Multicolor injection molding machine and use method thereof

A technology of injection molding machine and injection seat, which is applied in the field of injection molding, can solve the problems that the single-color injection molding machine does not meet the requirements of two-color injection molding, and the structure of the two-color injection molding machine is complicated, and achieves the effect of low cost, continuous operation, and simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

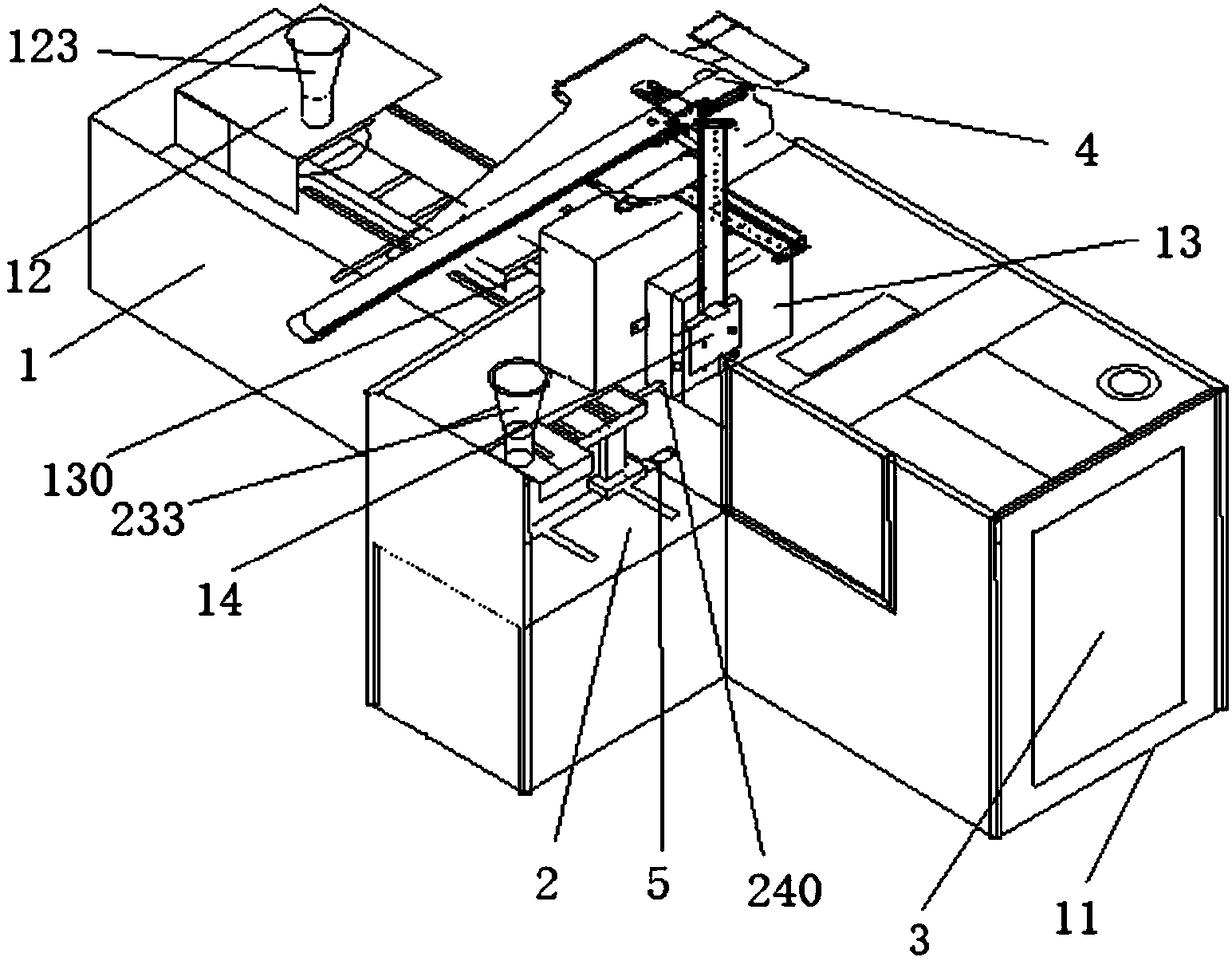

[0039] figure 1 It is a structural schematic diagram of a multi-color injection molding machine of the present invention;

[0040] Such as figure 1 As shown, a multi-color injection molding machine of the present invention includes: an injection molding machine body 1, a two-injection device 2, a controller 3 and a manipulator 4, the two-injection device 2 is connected to the injection molding machine body 1, and the manipulator 4 is connected to the injection molding machine The top of the body 1; the injection molding machine body 1 also includes a housing 11, a first screw injection device 12, a first cavity 13 and a second cavity 14, the first screw injection device 12, the first cavity 13, the second cavity The cavities 14 are all installed on the housing 11; the first screw injection device 12 is aligned with the first cavity 13, and the controller 3 is connected with the first screw injection device 12 and the manipulator 4; the second injection device 2 also includes ...

