Push rod capable of exhausting

An exhaust push rod and exhaust groove technology, which is applied in the field of exhaustable push rods, can solve the problems affecting the molding quality of products and the injection molding cycle, reducing the melt filling speed, and increasing the injection pressure, so as to improve the injection molding production efficiency. , the effect of ensuring quality and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

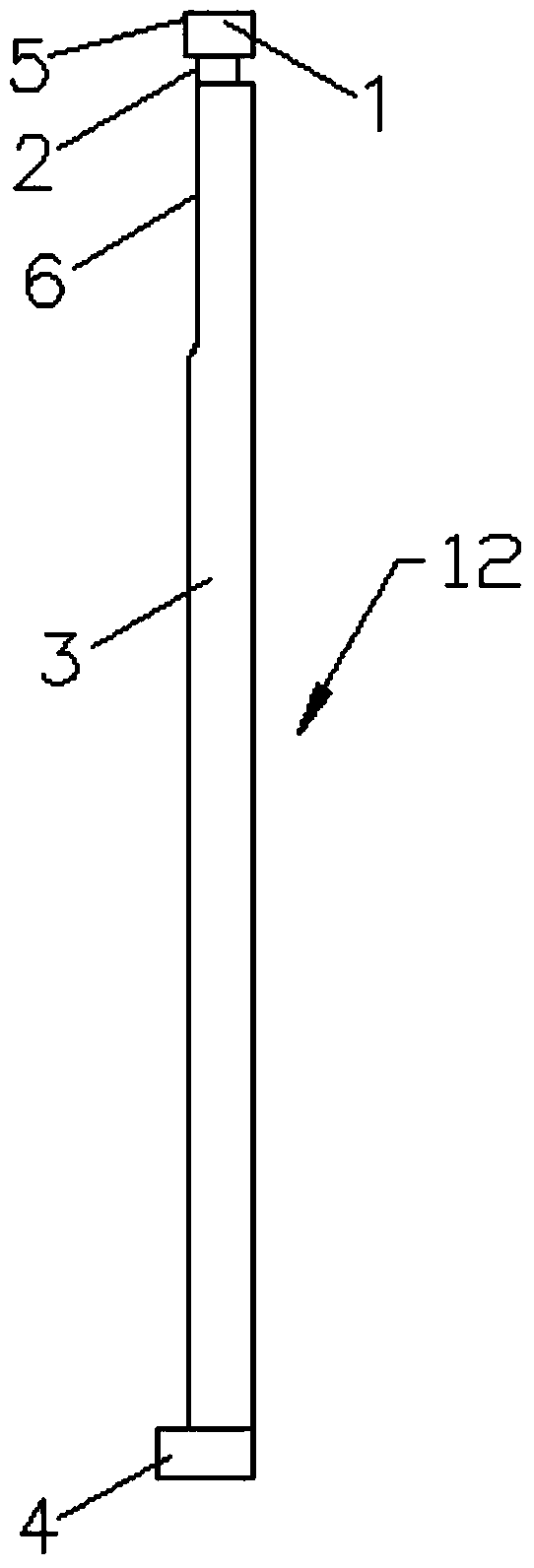

