Gear-driven bent pipe multi-directional demolding mechanism

A technology of gear-driven and demolding mechanism, applied in the field of gear-driven elbow multi-directional demolding mechanism, can solve the problem that the demolding mechanism is difficult to achieve one mold, improve reliability and mold injection production efficiency, and simplify complexity , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

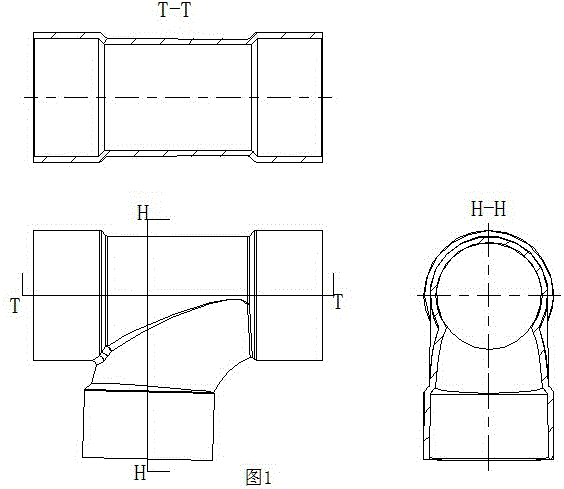

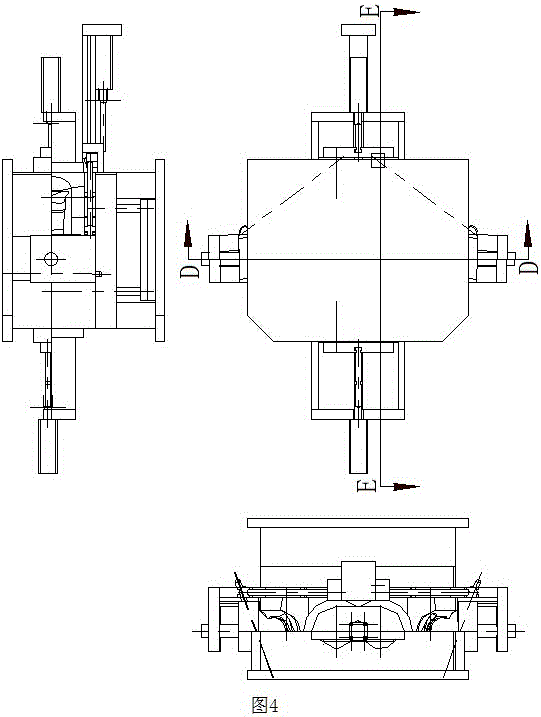

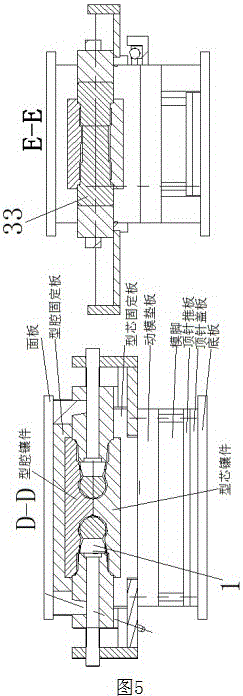

[0023] Figure 2-12 Shown is the relevant explanatory diagram of the present invention; the gear-driven curved pipe multi-directional demoulding mechanism includes the mold base structure and mold core-pulling and demoulding parts. The first curved pipe slider head 1, the first round pipe slider inclined guide post 2, The first round tube slider wedge block 3, the first round tube slider 4, the first curved tube slider head pull rod 5, the left baffle plate 6, the first round tube slider seat guide chute 7, the first groove bottom plate 8. The first circular tube slider seat 9, the left universal pull rod 1, the left universal seat 11, the first power cylinder 12, the first power cylinder mounting plate 13, the guide chute of the universal seat 14, the universal seat 15, Right universal seat 16, right universal tie rod 17, second groove bottom plate 18, second round tube slider seat 19, second round tube slider seat guide chute 2, right baffle plate 21, second elbow slider He...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com