Embodiment 2

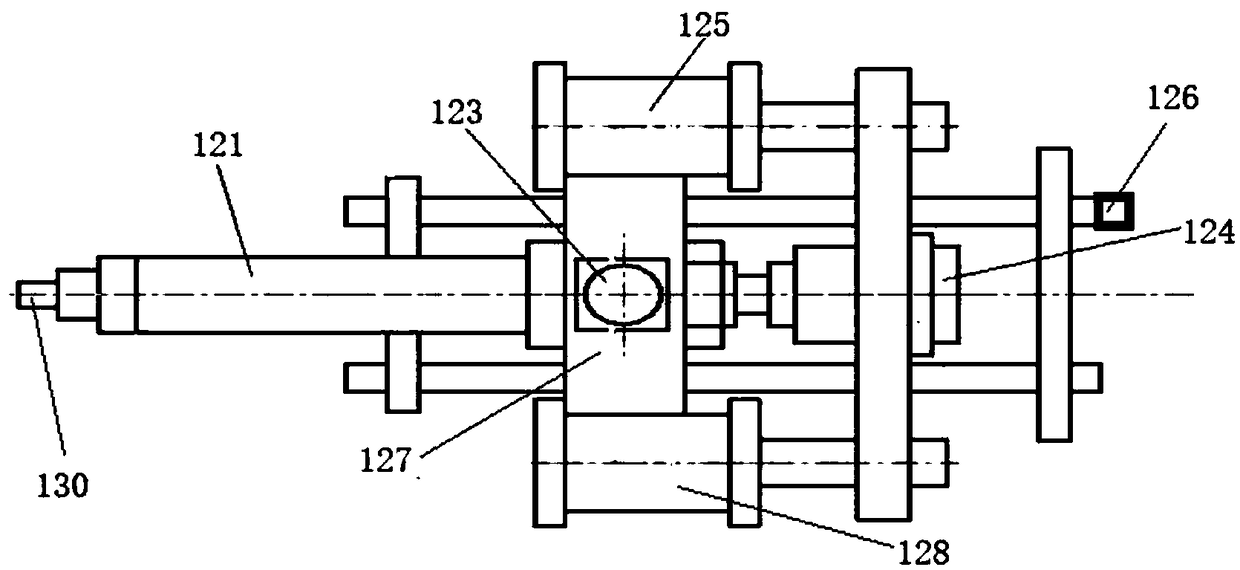

[0043] figure 2 is a schematic structural view of the first screw injection device of the present invention;

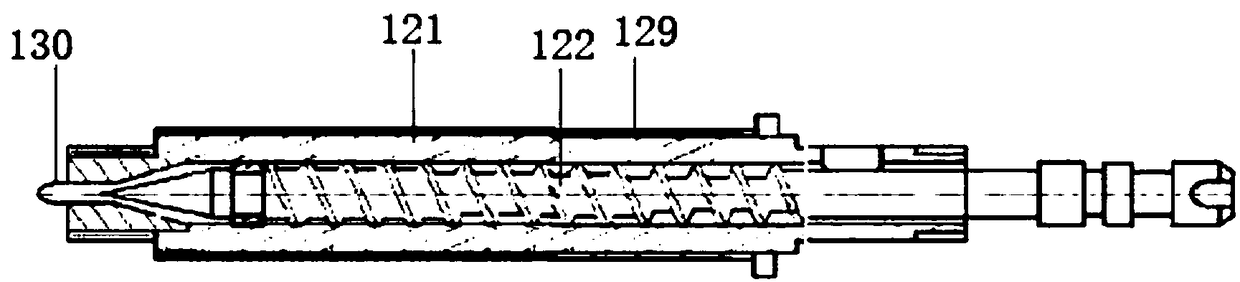

[0044] image 3 is a structural schematic diagram of the first barrel of the present invention;

[0045] Figure 4 is a schematic structural view of the second screw injection device of the present invention;

[0046] Figure 5 is a structural schematic diagram of the second barrel of the present invention;

[0047] Such as Figure 2-5 As shown, on the basis of Embodiment 1, the first screw injection device 12 of this embodiment includes: a first barrel 121, a first screw 122, a first hopper 123, a first screw transmission device 124, a first injection Oil cylinder 125, first metering device 126, first injection seat 127, first injection seat moving oil cylinder 128, first heating ring 129 and first nozzle 130; The barrel 121 is vertically connected; the first screw 122 is located in the first barrel 121, the end of the first screw 122 is connected with the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com