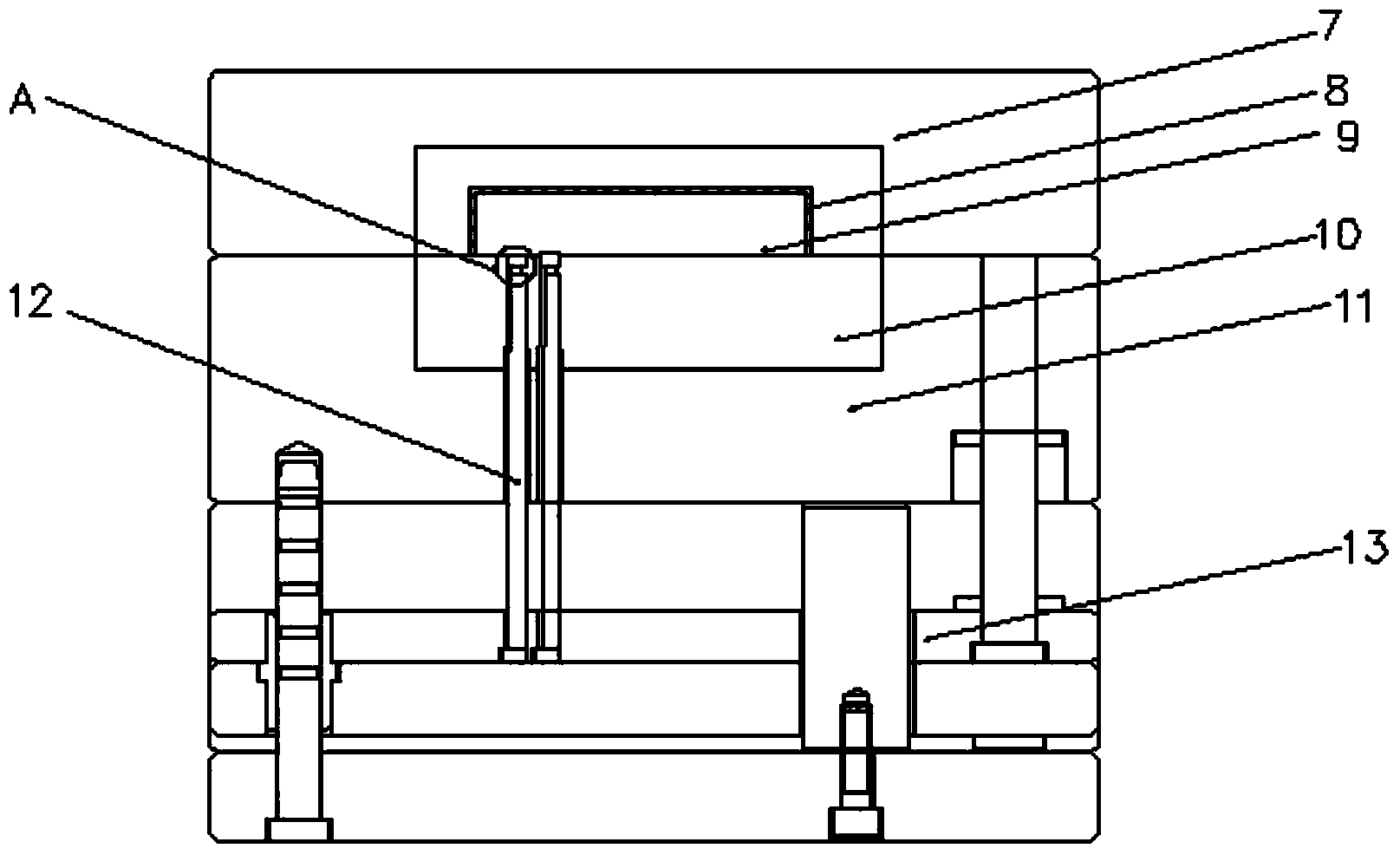

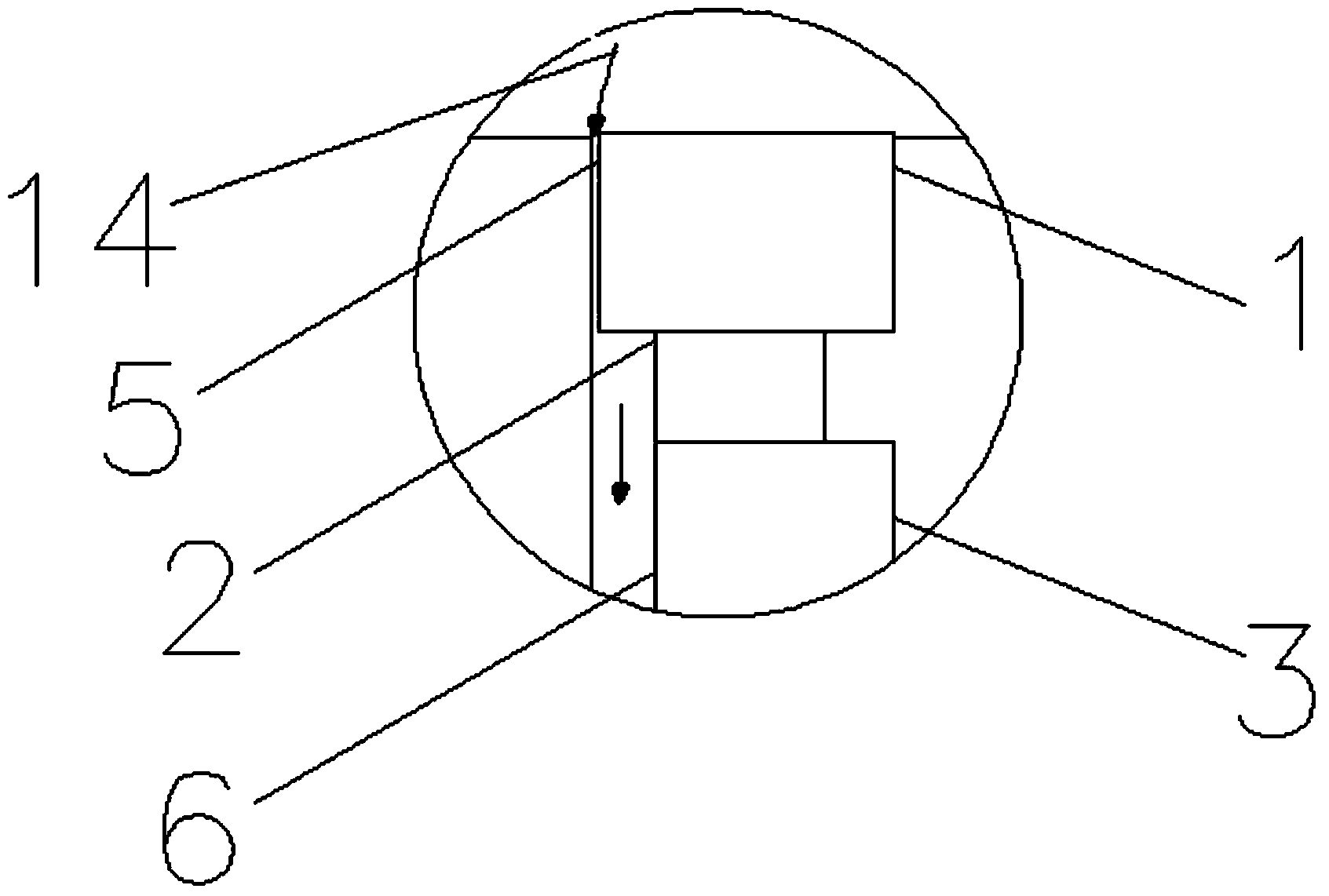

[0014] as attached Figure 1-3 Shown is the exhaustable push rod of the present invention, including a push rod head 1, a knife relief groove 2, a rod body 3, and a hanging platform 4; the lower end of the push rod head 1 is provided with a knife relief groove 2; A rod body 3 is arranged under the groove 2; a hanging platform 4 is arranged at the bottom end of the rod body 3; an upper exhaust groove 5 is provided on one side of the push rod head 1; the rod body on the same side of the upper exhaust groove 5 3 is provided with a side exhaust groove 6, the side exhaust groove 6 is on the same side as the upper exhaust groove 5, and the side surface of the side exhaust groove 6 is flush with the undercut groove 2; The hanging platform 4 on the same side of the side exhaust groove 6 is provided with a protruding shoulder, and the other side of the hanging platform 4 is flush with the rod b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com