Hair removing device and hair removing head ejector rod thereof

A technology of hair-pulling rods and hair pullers, which is applied to hair or scalp washing devices, clothing, hairdressing equipment, etc., can solve the problems of different lengths of hair-plucking head rods, cumbersome assembly process, time-consuming and labor-intensive, etc., and achieve comprehensive production Cost reduction, reduction of probability of wrong assembly, effect of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific examples.

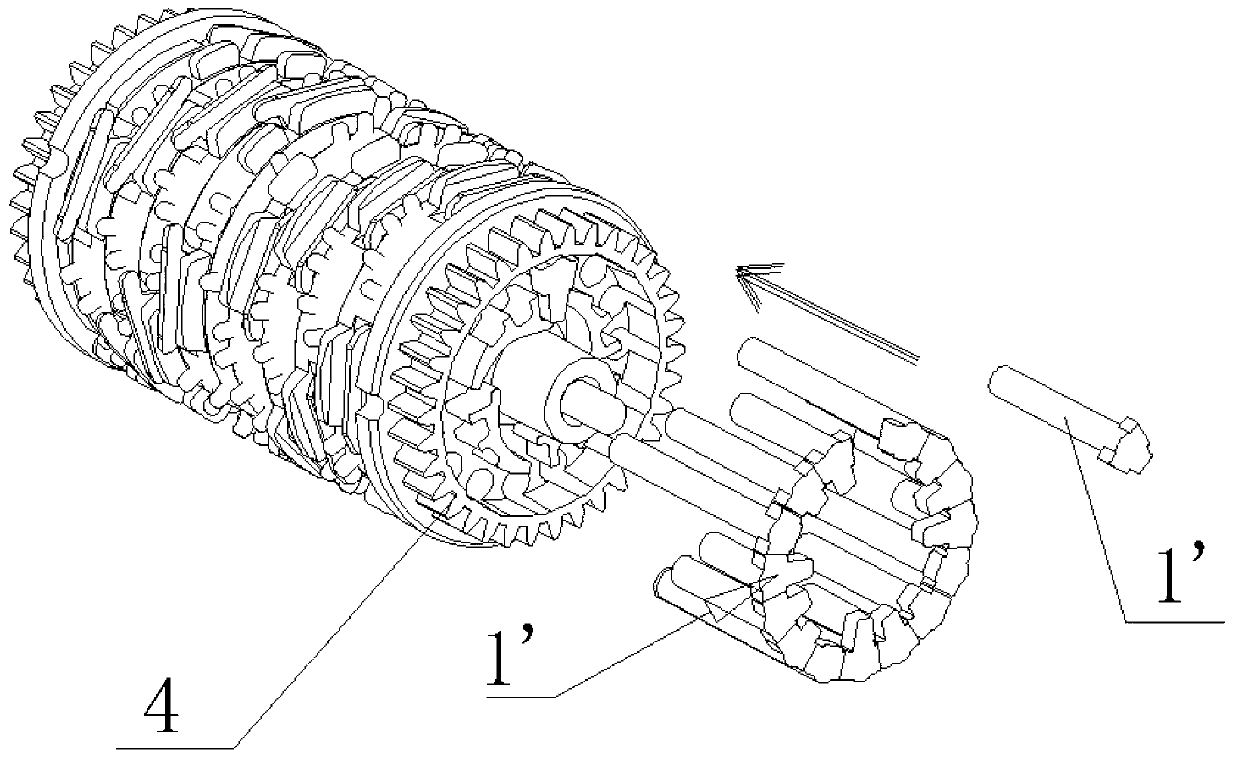

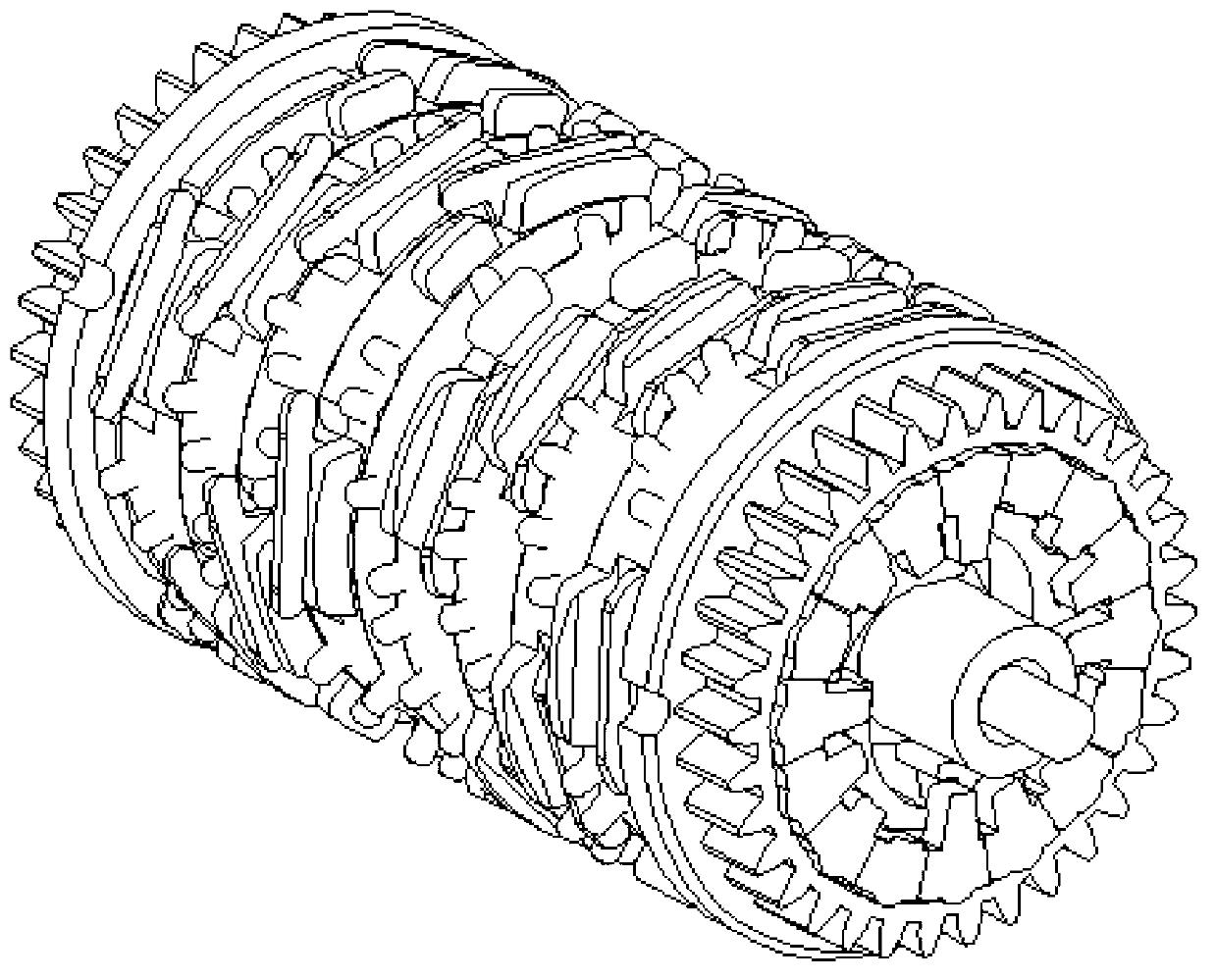

[0031] see Figure 6-Figure 7 , the plucking head assembly of the hair puller is composed of multiple sets of corresponding clamping units 3, the end cover of the rotating body 4, and the corresponding plucking head push rod 1 on the end cover of the rotating body, etc. There is a torque between each clamping unit 3 In the transmission structure, the corresponding position on the outside of the plucking head ejector rod 1 is provided with a pressing structure. When the plucking head assembly rotates, the push force F is given to each ejector rod in turn, so that the clamping unit 3 completes the clamping action.

[0032] see Figure 4-Figure 5 , the present invention mainly carries out a new design to the structure of the plucking head push rod 1, and provides a two-piece structure of the plucking head push rod, a pair of longer push rods 1a corresponding to the clamping unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com