Secondary ejecting mechanism and laminated injection die adopting same

A technology of secondary ejection and injection mold, applied in the field of ejector mechanism, can solve problems such as poor practicability, oscillation, and inability to provide upward power, so as to save manufacturing costs, ensure appearance quality, and improve injection molding production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

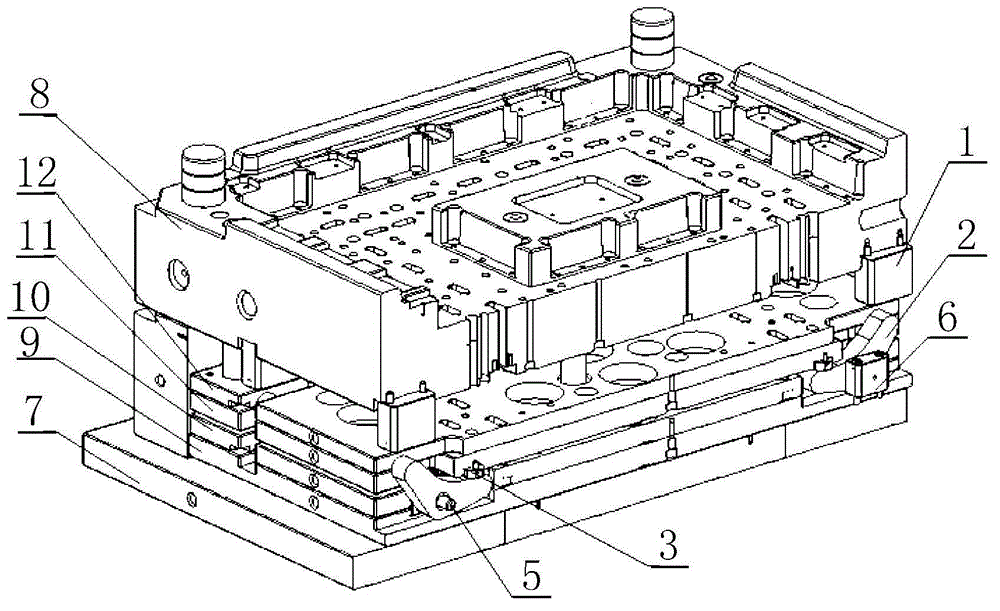

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

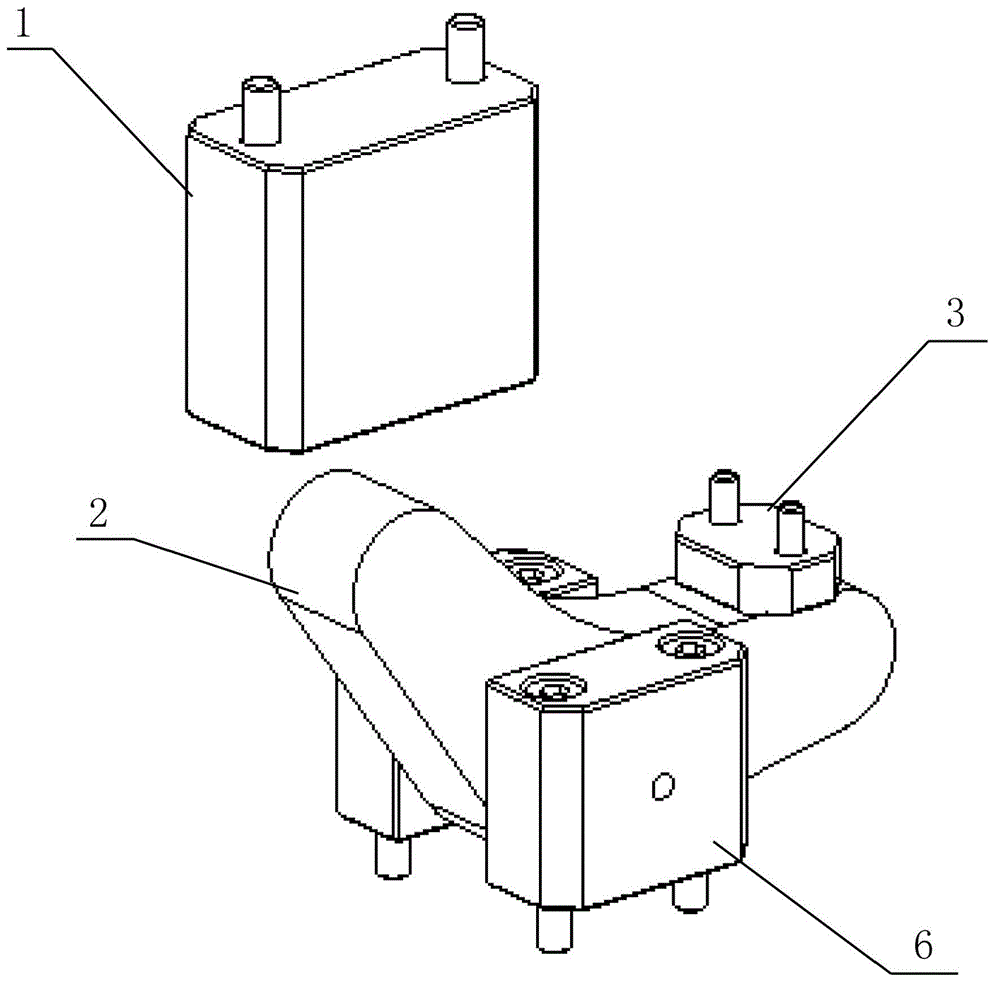

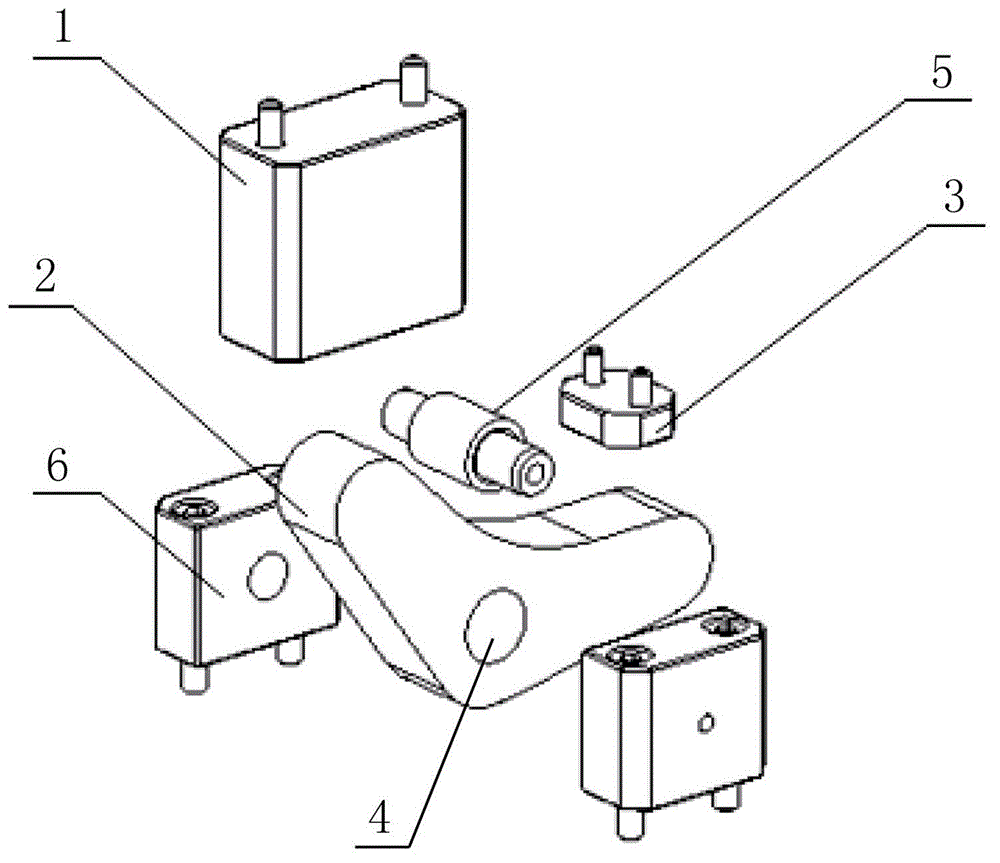

[0027] Such as Figure 1~2 As shown, a secondary ejection mechanism is suitable for the secondary ejection of the injection mold, which includes a limit block 1 and a seesaw 2, wherein the limit block 1 is fixed on the lower template of the injection mold The seesaw 2 includes a first arm 21 and a second arm 22 at an angle to each other, preferably, the angle between the first arm 21 and the second arm 22 is greater than 90 degrees, and the seesaw 2 is rotatable Set on the first ejector plate of the mold; the first arm 21 is located at the lower part of the limit block 1, the second arm 22 is located at the lower part of the second ejector plate, and the first arm 21 is used to receive the limit block 1 provides the force opposite to the mold opening direction, and the second arm 22 is used to prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com