Controller and writing instrument containing same

A technology for writing implements and controllers, which is applied to writing utensils, ink pens with ink storage tubes in the pen barrel, and printing, etc., which can solve problems such as difficulties, rising production costs, and high assembly requirements, and achieve reduced shape and position tolerances and mutual matching Dimensional tolerance requirements, accuracy requirements and manufacturing difficulty are reduced, and the effect of improving product qualification rate and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Different preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

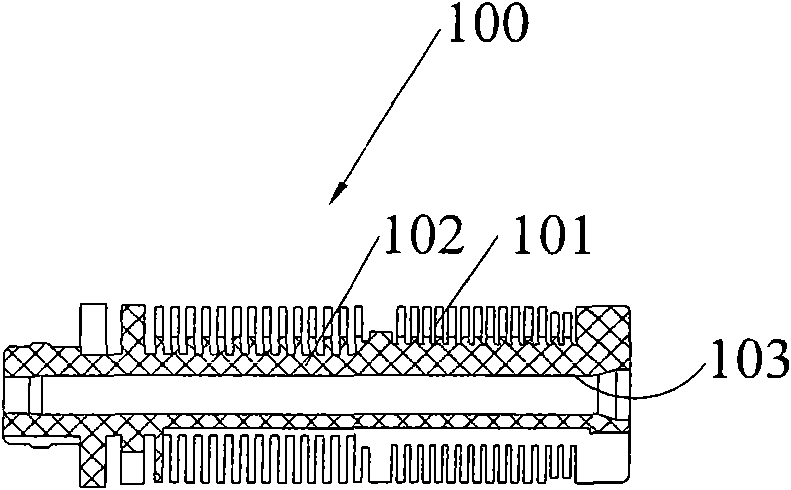

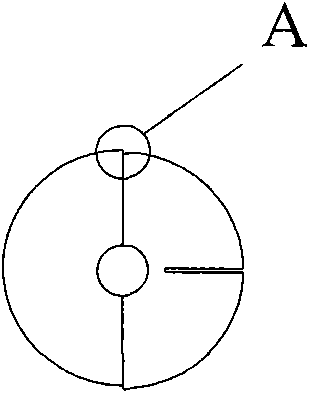

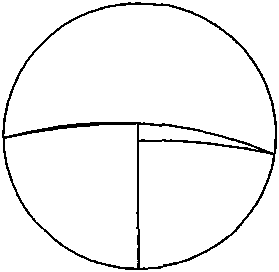

[0064] Figure 9 shows a writing instrument according to a first preferred embodiment of the present invention, Figure 10 shows the controller of the writing instrument in this embodiment, Figure 11 Schematically shows the state of use of the writing instrument, Figure 12 The air return route of the writing instrument is shown.

[0065] In this embodiment, the writing instrument is similar to a straight-liquid water-based ballpoint pen, which uses low-viscosity water-based ink. The writing tool 300 includes a nib unit 10 and a pen holder 20 , the nib unit 10 is connected to the lower end of the pen holder 20 by screw connection, clip connection and other known methods. The nib unit 10 includes a nib 11, a water diversion core 12, a nib cover 13, and a nib seat 14, wherein the water diversion core 12 is inserted into the inner h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com