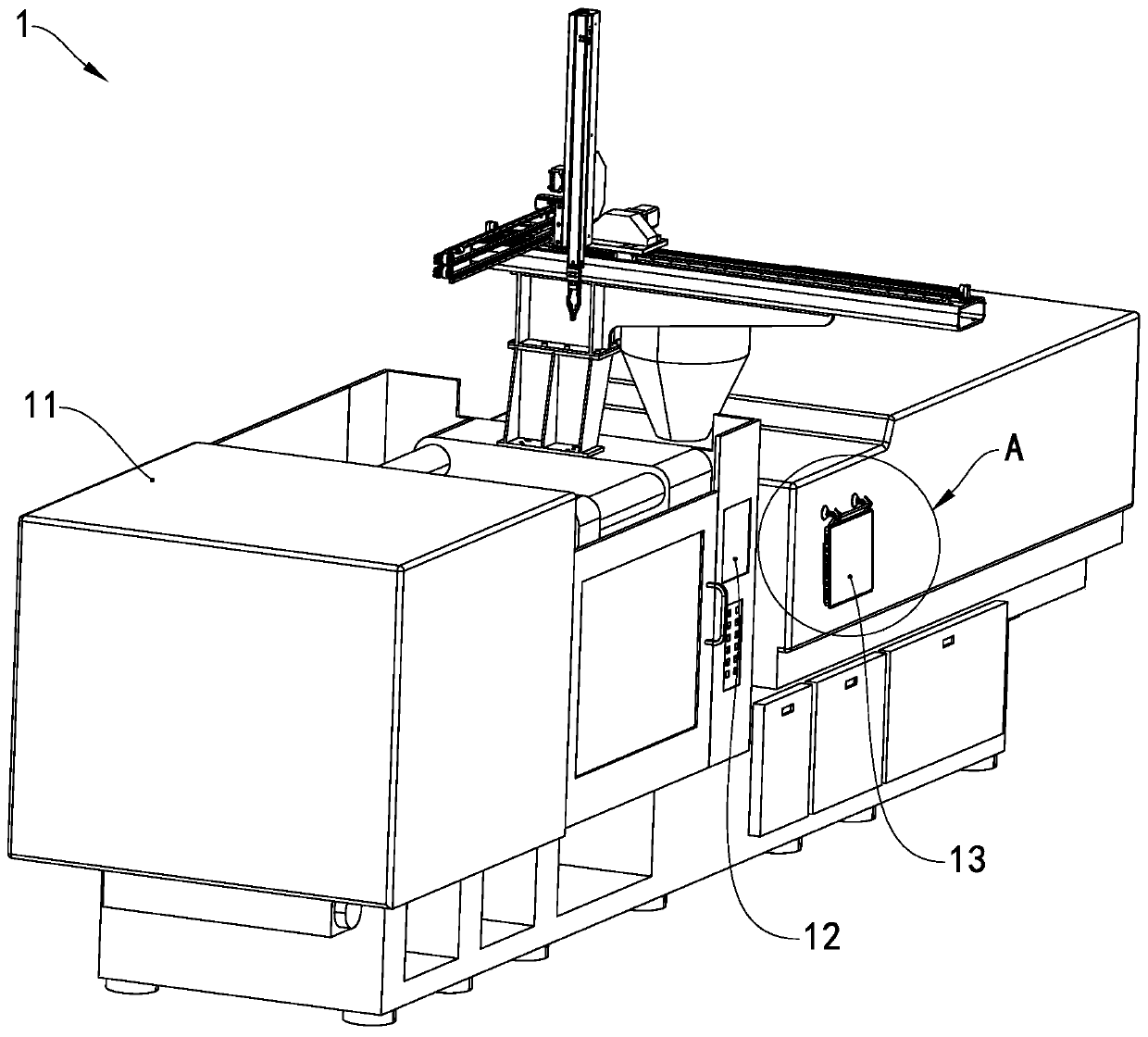

[0030] Examples of injection molding systems:

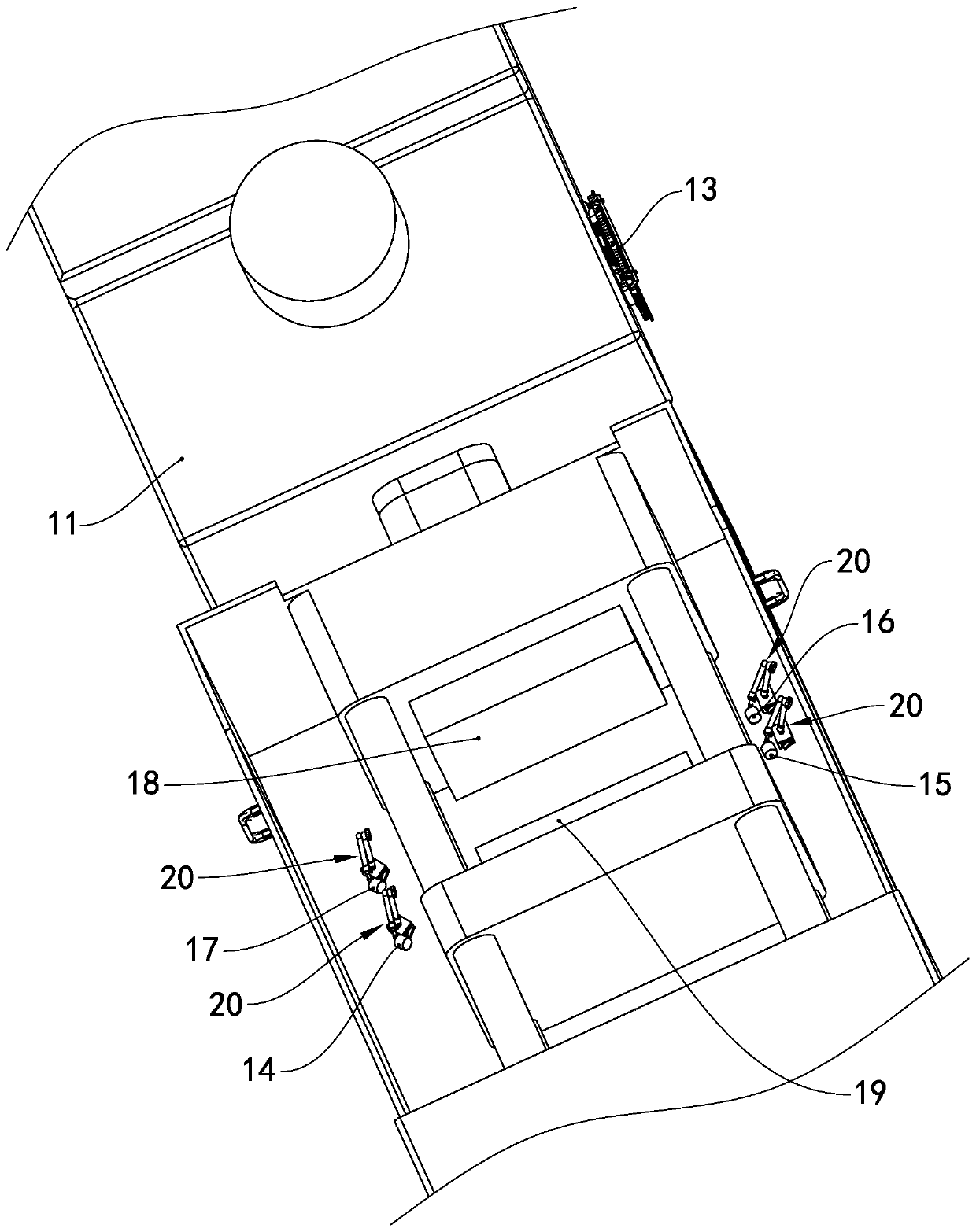

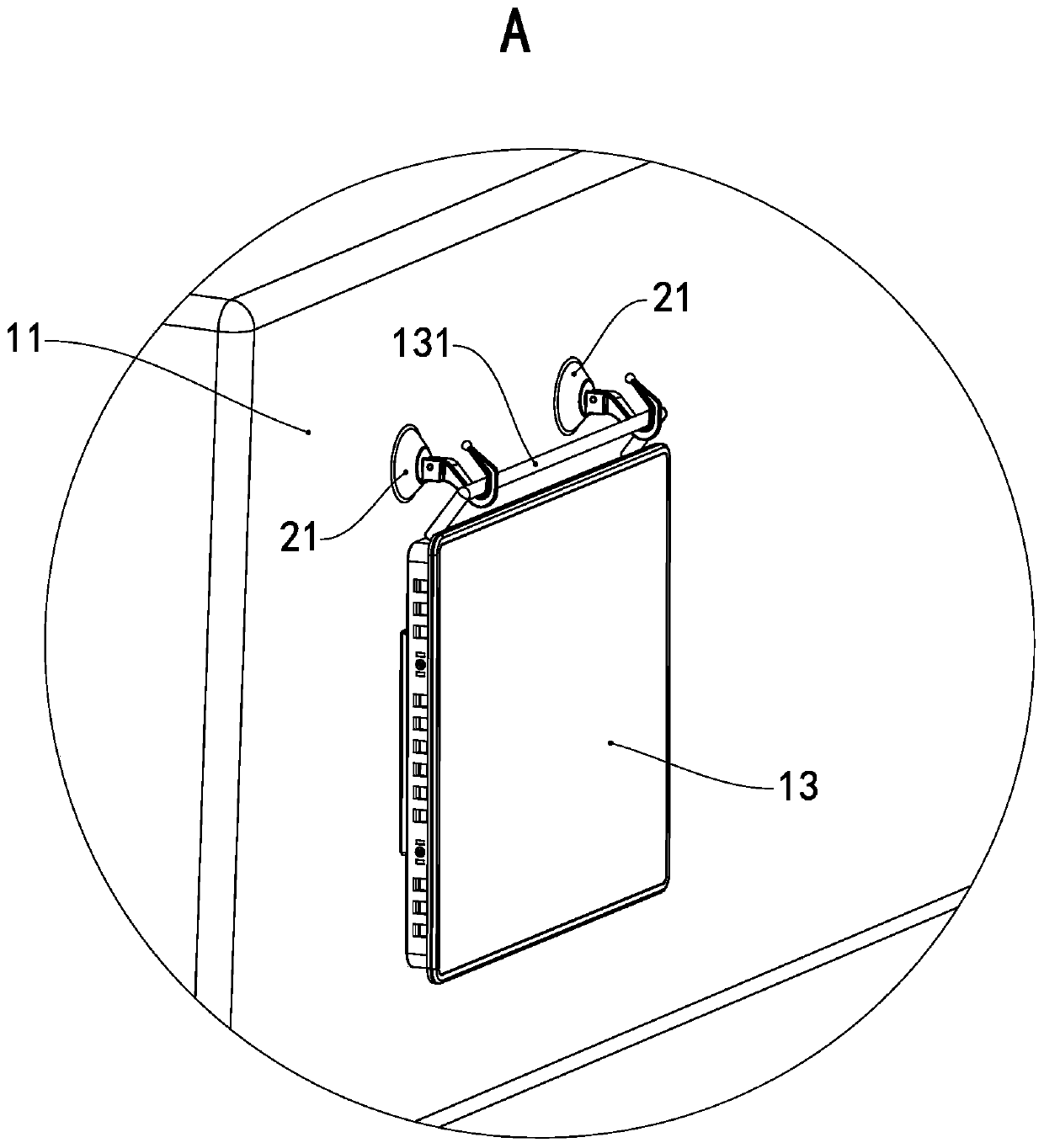

[0031] see Figure 1 to Figure 4 , the injection molding system 1 includes an injection molding machine 11, a monitor display 13, a first camera 14, a second camera 15, a first infrared lamp 17, a second infrared lamp 16, two hooks 21 and four support mechanisms 20, and the injection molding machine 11 is set There is a movable mold 18 , a fixed mold 19 compatible with the movable mold 18 and a main controller 12 , while a monitor display 13 is electrically connected to the main controller 12 and is located outside the injection molding machine 11 . The first camera 14 and the second camera 15 are respectively positioned at both sides of the working area between the movable mold 18 and the fixed mold 19, the monitoring area of the first camera 14 is the first monitoring area of the fixed mold 19, and the monitoring area of the second camera 15 It is the second monitoring area of the fixed mold 19, and the first monitorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com